Assembled type steel structure concrete external wall panel and node and construction method of node

A technology for exterior wall panels and steel structures, applied to walls, building components, building structures, etc., can solve problems such as long installation time, complicated procedures, and low requirements on the bearing capacity of connection nodes between wall panels and main structures, and achieve construction High efficiency, less on-site welding operations, and the effect of reducing high-altitude welding operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

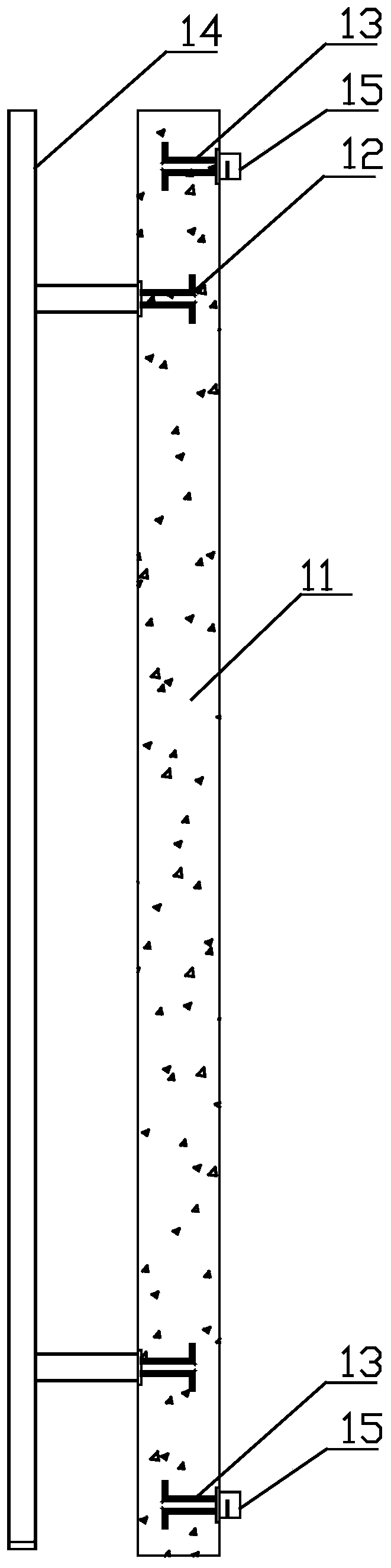

[0023] Such as figure 1 As shown, the assembled steel structure concrete exterior wall panel of the present invention, the exterior wall panel is a lightweight concrete exterior wall panel 11, wherein, the main keel embedded part 12 of the curtain wall is arranged in the exterior wall panel, and the The fixed end of the main keel embedded part of the curtain wall is exposed on one side of the lightweight concrete outer wall panel, and is used to fix the main keel 14 of the curtain wall; a node hook embedded part 13 is arranged in the outer wall panel. The fixed end of the node hook embedded part is exposed on the other side of the lightweight concrete outer wall panel, and is used for fixing the node hook 15 .

Embodiment 2

[0025] The assembled steel structure steel beam of the present invention is provided with assembly nodes for hanging the external wall panels on the side of the beam corresponding to the external wall panels.

[0026] Wherein, the assembly node includes an upper hanging plate for limiting the lower hanging parts of the upper outer wall panel, and a lower hanging plate for bearing the weight of the lower hanging parts on the lower outer wall panel.

