Patents

Literature

34results about How to "Not stable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aqueous ionically stabilized dispersions

InactiveUS20050090599A1Enhance ink performanceGood dispersionMeasurement apparatus componentsTransportation and packagingOptical densityPhotochemistry

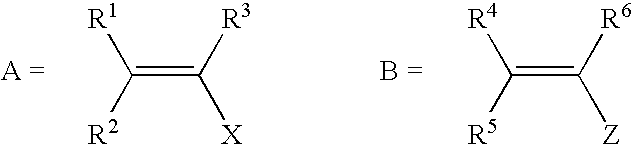

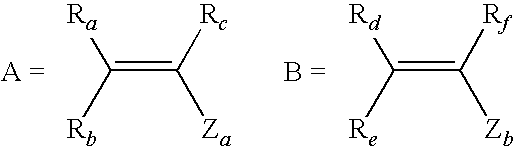

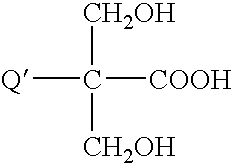

Tonically stabilized dispersions are described that are substantially free of steric stabilization of the pigment. These ionically stabilized dispersions are obtained from polymeric dispersants where the hydrophilic components are minimized. These stabilized dispersions can be utilized to prepare ink jet inks which when printed result in improved optical density and chroma. The stability of the ionically stabilized dispersions are sufficient for ink jet inks.

Owner:EI DU PONT DE NEMOURS & CO

Aqueous inkjet inks with ionically stabilized dispersions and polyurethane ink additives

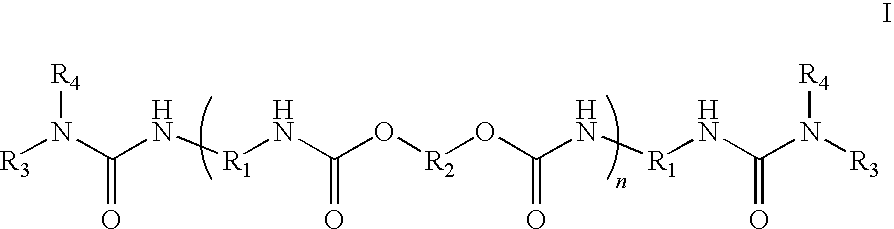

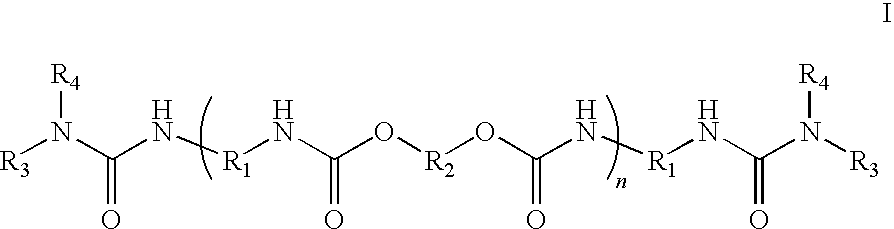

Inks that contain ionically stabilized dispersions and selected polyurethane ink additives are described. These ionically stabilized dispersions are obtained from polymeric dispersants where the hydrophilic components are minimized. These stabilized dispersions can be utilized to prepare ink jet inks which when printed result in improved optical density, chroma, gloss and especially distinctness of image. The stability of the ionically stabilized dispersions are sufficient for ink jet inks. The polyurethane ink additives are chosen from polyurethanes which are urea terminated or crosslinked.

Owner:EI DU PONT DE NEMOURS & CO

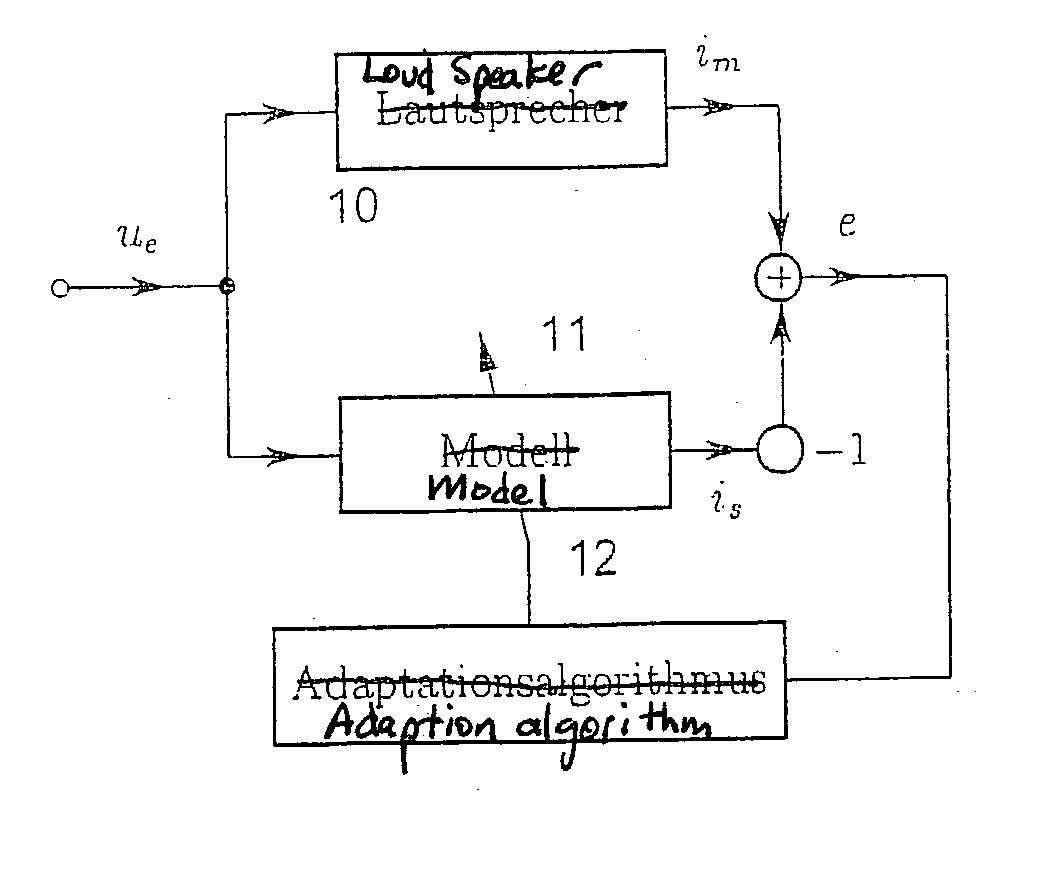

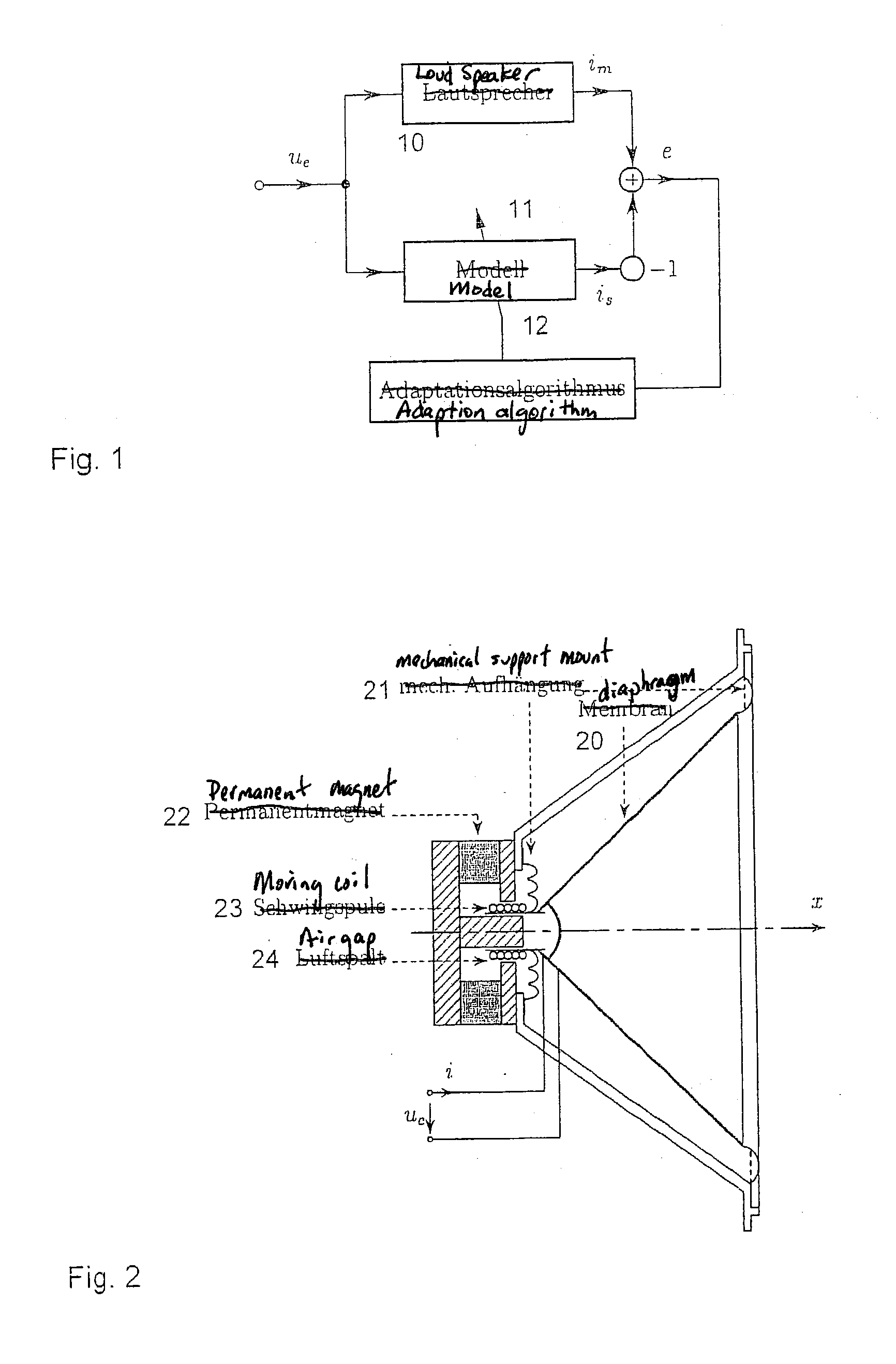

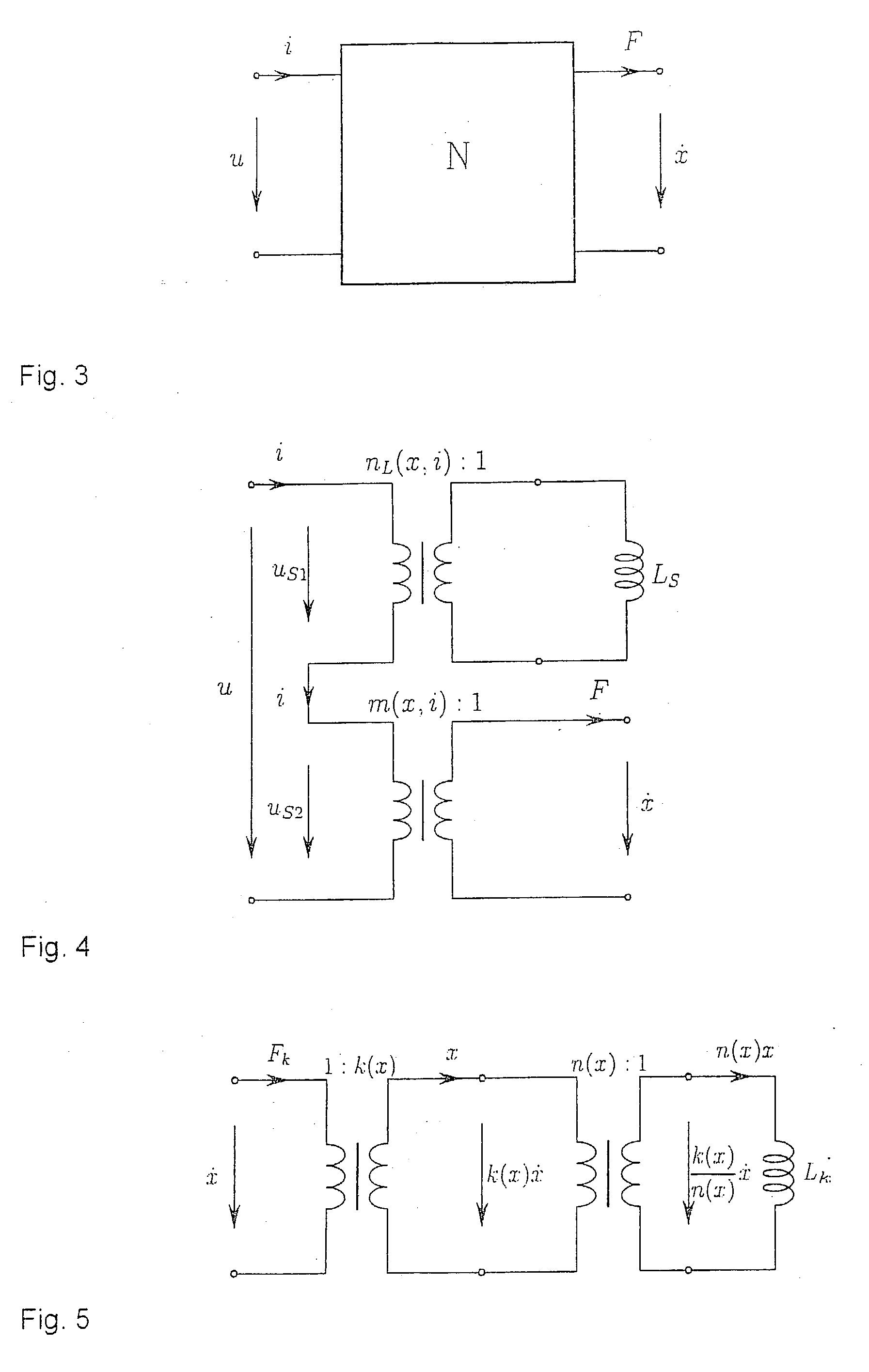

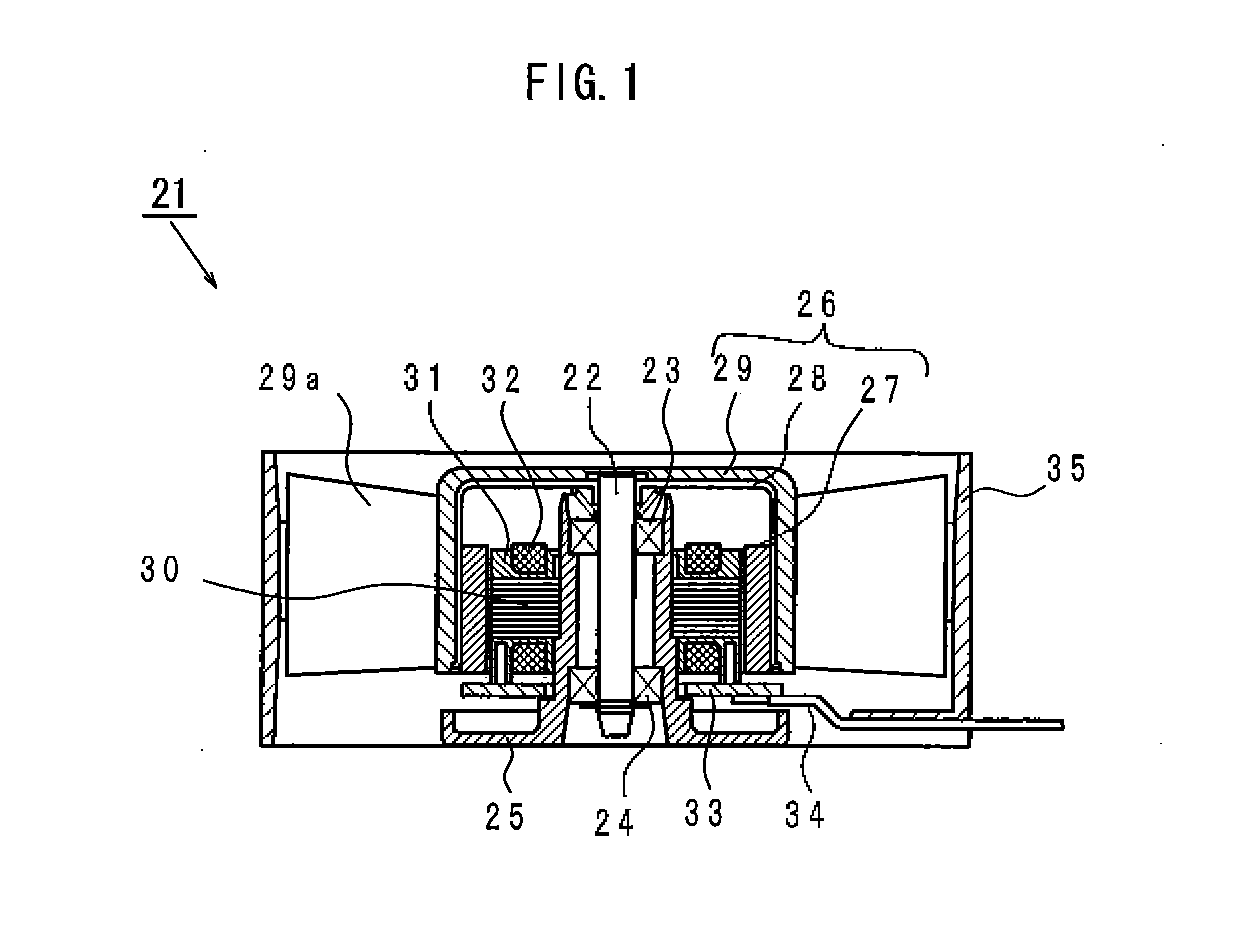

Adaptive method for detecting parameters of loudspeakers

InactiveUS20030142832A1Simple measureNot stableSound producing devicesTransducer casings/cabinets/supportsInductorLoudspeaker

