Plastic mold with automatically separated material overflow structure

A technology of overflow structure and plastic mold, applied in the field of plastic mold, can solve the problems of not being able to withstand working load, insufficient strength, product breakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

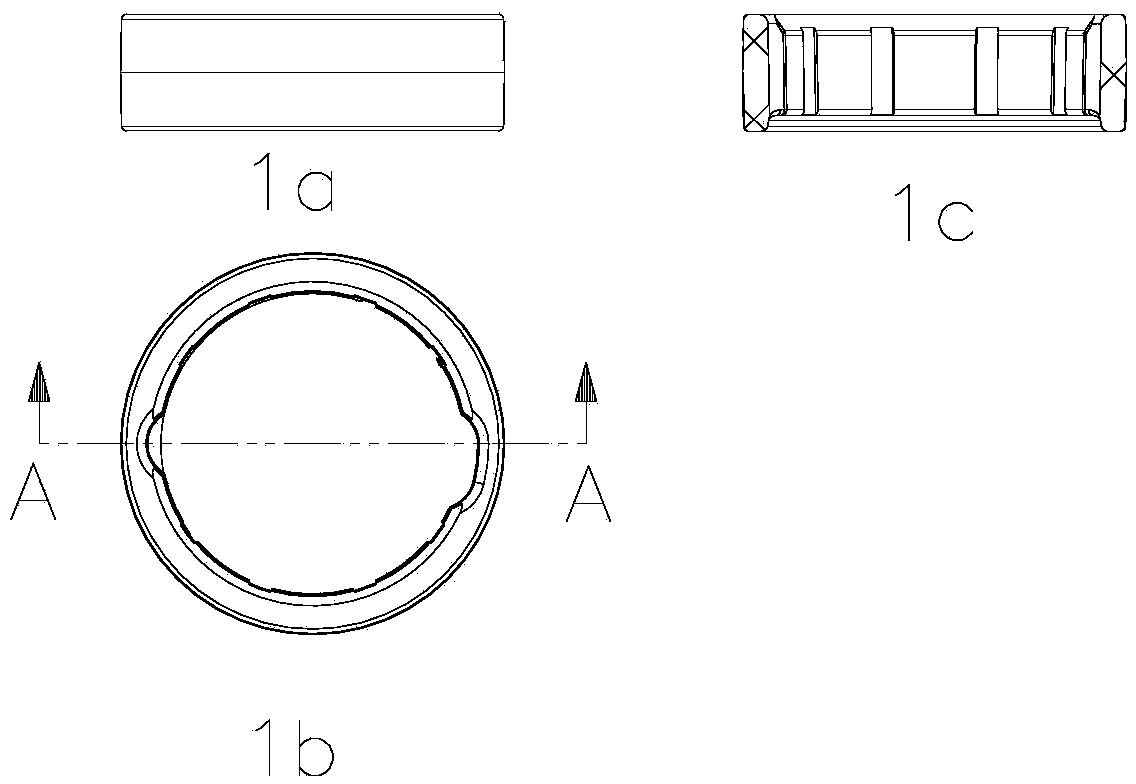

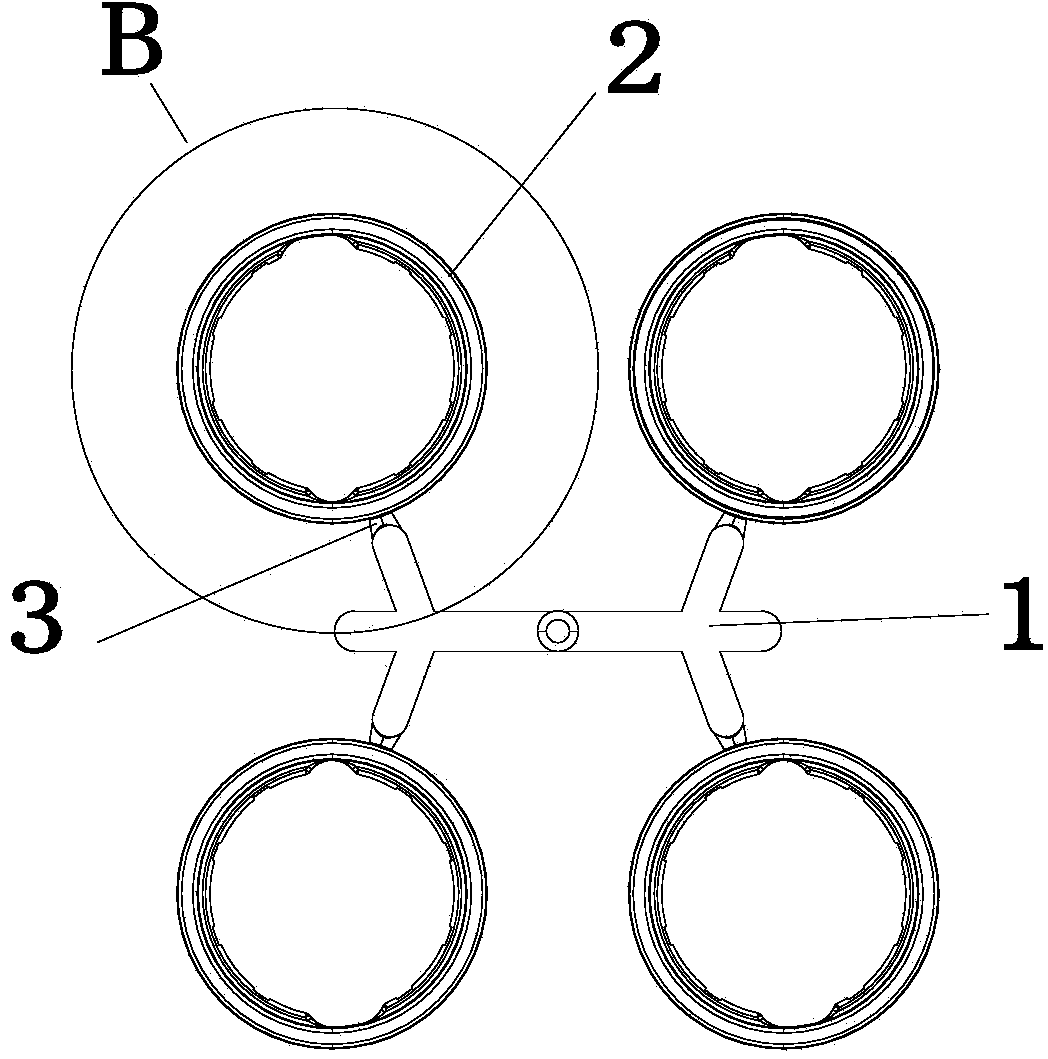

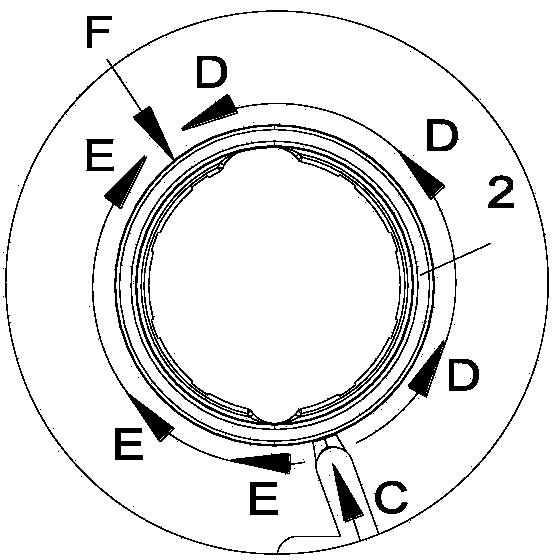

[0046] With reference to accompanying drawing, further illustrate the present invention:

[0047] A plastic mold with an automatically separable overflow structure, comprising a combined movable template 8 and a fixed template 10, the movable template 8 reciprocates longitudinally to complete mold opening or mold closing, and the movable template 8 is provided with There is a movable mold core 9, a fixed mold core 11 is arranged on the fixed template 10, and a molding cavity of a plastic product is provided on the parting surface between the movable mold core 9 and the fixed mold core 11. The cavity is connected to the pouring mechanism;

[0048] The movable template 8 is provided with a longitudinally moving thimble backing plate 4 and a thimble fixing plate 5, and the thimble backing plate 4 is connected to the thimble fixing plate 5; The runner thimble 6 of the runner 1, the thimble 14 and the pulling rod 7 for ejecting the product 2;

[0049] The mold cavity communicates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com