Engineering machinery cooling device collocating structure

A technology for cooling devices and construction machinery, which is applied in the direction of engine cooling, mechanical equipment, and the arrangement of cooling combination of power devices, etc., which can solve the problems of shrinking heat exchanger configuration space, increasing manufacturing man-hours, and increasing manufacturing costs. Effect of miniaturization, reduction of production cost, and reduction of production man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

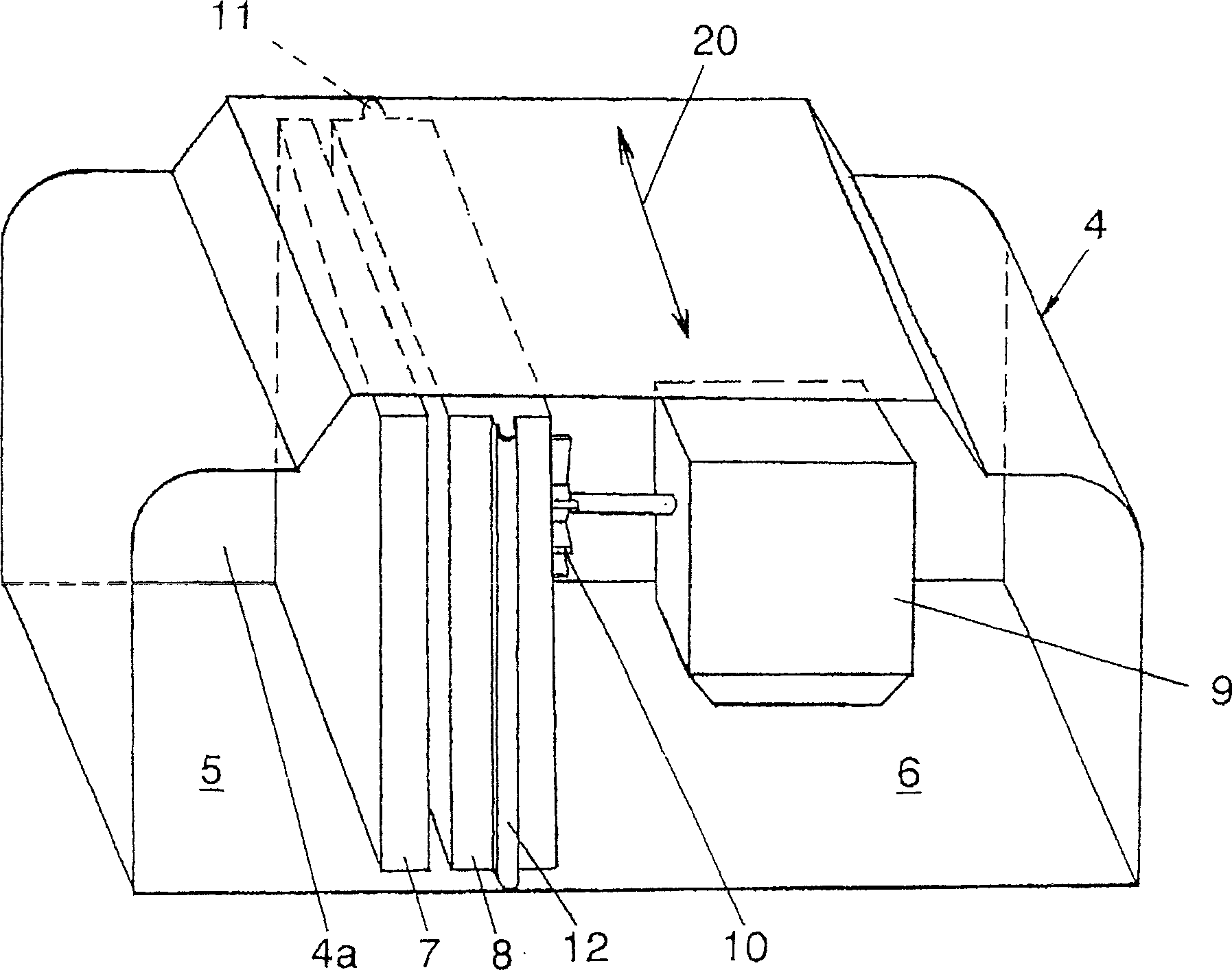

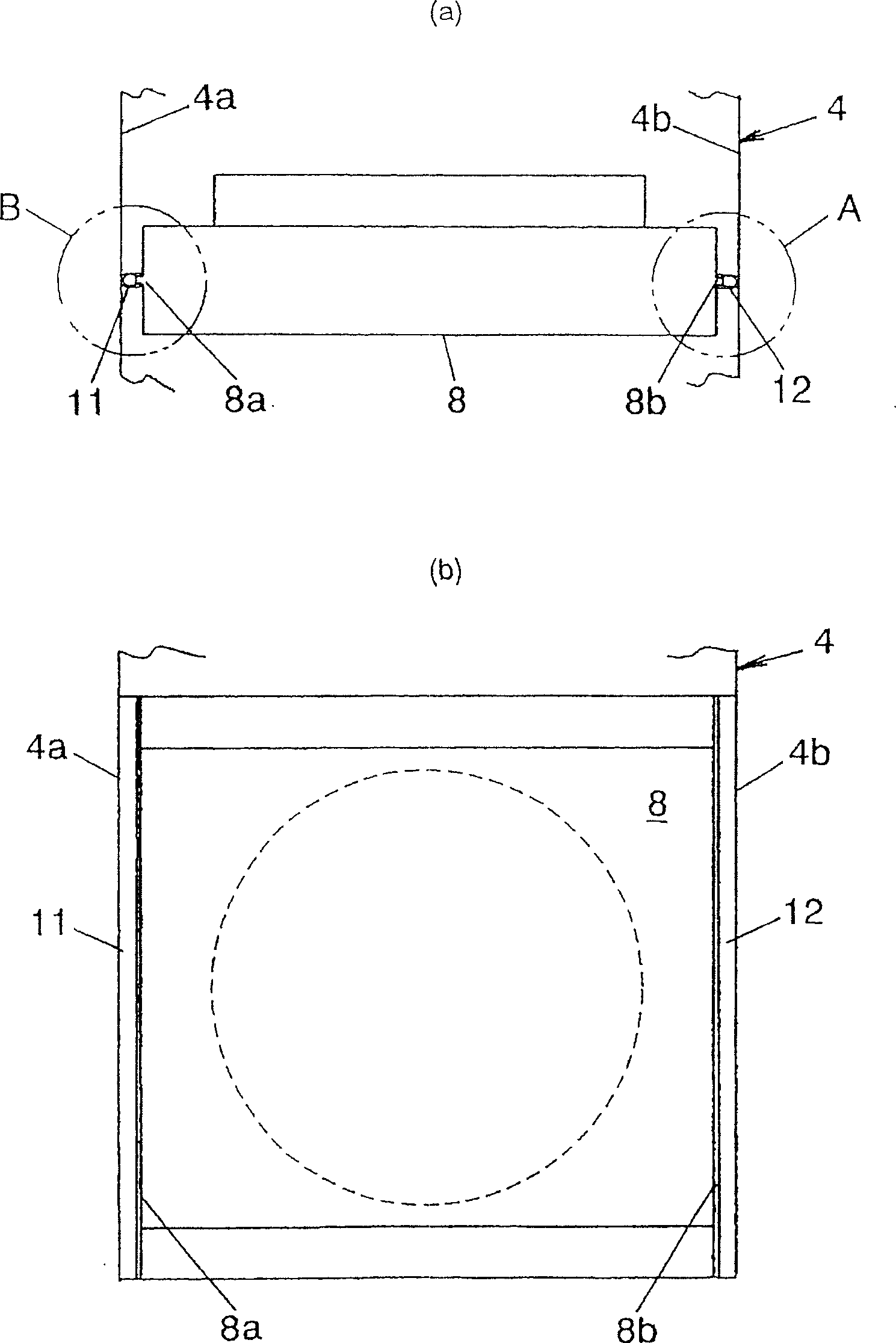

[0021] The best mode of the cooling device arrangement structure for the construction machine for carrying out the present invention will be described below with reference to the drawings.

