Rotational moulding reinforced supporting body and rotational moulding product

A support body and rotomoulding body technology, applied in the direction of ship hull, non-magnetic metal hull, box, etc., can solve the problems of insufficient strength of rotomolding products, broaden the application field and scene range, improve the anti-deformation strength, and compensate for stretching and the effect of insufficient compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

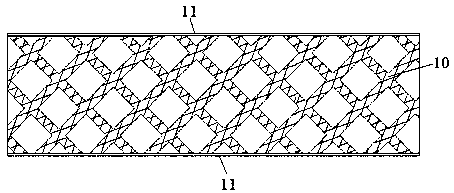

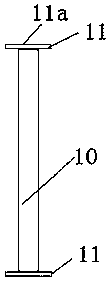

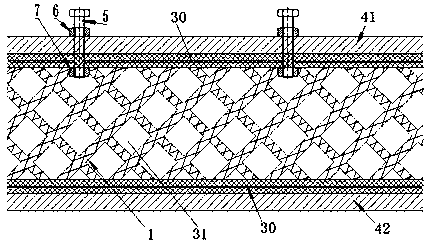

[0029] The rotomolding reinforced support body of this embodiment adopts the rotomolding process and the rotomolded product is formed synchronously at one time, and the rotomolded reinforced support body is located in the hollow cavity of the rotomolded product; The rotomolding body 2 on the surface layer of the base body, the rotomolding body 2 and the product wall of the rotomolding product are an integral structure of rotomolding. The supporting base 1 includes an intermediate main body 10 and bases 11 at both ends. The intermediate main body 10 is connected between the product walls 30 of the rotationally molded product, and can bear pressure, partially seal, and isolate the hollow cavity 31. and the function of compartments; the bases 11 at both ends are respectively embedded in the product wall 30 of the rotomolded product through the rotomolding process, and are used to stably and firmly connect the support base 1 to the product wall 30 of the rotomolded product; Corres...

Embodiment 2

[0031] The difference between this embodiment and Embodiment 1 is that the supporting base 1 adopted is a full plate without any hollow structure, and its material is an iron plate. Also in order to avoid corrosion, the surface layer of the iron plate is coated with Plastic.

Embodiment 3

[0033] This embodiment provides a rotomolded product with a reinforced support body. The hollow cavity 31 of the rotomolded product has at least one rotomolded reinforced support body. The plastic product is rotationally molded synchronously at one time, and its two ends are respectively connected between the product walls 30 of the rotationally molded product.

[0034] The structural composition of the rotomolding reinforced support includes a support base 1, and a rotomolded body 2 formed on the surface of the support base by rotomolding. The support base 1 includes a middle main body 10 and two end bases 11. The middle main body The part 10 is connected between the product walls 30 of the rotomoulding product, and can play the role of bearing pressure, partially sealing, partitioning and dividing the hollow cavity 31; the base parts 11 at both ends are respectively embedded in the The inside of the product wall 30 of the rotomolded product is used to stably and firmly conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com