Base substrate, resonator, oscillator, and electronic device

A technology for base substrates and electronic components, applied in piezoelectric devices/electrostrictive devices, circuits, electrical components, etc., can solve problems such as inability to ensure package sealing and poor wiring tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

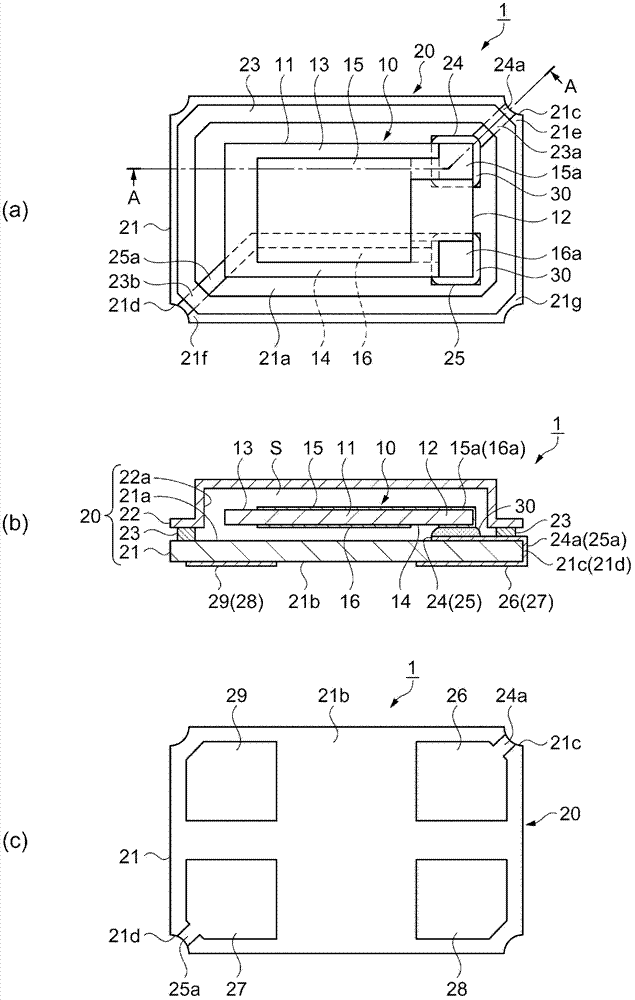

[0043] First, a quartz resonator as an example of a resonator will be described.

[0044] figure 1 It is a schematic diagram showing the schematic structure of the crystal resonator of the first embodiment. figure 1 (a) is a front plan view viewed from the lid side, figure 1 (b) is alongfigure 1 A sectional view of line A-A in (a), figure 1 (c) is a rear plan view seen from the lid side. In the front plan view, the cover portion is omitted. In addition, the dimensional ratios of the respective constituent elements are different from actual ones.

[0045] Such as figure 1 As shown, the crystal vibrator 1 includes a crystal vibrating piece 10 as a vibrating piece, and a package 20 that accommodates the quartz vibrating piece 10 .

[0046] The quartz vibrating piece 10 is an AT-cut shape cut out at a predetermined angle from a quartz rough or the like, and its planar shape is formed into a substantially rectangular shape. The quartz vibrating piece 10 has a vibrating part 1...