The method makes possible the determination of loudspeaker parameters in real operation through a measurement of the moving-coil current im and it contains the following steps: 1) The measurement of the moving-coil current im resulting from the excitation of the loudspeaker using a known input signal ue; 2) The simulated estimation of the moving-coil current for the same input signal using an equivalent electrical network and a time-discrete model that is derived therefrom by wave digital realization; 3) The change of the parameters in the loudspeaker model through a preceding determination of starting values and the minimization of the average squared error from the measured and simulated moving-coil current, using a gradient method. The equivalent network contains a series circuit of two transformers, the first transformer on the secondary side having an inductor (Ls), and the second transformer on the secondary side having the parallel circuit of a resistor (1 / r), a capacitor (M), and a third transformer.

Owner:ROBERT BOSCH GMBH

Aqueous ionically stablized dispersions

InactiveUS20080071007A1Good dispersionNot stableMeasurement apparatus componentsInksOptical densityPolymer

Ironically stabilized dispersions are described that are substantially free of steric stabilization of the pigment. These ionically stabilized dispersions are obtained from polymeric dispersants where the hydrophilic components are minimized. The dispersions can be utilized to prepare ink jet inks which when printed provide advantageous optical density and chroma. Inkjet inks comprising ionically stabilized dispersion are particularly well suited for use in combination with a fixer and the present invention is directed to an inks set with such a combination of inks and to a printing method using this ink set.

