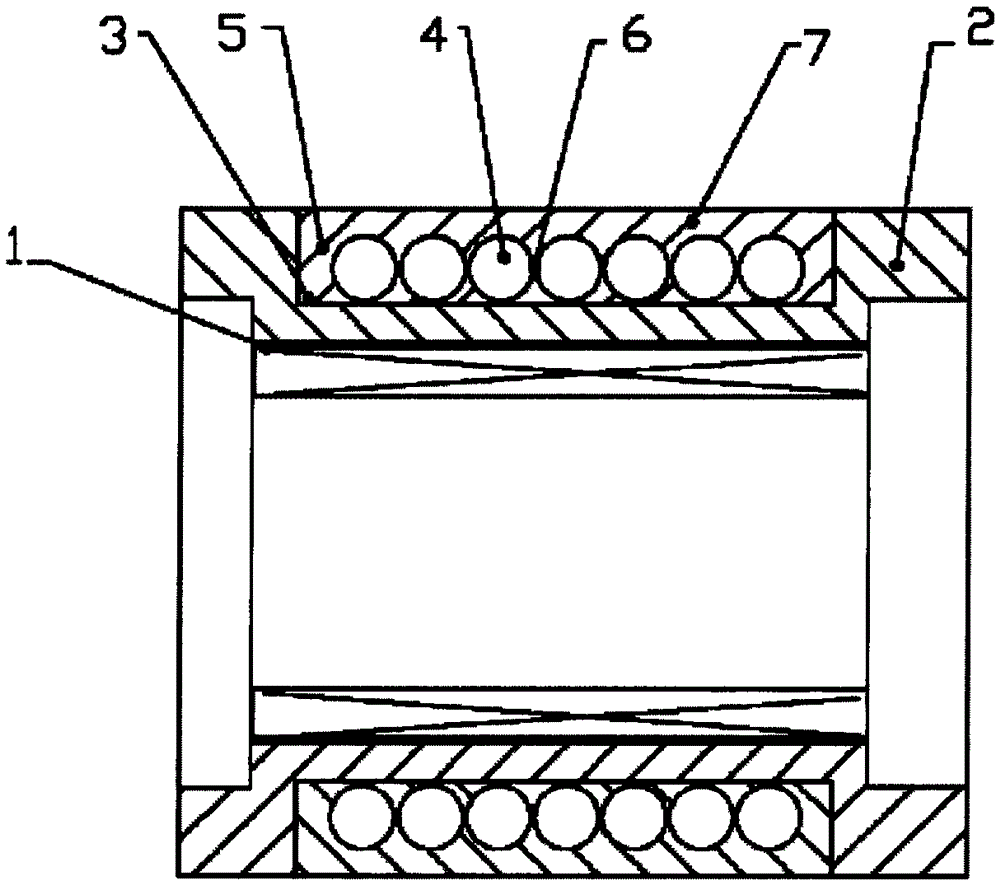

Motor cooling apparatus

A technology of water cooling device and motor housing, which is applied in the direction of cooling/ventilation device, electromechanical device, electrical components, etc., and can solve the problems of imperfect implementation process, unsatisfactory cooling effect, and motor temperature rise and heat generation, etc. Achieve the effects of easy implementation, high cooling efficiency and avoiding water leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described through embodiment now in conjunction with accompanying drawing. The water cooling method of the motor of the present invention is to arrange a water jacket device on the motor casing, first to set a steel cylinder as a skeleton layer on the peripheral wall of the motor casing, and to have an annular groove on its peripheral wall surface, and then The stainless steel pipe is wound in the groove of the steel cylinder to form a spiral pipe to make a water jacket; finally, an aluminum alloy is cast in the groove of the steel cylinder and on the spiral pipe of the stainless steel pipe to connect the steel pipe and the stainless steel pipe as a whole; When alloying, the spiral tube is buried in the aluminum alloy casting body, and a heat conduction layer is formed on the outer surface of the spiral tube (that is, a heat conduction layer is provided on the outer wall surface of the water jacket); thus, a water jacket device is fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com