Discharge tube connector

A discharge tube and connector technology, which is applied in the field of discharge tube connectors, can solve the problems of difficult assembly, time-consuming, labor-intensive, etc., and achieves the effect of eliminating welding operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Hereinafter, embodiments of the present invention will be described with reference to the drawings. Reference numerals in the drawings indicate parts or components. In addition, redundant descriptions of configurations, materials, manufacturing methods, and the like that are common to the respective embodiments are omitted.

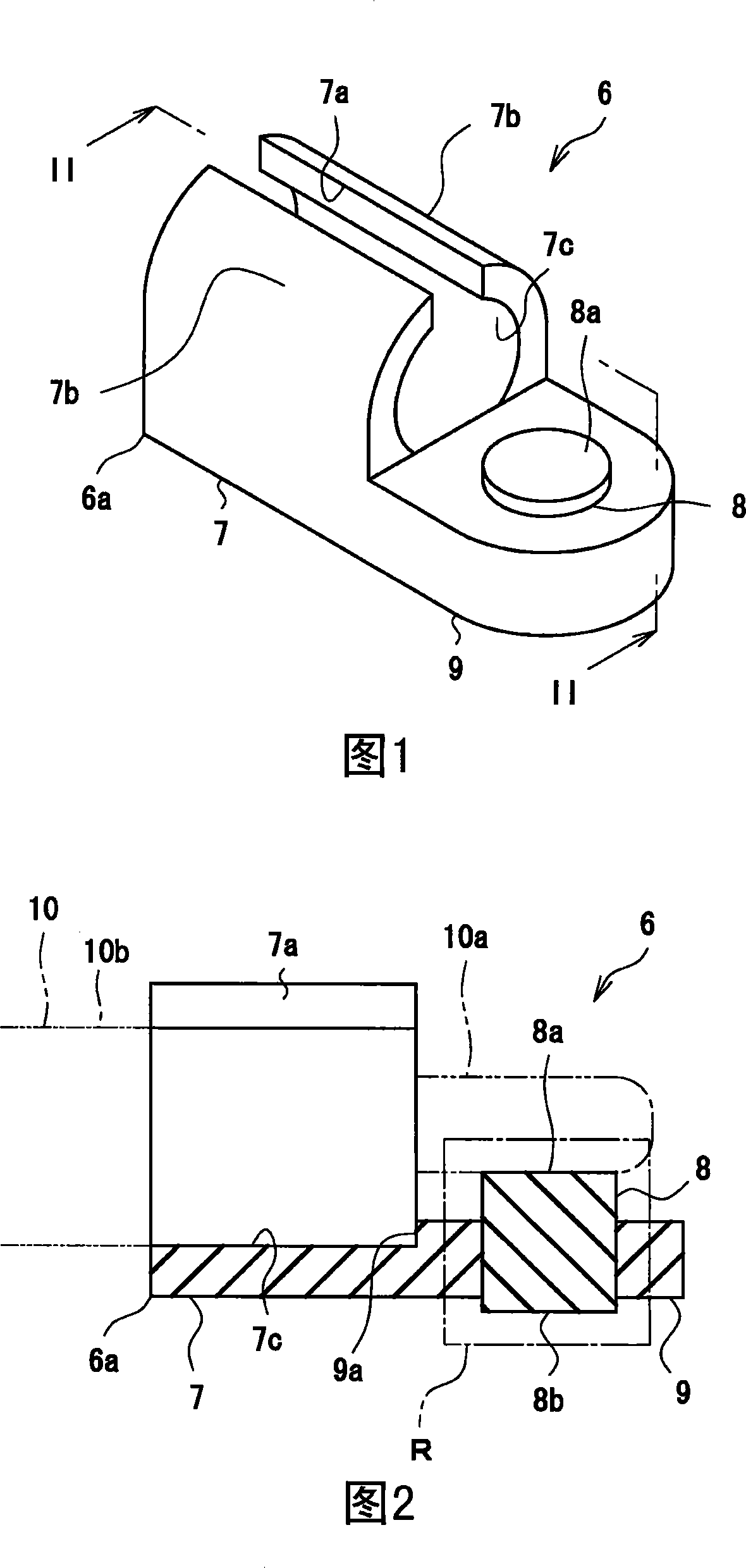

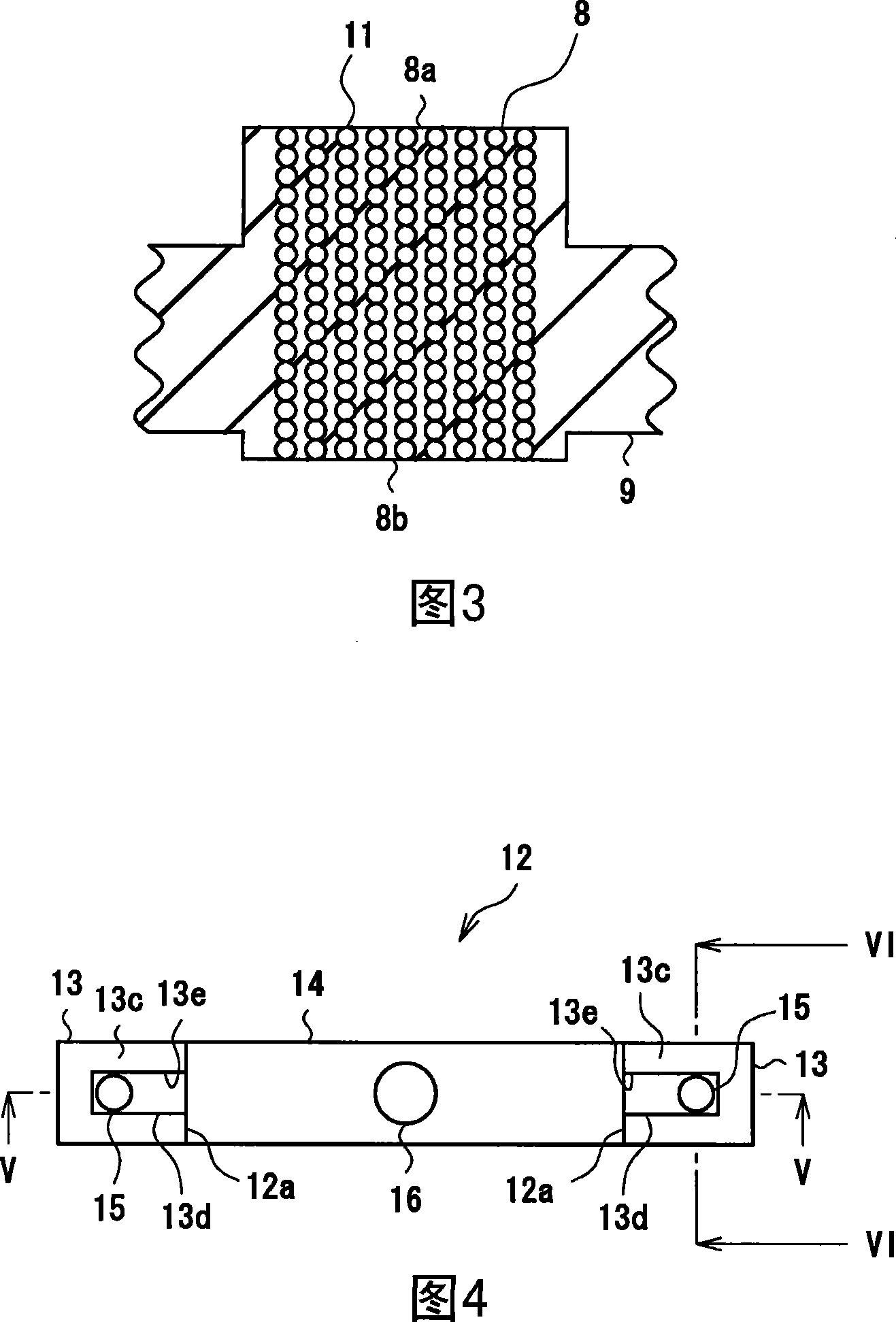

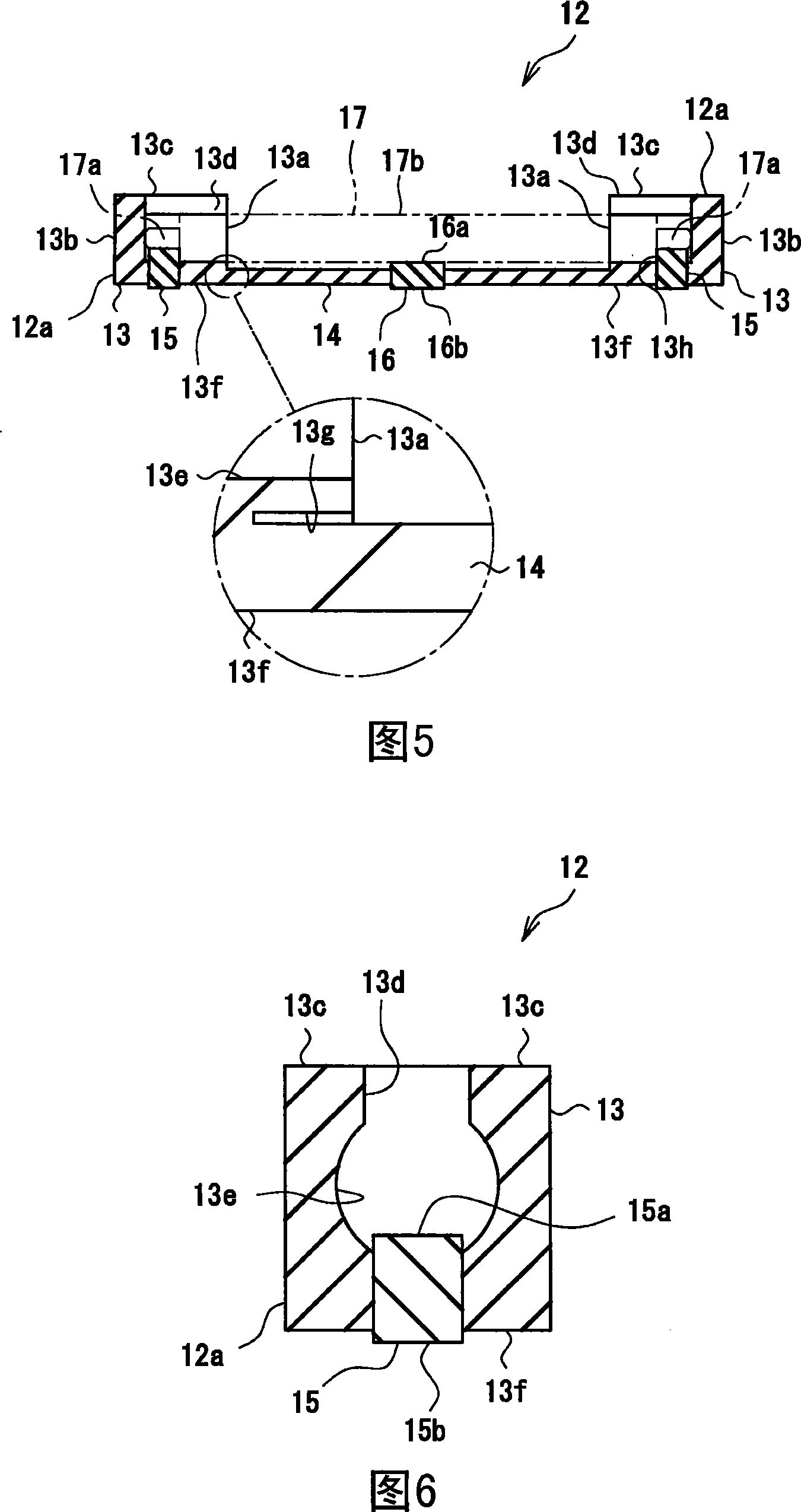

[0052] First Embodiment {FIGS. 1 to 3}: FIGS. 1 to 3 show a discharge tube connector 6 according to a first embodiment. FIG. 1 is a perspective view of a discharge tube connector 6 according to this embodiment, FIG. 2 is a sectional view taken along line II-II in FIG. 1 , and FIG. 3 is an enlarged sectional view of a portion R in FIG. 2 . The discharge tube connector 6 has a holding portion 6a attached to the end of the discharge tube 10, and the holding portion 6a has: a locking surface 7 that holds the light emitting tube 10b of the discharge tube 10; The face part 7 protrudes along the end electrode 10a; the conductive connection part 8 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com