Method for manufacturing gear case

A technology of a gear box body and a manufacturing method, which is applied in the field of industrial manufacturing, can solve the problems of reducing the effective area of the casting, the mechanical properties of the casting, the environmental impact, etc., and achieves the effects of easy residual stress, suppression of vibration, and increased safety factor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] An embodiment of the manufacturing method of the gear case of the present invention will be further described below in conjunction with the accompanying drawings:

[0046] The specific operation steps of the manufacturing method of a kind of gear housing of the present invention are:

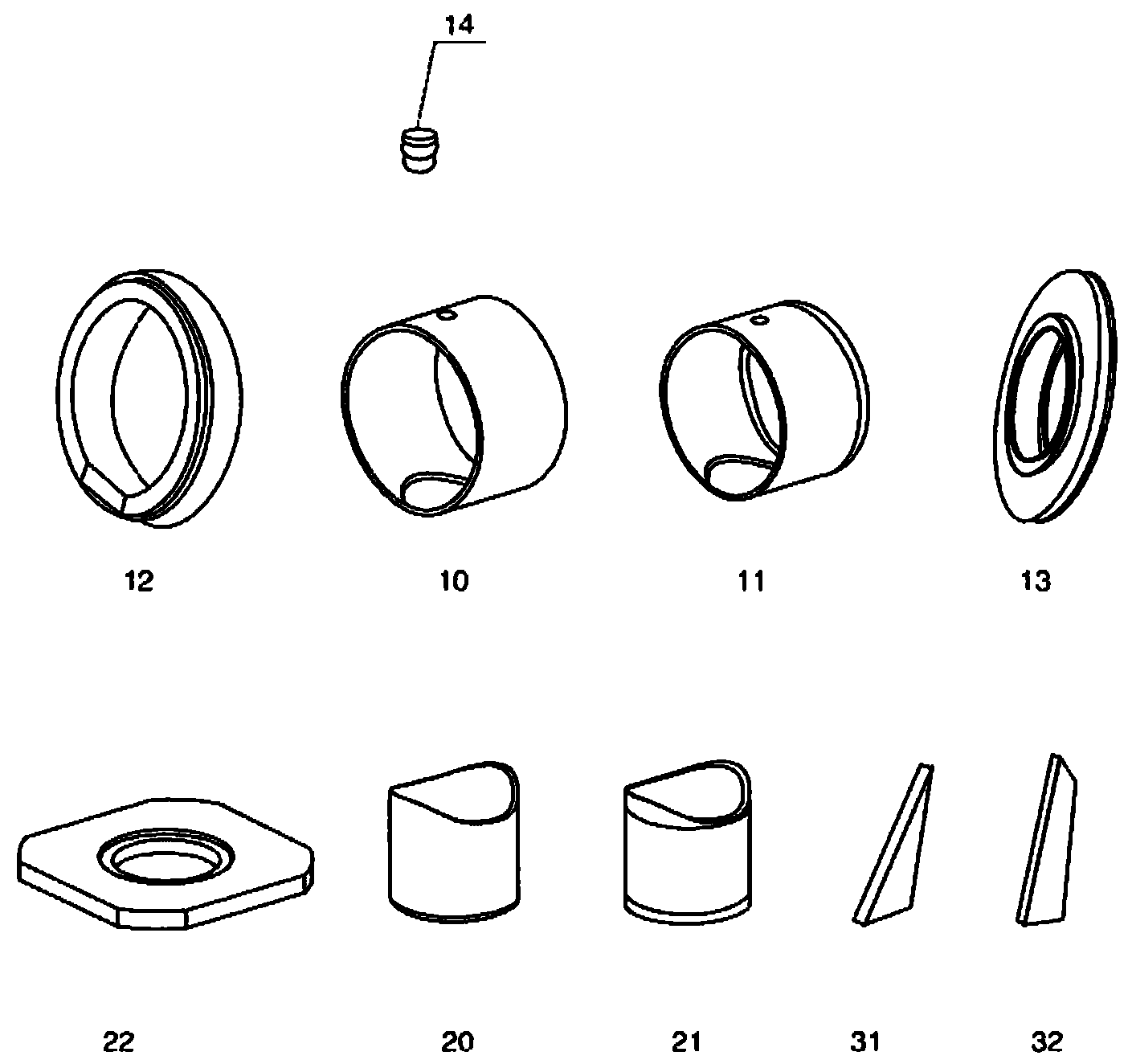

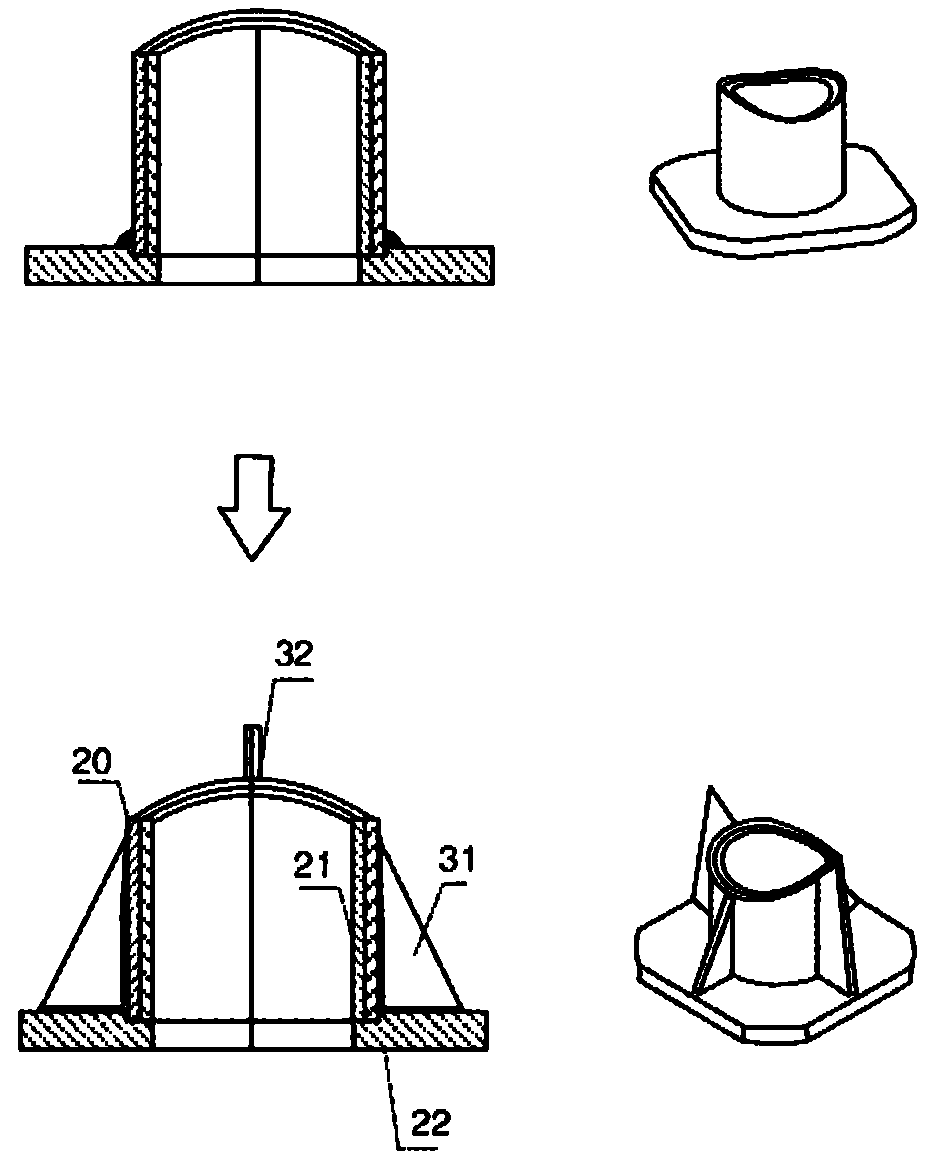

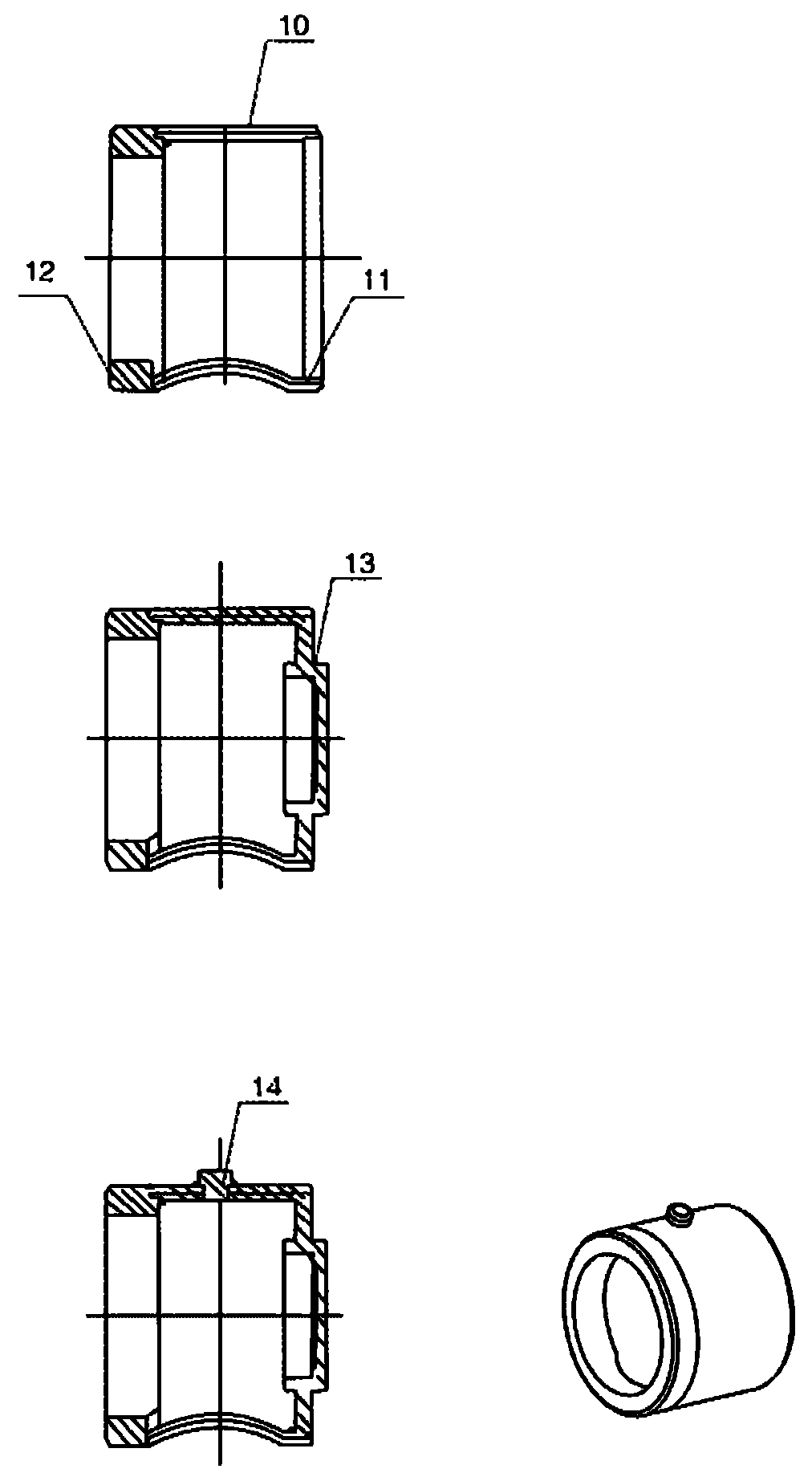

[0047] (1) Select low-carbon steel material, cut according to the size of the box, and form the components of the box, such as figure 1 As shown, it includes input housing 10 and input housing additional plate 11, bushing 12, rear end cover 13, plug seat 14, output end bearing seat 20 and output end bearing seat additional plate 21, bottom plate 22, two A triangular rib 31 and two quadrilateral ribs 32, each component maintains a cutting allowance of 3mm.

[0048] Among them, the thickness of the input end housing 10 and the output end bearing seat 20 is 4 mm, the thickness of the input end housing additional plate 11 and the output end bearing seat additional plate 21 is 2 mm, the input...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com