Coil spring combined elastic mechanism through rope transmission

A clockwork spring and rope transmission technology, which is applied to the spring assembly composed of several springs, the functional characteristics of the spring/shock absorber, the spring, etc., can solve the problem of reducing the space of the rear seat and the trunk space, and the volume of the coil spring Problems such as high energy density and difficulty in meeting the strength requirements of the inner shaft achieve the effects of low manufacturing cost, small size and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

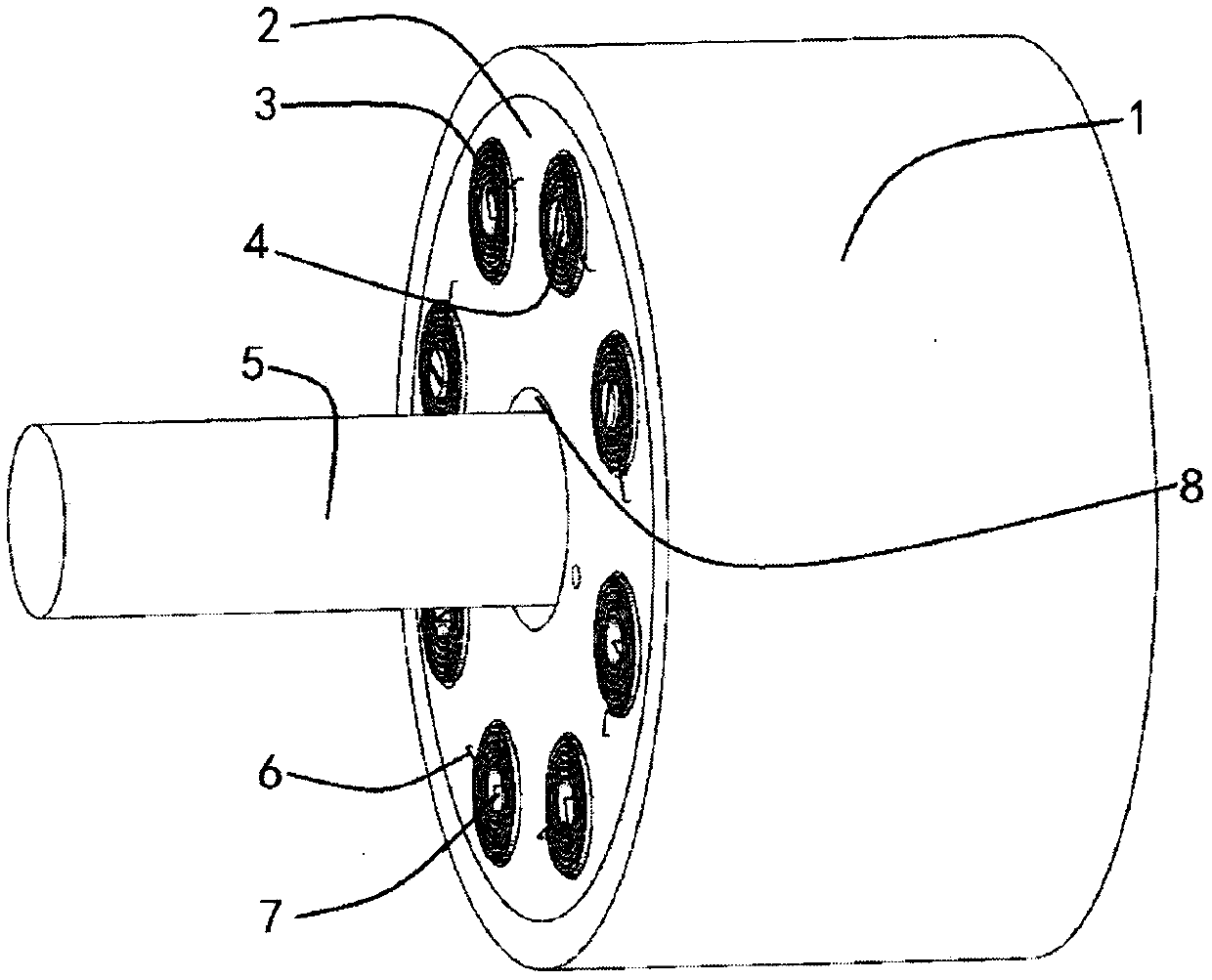

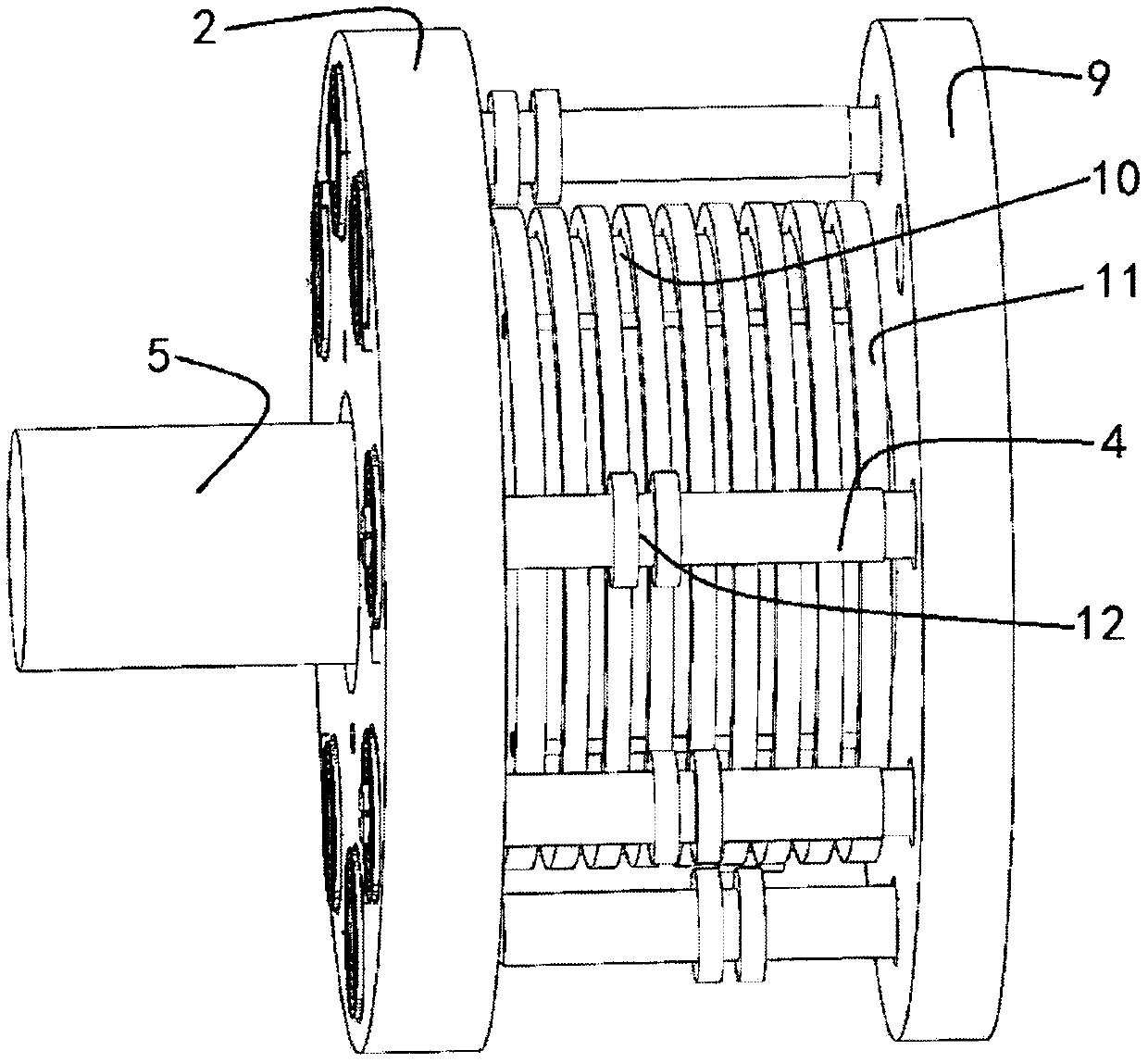

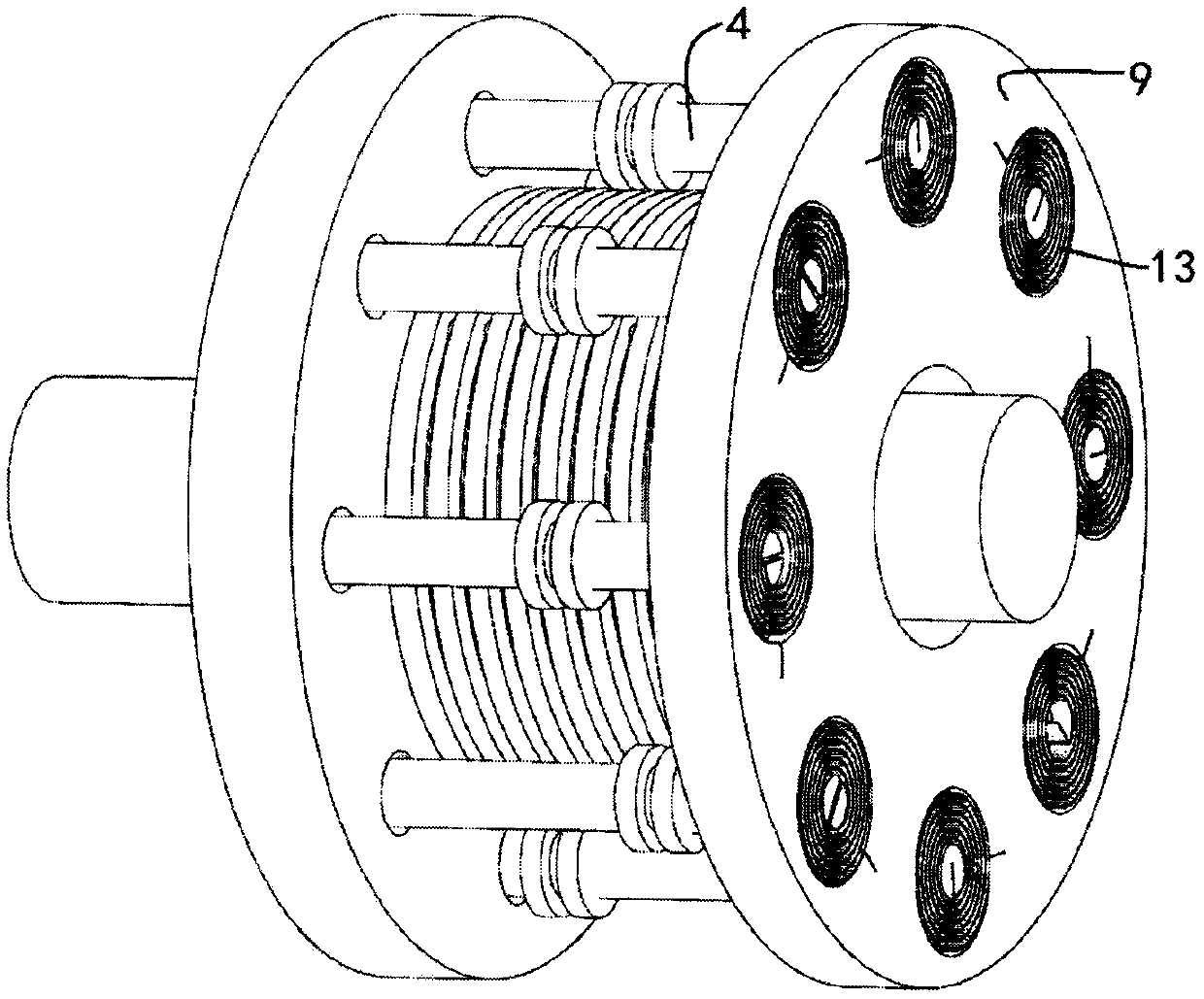

[0015] Refer to attached figure 1 , attached figure 2 , attached image 3 , attached Figure 4 , attached Figure 5 And attached Figure 6, a kind of rope-driven clockwork spring combination elastic mechanism is characterized in that: the first side plate 2 and the second side plate 9 are coaxially fixedly connected and installed through the outer cylinder 1, the outer diameter of the outer cylinder 1 is 120mm, and the first side plate The outer diameter of plate 2 and second side plate 9 is 120mm, left side spring 3 is installed on the first side plate 2, and right side spring 13 is installed on the second side plate 9, left side spring 3 and The thickness of the right clockwork spring 13 is 0.6mm, the width is 7mm, the outer diameter is 20mm, and the inner diameter is 10mm. The left clockwork spring 3 is distributed on the first side plate 2, and there are 6 left clockwork springs 3 in total. , the second side plate 9 is also equipped with 6 right clockwork springs 13,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com