Piston pin bearing for pistons of an internal combustion engine

A technology of piston pin and piston pin seat, which is applied to the direction of piston, cylindrical piston, plunger, etc., and can solve problems such as unsatisfactory results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

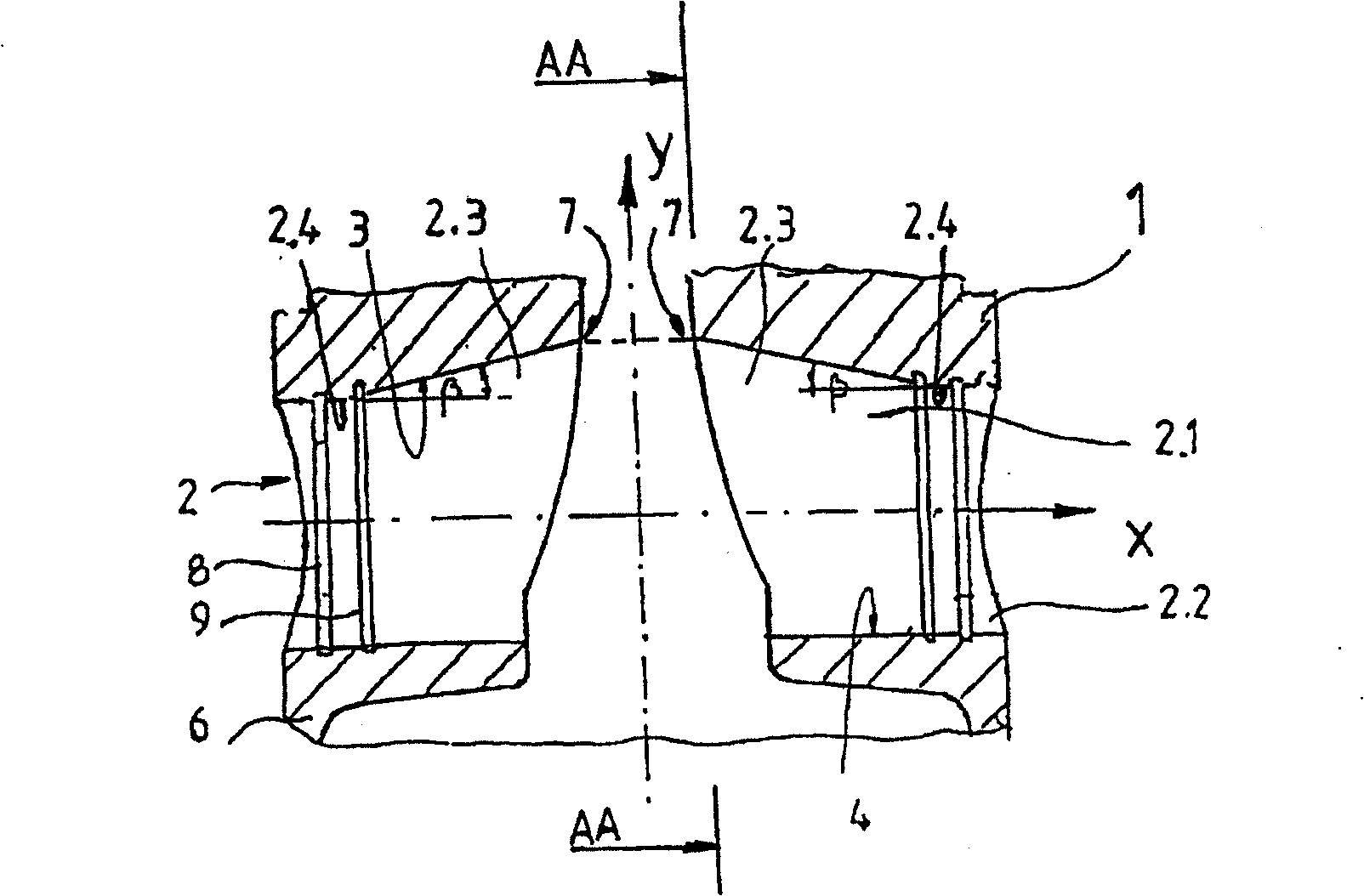

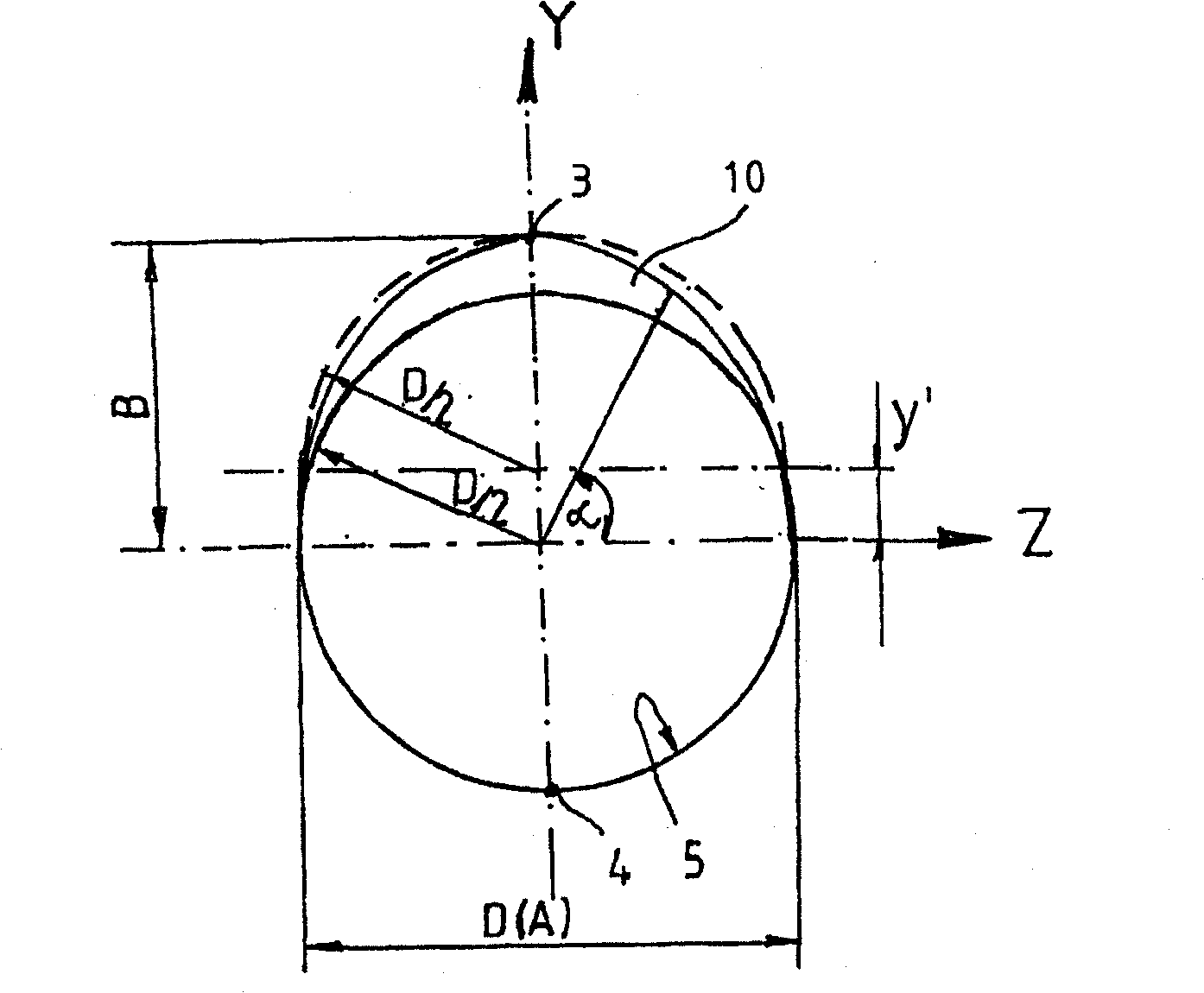

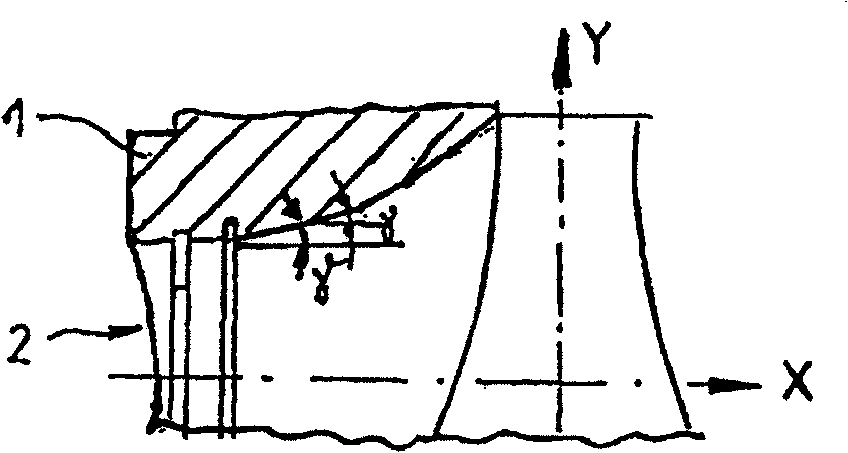

[0033] Such as figure 1 As shown, a piston 1 for an internal combustion engine has a pin housing 2 comprising an upper pin housing area 2.1 and a lower piston housing area 2.2, in which a cylindrical piston is supported pin (not shown). At the radially outer end of the piston pin housing on the side close to the piston, a piston pin retaining ring groove 8 and an oil groove 9 are provided, wherein the oil groove can surround or partially surround the circumferential side of the piston pin housing. according to figure 1 and figure 2 , the upper piston pin seat area is arranged on the gas pressure side, in which the surface 5 of the piston pin seat hole 2 is along the piston pin seat axis on the circumferential side, at the piston pin seat equator-piston pin seat apex-piston In the equatorial region of the pin socket, it is highly elliptical in the partial region 2.3 and cylindrical in the partial region 2.4. In particular, there are oil grooves, oil pockets, slots and oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com