Online hot pressed composite panel production equipment and production process thereof

A technology for composite plates and production equipment, which is applied to other household appliances, household appliances, optical components, etc., can solve the problems of low production efficiency, complex structure of light guide plate production equipment, complex production process, etc. The effect of small impact and low material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

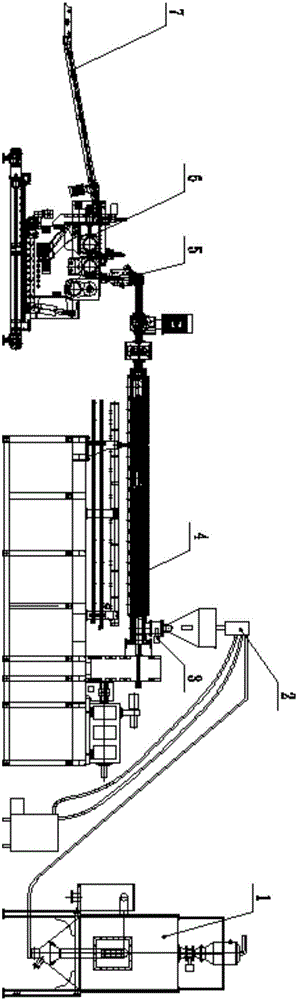

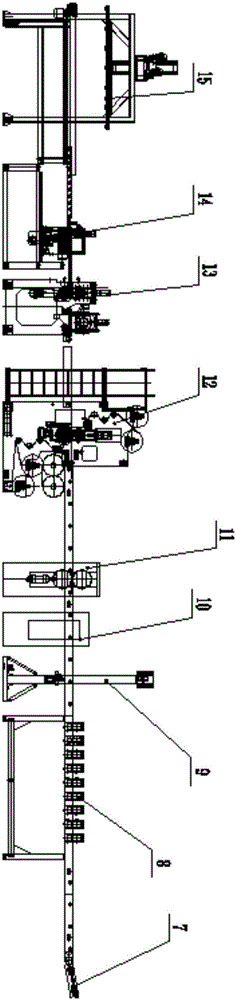

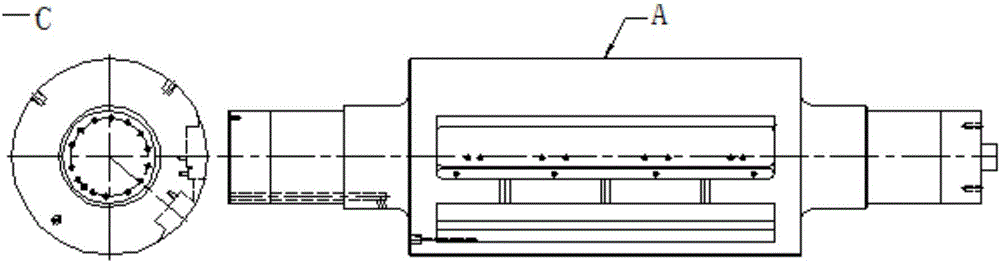

[0049] Such as Figure 1 to Figure 12 As shown, the online hot-pressing composite plate production equipment of the present invention includes a dryer 1, a dust remover 2, a portioning machine 3, a single-screw extruder 4, a fully automatic multi-layer co-extrusion hanger type die head 5, a multi-roller calender Machine 6, slow cooling frame 7, defect detector 8, temperature equalizer 9, thickness detector 10, precision temperature hot press 11, traction laminating machine 12, traction trimming machine 13, cross-cutting machine 14 and manipulator 15 The dryer 1 transports the dried raw materials to the dedusting machine 2 for dedusting, and the dedusting machine 2 transports the dedusted raw materials to the hopper of the single-screw extruder 4, and at the same time, the distributor 3 quantitatively distributes the additives to the single-screw extruder 4 , the single-screw extruder 4 mixes and plasticizes the raw materials into a melt, and then transports them to the fully a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com