Assembled type unit framework installing method

An installation method and prefabricated technology, which can be used in construction, building structure, construction material processing, etc., can solve the problems of inability to perform three-dimensional cross operation, difficult vertical transportation, long construction period, etc., so as to save production time and reduce welding operations. , the effect of safety production and construction quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

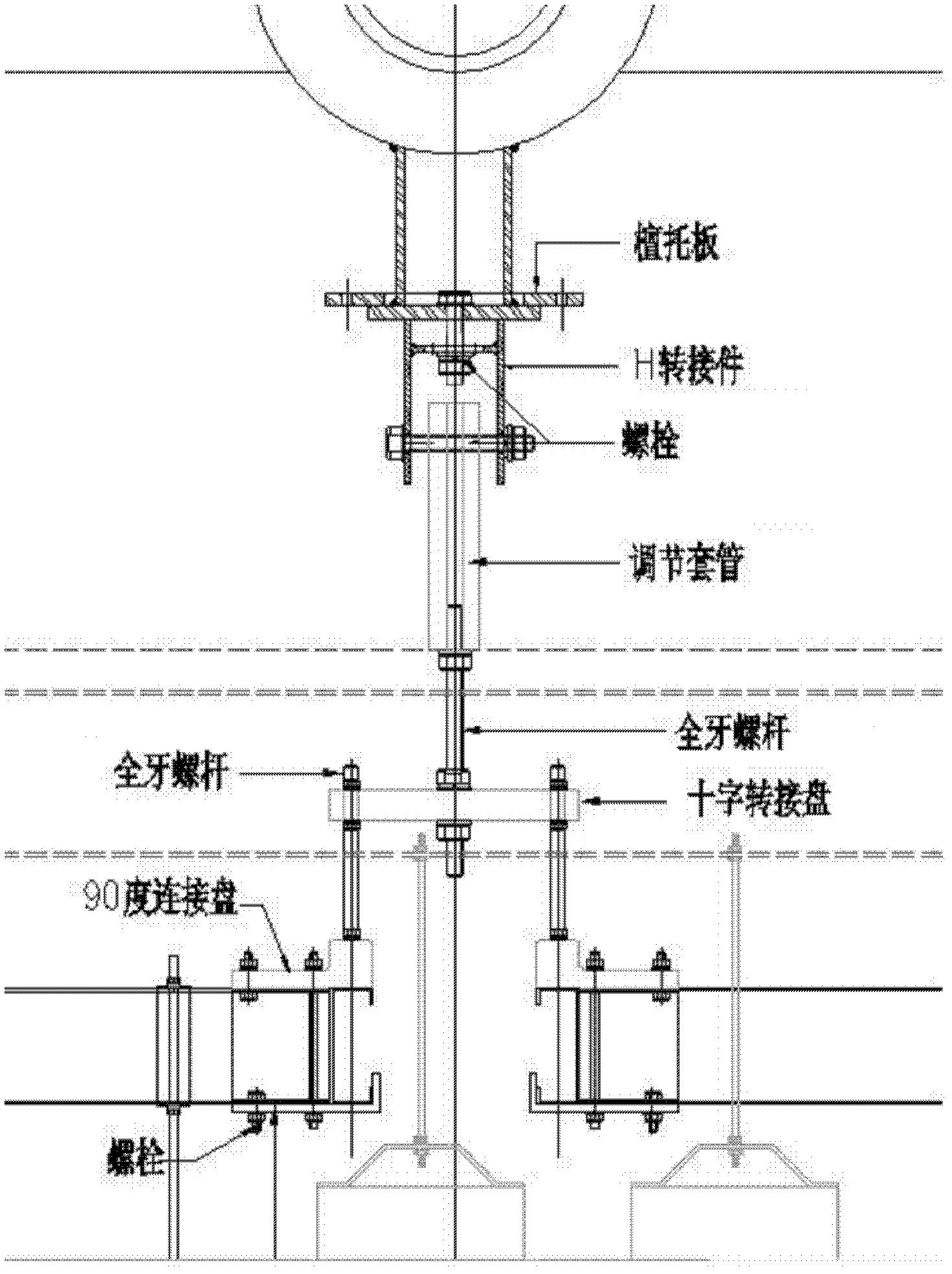

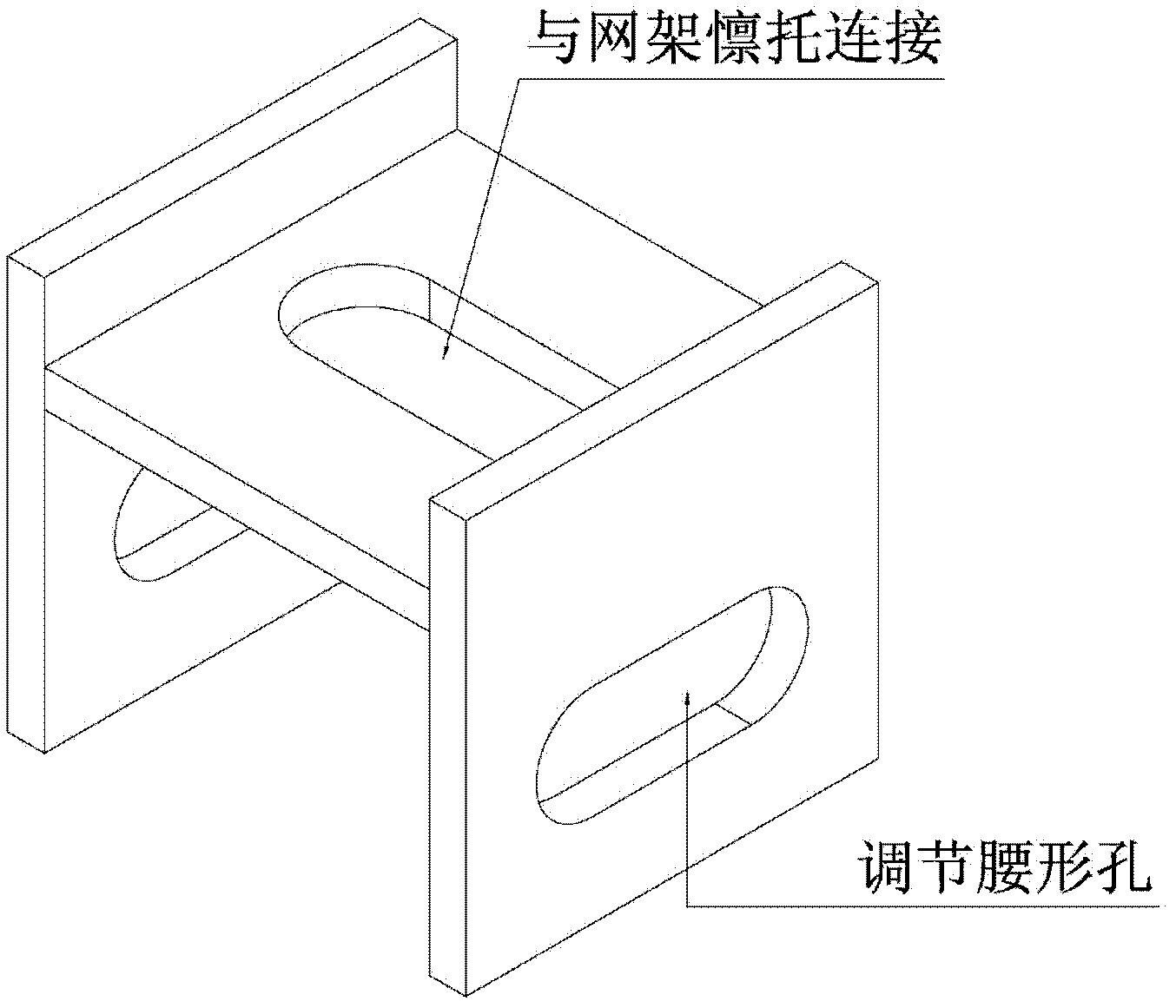

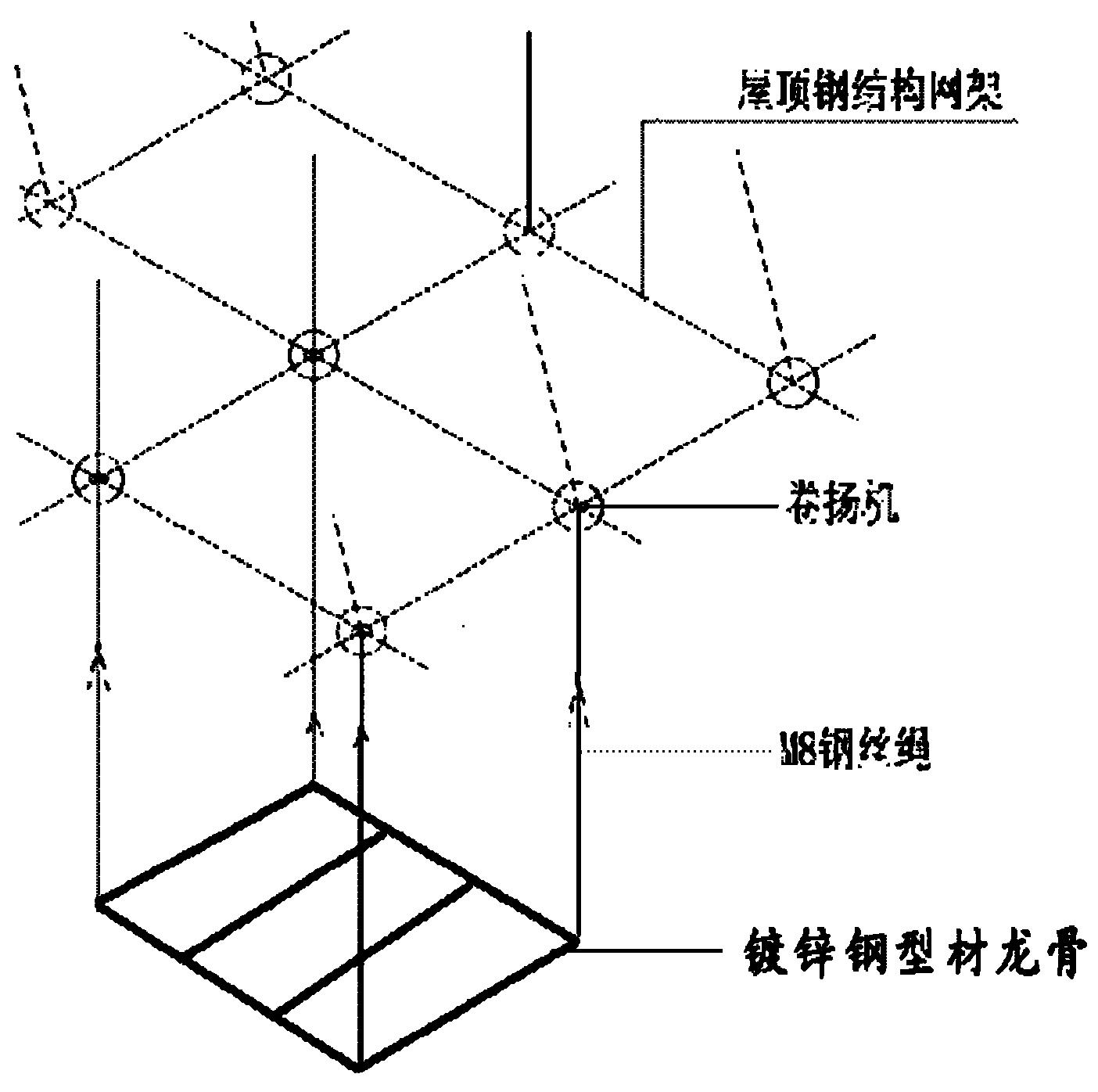

[0021] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0022] Prefabricated unit skeleton overall lifting and reverse installation of metal strip ceiling is a new technology different from traditional metal ceiling. The ceiling components are processed and assembled in the factory, and then the skeleton is hoisted as a whole according to the unit. After the unit skeleton is installed, the ceiling skeleton can be used again. Installing the ceiling tiles in reverse for the operating platform allows for ceiling tile installations without scaffolding.

[0023] A method for installing a prefabricated unit skeleton is characterized in that it comprises the following steps:

[0024] Step 1: Measure, set out, and positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com