Connecting structure for use in piled anchor supporting system and its construction method

A technology for connecting structures and implementing methods, applied in infrastructure engineering, excavation, sheet pile walls, etc., can solve problems such as poor safety, many processes, and long construction periods, and achieve the effects of short construction periods, good integrity, and fewer procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

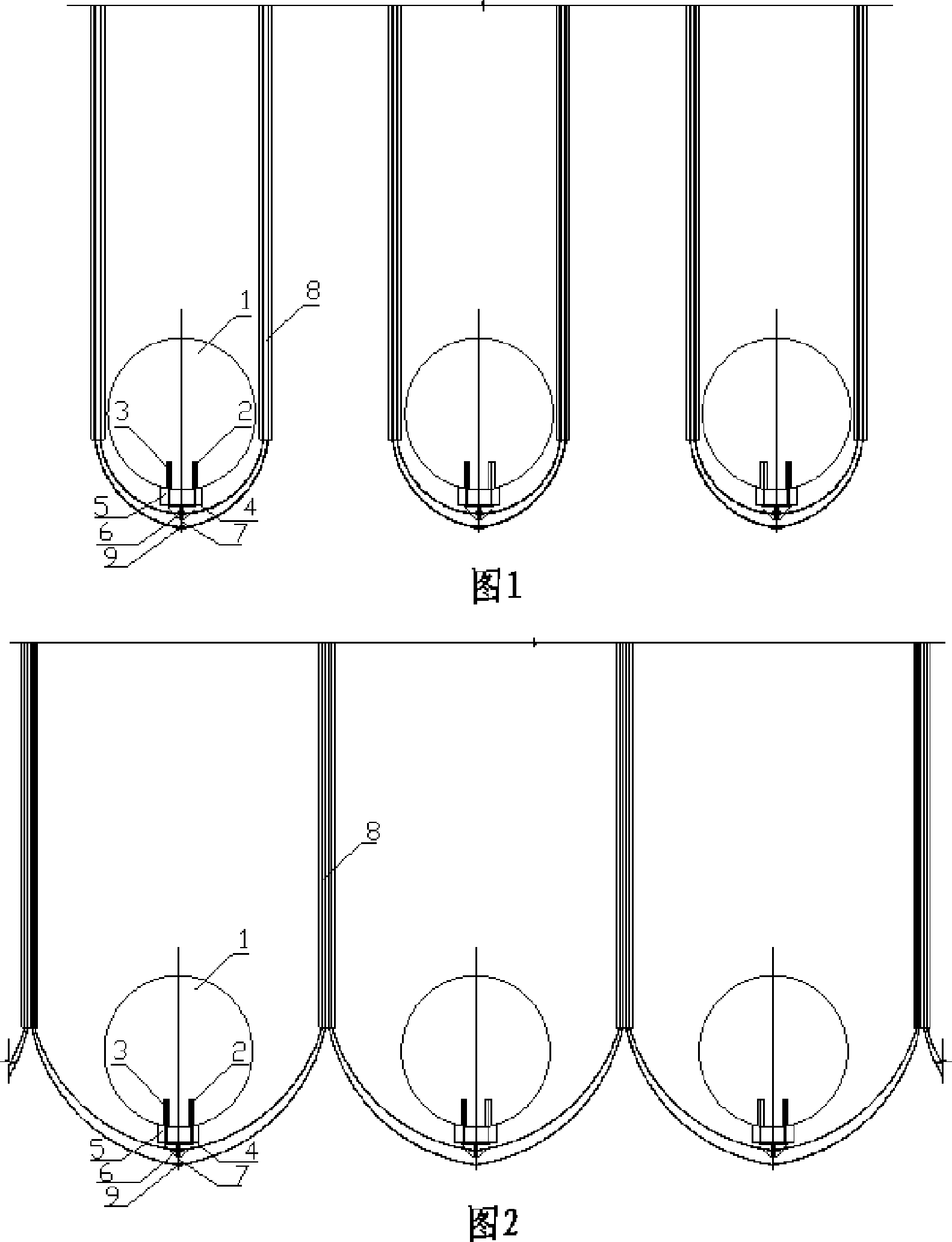

