Advanced reinforcing construction method for building tunnel in soft surrounding rock

A technology of advanced reinforcement and construction method, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc. It can solve problems such as water inrush and sand inrush, unstable soil on the tunnel surface, and easy collapse, so as to shorten the construction period and increase construction efficiency , The effect of facilitating project implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

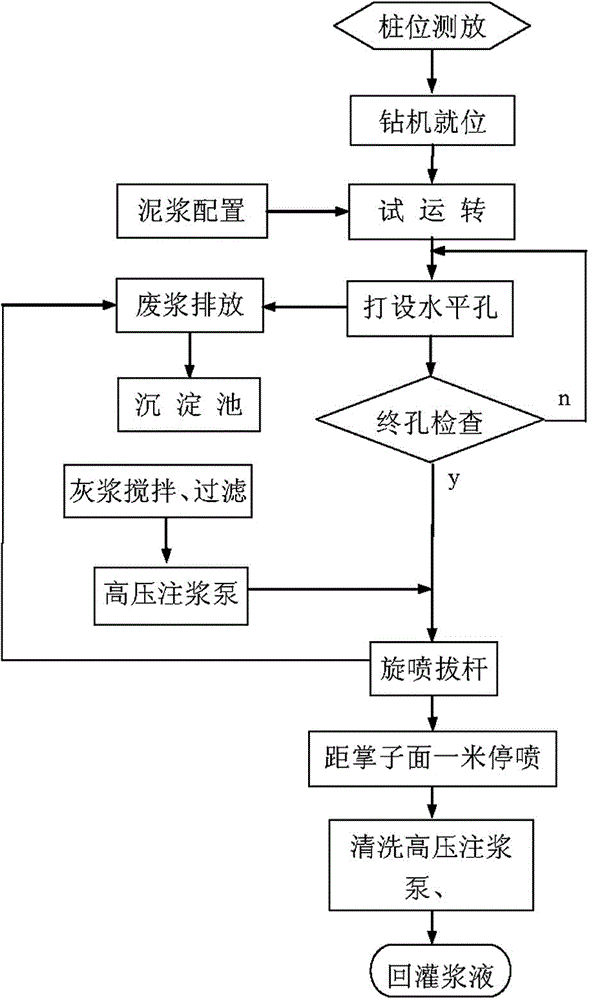

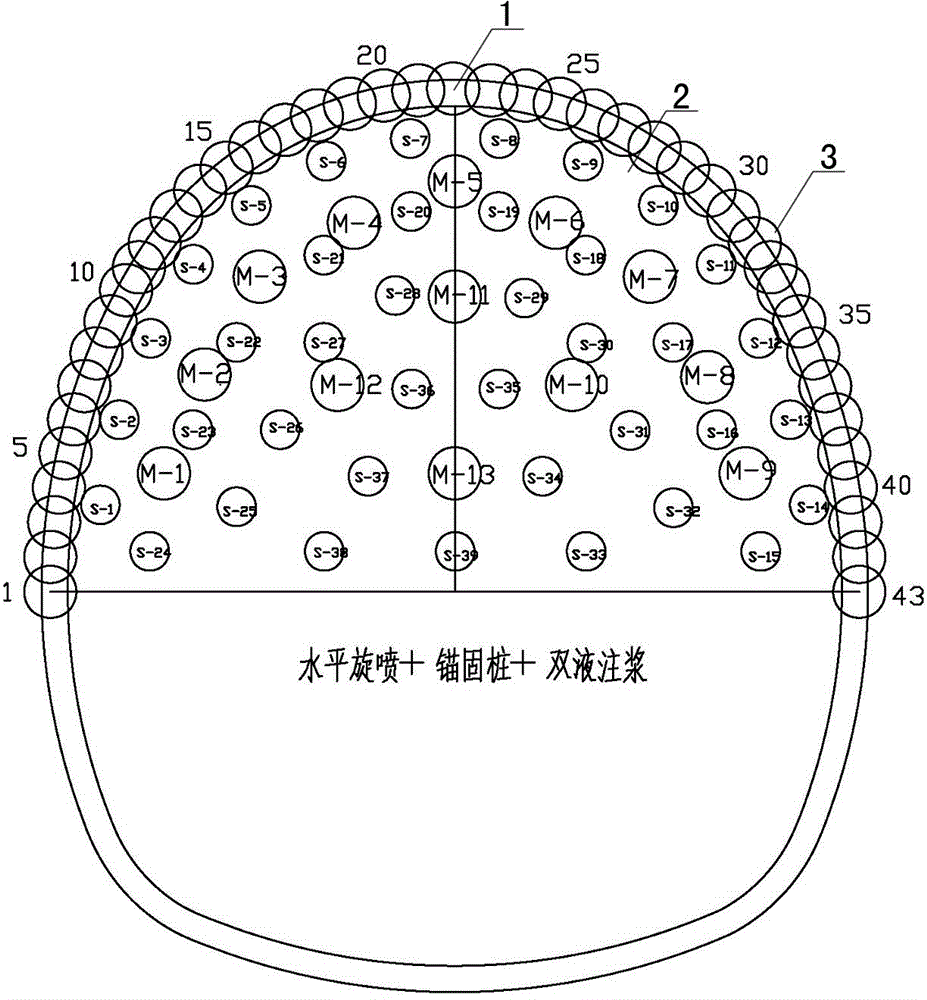

[0032] Examples see figure 1 As shown in Fig. 1, an advanced reinforcement construction method for tunnel construction with weak surrounding rock, the applied stratum is seriously water-rich stratum. In order to prevent water inrush and sand inrush during the construction process, phosphoric acid water glass double-liquid grouting is adopted on the tunnel face. The method combined with the horizontal jet grouting process, the reinforcement pile is formed after the horizontal jet grouting, and phosphoric acid water glass grouting is carried out on other parts of the tunnel face. The specific steps are as follows:

[0033] Step 1. Measure and set out the pile position at tunnel vault 1: measure and set out on both sides of the tunnel to determine two identical mileage points and the tunnel axis, and measure and mark the tunnel excavation contour line on the face of the tunnel, and measure and determine The pile position, and each stake number is compiled, and the pile position m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com