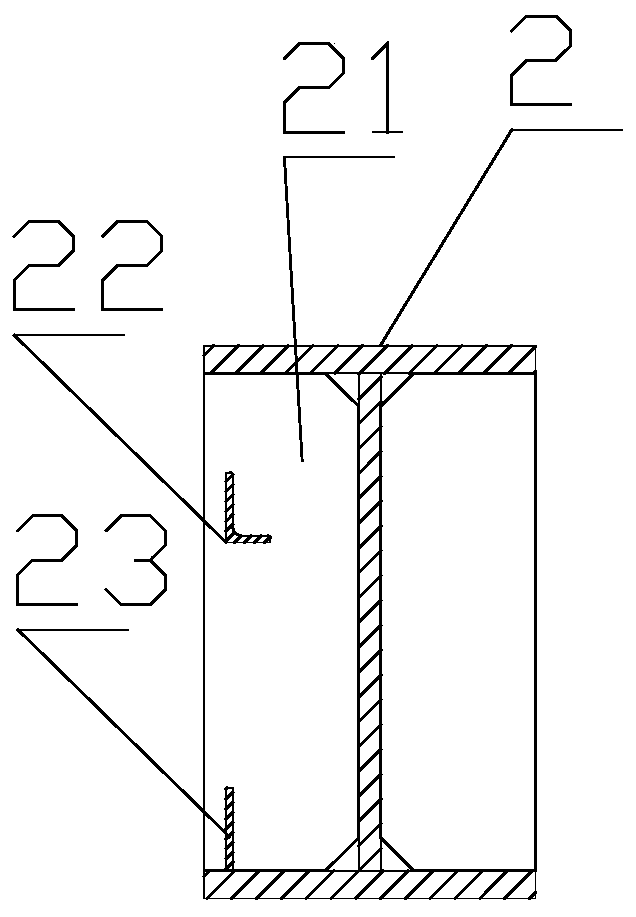

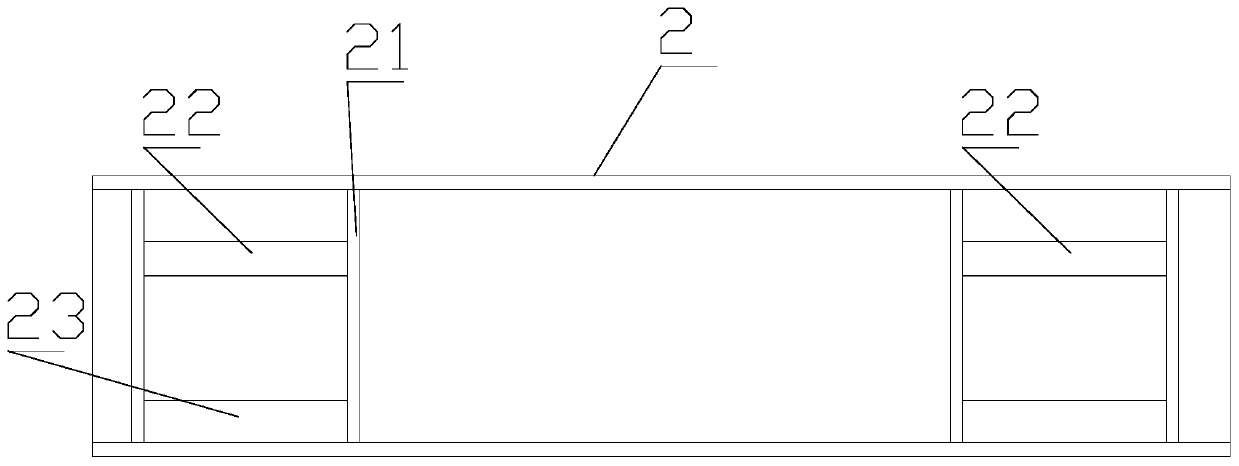

[0027] Wherein, the beam is an H-shaped steel beam; the node includes two gusset plates arranged at intervals between the flange plates on one side of the H-shaped steel beam, and the upper hanging plate is arranged between the two gusset plates upper position, such as figure 2 As shown, it can be made of angle steel; the lower hanging plate is set at the lower position between the two gusset plates, and is preferably welded on the upper surface of the lower flange plate.

Embodiment 3

[0029] Such as Figure 4 , Figure 5 As shown, the separate connection node of the assembled steel structure steel beam of the present invention is connected with the external wall panel, the described assembled steel structure steel beam is the assembled steel structure steel beam of embodiment 2; the described external wall panel is The fabricated steel structure concrete exterior wall panel described in embodiment 1;

[0030] Wherein, the fixed end of the node hook embedded part is a hook 15, and the upper end and / or lower end of the outer wall panel are hung on the upper hanging plate and the lower hanging plate of the assembly node of the assembled steel structure steel beam through the hook. plate, wherein the upper hanging plate is set at the upper position between the two gusset plates, such as figure 2 As shown, it can be made of angle steel; the lower hanging plate is set at the lower position between the two gusset plates, and is preferably welded on the upper su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com