Owner:EI DU PONT DE NEMOURS & CO

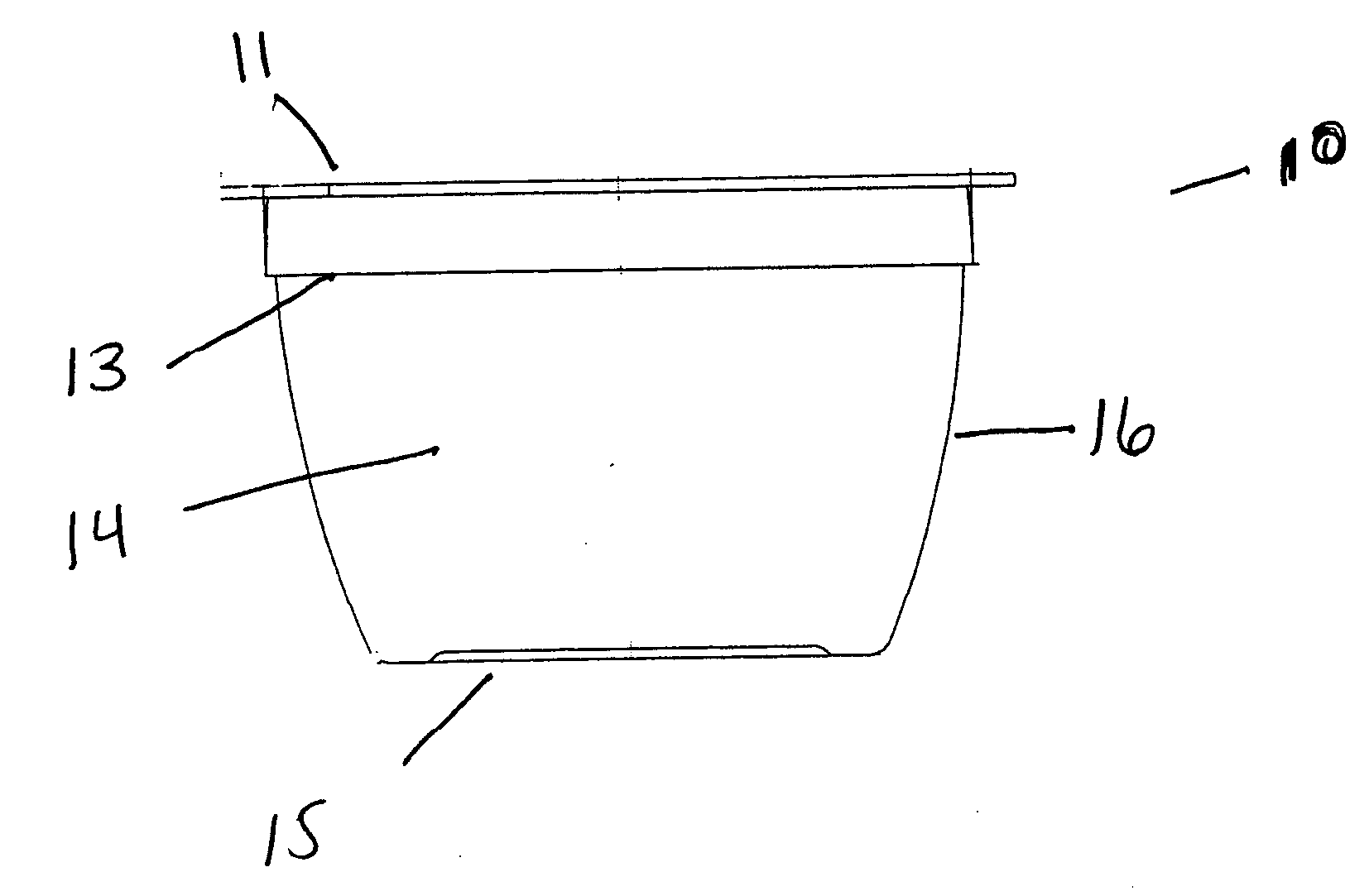

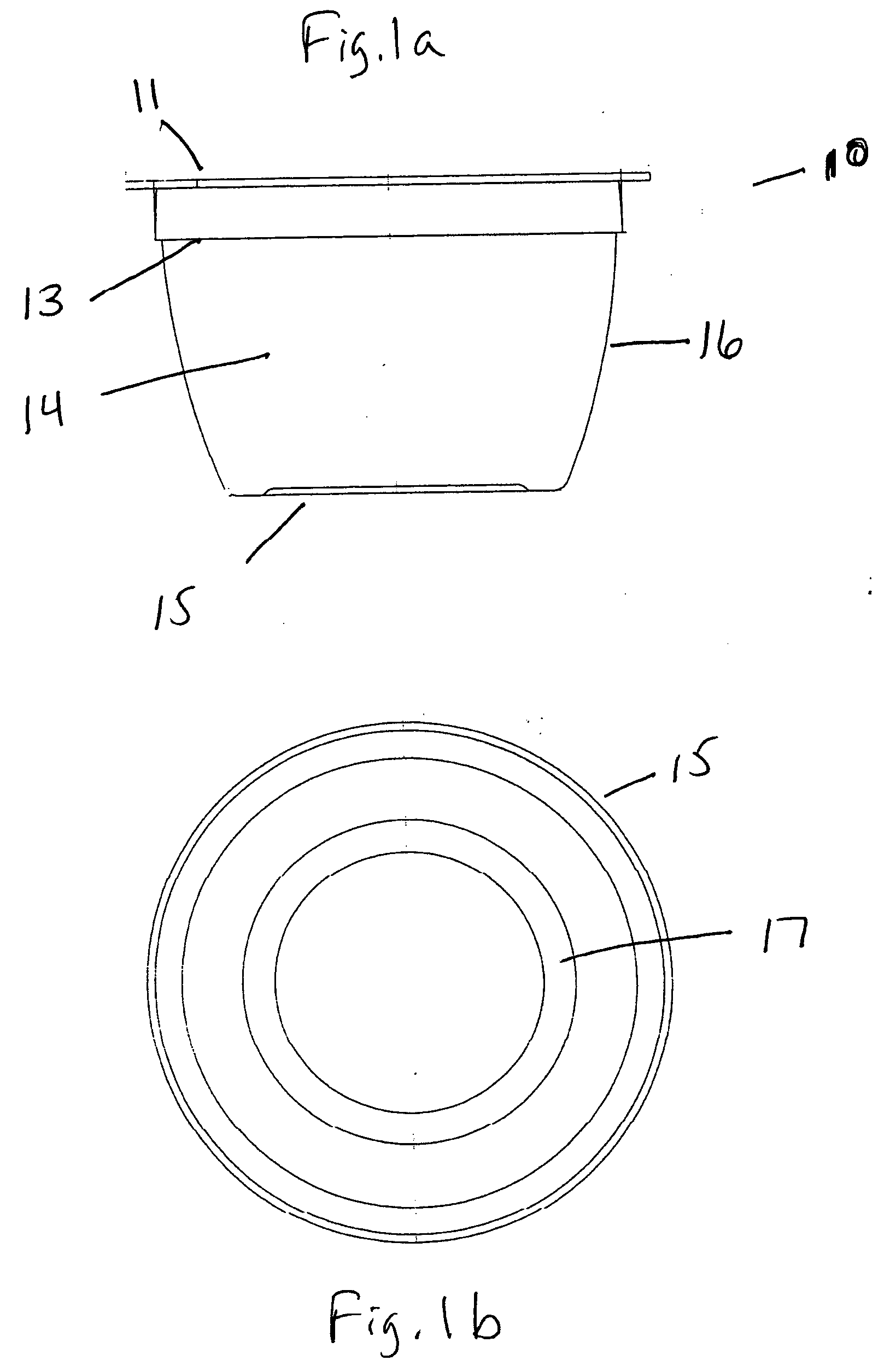

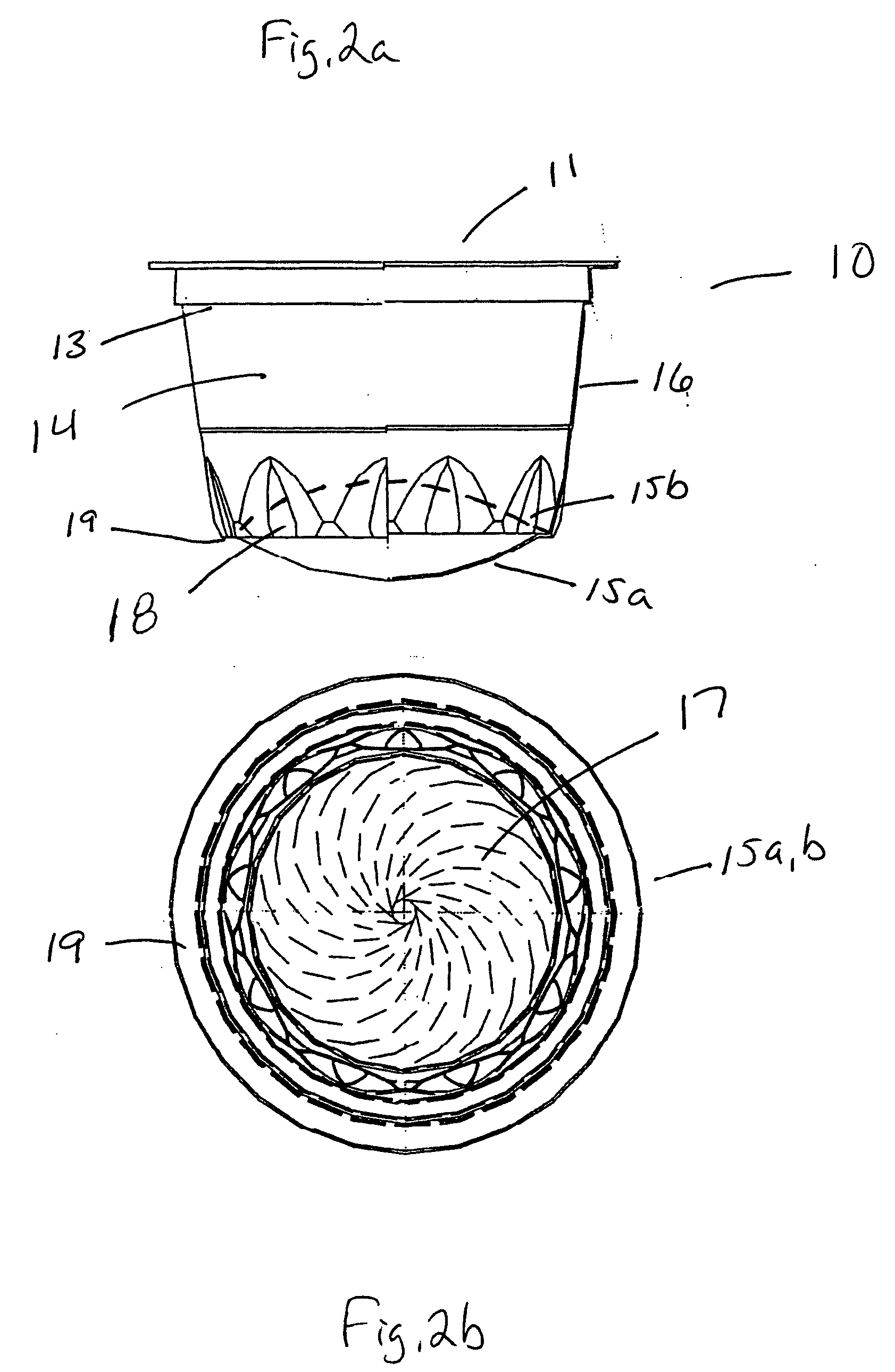

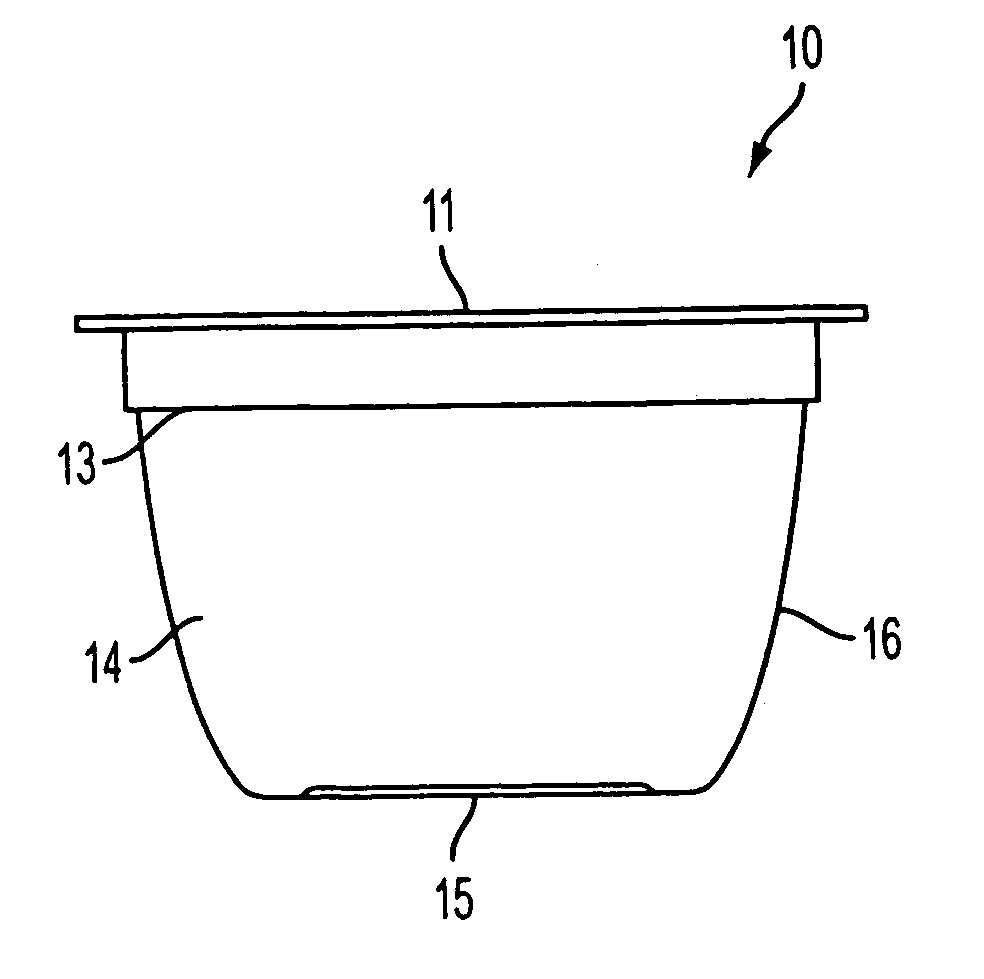

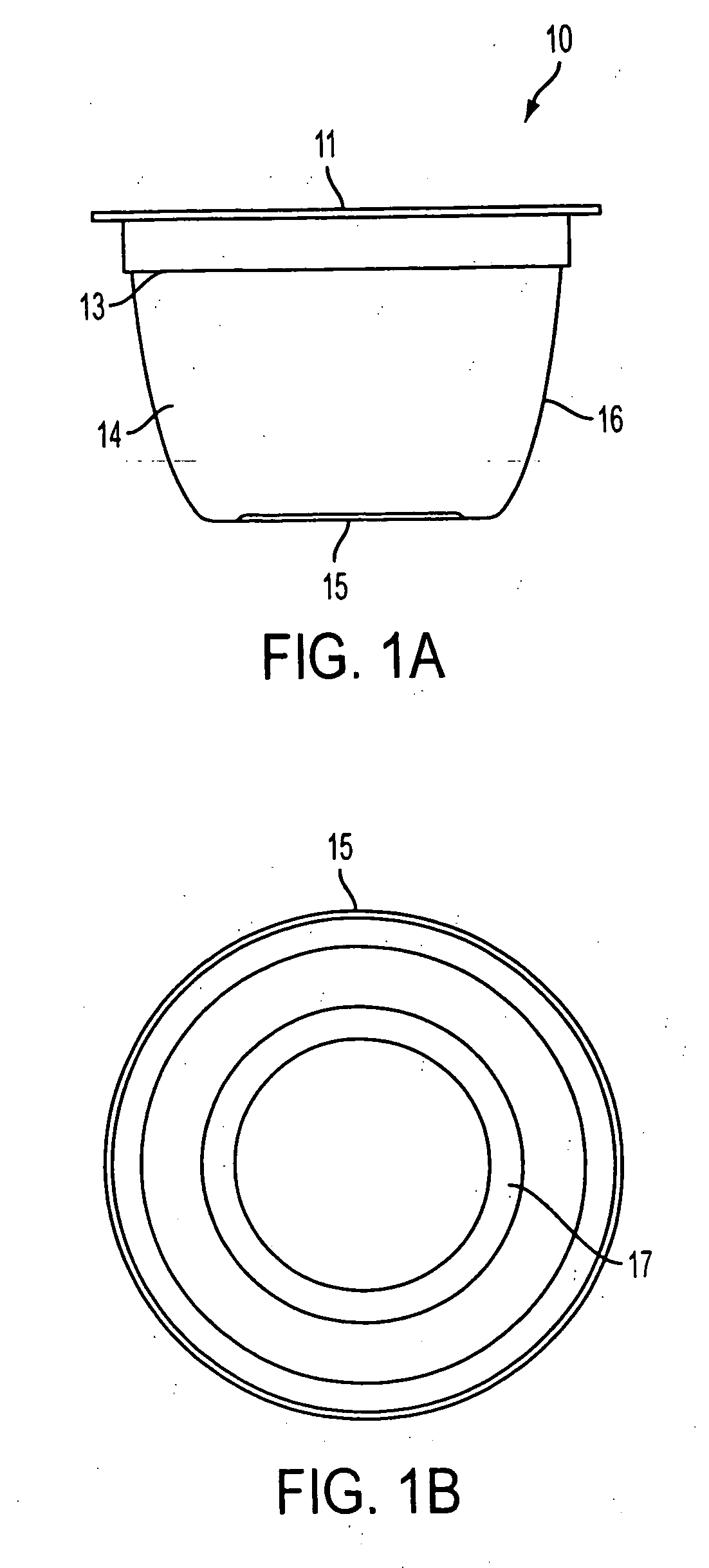

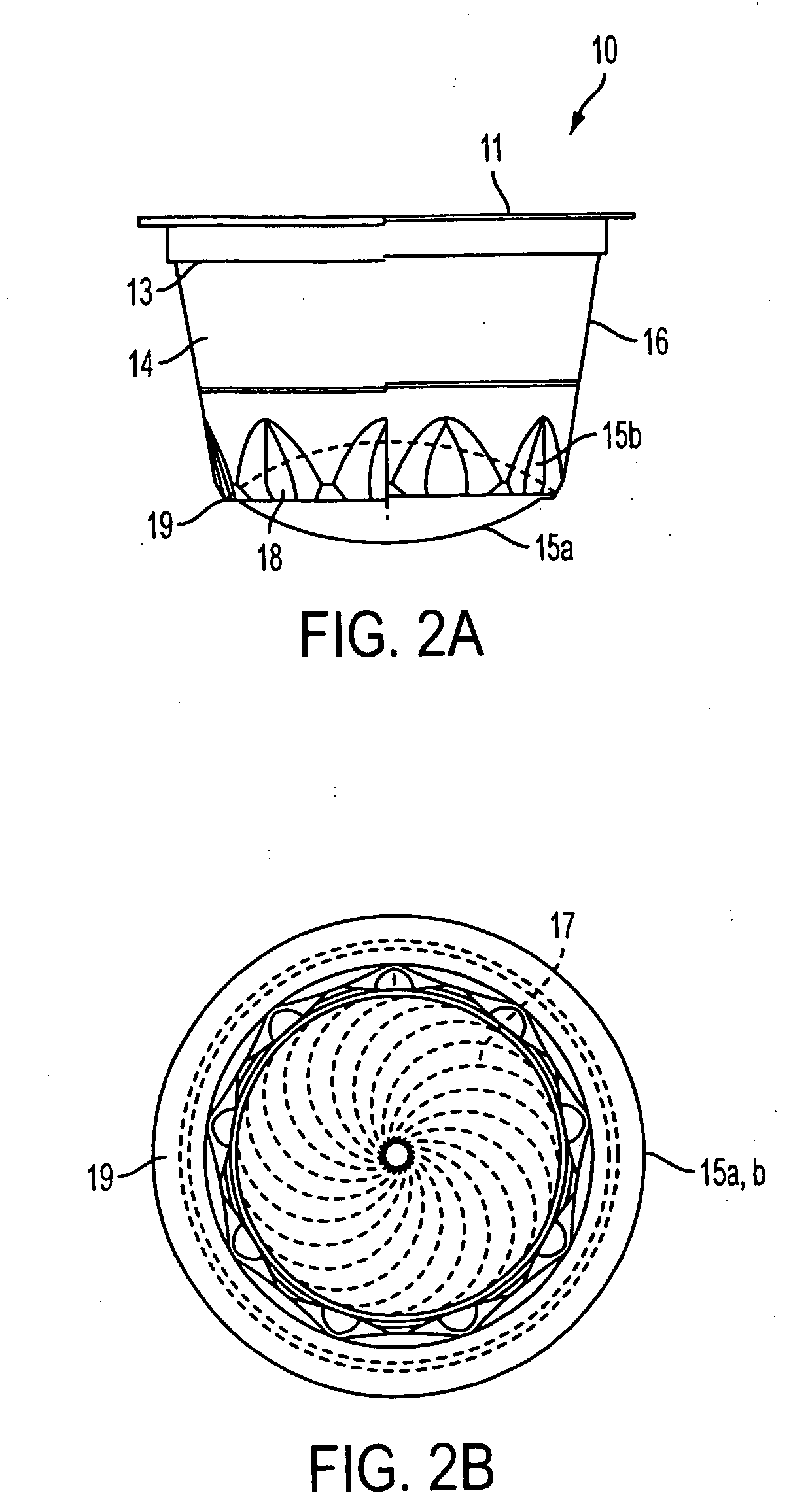

Container for hot fill food packaging applications

A plastic container suitable for hot-fill food packaging applications is disclosed which is characterized by walls of proportionately decreasing thickness from the mouth of the container to a predetermined collapsible point. The wall thickness is designed such that the container walls will collapse, or deform, only at the collapsible point during cooling after hot-filling of food product or during transportation of the container between locations of varying altitudes and pressures. The container preferably collapses in the base area such that the collapse is not visible to the consumer and also the collapse does not affect stability of the container while in use or during loading and storage. The container of the invention is advantageous in that it requires less plastic material to form than other known hot-fill containers, and also can be formed out of any suitable food-grade plastic material or by any process.

Owner:PHOENIX CAPITAL

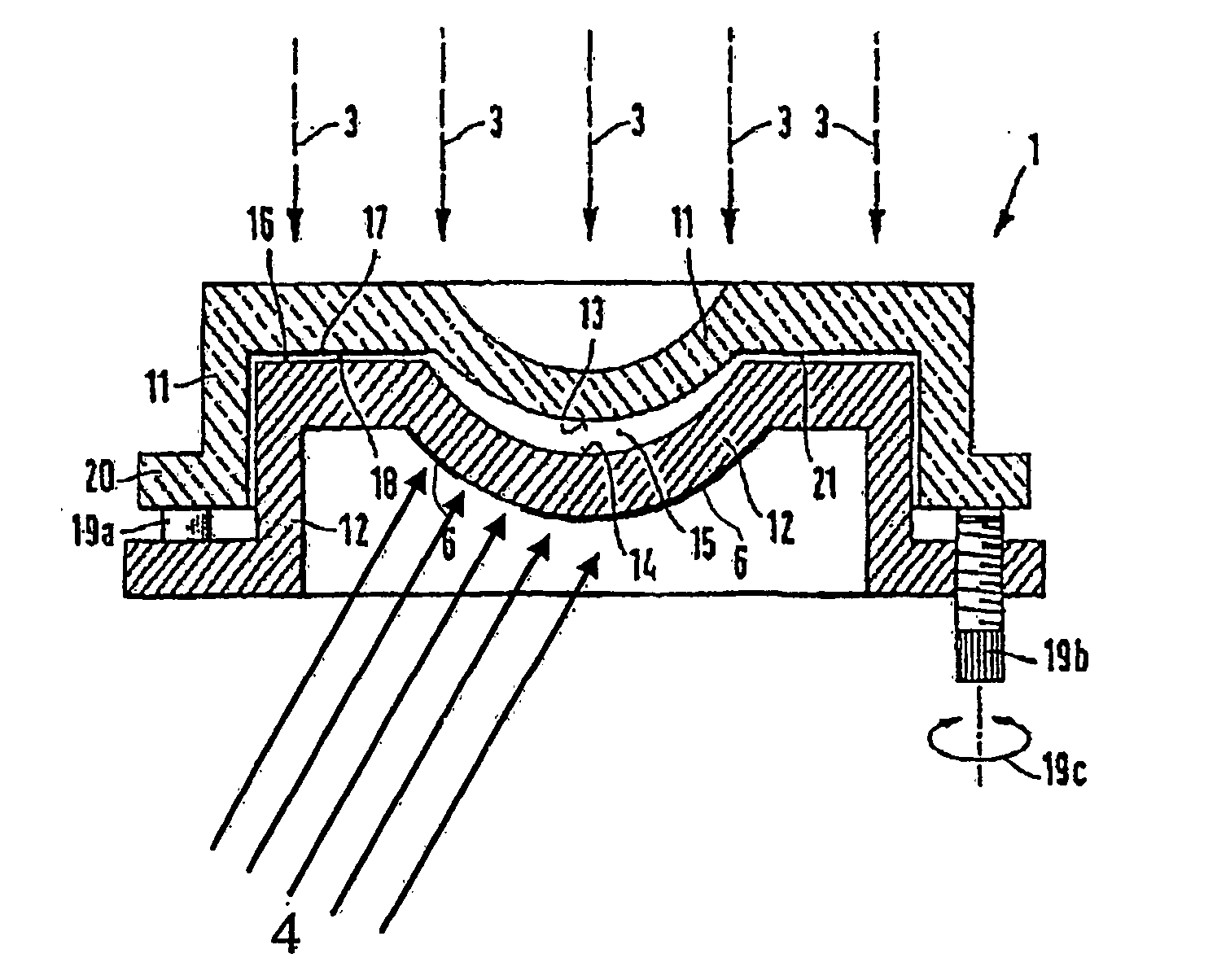

Reflection hologram sensor in contact lens

ActiveUS20070002470A1Cost-effectiveNot stableMaterial analysis by observing effect on chemical indicatorOptical articlesChemistryBody fluid

This invention is generally related to a biocompatible sensor for detecting / measuring an analyte of interest in a body fluid and a method for making the biocompatible sensor. A biocompatible sensor of the invention comprises, consists essentially, or consists of a reflection hologram therein or thereon, wherein the reflection hologram is produced in a crosslinkable and / or polymerizable fluid material. The polymer matrix contains a molecular sensing moiety which interacts or reacts with an analyte of interest to provide an optical signal which is indicative of a change in one or more optical properties of the reflection hologram.

