Method for installation construction of roof free-form surface single-layer latticed shell structure of super high-rise building

A single-layer reticulated shell and construction method technology, which is applied in the direction of building structure, construction, and building material processing, can solve the problems of high-altitude assembly and welding, large volume, difficult closing of accumulated deformation, and difficult spatial positioning, etc., to achieve quality Strong controllability, reduced construction management costs, and guaranteed machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

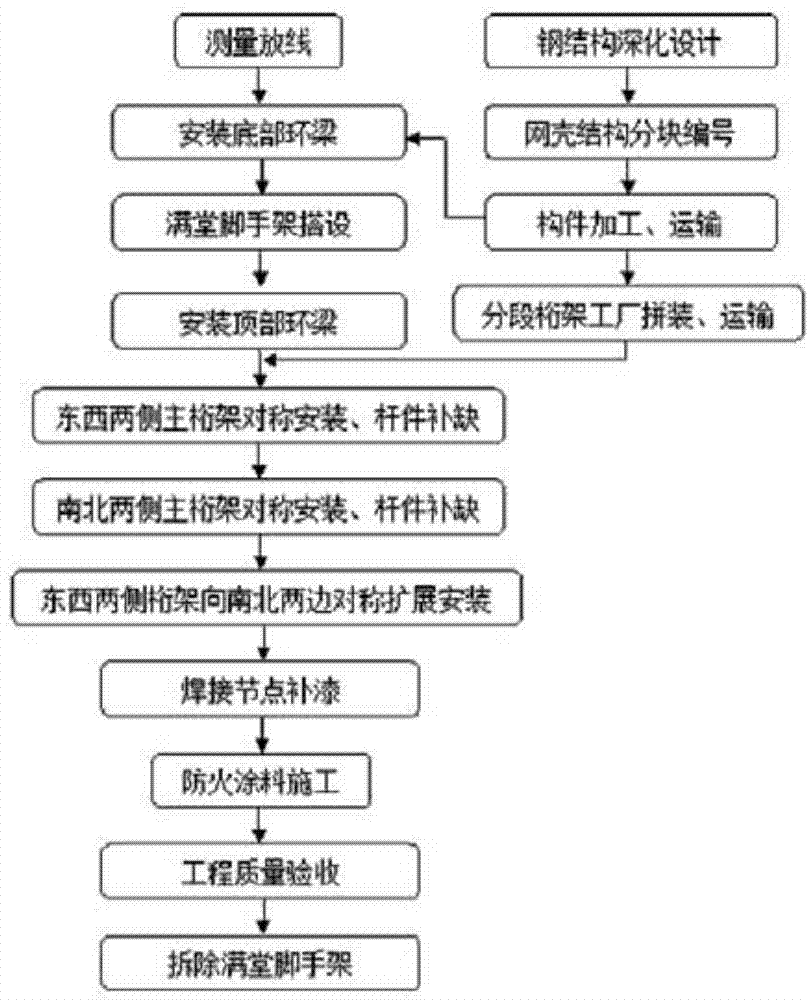

[0043] Such as figure 1 As shown, the installation and construction process of the free-form surface single-layer reticulated shell structure on the roof of a super high-rise building:

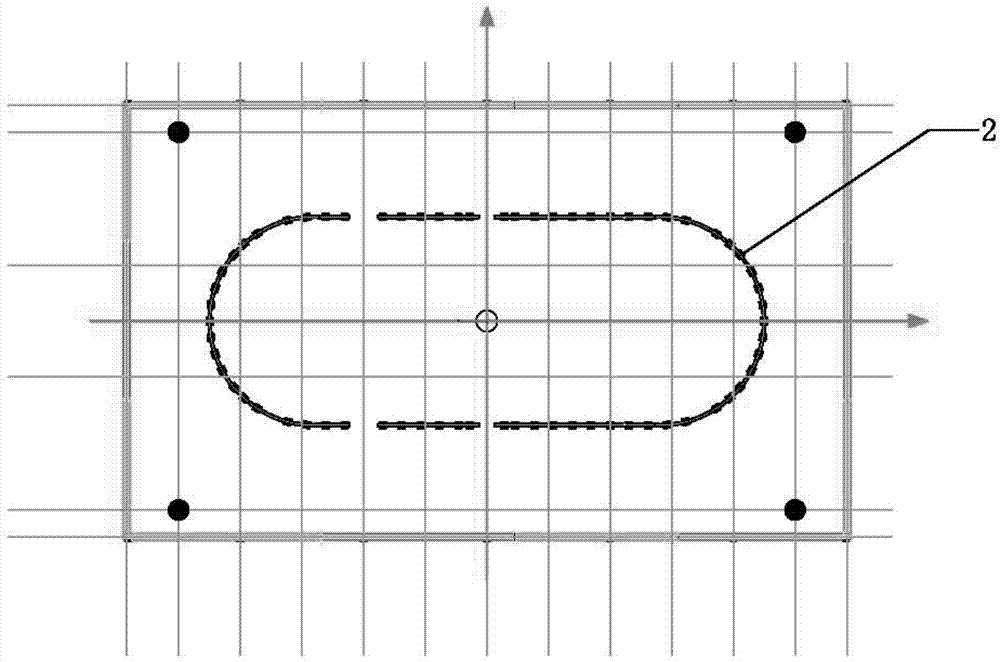

[0044] (1) Measurement and setting out, ①Main control axis, set four projection reference points at the four corners of the floor surface, and ensure that each reference point can see through two adjacent reference points, ②Reticulated shell structure 1 solid line lead measurement ;

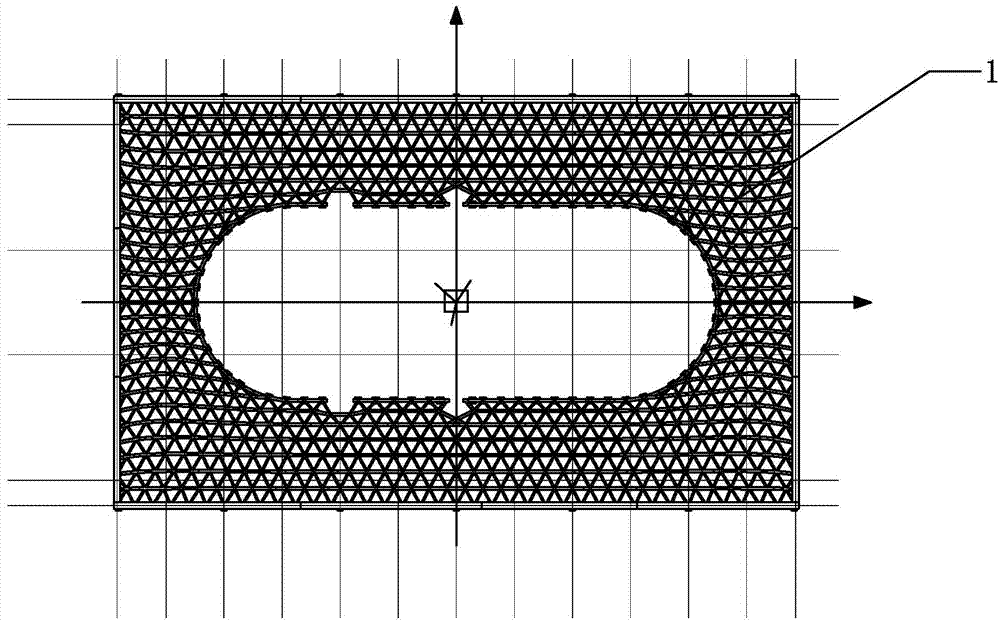

[0045] (2) Divide the reticulated shell structure 1 into blocks, segment the reticulated shell structure 1 according to the structural conditions, on-site installation conditions and transportation conditions, and divide the reticulated shell structure 1 into 62 small trusses and filling rods 5;

[0046] (3) Install the reticulated shell structure 1, ① install the bottom ring beam 2, ② set up a full hall scaffold, ③ install the top ring beam 3, ④ symmetrically install the main truss 4 on both sides of the east ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com