Production line and production method of heat preservation and non-disassembling formwork

A technology that avoids dismantling templates and production methods. It is applied in ceramic molding workshops, auxiliary molding equipment, and supply devices. It can solve the problems of large maintenance equipment investment, waste of resources, and limited output, so as to improve equipment utilization and reduce equipment investment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

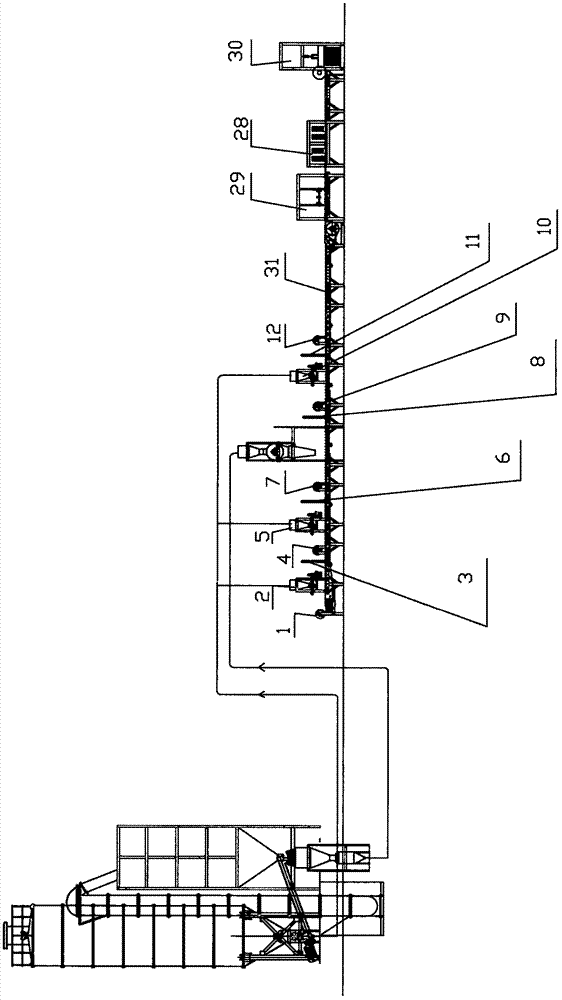

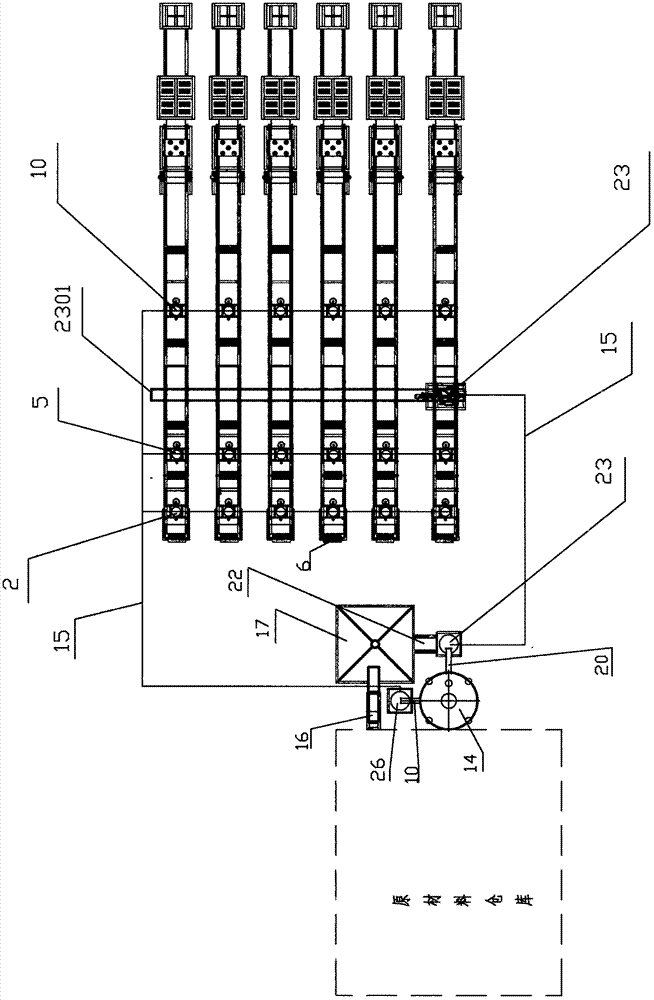

[0206] Such as figure 1 , figure 2 As shown in the figure, a production line for thermal insulation free formwork is characterized in that the production line for thermal insulation free formwork includes a raw material warehouse, a conveying system, a moving and unloading system for thermal insulation slurry, a mixing system, and a combination designed according to production capacity requirements. Production line, the production line is arranged together, a single production line includes the first laying system 1, the first cloth system 2, the first scraping system 3, the second web laying system 4, the second cloth system 5, the second scraping system 6, The third laying system 7, the third scraping system 8, the fourth laying system 9, the third distribution system 10, the fourth scraping system 11, the fifth laying system 12, the cutting system 28,

[0207] The first laying system 1, the first fabric system 2, the first scraping system 3, the second laying system 4, th...

Embodiment approach 2

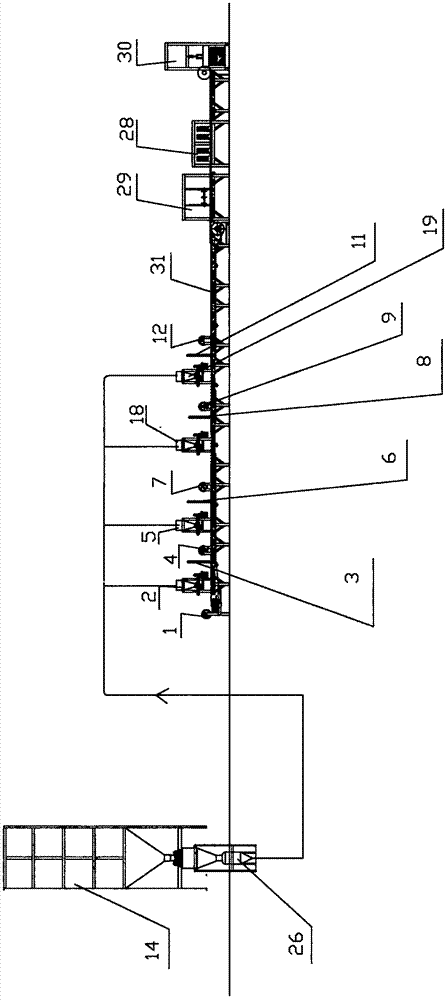