Owner:EYESENSE AG

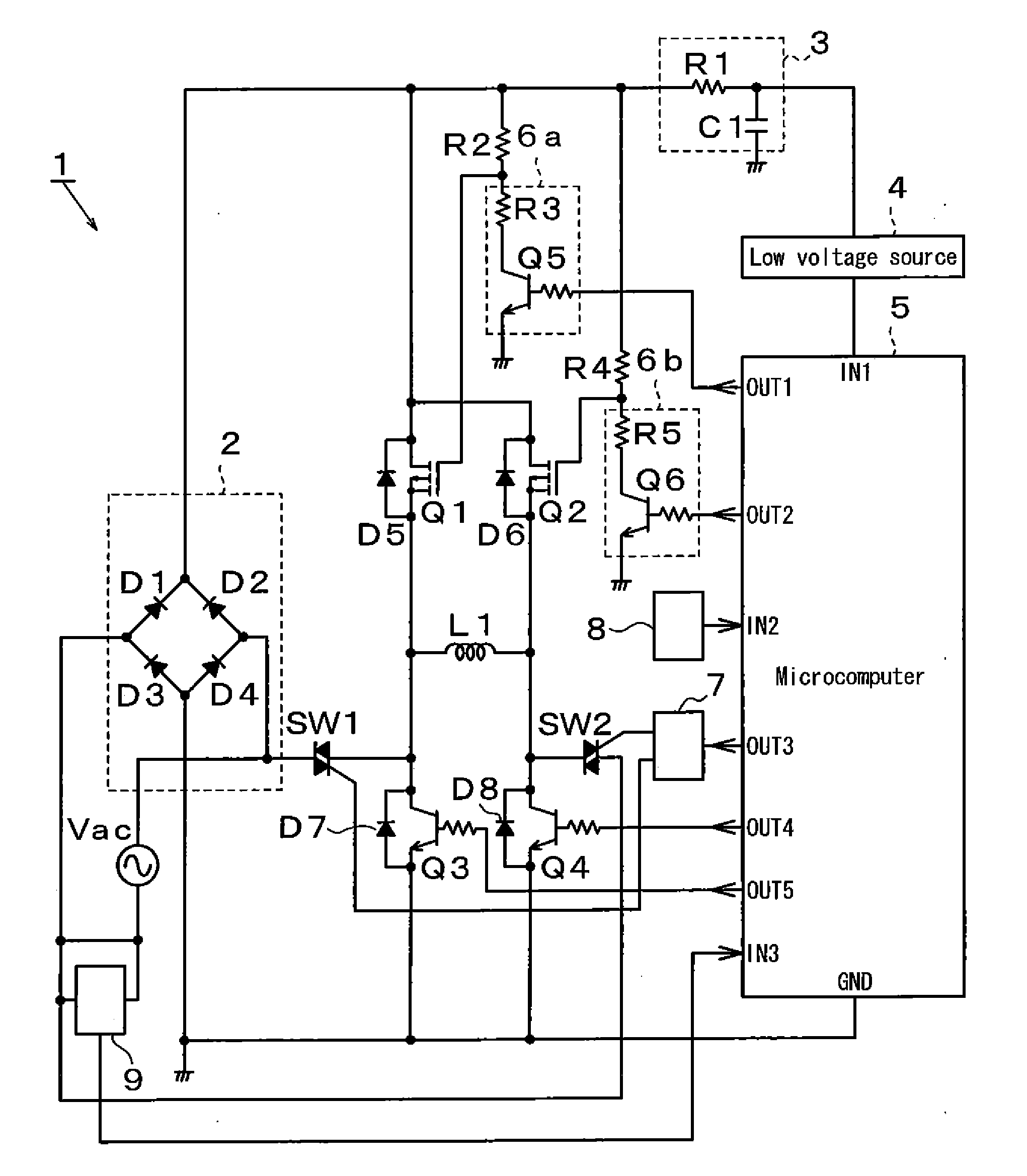

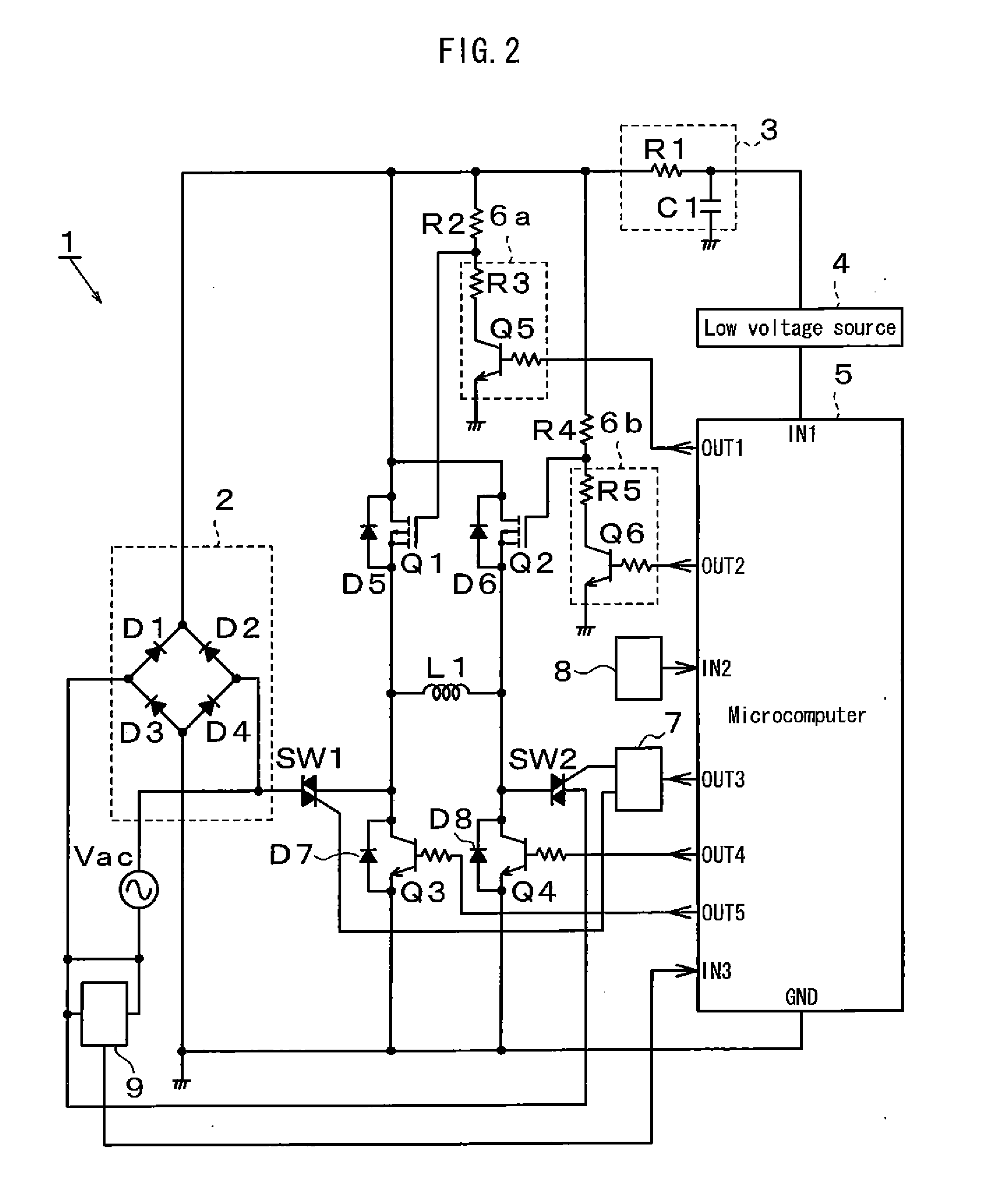

Single-phase ac synchronized motor

InactiveUS20110291605A1Not stableImprove performanceAC motor controlSynchronous motors startersSynchronous motorControl theory

There is provided a single-phase AC synchronized motor that does not need smooth of rectifier waves but stably performs shift from a starting operation to a synchronized operation. In the motor, based on detected signals of a position sensor, rectified current is reciprocally flowed to each direction of a single-phase coil which starts the motor. The motor includes a start-up operation circuit with a sensor starting period that increases a rotational speed until reaching to a first predetermined rotational speed; and a control device that controls operation of the motor as that shift to synchronized operation is performed when a rotational speed of a permanent magnetic rotor is reached to a second predetermined rotational speed nearby a synchronized rotational speed but not exceeding the synchronized rotational speed, and when the rise and fall of detected signals of the position sensor and the zero-cross point of AC current are approximately correspondent to each other.

