Elastic mechanism used for suspension

An elastic mechanism and suspension technology, which is applied in the field of electric vehicle suspension, can solve the problems of low energy density, small torque, and large coil spring volume, and achieve the effects of expanding the application range, convenient vibration energy, and high energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

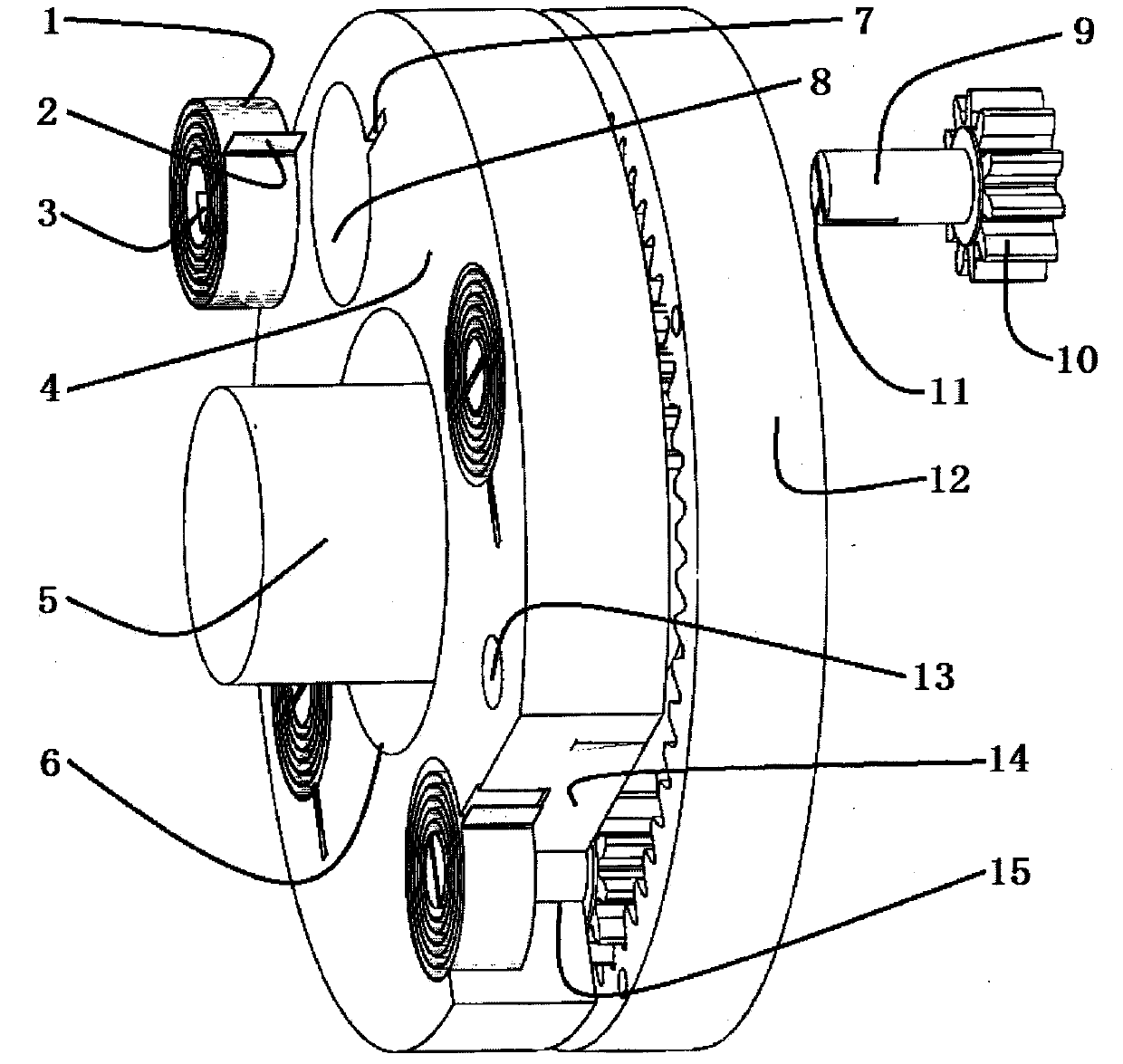

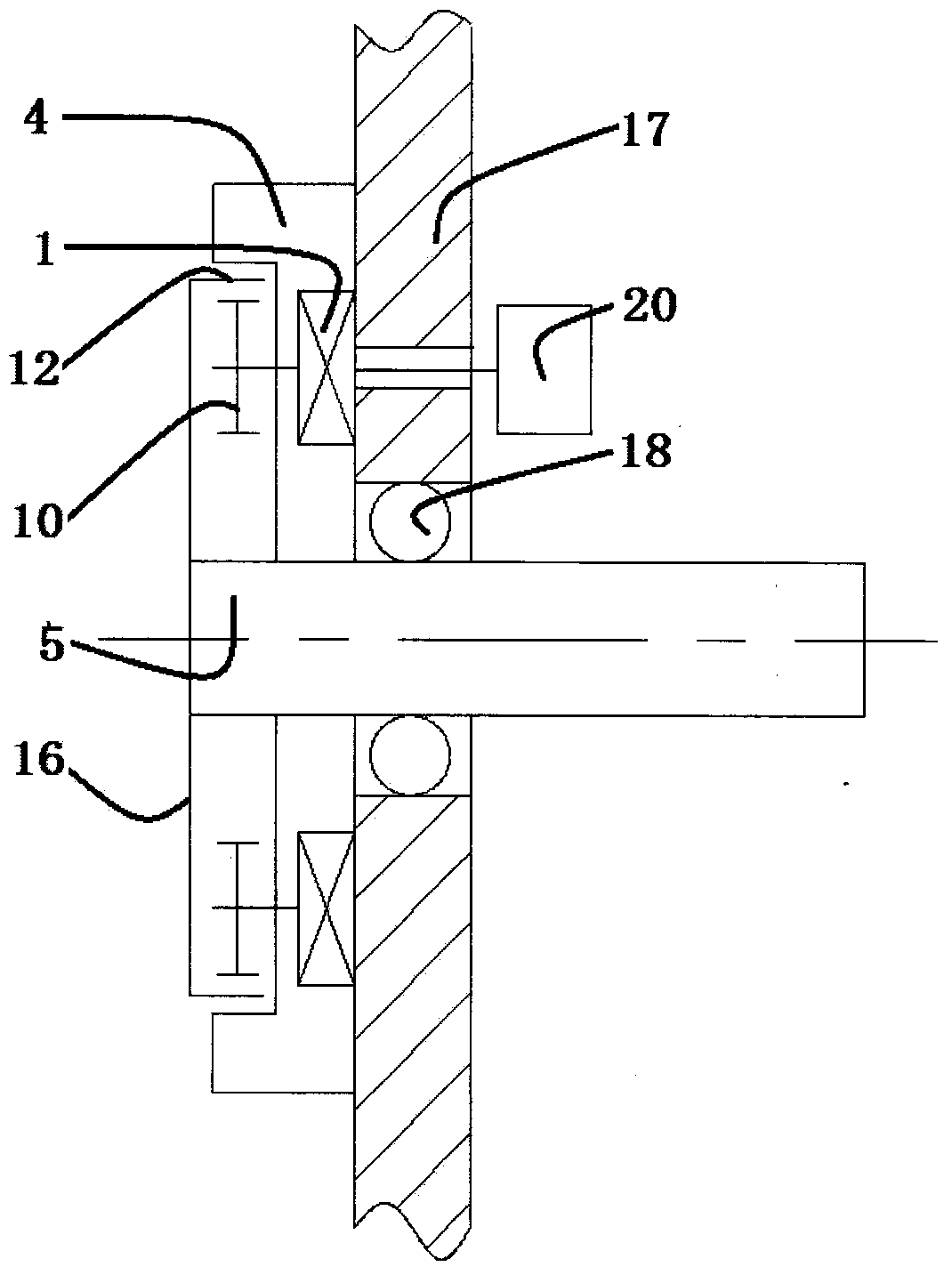

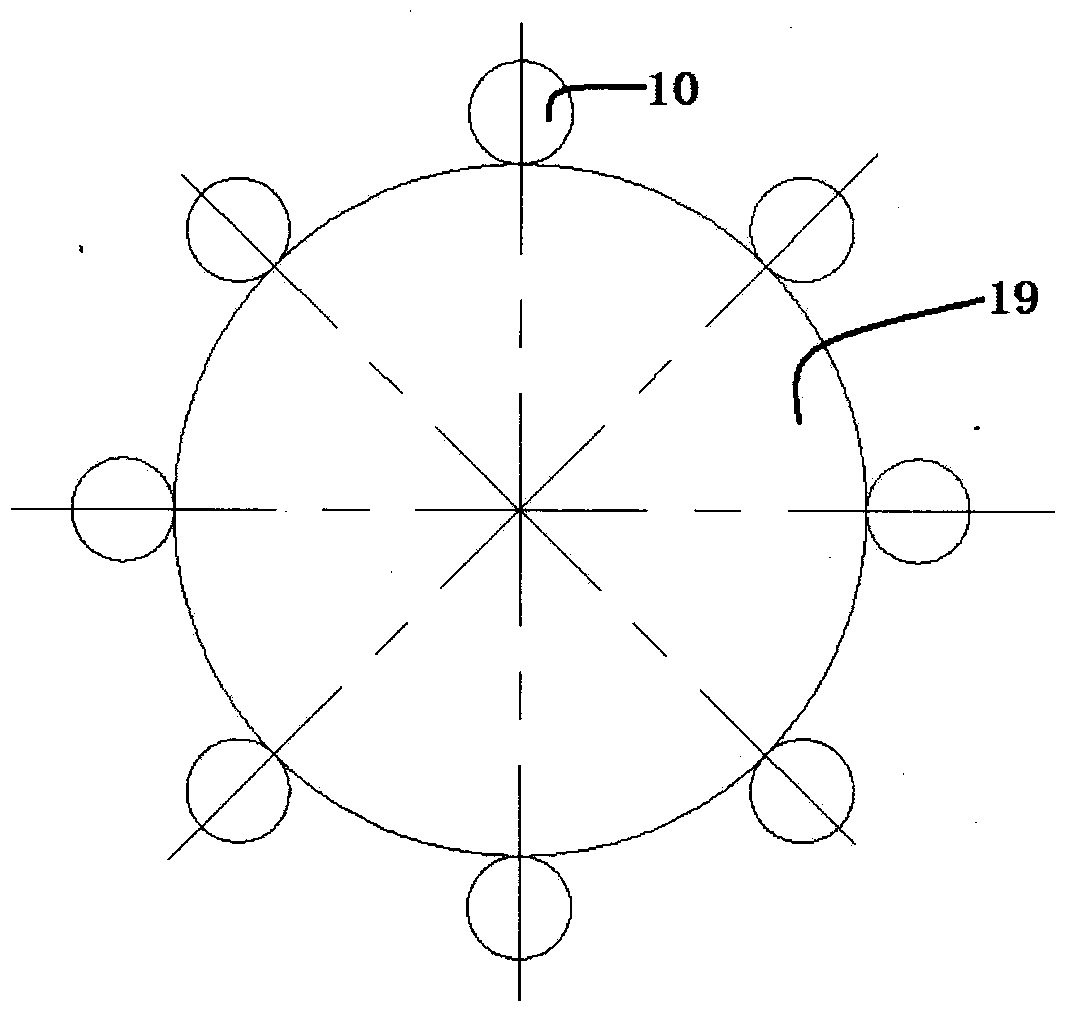

[0013] refer to figure 1 , figure 2 with image 3 , a kind of elastic mechanism structure feature for suspension is: the mounting base plate 4 has the clockwork spring mounting hole 8 and the mounting spring outer ring structure 7, the external diameter of the mounting base plate 4 is 140mm, the material is aluminum alloy, and the diameter of the spring mounting hole 8 is 30mm, the depth is 10mm, the width of the spring outer ring structure 7 is 1mm, and the length is 10mm. , the width is 10mm, one end of the planetary gear shaft 9 is coaxially installed and connected to the planetary gear 10, the length of the planetary gear shaft 9 is 22mm, the diameter is 10mm, the thickness of the planetary gear 10 is 10mm, the module is 2, the number of teeth is 11, and the mounting substrate 4 has The planetary gear shaft mounting hole 15, the planetary gear shaft 9 is installed in the planetary gear shaft mounting hole 15, the other end of the planetary gear shaft 9 has the inner ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com