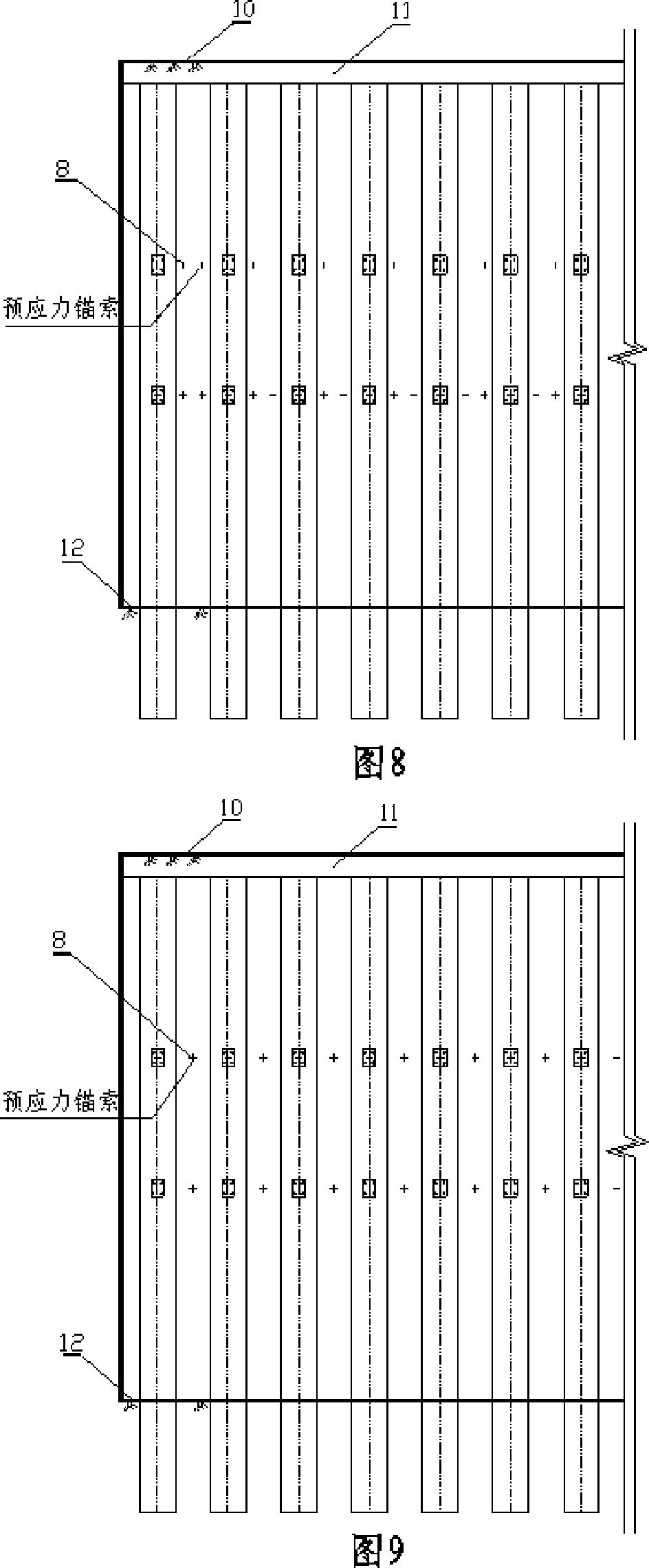

[0037] For deep foundation pit projects with poor geological conditions, pile-anchor support systems are usually used. As shown in Figures 8, 9, and 10, the depth of the foundation pit in this example is 12.4m, and the wall protection piles used are 15m long, 0.8m in pile diameter, and 1.6m in pile spacing, and two rows of anchor cables are arranged at positions of 5.0m and 7.5m respectively , the inclination angle of the anchor cable is 25°.