Owner:MINEBEAMITSUMI INC

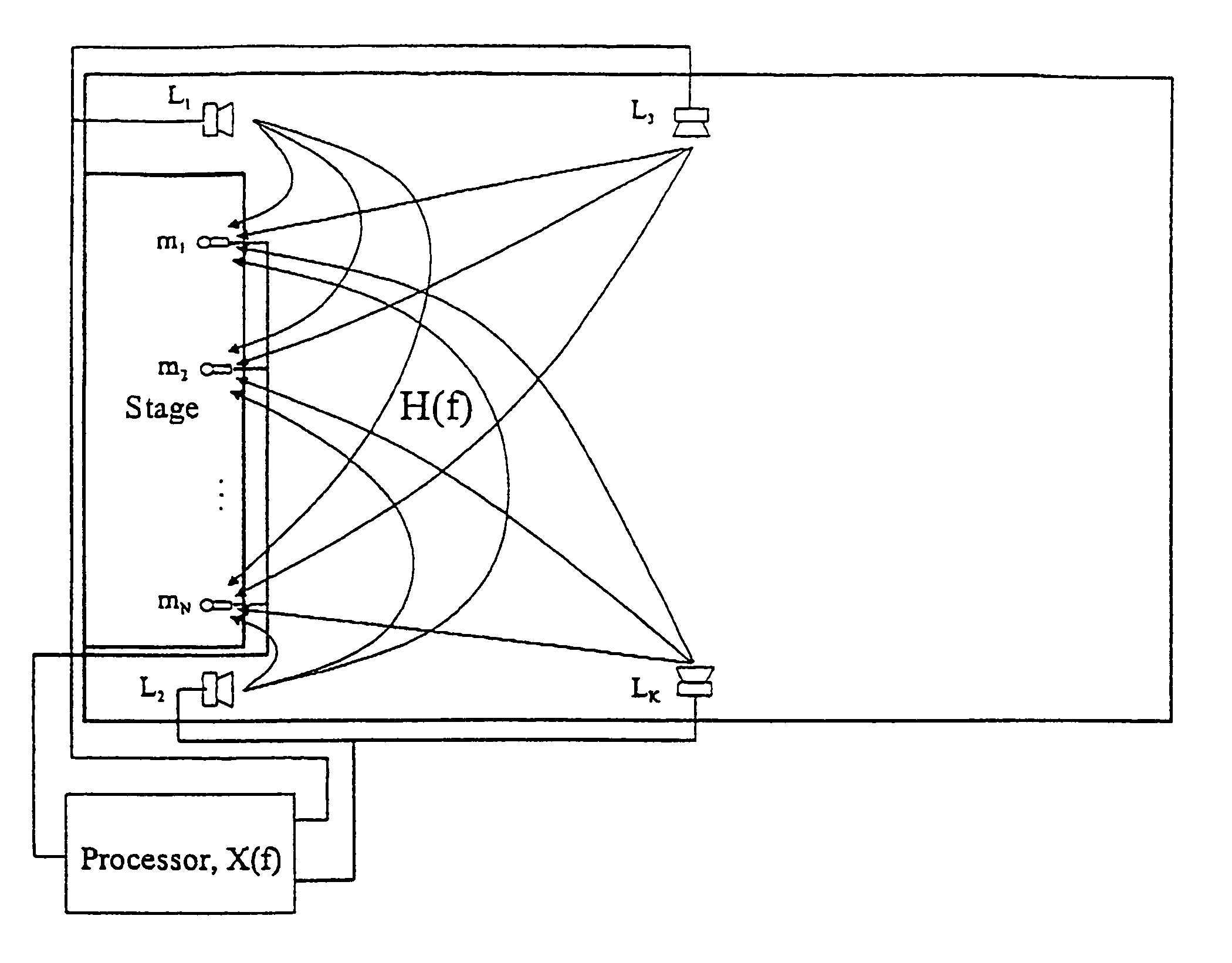

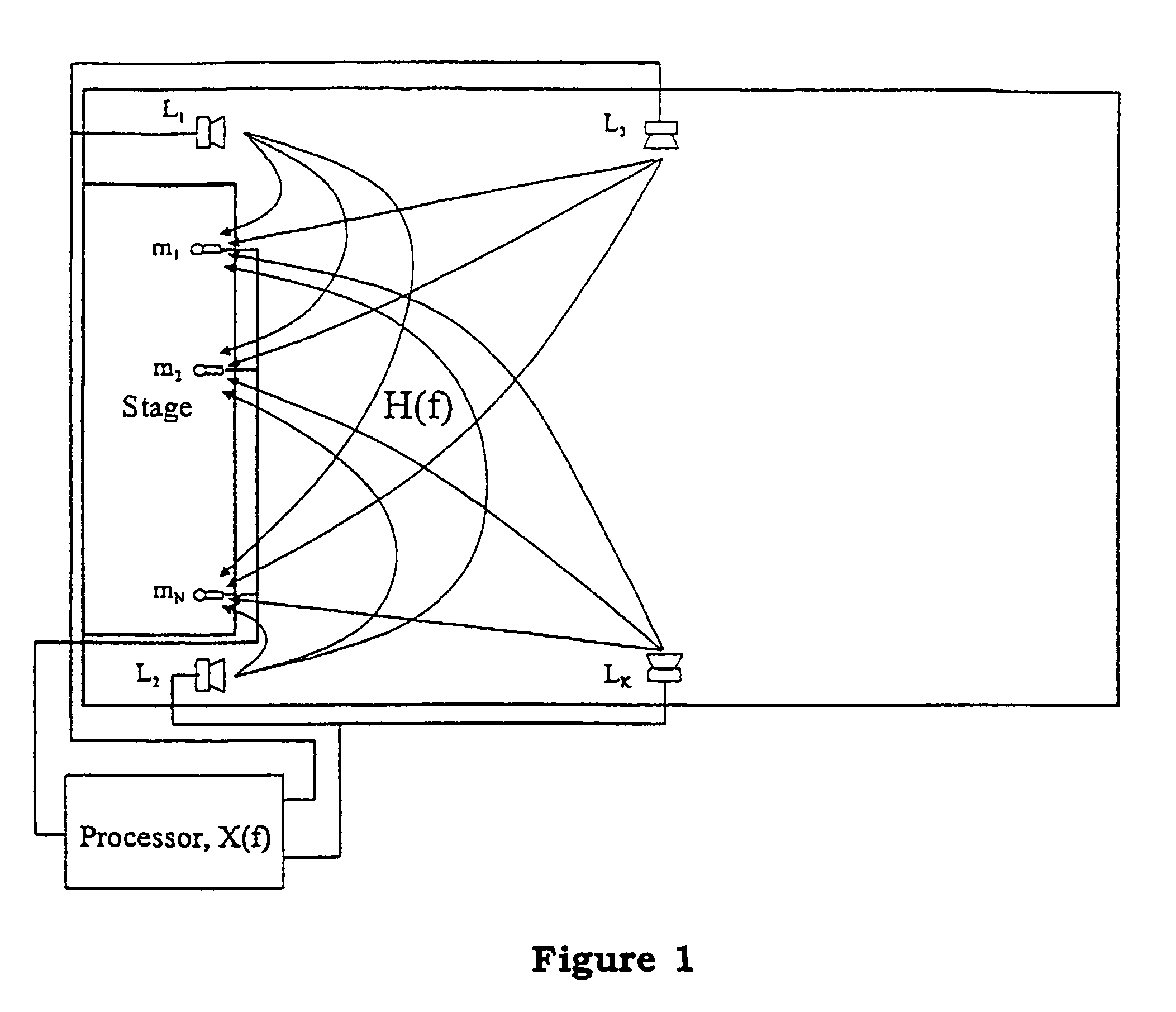

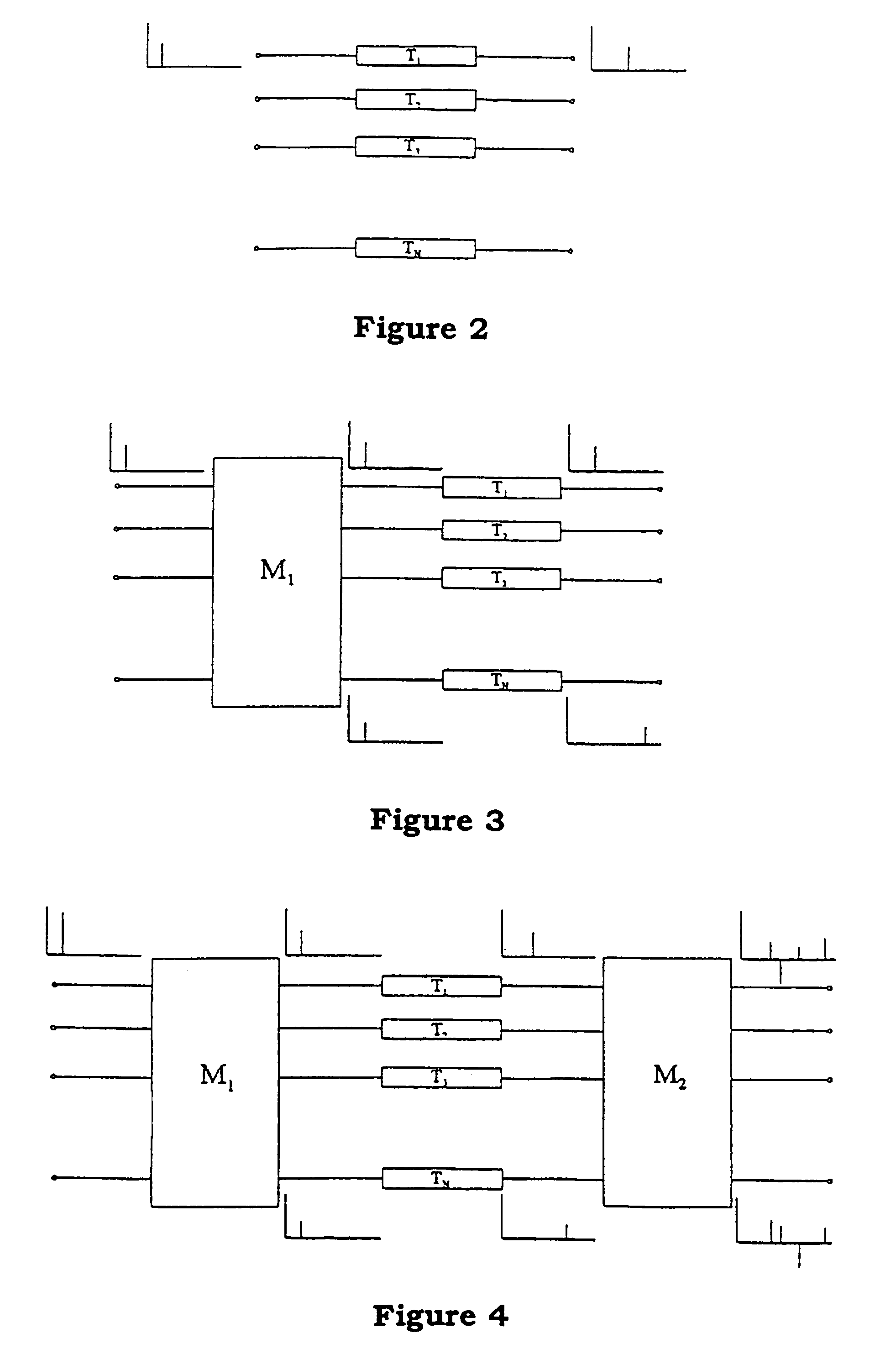

In-line early reflection enhancement system for enhancing acoustics

InactiveUS7233673B1Not stableExtended latencyElectrophonic musical instrumentsGain controlSound sourcesMicrophone signal

An in-line early enhancement generation system comprises one or more microphones positioned close to one or more sound sources so as to detect predominantly direct sound, an early reflection generation stage which generates a number of delayed reproductions of the microphone signals and which has unitary power gain whereby the stability of the system is independent of the delay times and amplitudes, and a number of loudspeakers placed to broadcast said early reflected energy into the room.

