Temperature field adjustable type high efficiency burnt gas pulsating combusting device

A pulsating combustion and adjustable technology, applied in the direction of gas fuel burners, burners, combustion methods, etc., can solve the problems of pulsating burner tail pipe failure, heating furnace not working normally, uneven surface temperature distribution, etc., and achieve service life Long life, improved work efficiency, and low pollutant content

Inactive Publication Date: 2010-12-01

大庆石油化工机械厂有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The key component of the heating furnace equipment is the burner. The temperature field test of the existing pulsating burner shows that the temperature field gradient is extremely large when the pulsating burner is burning, and the surface temperature distribution is extremely uneven, especially the temperature at the junction of the tailpipe and the combustion chamber. Extremely high, with a difference of more than 300 degrees from the average temperature of the combustion chamber. In addition, the scale of the oily medium causes the heat to not be transmitted in time, which eventually leads to the failure of the tailpipe of the pulsation burner, and then the pulsation combustion heating furnace cannot work normally, affecting the normal operation of production

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

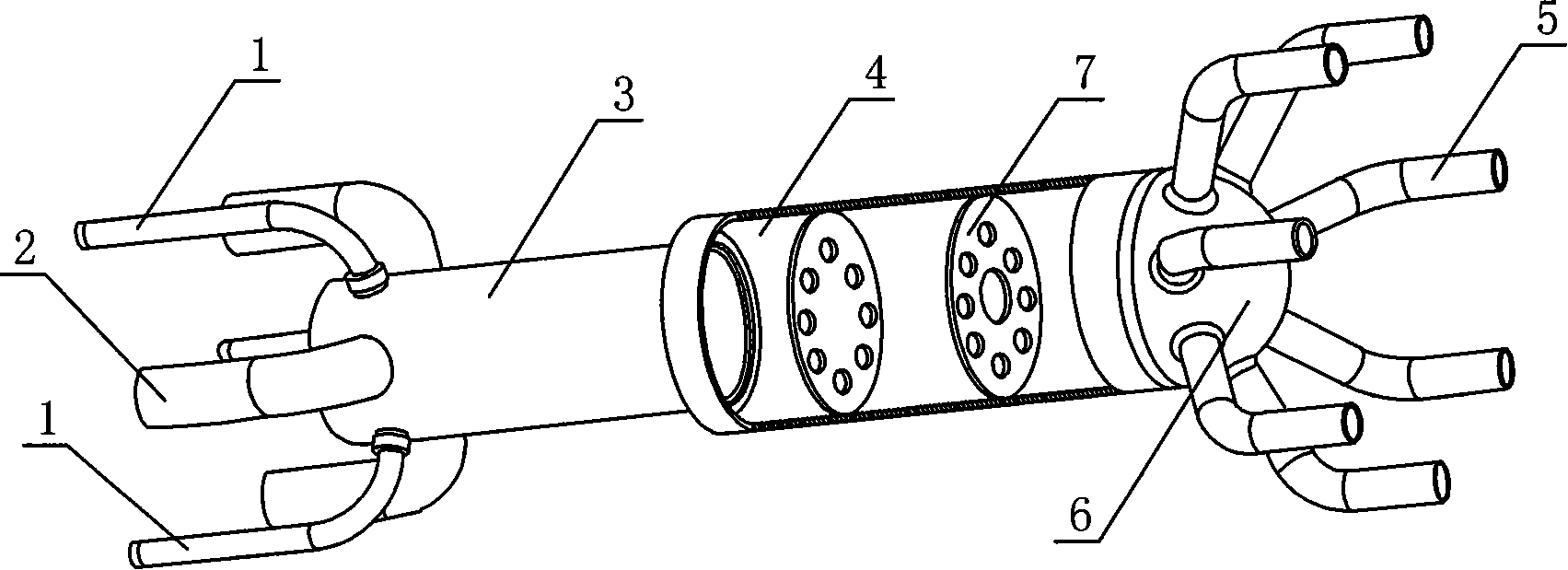

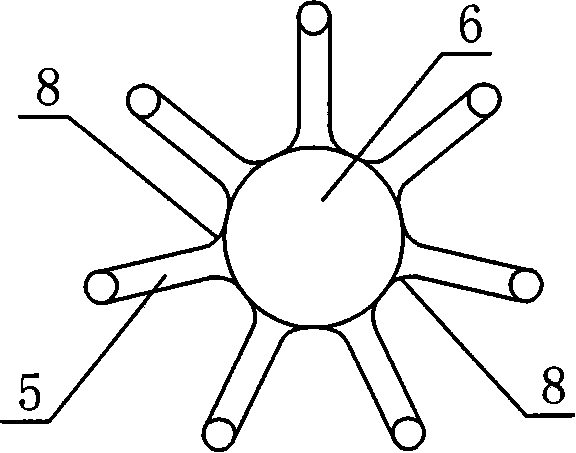

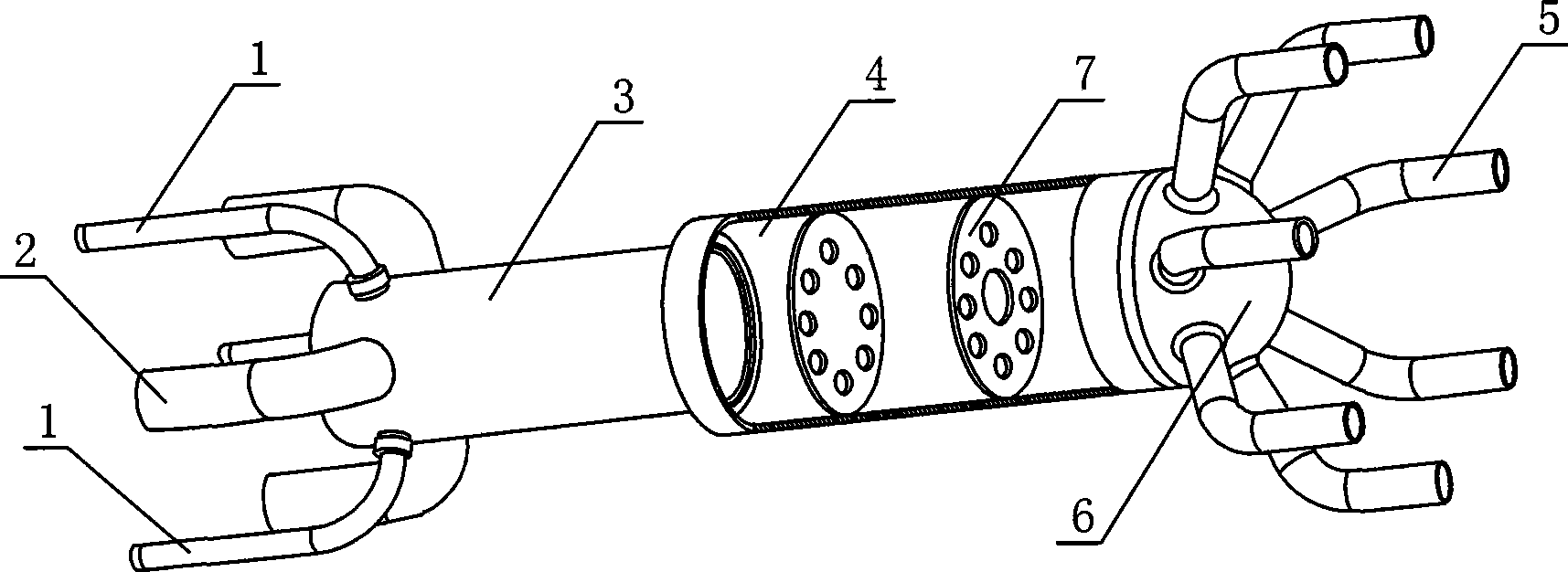

The invention relates to a highly efficient fuel gas pulsating combustor with an adjustable temperature field, which is composed of fuel gas inlet pipes, air inlet pipes, a combustion chamber, a heat releasing chamber and a furnace pipe, wherein, at least a group of fuel gas inlet pipes and air inlet pipes are arranged and connected at intervals at a tubular end of the combustion chamber, the other end of the combustion chamber is connected with the