Golf club head component and punch table of producing said club head component and the method thereof

A golf club head and punching machine technology, applied in golf balls, golf clubs, presses, etc., can solve problems such as residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

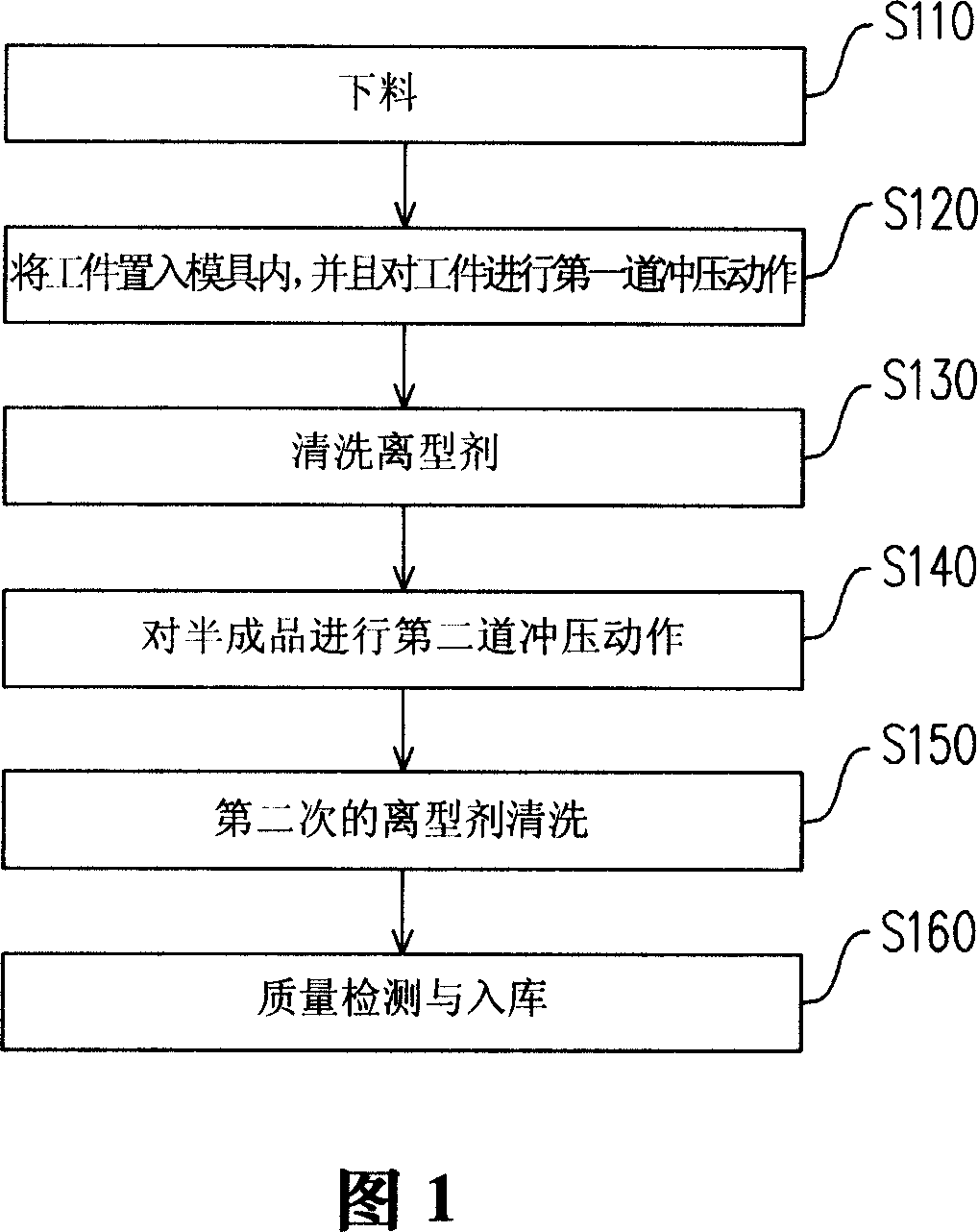

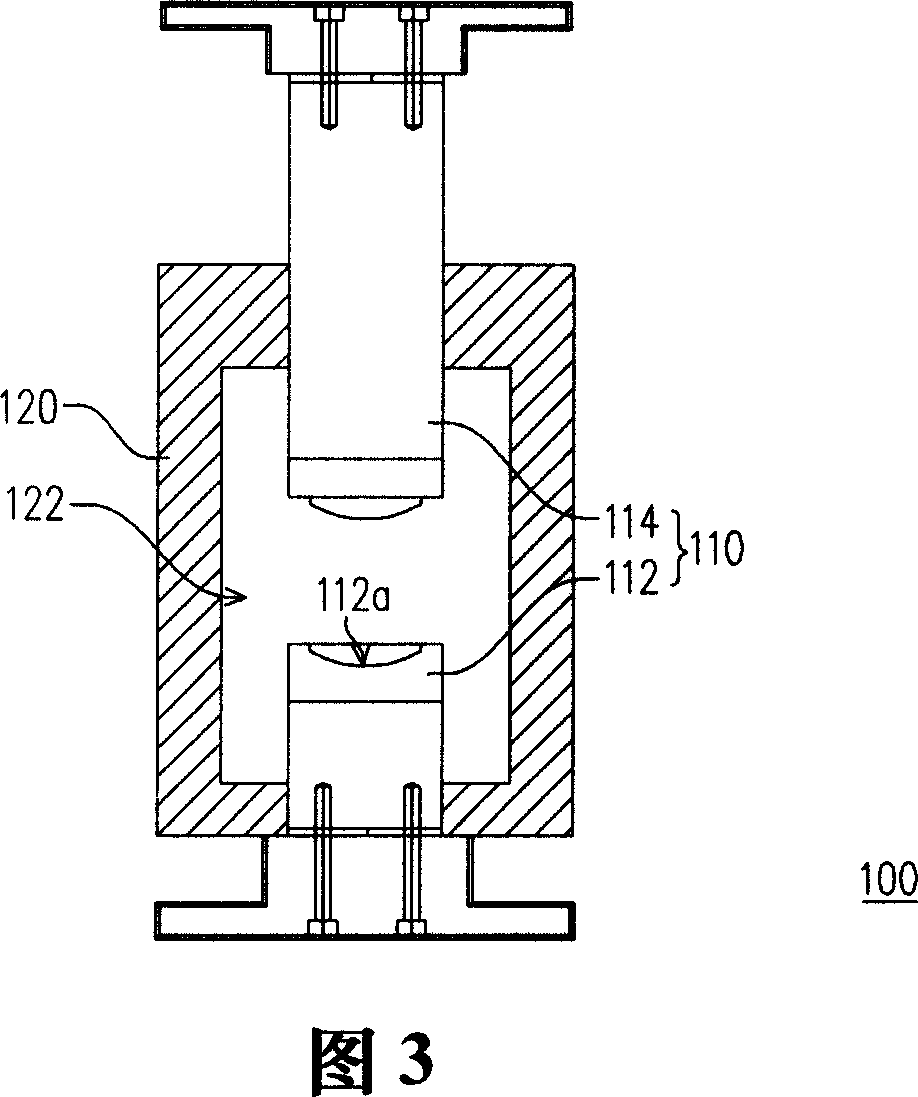

[0036] The invention provides a club head component of a golf club head and a stamping machine and method for making the club head component. Wherein, the club head member made by this method and the stamping machine can be used as a hitting face plate, upper cover, lower plate or other parts of the golf club head.

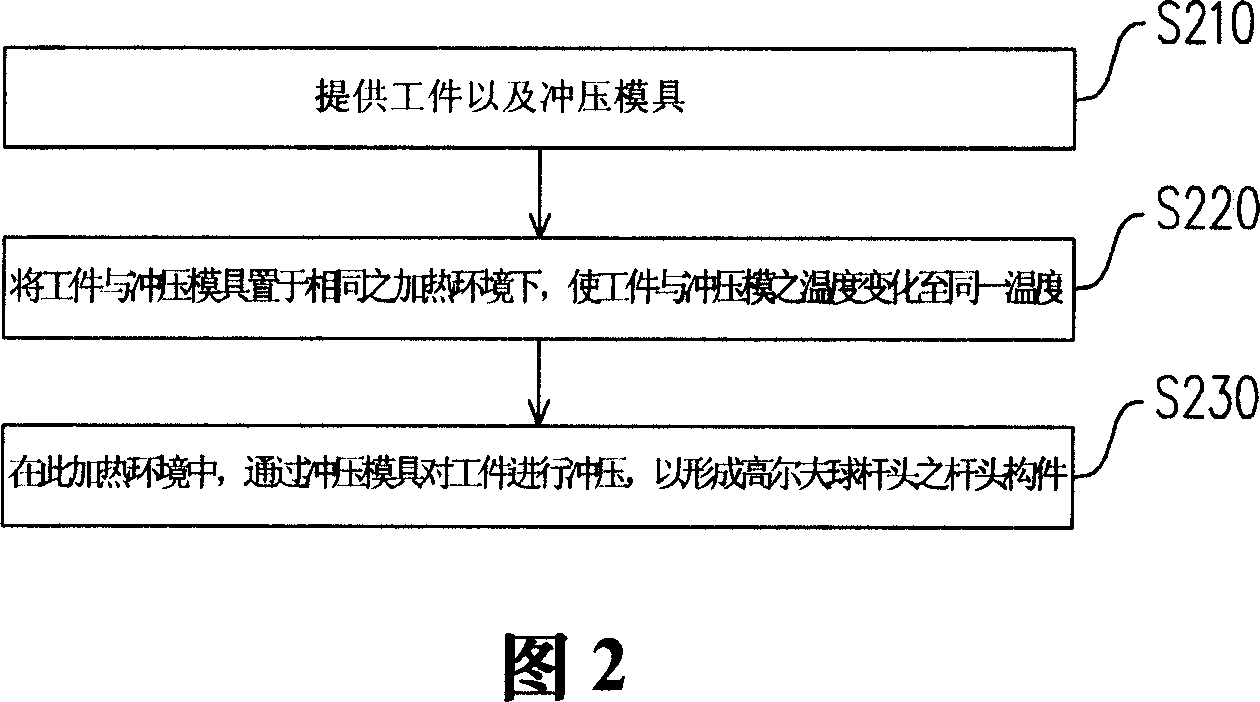

[0037] Fig. 2 is a flow chart of making a club head member of a golf club head according to the present invention. Please refer to FIG. 2 , firstly, the workpiece and the stamping die are provided (step S210), and the workpiece and the stamping die are placed in the same heating environment, so that the temperature of the workpiece and the stamping die is changed to the same temperature (step S220). Wherein, since the workpiece and the stamping die are heated in the same environment, the known problem of heat loss of the workpiece can be improved. In this embodiment, the heating environment is, for example, a closed heating chamber, and the stamping die is locate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com