Owner:CALLAGHAN INNOVATION

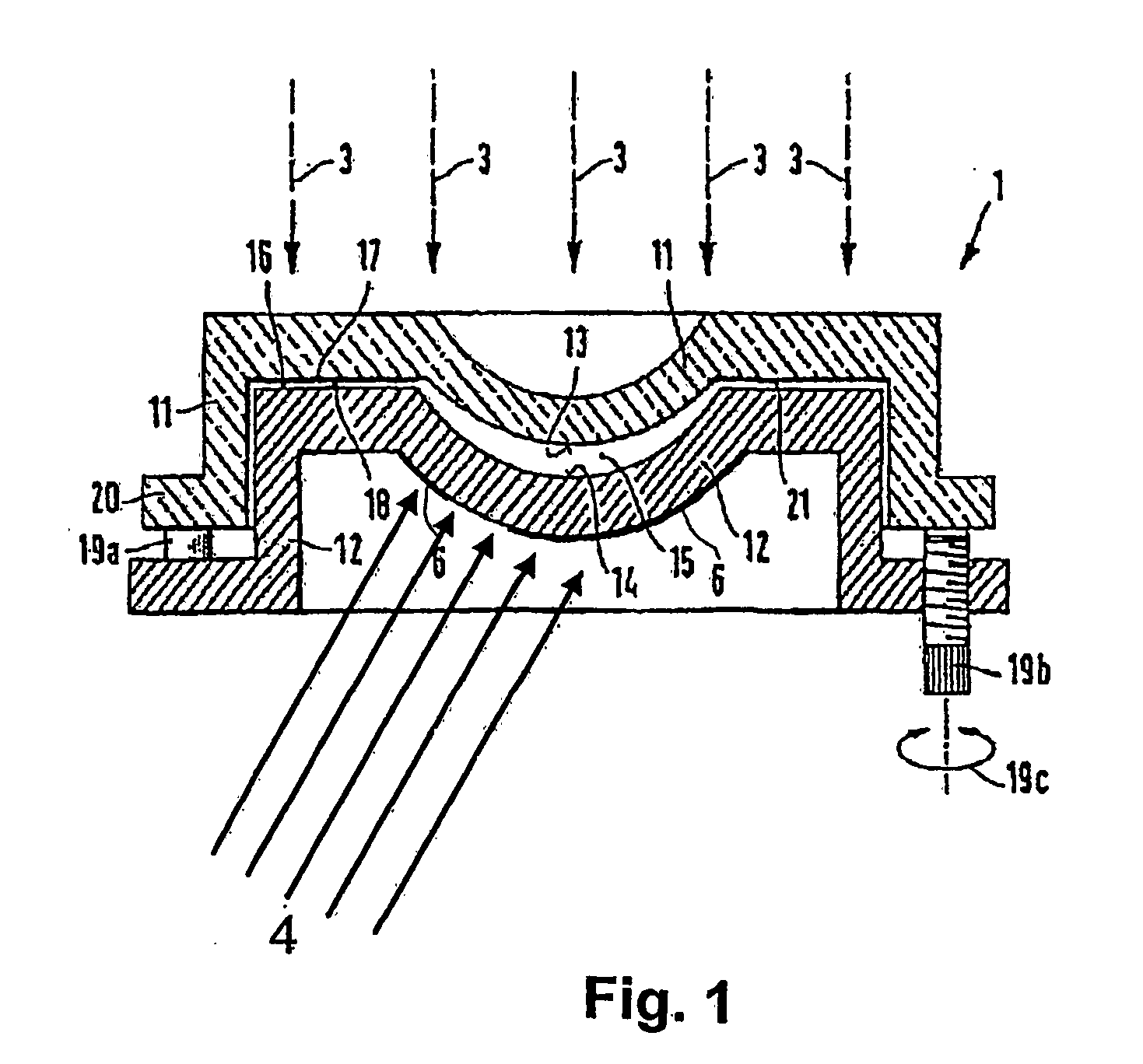

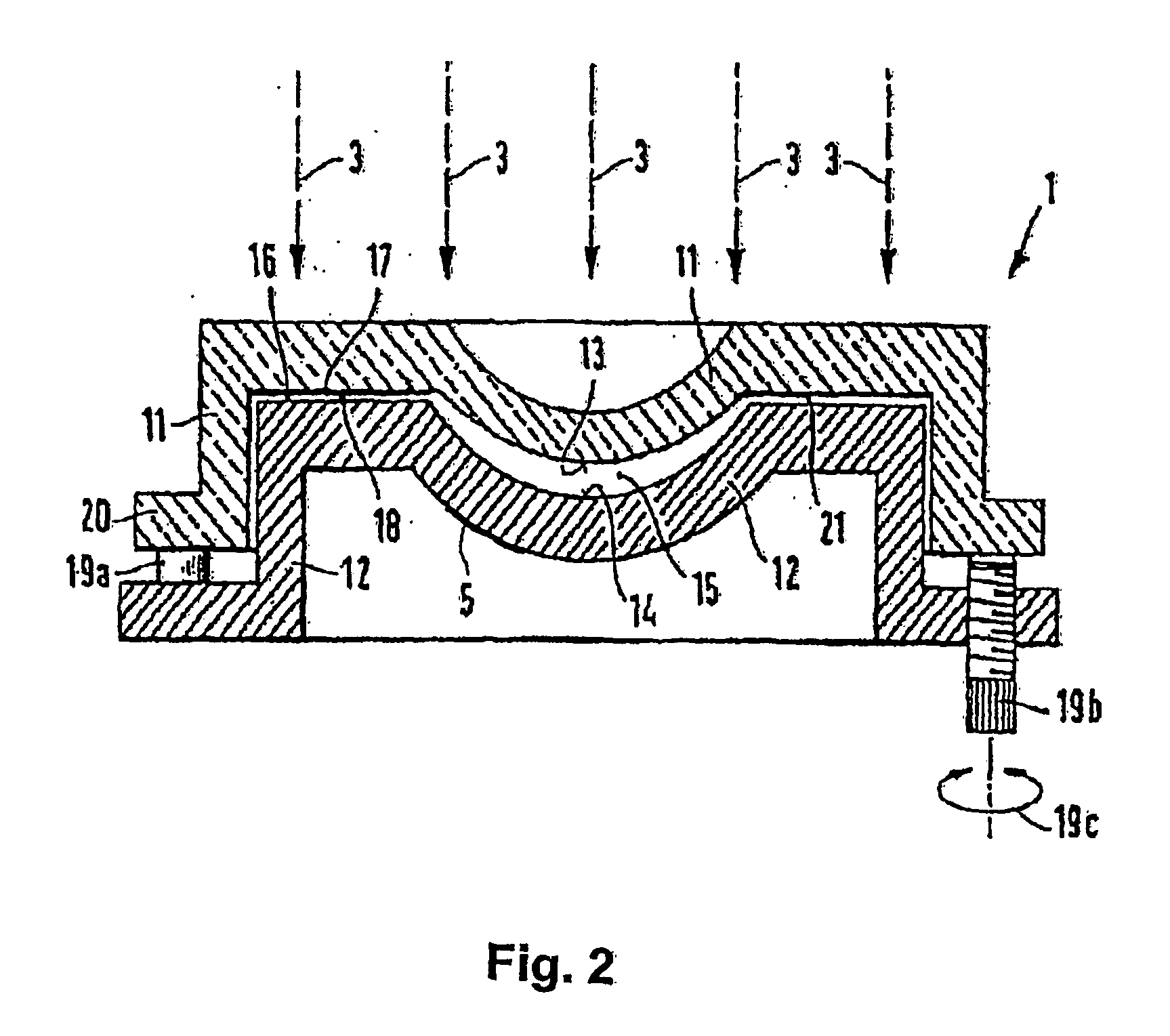

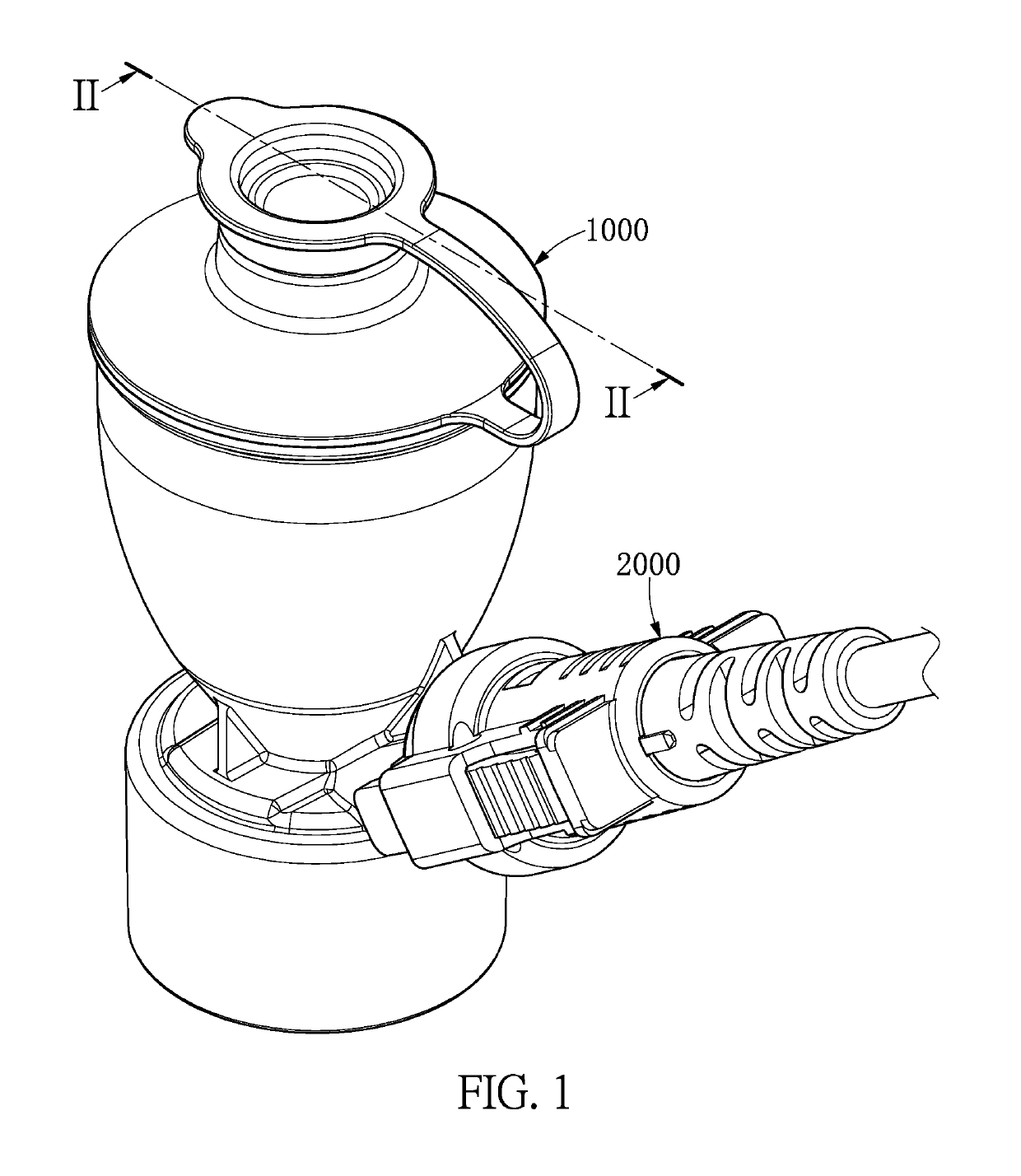

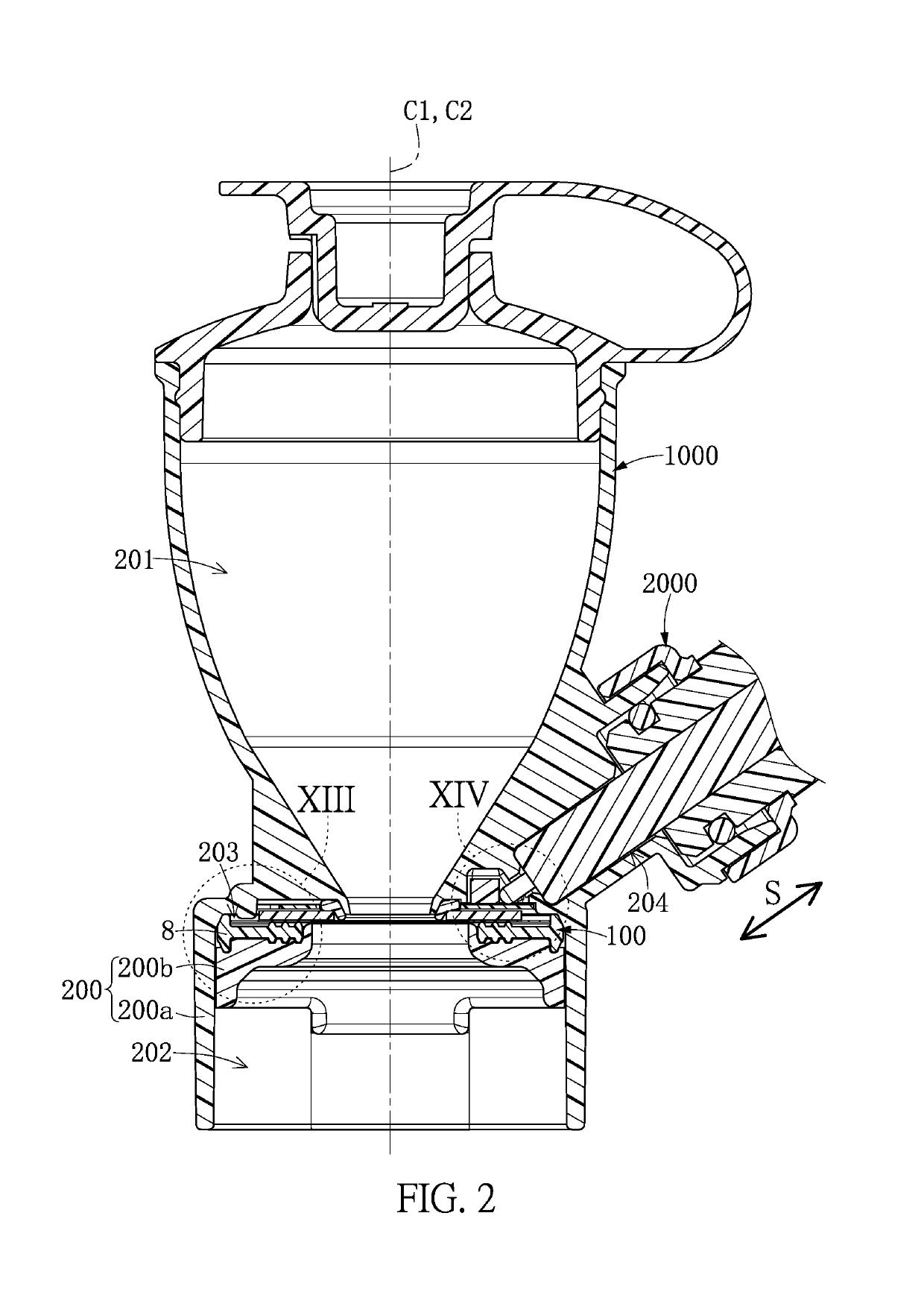

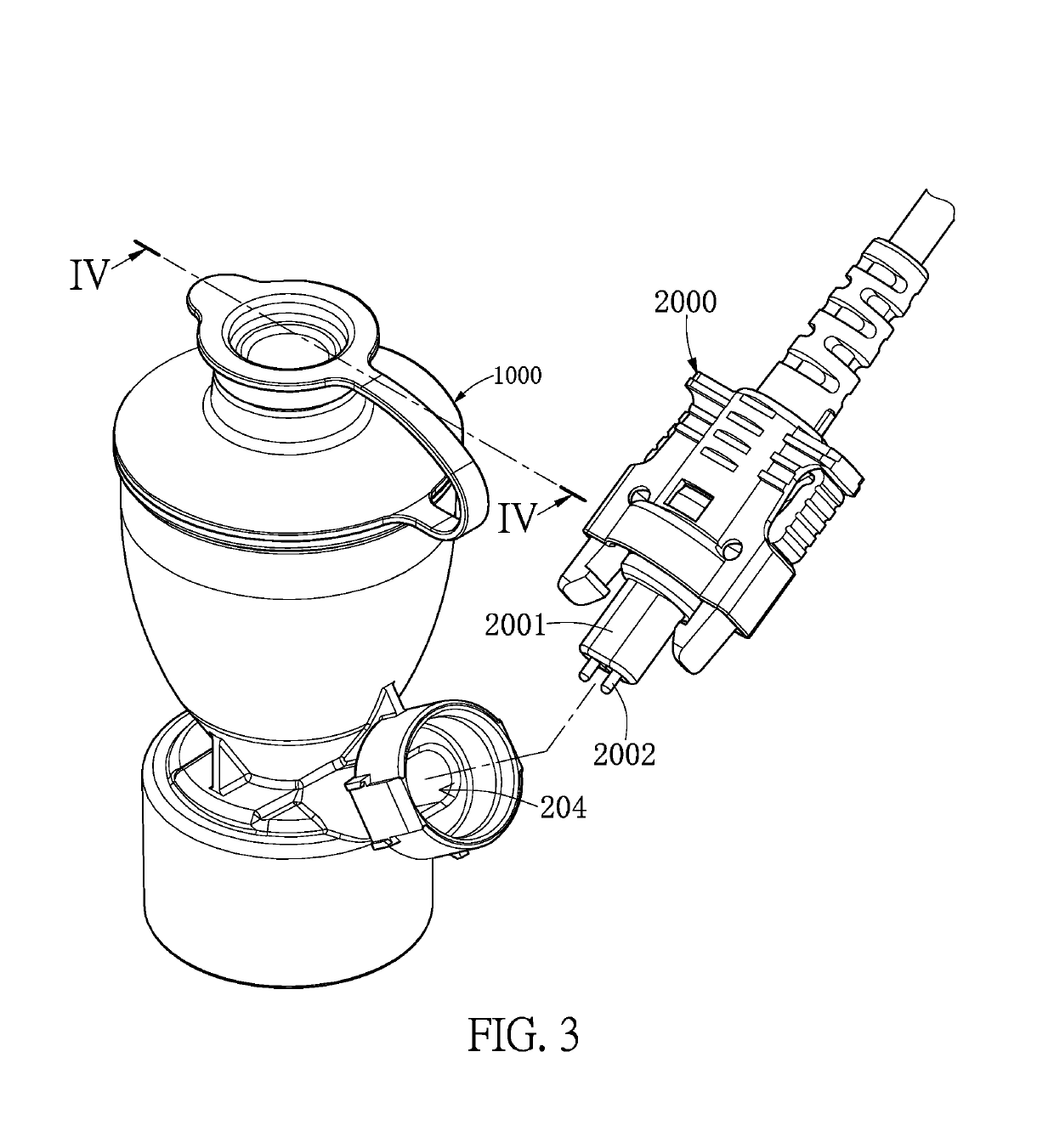

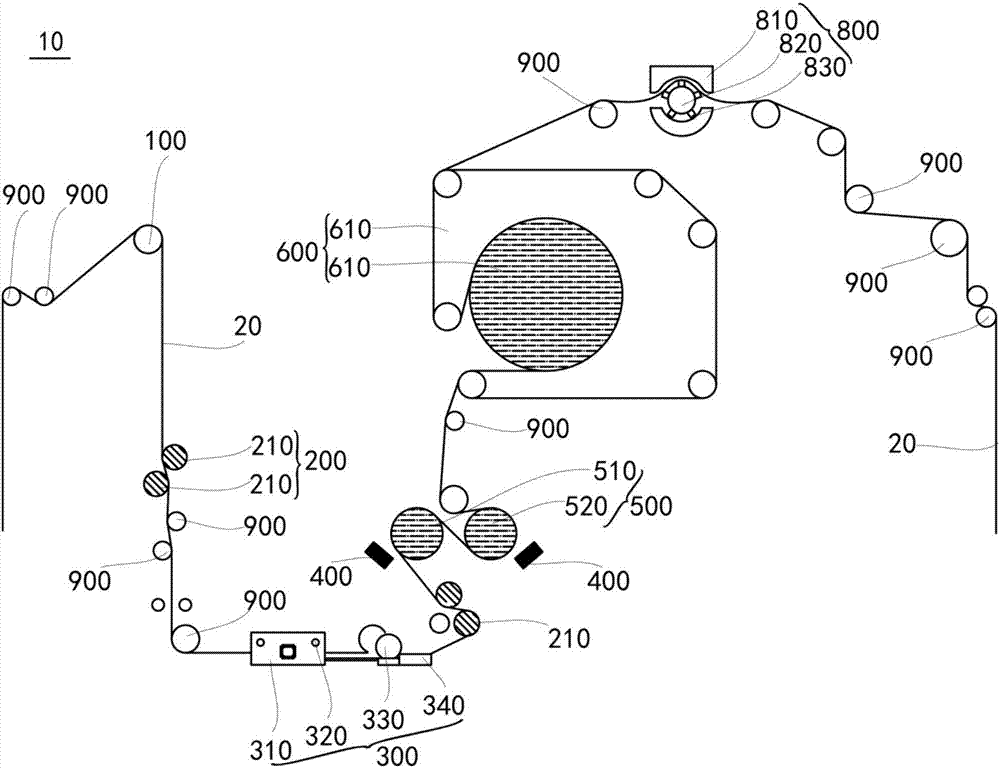

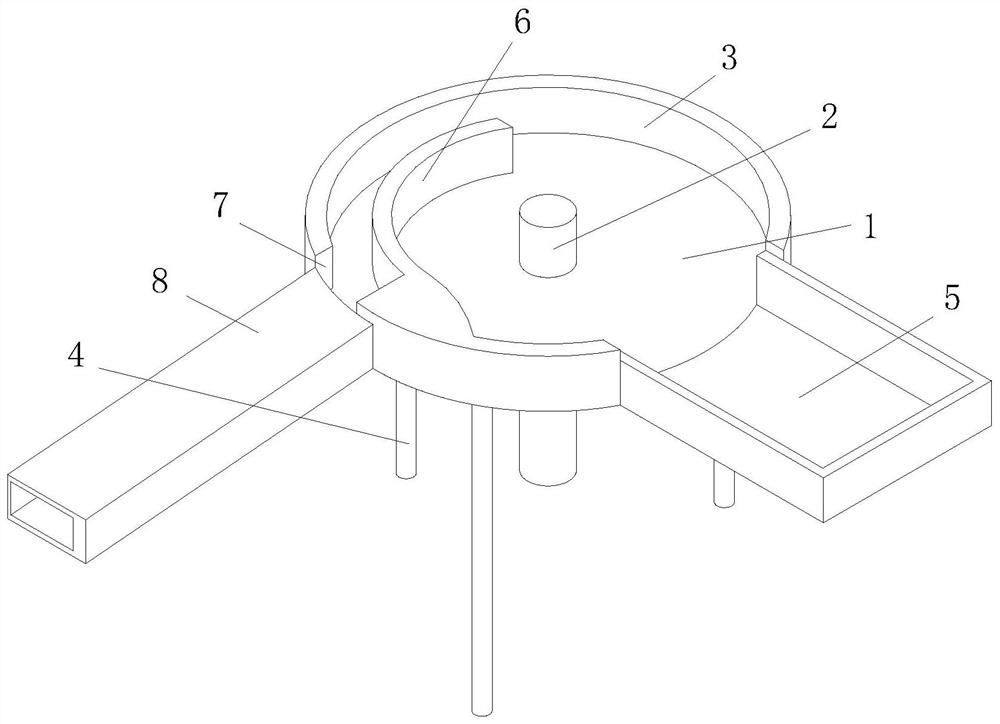

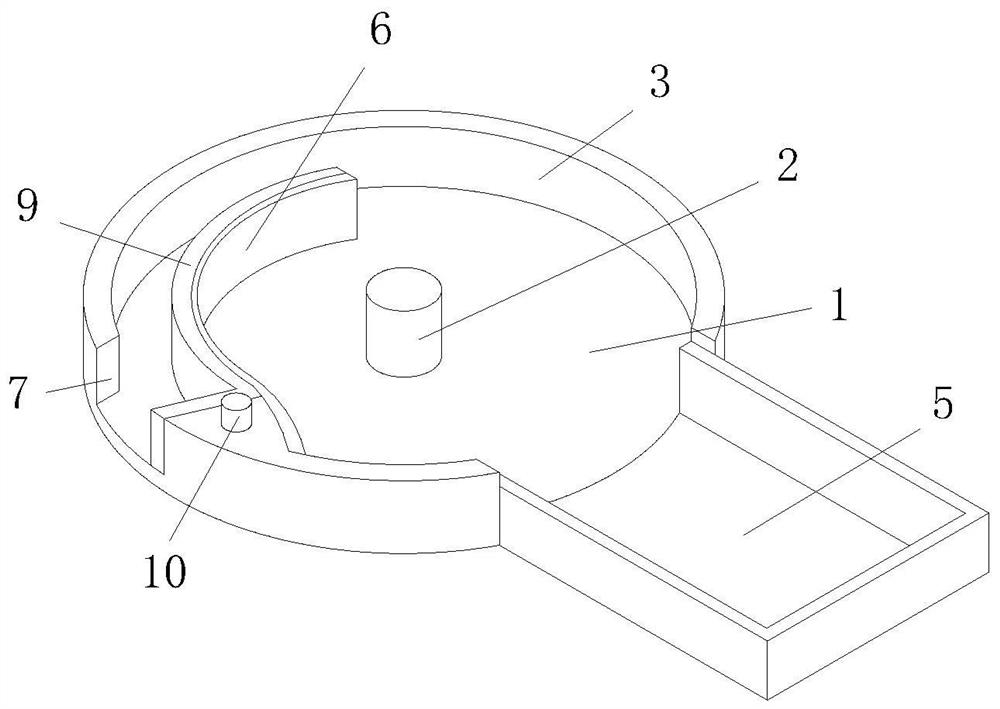

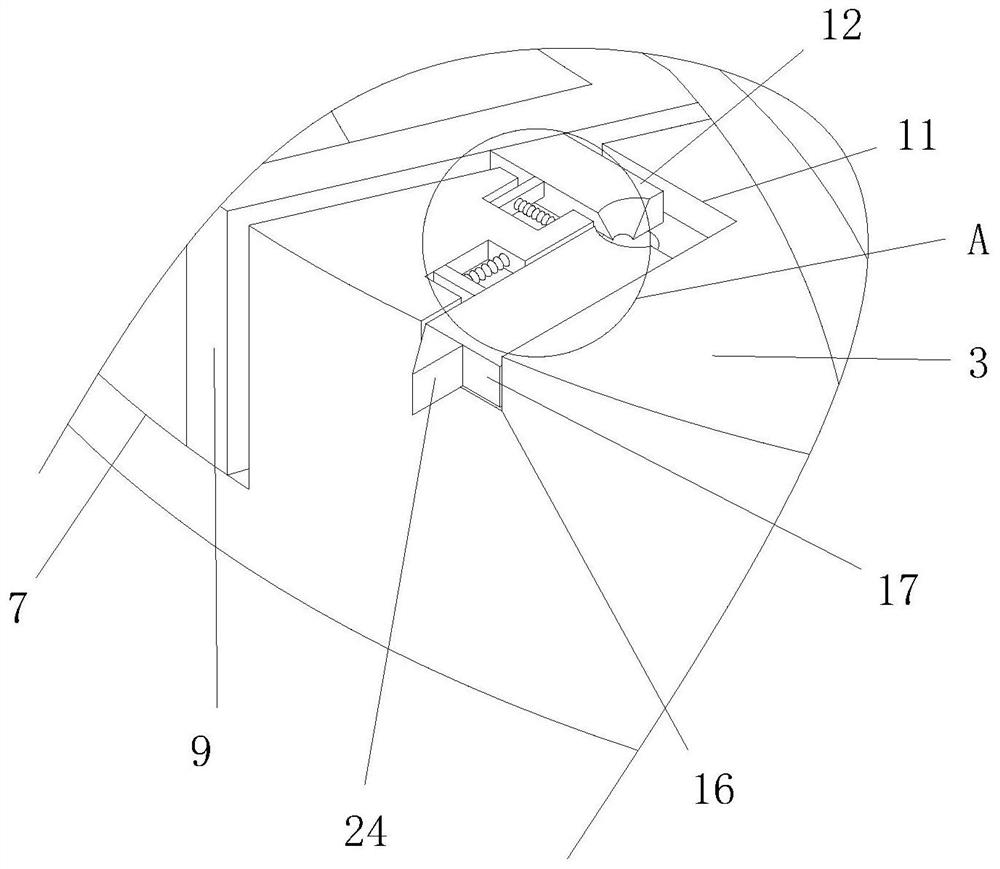

Aerosol generator and atomizing module

ActiveUS20190335580A1Not stableImprove the conventional atomizing modulesCoupling device connectionsCircuit bendability/stretchabilityAerosol sprayEngineering

An aerosol generator includes a container and an atomizing module arranged in the container. The container has a liquid chamber and an aerosol chamber respectively arranged at two opposite sides of the atomizing module. The atomizing module includes an annular vibration plate, a microporous member, and a circuit board. The vibration plate has a first hole, and the microporous member is disposed on the vibration plate and covers the first hole. The circuit board is electrically coupled to an electrical contact of the vibration plate. The circuit board is arranged at one side of at least part of the vibration plate, and the circuit board and the at least part of the vibration plate have a gap there-between. A projected region defined by orthogonally projecting the circuit board onto a plane overlapping with the electrical contact partially covers the least part of the vibration plate.