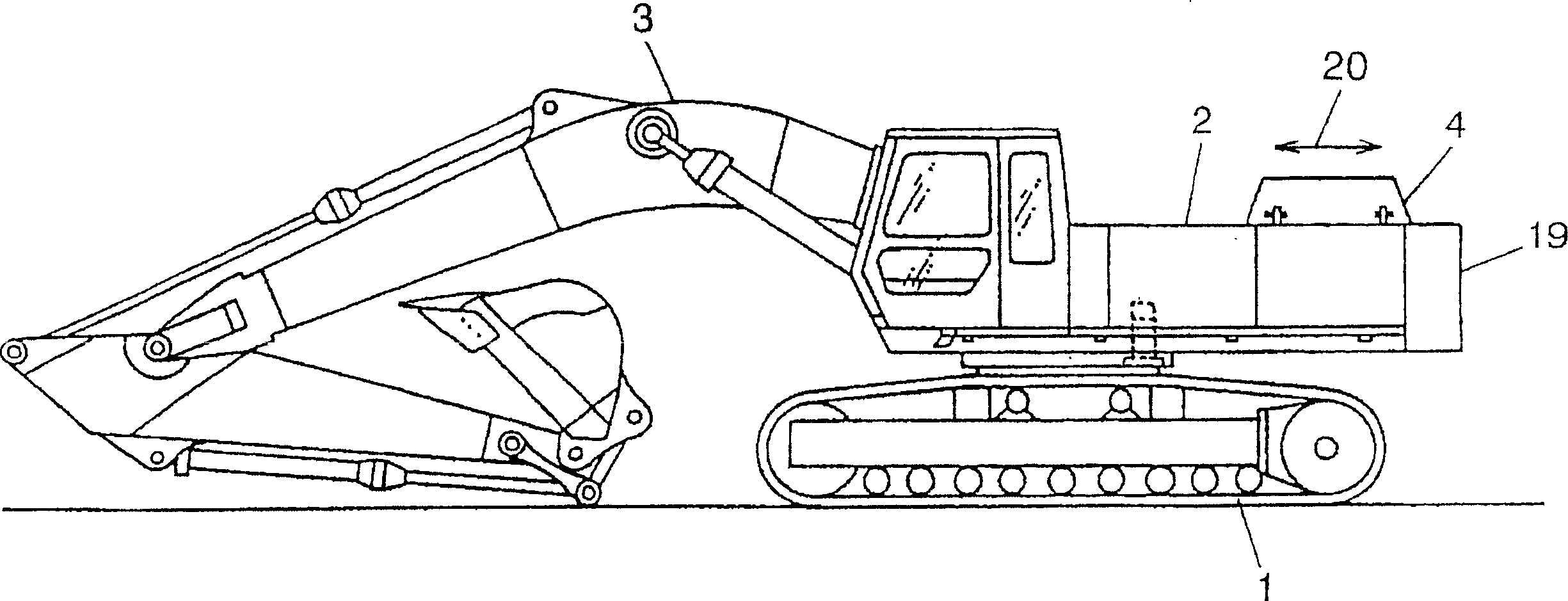

[0022] figure 1 As an example of a construction machine, a side view of a hydraulic excavator provided with the first embodiment of the construction machine cooling device arrangement structure of the present invention is shown.

[0023] Should figure 1 The hydraulic excavator shown has: a walking body 1; a main body arranged on the walking body 1, that is, a revolving body 2; The machine 3 includes a boom, a boom, a bucket, and the like. The revolving body 2 is provided with an engine room 4 which is a cabin, and the engine room 4 is provided with the first embodiment of the arrangement structure of the cooling device which is the object of the present invention. In addition, the figure 1 Reference numeral 19 in the figure indicates a counterweight for ensuring weight balance, and 20 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com