Touch panel structure and manufacture method thereof

A technology of a touch panel and a manufacturing method, which is applied in the field of touch panel structure and its manufacture, can solve the problems of consuming manufacturing costs and man-hours, prolonging the production time of touch panels, etc., and achieve the goal of reducing manufacturing man-hours and reducing manufacturing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical means and effects used by the present invention to achieve the purpose will be described below with reference to the attached drawings, and the embodiments listed in the following drawings are only for auxiliary explanation, so as to facilitate the understanding of the review committee, but the technical means of this case are not Not limited to the listed drawings.

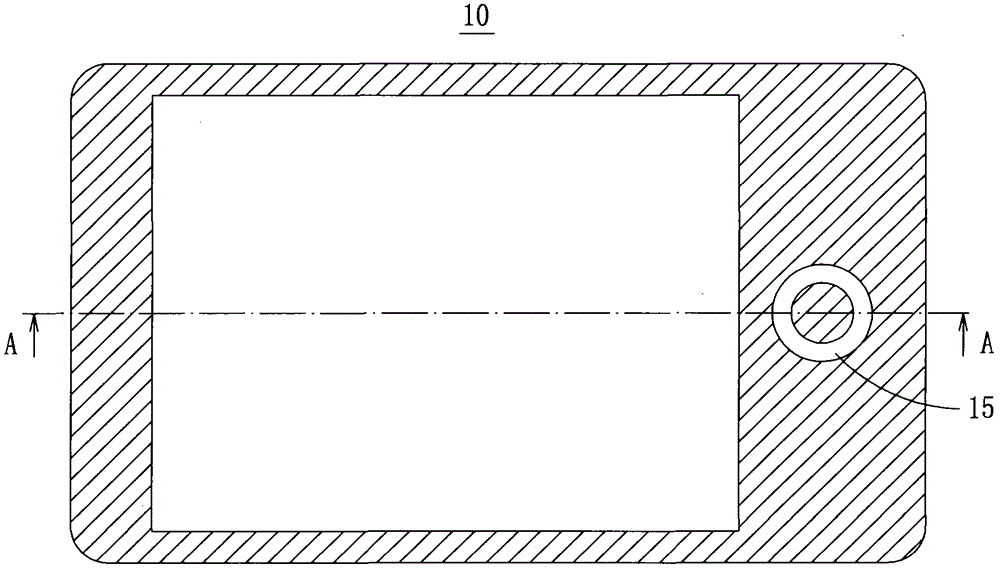

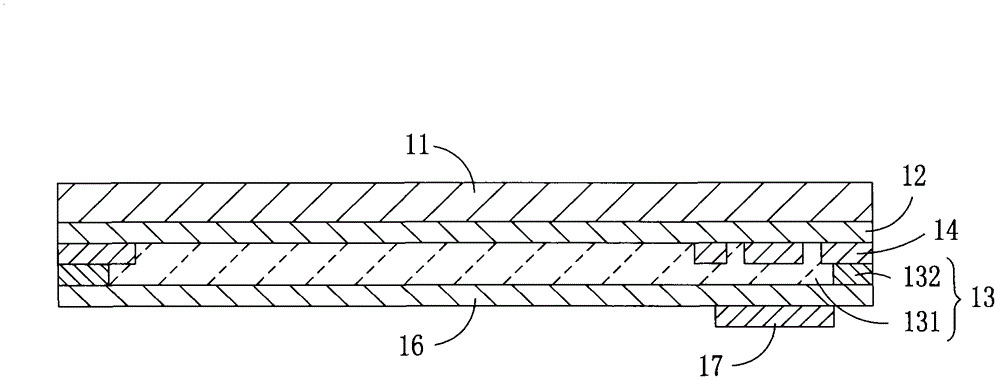

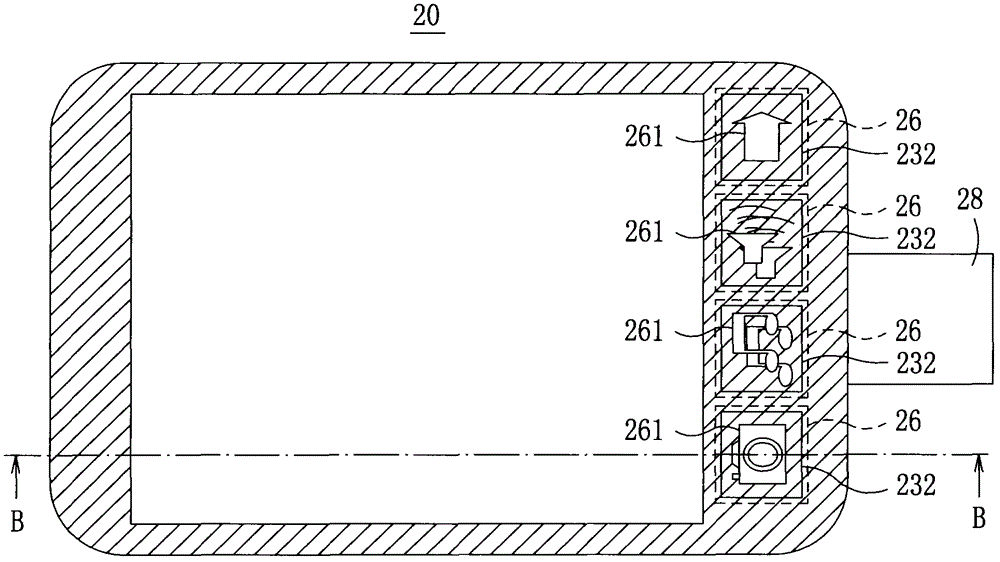

[0038] see image 3 and Figure 4A An embodiment structure of the touch panel of the present invention is shown, and Figure 5 As shown in its manufacturing steps, the touch panel 20 includes a substrate 21, a buffer insulating layer 22, a decoration layer 23, a touch unit 24, a protective insulating layer 25, a first ink layer 26 and a second ink Layer 27, the manufacturing process 30 of the touch panel 20 includes the following steps:

[0039] Step 31: Set a buffer insulating layer 22 of transparent material on one side of the substrate 21 made of transparent material. The substrate 21 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com