Owner:MICRO BASE TECH CORP

Aqueous ionically stabilized dispersions

InactiveUS20070299198A1Good dispersionNot stableMeasurement apparatus componentsTransportation and packagingOptical densityPolymer

Ionically stabilized dispersions are described that are substantially free of steric stabilization of the pigment. These ionically stabilized dispersions are obtained from polymeric dispersants where the hydrophilic components are minimized. These stabilized dispersions can be utilized to prepare ink jet inks which when printed result in improved optical density and chroma. The stability of the ionically stabilized dispersions are sufficient for ink jet inks.

Owner:EI DU PONT DE NEMOURS & CO

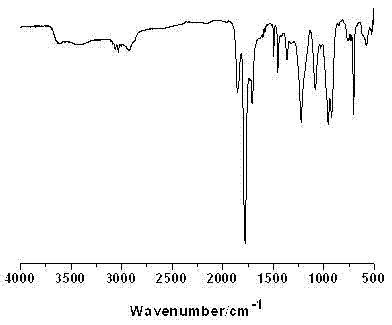

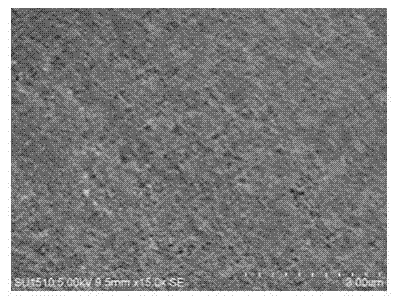

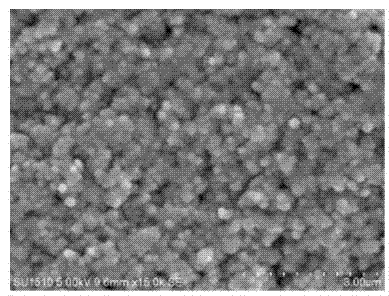

Preparation method of branched polystyrene-maleic anhydride and application thereof

InactiveCN102344526APolymerization conditions are mildControllable polymer structure and propertiesTransportation and packagingOrganic dyesMaleic anhydrideSolvent

The invention relates to a preparation method of branched polystyrene-maleic anhydride, comprising the steps of: (1) under normal pressure, dissolving p-vinylbenzyl mercaptan, styrene, maleic anhydride, and an initiator for free radical polymerization in a polymerization solvent; (2) under stirring, heating the solution obtained in step (1) to a temperature of 30-40DEG C and introducing nitrogen to the solution, sealing the reaction container, keeping stirring, raising the temperature of the solution to 65-80DEG C and preserving the heat for a reaction of 10-24h; (3) after the reaction, conducting pumping filtration to the solution obtained in step (2), leaching the solid from filtration with a hot precipitating agent, then dissolving the solid in an organic solvent, filtering out insoluble impurities therein, conducting precipitation and pumping filtration to the obtained solution in a precipitating agent, subjecting the solid obtained from filtration to dissolution, precipitation and pumping filtration, and carrying out vacuum drying to the generated solid. According to the invention, the polymerization conditions are mild, the polymers have controllable structural performance, and the polymerization product has excellent performance, simple and convenient preparation operations, as well as good application.