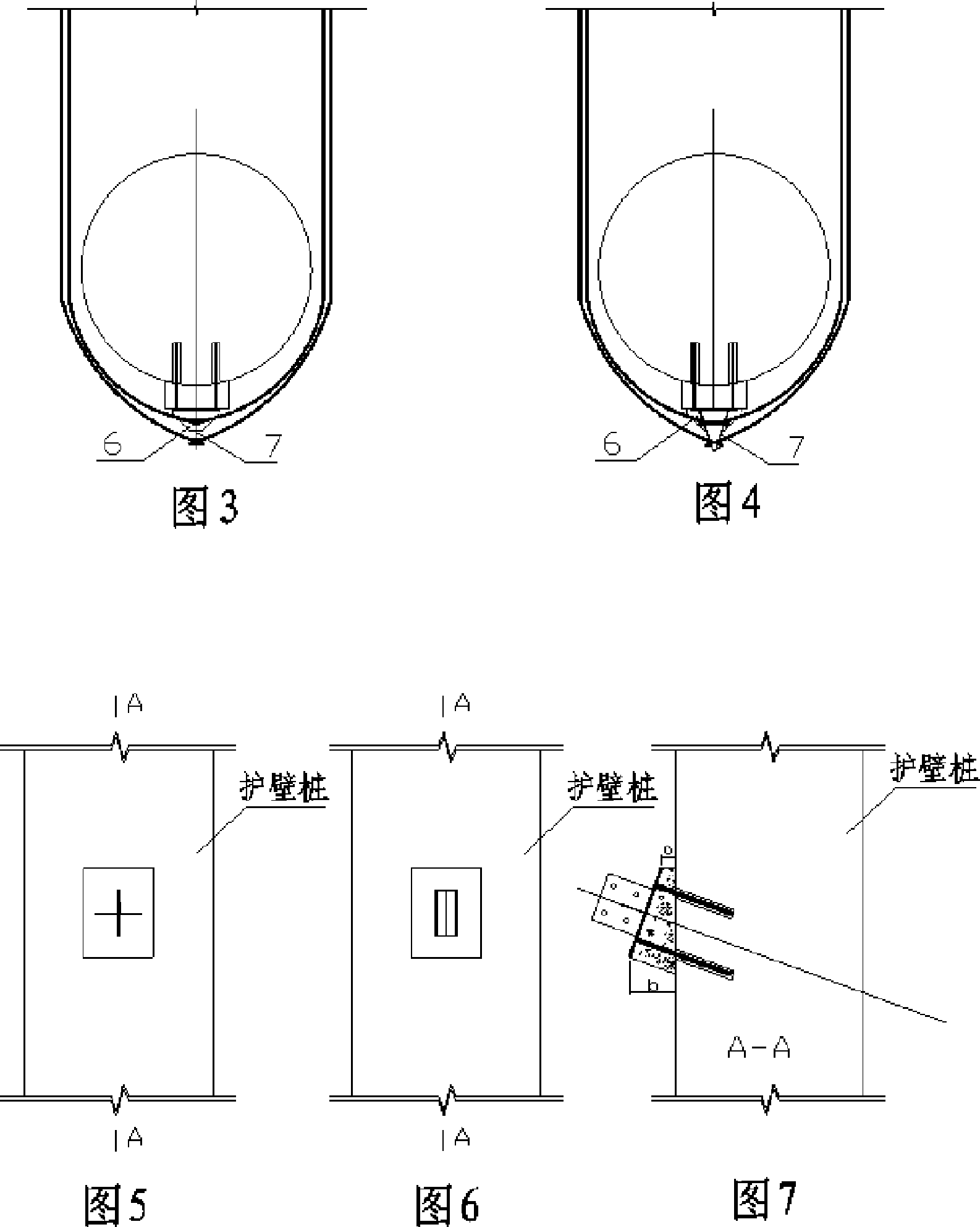

[0038] As shown in Figures 1 to 7, the construction of the retaining pile 1 is carried out according to the design drawings, and then the foundation pit is excavated from the ground 10 to 5.0m for the construction of the first row of anchor cables 8; Pull a pass line to accurately determine the elevation of the first row of anchor cables 8 boreholes 2 positions; in Figure 7, the concrete pad wedge size a=125mm, b=208mmmm, the position and reserved length of the reinforcement can be calculated according to the sizes of a and b. Among th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com