[0226] Such as image 3 , Figure 4 As shown, a production line for thermal insulation free formwork is characterized in that the production line for thermal insulation free formwork includes a raw material warehouse, a gelling material conveying system, and a combined production line designed according to production capacity requirements. The production lines are arranged together, and a single The production line includes the first laying system 1, the first laying system 2, the first scraping system 3, the second laying system 4, the second laying system 5, the second scraping system 6, the third laying system 7, the first Three cloth system 18, third scraping system 8, fourth web laying system 9, fourth cloth distribution system 19, fourth scraping system 11, fifth web laying system 12, cutting system 28;

[0227] The first laying system 1, the first fabric system 2, the first scraping system 3, the second laying system 4, the second fabric system 5, the second scraping s...

Embodiment approach 3

[0244] Such as Figure 5 As shown, a production line of thermal insulation free formwork is characterized in that the production line of thermal insulation free formwork includes a raw material warehouse, a conveying system, and a combined production line designed according to production capacity requirements. The production lines are arranged together, and a single production line includes the first One laying system 1, the first laying system 2, the first scraping system 3, the second laying system 4, the second laying system 5, the second scraping system 6, the third laying system 7, the third laying system 18. The third scraping system 8, the fourth laying system 9, the first laying system 1, the first cloth system 2, the first scraping system 3, the second laying system 4, the second cloth system 5, the first The second scraping system 6, the third laying system 7, the third distribution system 18, the third scraping system 8, the fourth laying system 9, the group drillin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com