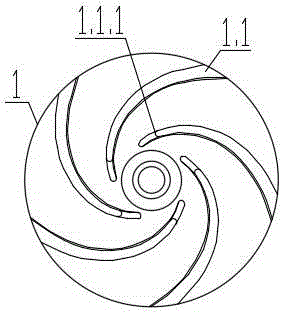

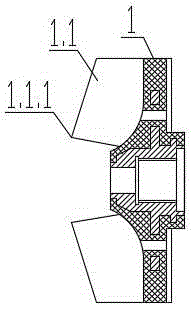

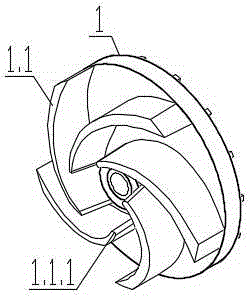

Semi-open plastic impeller for lining plastic corrosion prevention pump

A semi-open impeller technology, which is applied in the field of desulfurization spray circulating pumps, can solve problems such as insufficient blade strength, difficult demoulding of metal pressing molds, and blade distortion, so as to achieve good social and economic benefits, reduce operating costs, and improve usage. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: A plastic-lined anti-corrosion pump, including a plastic-lined pump casing 1, a plastic impeller 2, front and rear pump covers (3.1, 3.2), a main shaft 4, a bearing seat 5, and a shaft seal 6. The plastic impeller 2 includes an impeller The web 2.1 and five radially curved cylindrical blades disposed on the impeller web 2.1 at intervals in the circumferential direction, the cylindrical blades are located above and below the vertical end surface 2.2.1 at the end of the suction port 7 of the anti-corrosion pump The two ends are displaced in opposite directions along the horizontal plane, so that the cylindrical blade is radially twisted to form a twisted blade 2.2, and a mouth ring 2.3 is set at the suction inlet angle 2.2.2 of the twisted blade 2.2, and the diameter of the mouth ring 2.3 is equal to that of a plurality of twisted blades 2.2 The diameter of the circle surrounded by the attack angle 2.2.2, the bottom end of the mouth ring 2.3 is fixedly connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com