Piston-pin bearing for internal combustion engines

A technology of piston pin and internal combustion engine, which is applied in the direction of piston, cylindrical piston, plunger, etc., can solve the problems of improving the possibility and noise of the engagement between the piston pin and the hub hole, achieve the effect of small tangential stress and improve the life of the piston

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

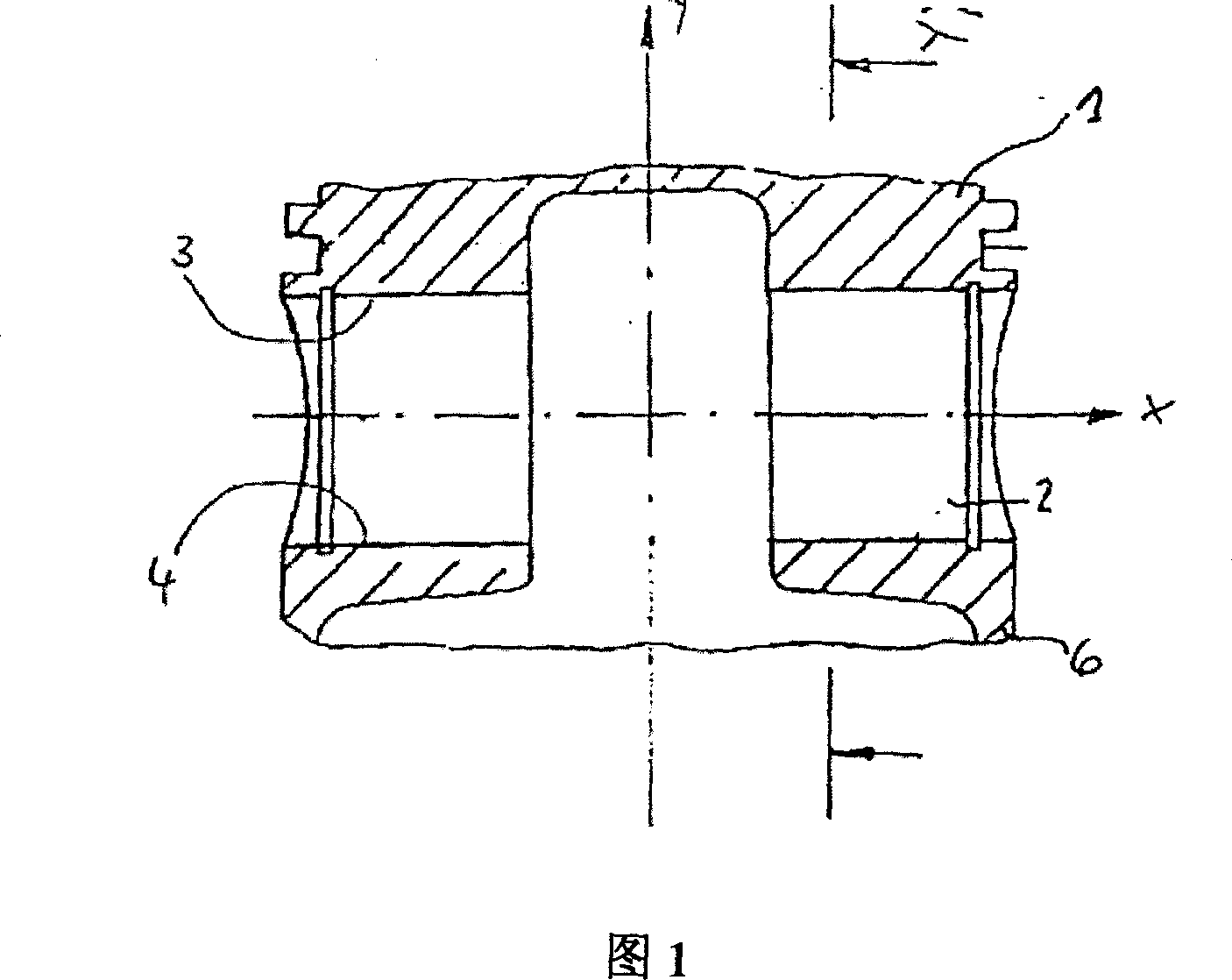

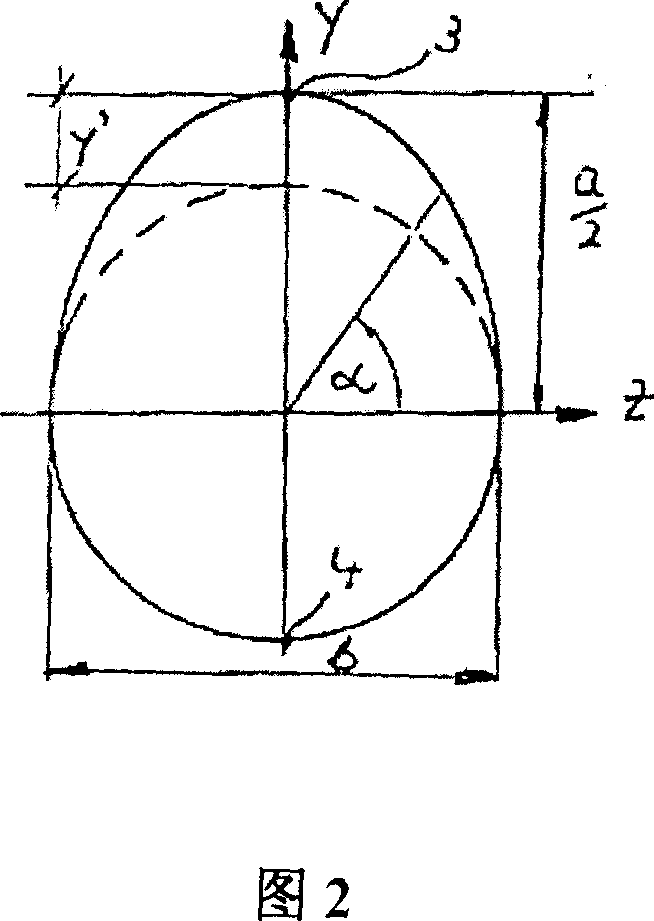

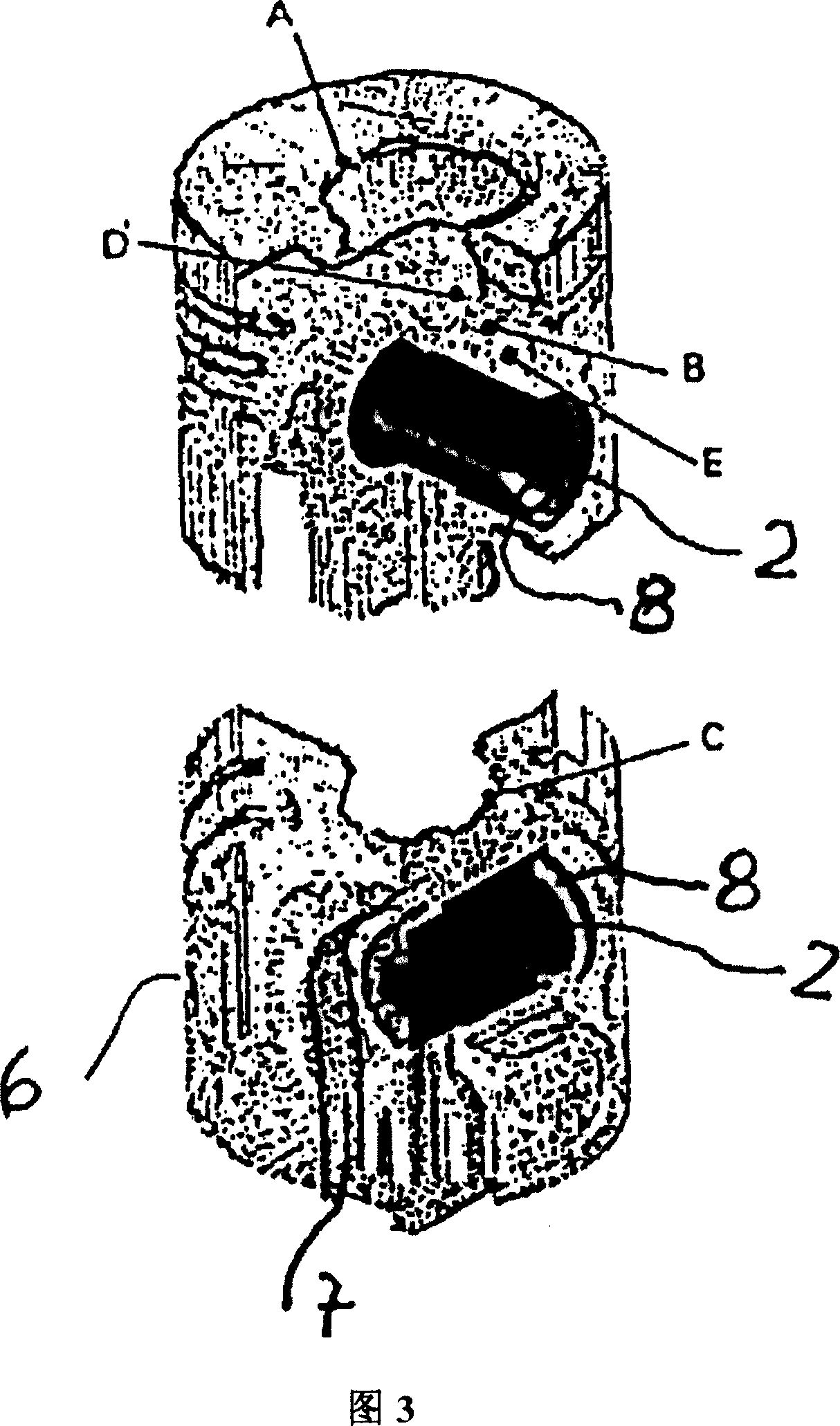

[0026] As can be seen in FIG. 1, a piston 1 for an internal combustion engine has a hub bore 2 with an upper hub region and a lower hub region, in which bore a cylindrical piston pin (not shown) is supported. According to FIGS. 1 and 2 , the upper hub area is arranged on the gas side, wherein the surface of the hub bore 2 is formed on the periphery along the entire hub longitudinal axis X in the region of hub equator-apex-hub equator in a highly elliptical manner, The parameters of the ellipse are:

[0027] z=b / 2×cosα

[0028] y=a / 2×sinα, 0°≤α≤180°

[0029] Wherein, (z, y) is the coordinate of any point on the ellipse in the coordinate system shown in FIG. 2 .

[0030] In the lower region 2.2 of the hub bore 2, the surface of the hub bore 2 is formed cylindrically along the entire hub longitudinal axis X between the hub equator-the hub bottom point-the hub equator, wherein the two hub regions are suitable for :

[0031] a : large ellipse diameter,

[0032] b=D: small elli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com