Reduction of pt and rh evaporation losses at high temperatures by using a barrier layer

A technology of evaporation loss and ceramic layer, which is applied in the direction of glass manufacturing equipment, glass furnace equipment, feeding trough, etc., can solve the problems of scrapped parts, reduced amount of precious metals, and reduced firmness of parts, etc., and achieves reduced equipment size and short passage Time, purification and efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

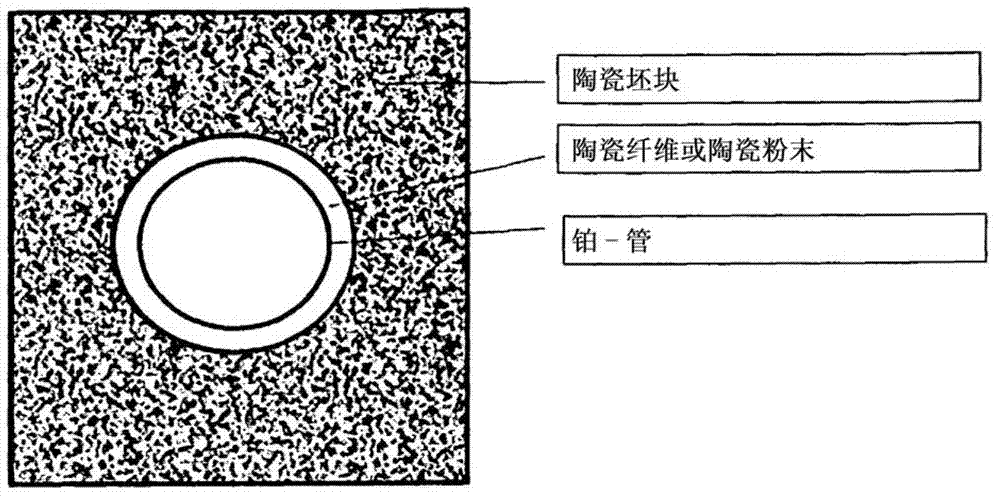

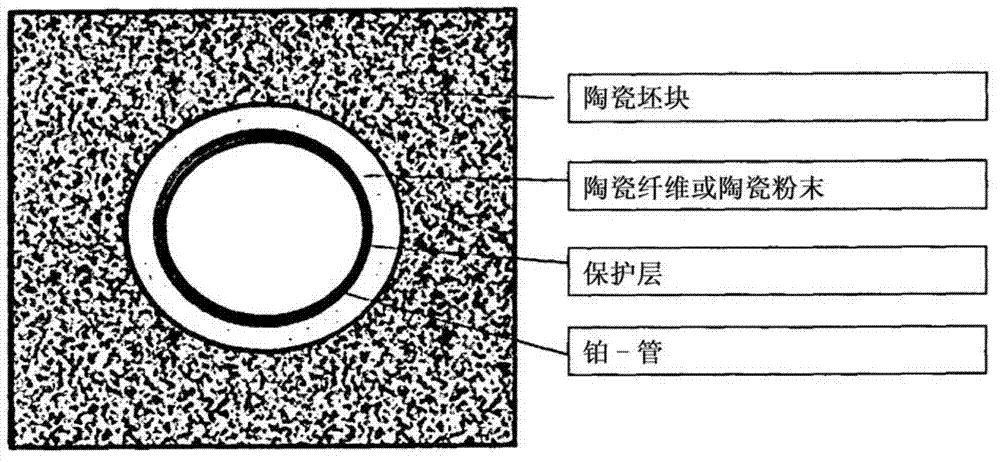

[0044] exist figure 2 The device shown in cross-section in , shows a glass guide tube wrapped by ceramic fiber or powder and ceramic compact, which is different from the prior art ( figure 1 ) are wrapped by a layer with the following components:

[0045] Materials with open pores: Al 2 o 3 .

[0046] Impregnation agent: SiO 2 60% and B 2 o 3 40%.

[0047] This layer is placed through the following processing steps:

[0048] i) with Al 2 o 3 The powder is flame sprayed on the surface of the tube. As mentioned at the beginning, flame spraying is only suitable for parts with simple geometries.

[0049] ii) Immersion in suspension (zirconium silicate suspended in water).

[0050] iii) Thermal drying.

Embodiment 2

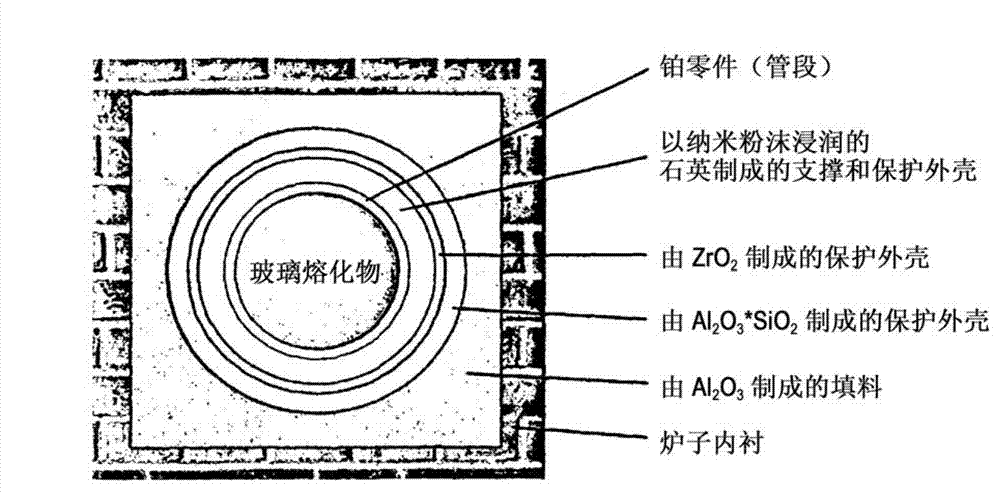

[0052] Taking into account the parameters of the task setting, a system of multi-layer protection layers was developed ( image 3 ).

[0053] In order to avoid possible extension and tension gaps in this system, the part is wrapped with a flexible ceramic quartz fiber fabric, which acts as a stress-absorbing support frame. The quartz fiber fabric is impregnated (wetted) with the particle size of the homogeneous nanomaterial. Preference is given here to fine-grained silicic acid It has a primary particle size of 3-200 nm, preferably 3-50 nm. At the temperature of use, the impregnated material is molten and liquid and closes the pores of the quartz fiber fabric as a melt, thus producing a gas-tight protective casing. This prevents oxygen from reaching the platinum surface and reacting with the platinum there to form platinum oxide, which then evaporates.

[0054] In order to protect the protective shell from reactions with the environment, a refractory zirconia fiber fabric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com