Cylindrical reinforcing steel bar connecting method and connecting structure in reverse building method

A connection method and a technology for connecting structures, which are applied in infrastructure engineering, excavation, construction, etc., can solve problems such as long construction period, heavy welding workload, and enhanced brittleness, so as to reduce welding workload, reduce welding workload, and prevent The effect of foundation pit uplift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

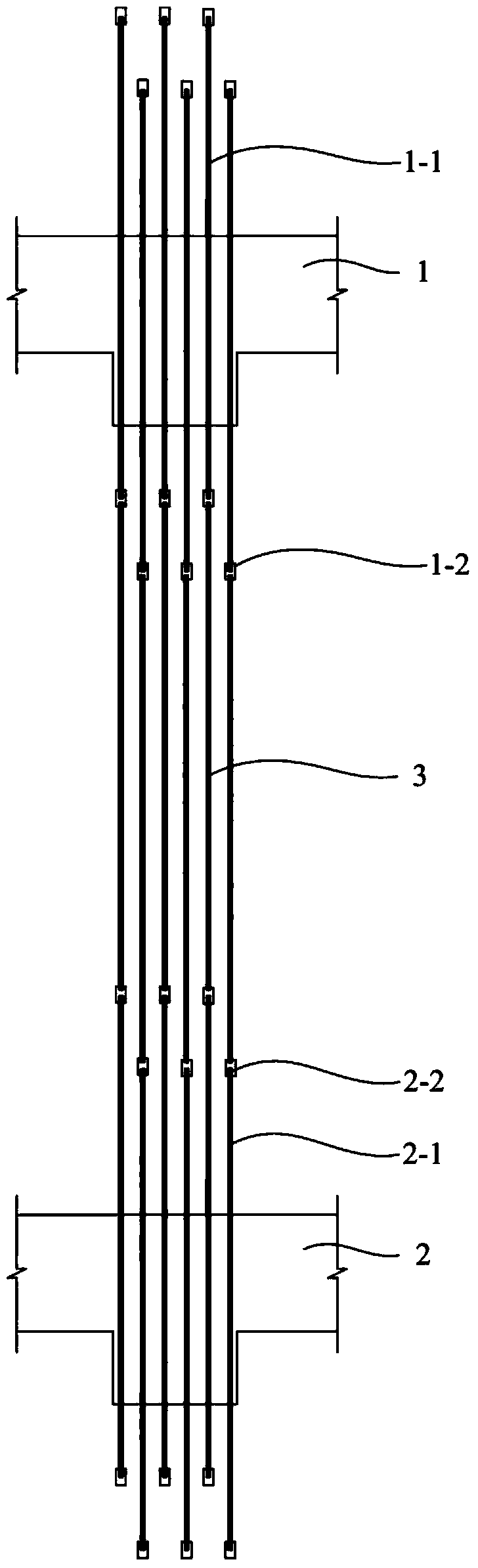

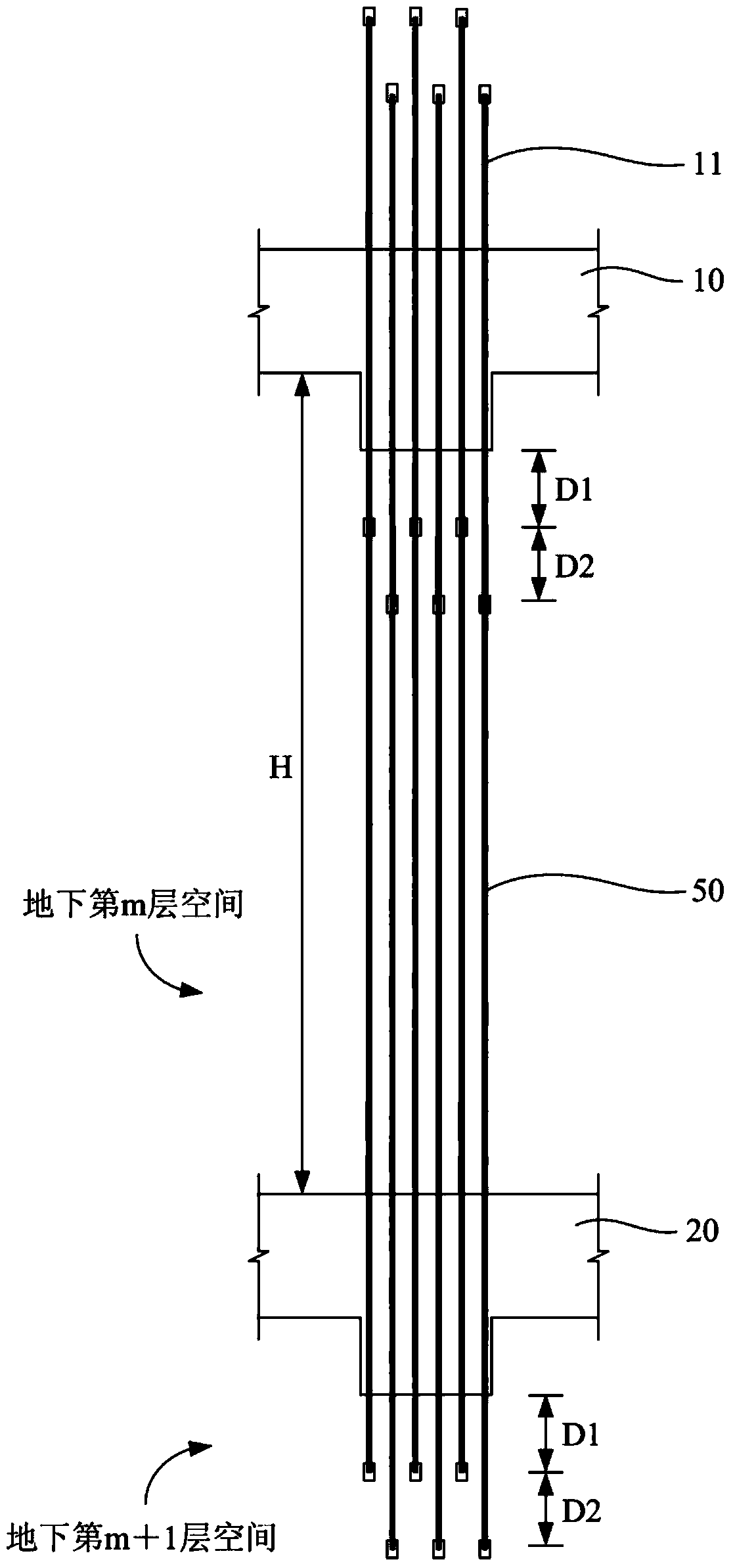

[0026] Example 1: Combining Figure 2 to Figure 4 Illustrate the connecting method of column steel bar in a kind of inversion method of the present invention, concrete steps are as follows:

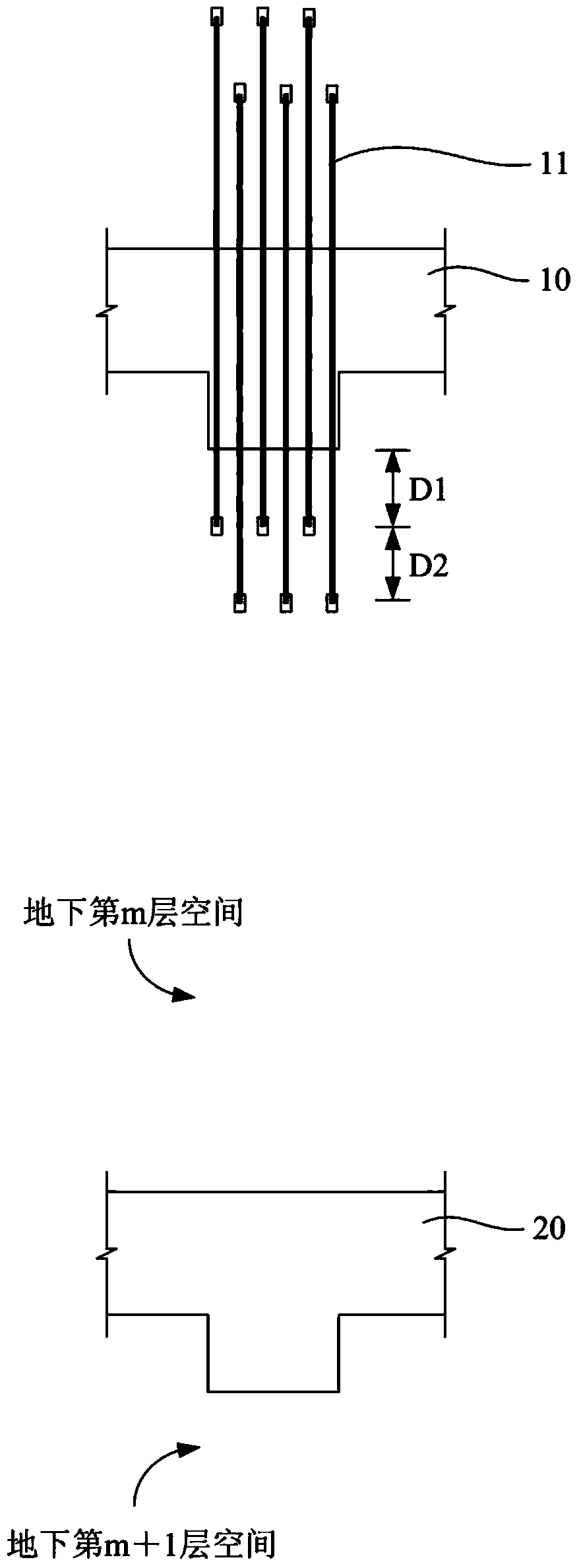

[0027] Step 1: If figure 2 As shown, a number of column inserts 11 are reserved in the beam 10 of the mth floor space underground, so that the bottom end of the column insert 11 passes through the beam 10 and is located in the interior space of the mth floor underground;

[0028] Step 2: processing several connecting steel bars 50;

[0029] Step 3: If image 3 As shown, the top of the connecting steel bar 50 in the above step 2 is fixedly connected to the bottom end of the column insertion bar 11 reserved in the beam 10, and the bottom end of the above connecting steel bar 50 passes through the beam 20 in the space of the m+1th floor underground. The inner space of the m+1th underground floor forms the column reinforcement in the space of the mth underground floor;

[0030] Step 4: R...

Embodiment 2

[0036] Embodiment 2: Combination Figure 2 to Figure 4 The connection structure of the column reinforcement in a reverse method of the present invention includes a plurality of connection reinforcements 50, and the top of each connection reinforcement 50 is fixedly connected with the column insertion reinforcement 11 reserved in the beam 10 of the underground m-th floor space , the bottom end of each connecting rib 50 passes through the beam 20 in the space of the m+1th underground floor and enters the inner space of the m+1th underground floor.

[0037] Further, the top end of the connecting steel bar 50 is provided with an external thread, and its bottom end is connected to a sleeve with an internal thread. The top of the connecting steel bar 50 is threadedly connected to the sleeve at the bottom of the column inserting bar 11 in the beam 10, and the bottom end of the connecting bar 50 passes through the beam 20 to become the column inserting bar reserved in the beam 20 in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com