Deformed example 1

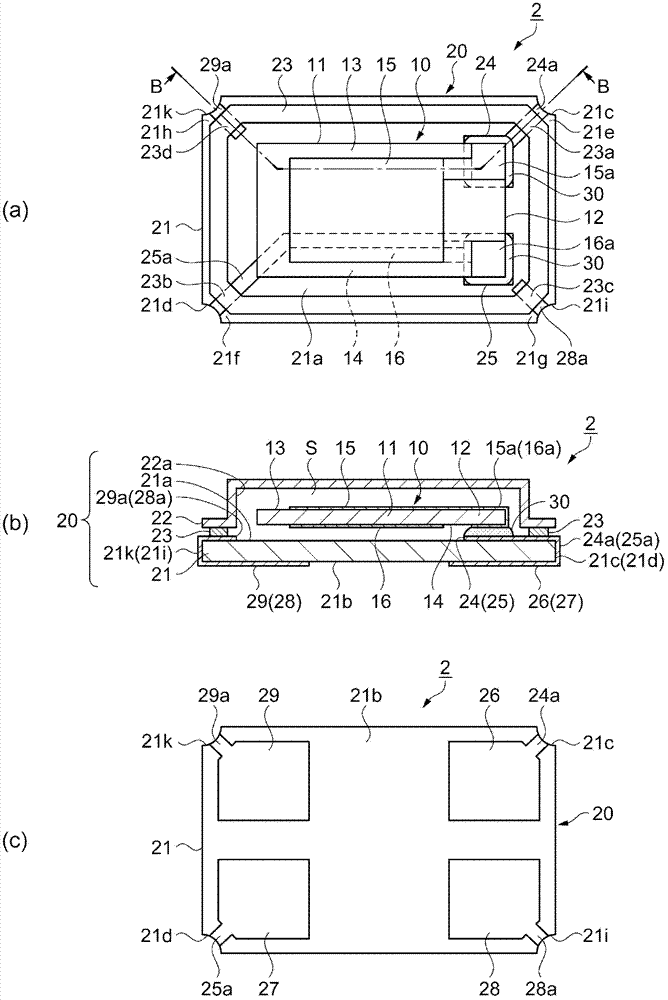

[0089] figure 2 It is a schematic diagram showing a schematic configuration of a crystal resonator in Modification 1. FIG. figure 2 (a) is a front plan view viewed from the lid side, figure 2 (b) is along figure 2 Sectional view of line B-B in (a), figure 2 (c) is a rear plan view seen from the lid side. In the front plan view, the cover portion is omitted. In addition, the dimensional ratios of the respective constituent elements are different from actual ones. In addition, the same code|symbol is attached|subjected to the same part as the said 1st Embodiment, a detailed description is abbreviate|omitted, and it demonstrates centering on the part different from the said 1st Embodiment.

[0090] Such as figure 2 As shown, with regard to the quartz vibrator 2, the wirings 28a, 29a intersect the bonding material 23 at the third corner 21g and the fourth corner 21h located at the other diagonal corner of the one main surface 21a of the base part 21, and the wirings 28a...

Deformed example 2

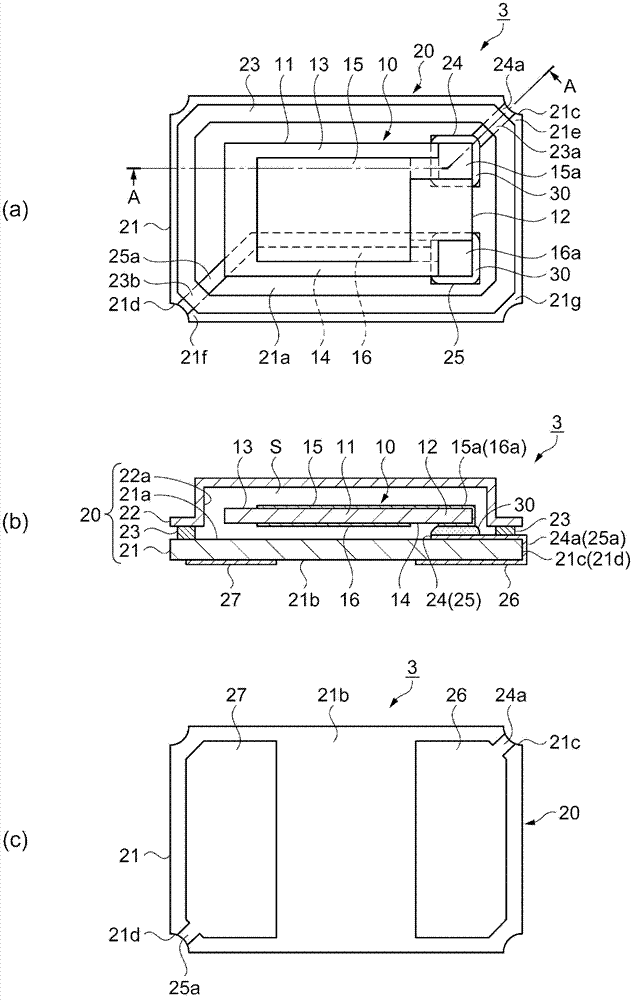

[0099] image 3 It is a schematic diagram showing a schematic configuration of a crystal resonator in Modification 2. FIG. image 3 (a) is a front plan view viewed from the lid side, image 3 (b) is along image 3 A sectional view of line A-A in (a), image 3 (c) is a rear plan view seen from the lid side. In the front plan view, the cover portion is omitted. In addition, the dimensional ratios of the respective constituent elements are different from actual ones. In addition, the same code|symbol is attached|subjected to the same part as the said 1st Embodiment, a detailed description is abbreviate|omitted, and it demonstrates centering on the part different from the said 1st Embodiment.

[0100] Such as image 3 As shown, regarding the crystal vibrator 3, the external electrodes 28, 29 are removed (refer to figure 1 ), and the external electrodes 26, 27 extend to their positions.

[0101] As a result, since the area of the external electrodes 26 and 27 of the base ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com