heat releasing chamber, and a plurality of branch furnace pipes are radially connected on an arc shaped end socket of the outlet of the heat releasing chamber. The diameter of the cylinder of the heat releasing chamber connected with the combustion chamber is larger than that of the combustion chamber, at least one flow flexing plate is radially arranged inside the heat releasing chamber, and isomorphic or heterogeneous pore passages are arranged on each flow flexing plate. The highly efficient fuel gas pulsating combustor with the adjustable temperature field of the invention has the advantages of high combustion efficiency, combustion intensity and heat exchange performance, low pollutant content in the discharged flue gas, long service life and improved working efficiency.

Description

High-efficiency gas pulse burner with adjustable temperature field technical field The invention belongs to burners, in particular to a high-efficiency gas pulse burner with adjustable temperature field. Background technique Crude oil plus (heat) water transportation in my country's oilfields is an indispensable process link in crude oil production. At present, the main technical means to ensure the realization of this link is to use conventional heating (furnace) equipment that uses natural gas as fuel and adopts a steady-state combustion method, such as a water-jacketed heating furnace. The key component of the heating furnace equipment is the burner. The temperature field test of the existing pulsating burner shows that the temperature field gradient is extremely large when the pulsating burner is burning, and the surface temperature distribution is extremely uneven, especially the temperature at the junction of the tailpipe and the combustion chamber. It is extremely ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): F23D14/22F24H9/18F24H1/00

Inventor 梁启国赵福臣王凤君杨开远刘颖韩超张明霞

Owner 大庆石油化工机械厂有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com