Owner:JIANGNAN UNIV

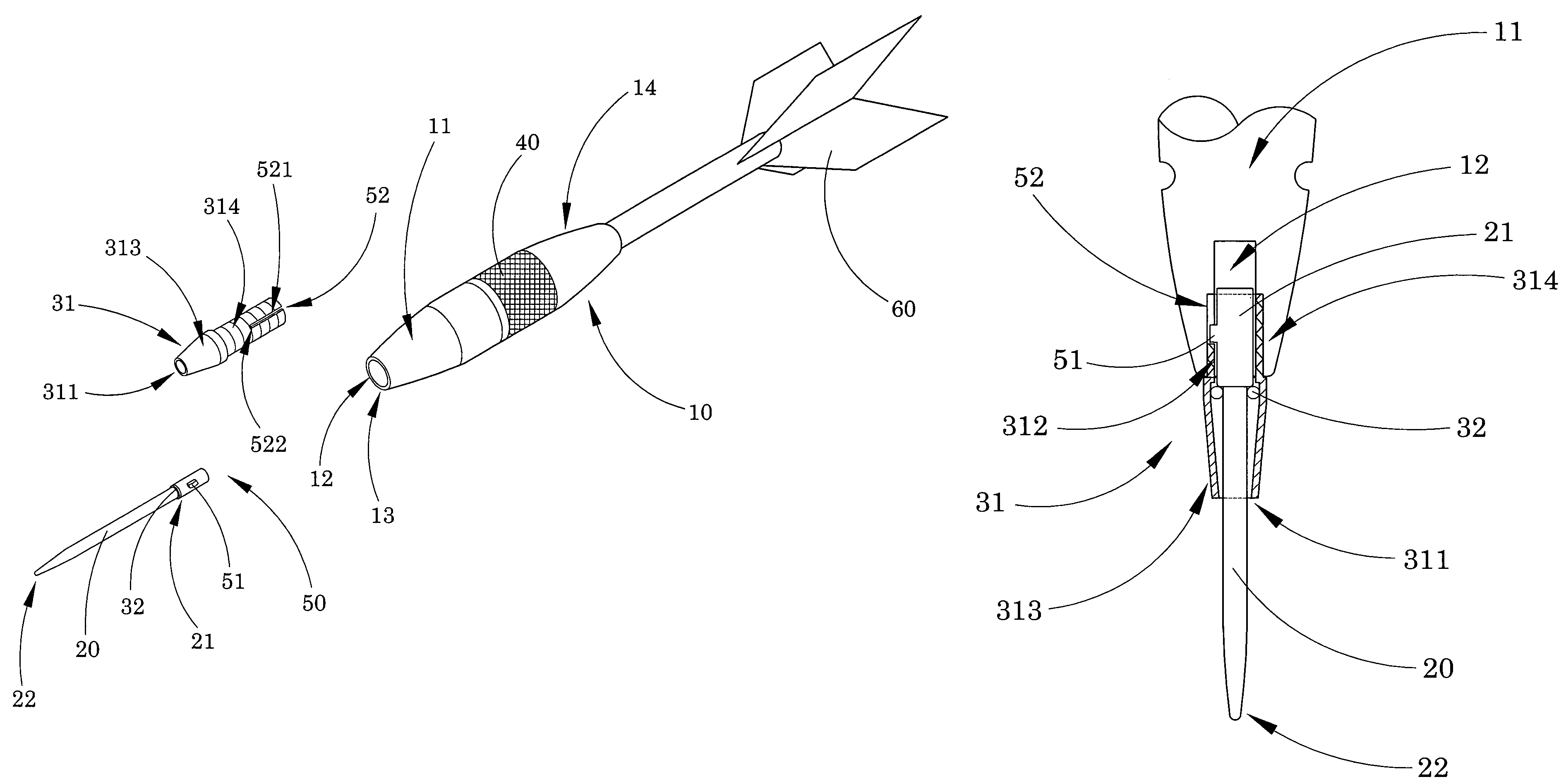

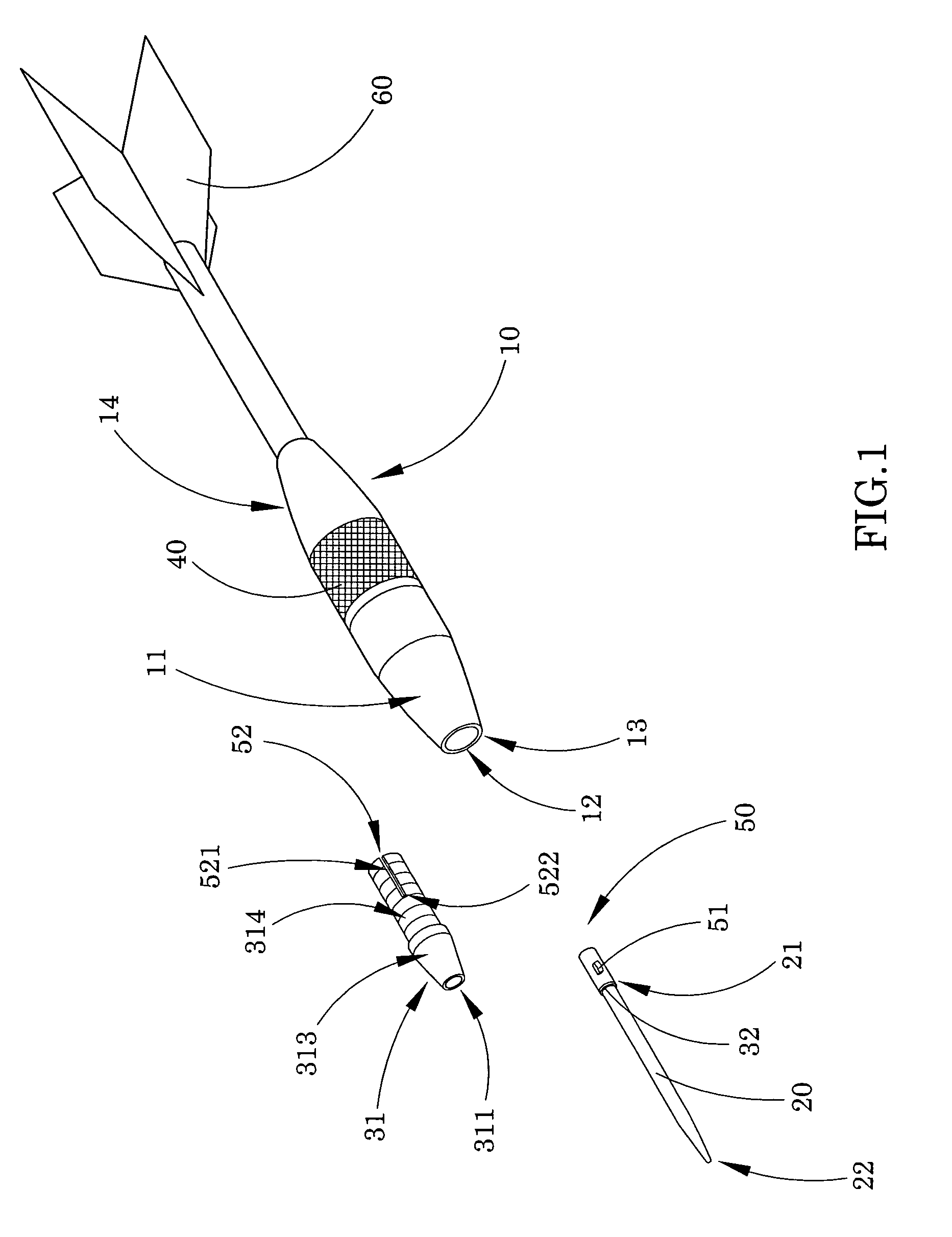

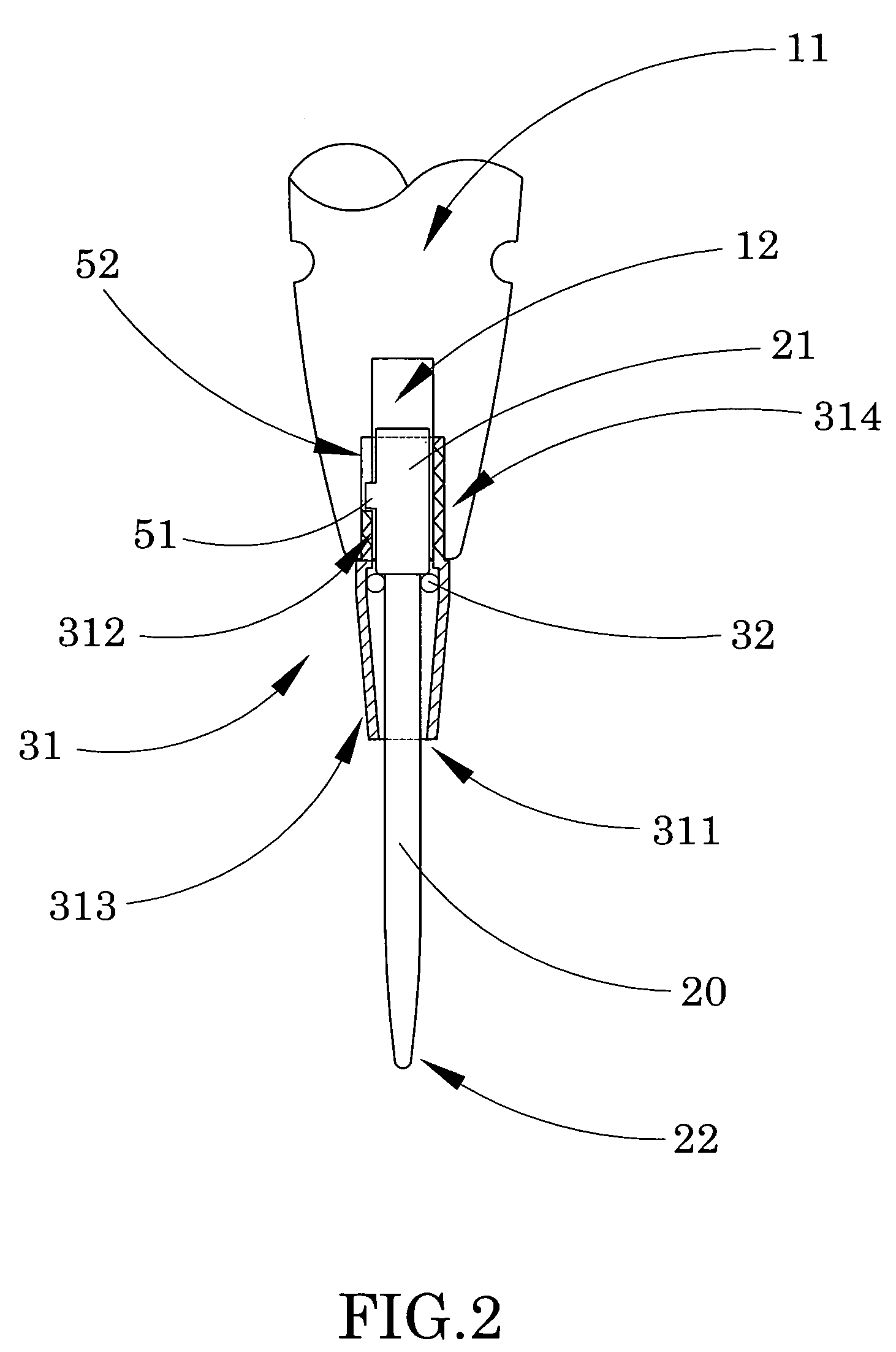

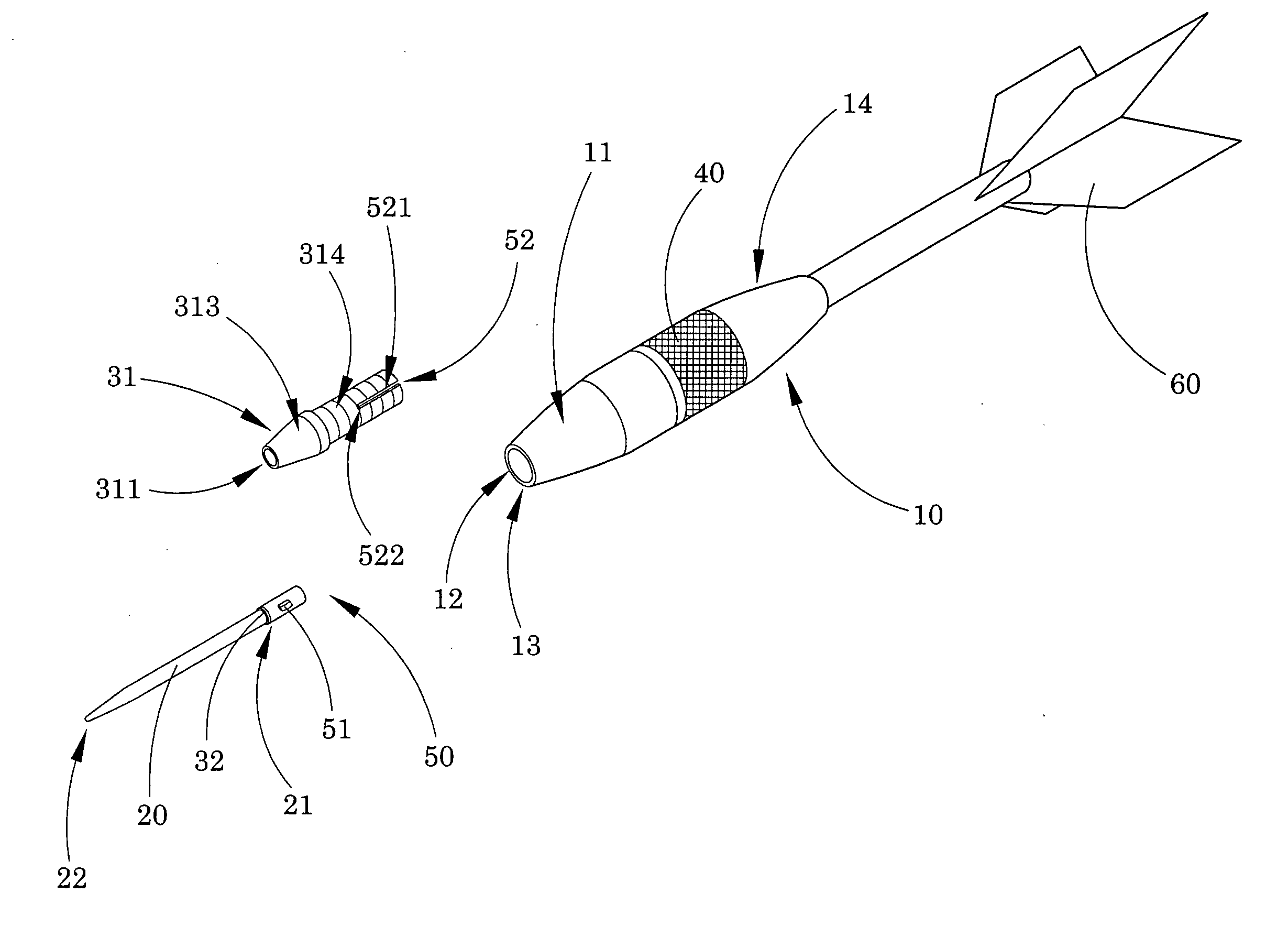

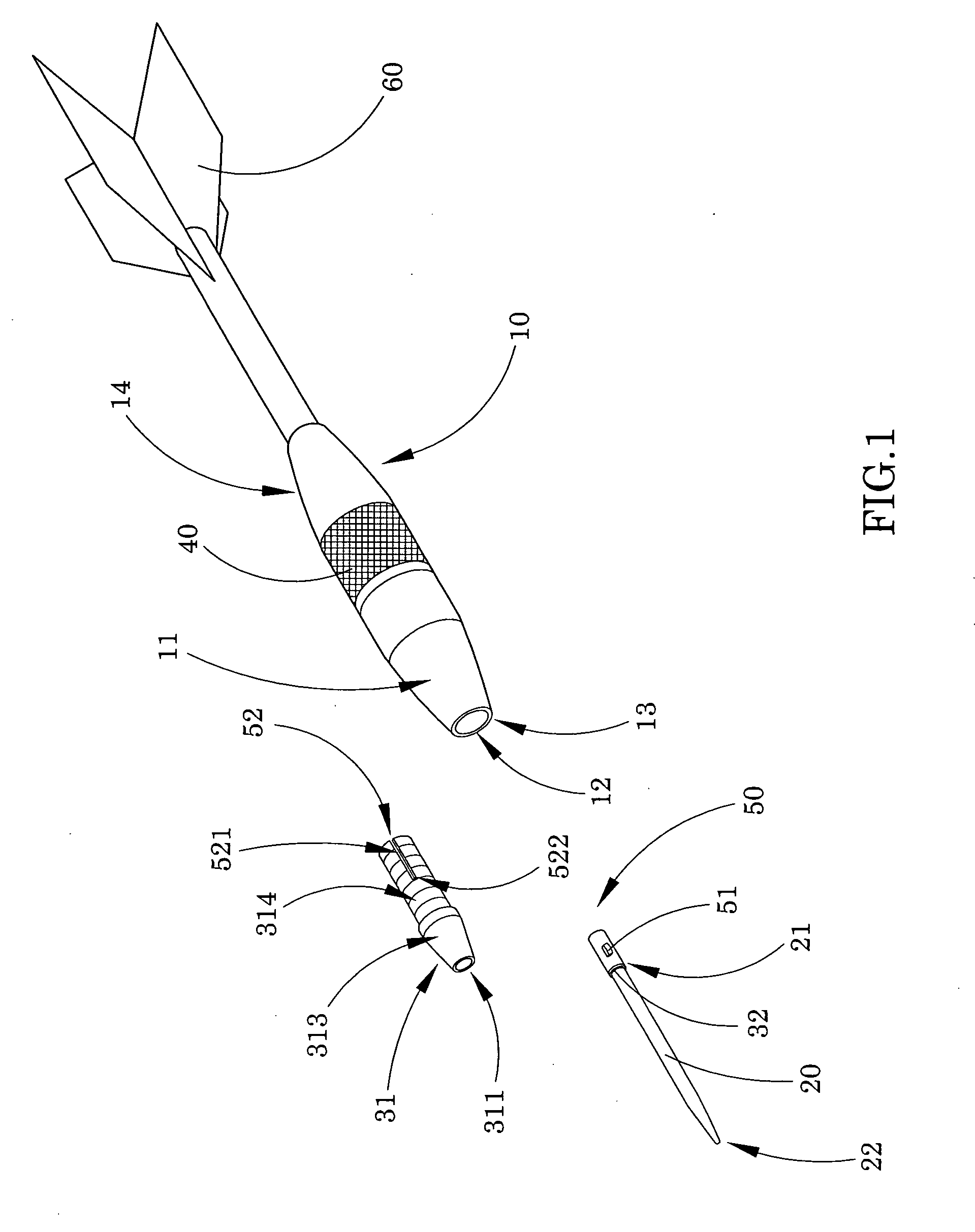

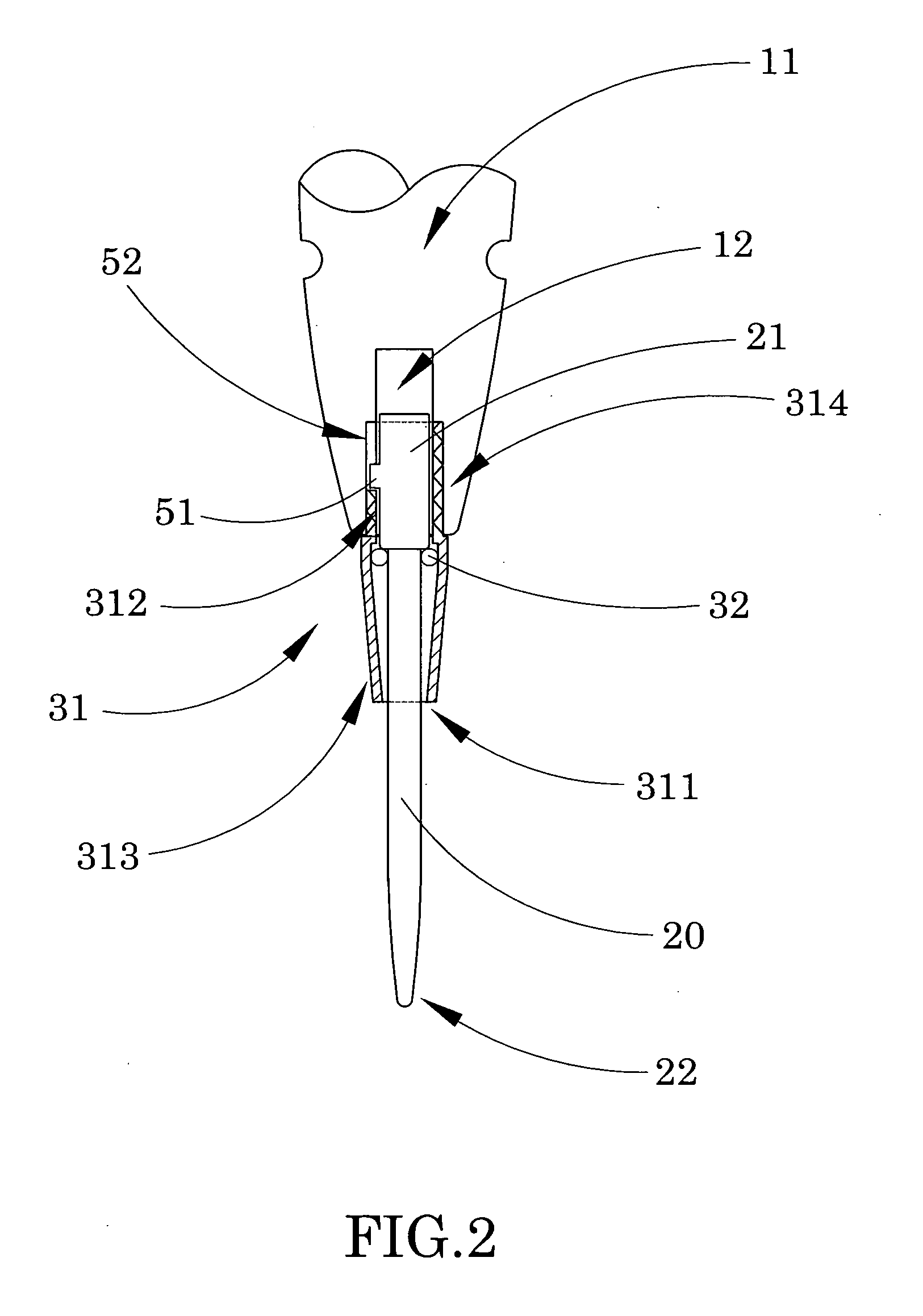

Dart with dual action arrangement

InactiveUS7241236B1Improve stabilityEasy to disassembleAmmunition projectilesThrow gamesDual actionEngineering

A dart includes a dart barrel, a shaft having a sliding end portion, and a dual action arrangement. The dart barrel has a head portion and a shaft channel coaxially extending at the head portion, and defining a head opening at the head portion to communicate with the shaft channel. The dual action arrangement includes a tubular shaft housing detachably mounted at the head opening of the dart barrel, wherein the shaft housing has a sliding slot coaxially aligning with the shaft channel for the a sliding end portion of the shaft sliding therealong. The tubular elastic element is coaxially mounted at the sliding end portion of the shaft for applying an urging force against an inner circumferential wall of the sliding slot so as to minimize a clearance between the sliding slot and the sliding end portion of the shaft.

Owner:CHEN TE TSAO

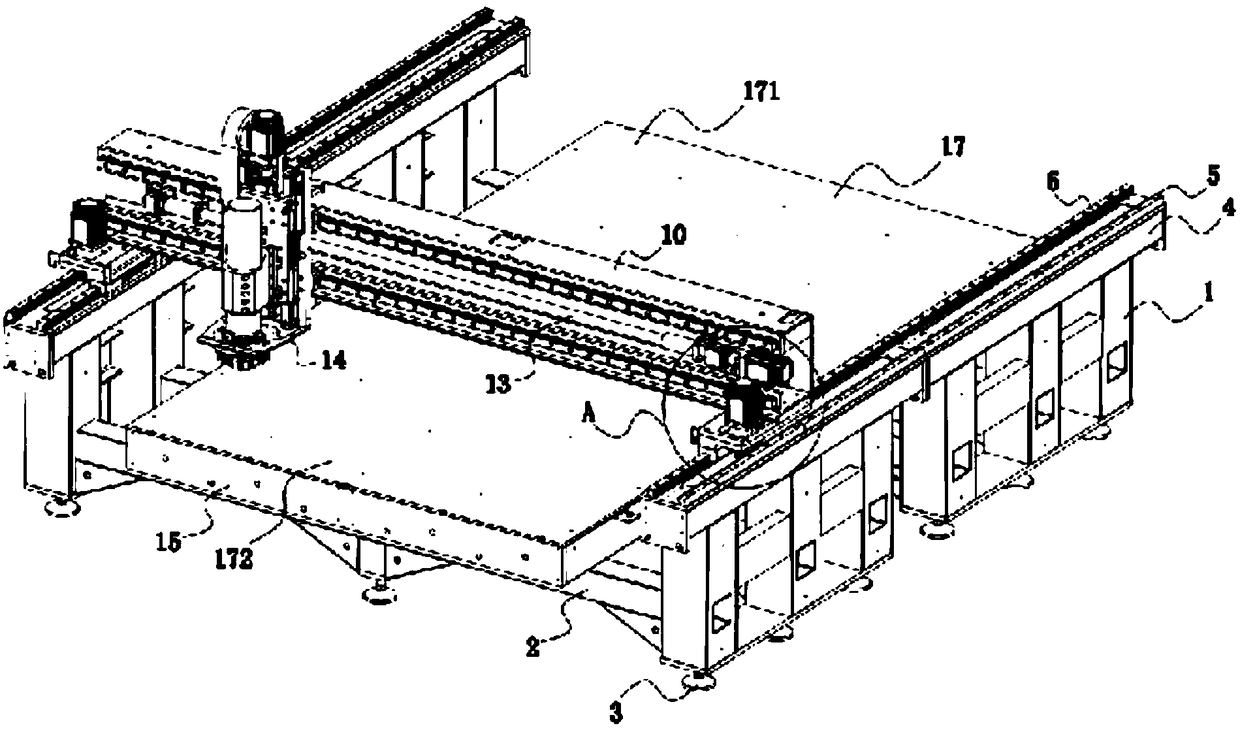

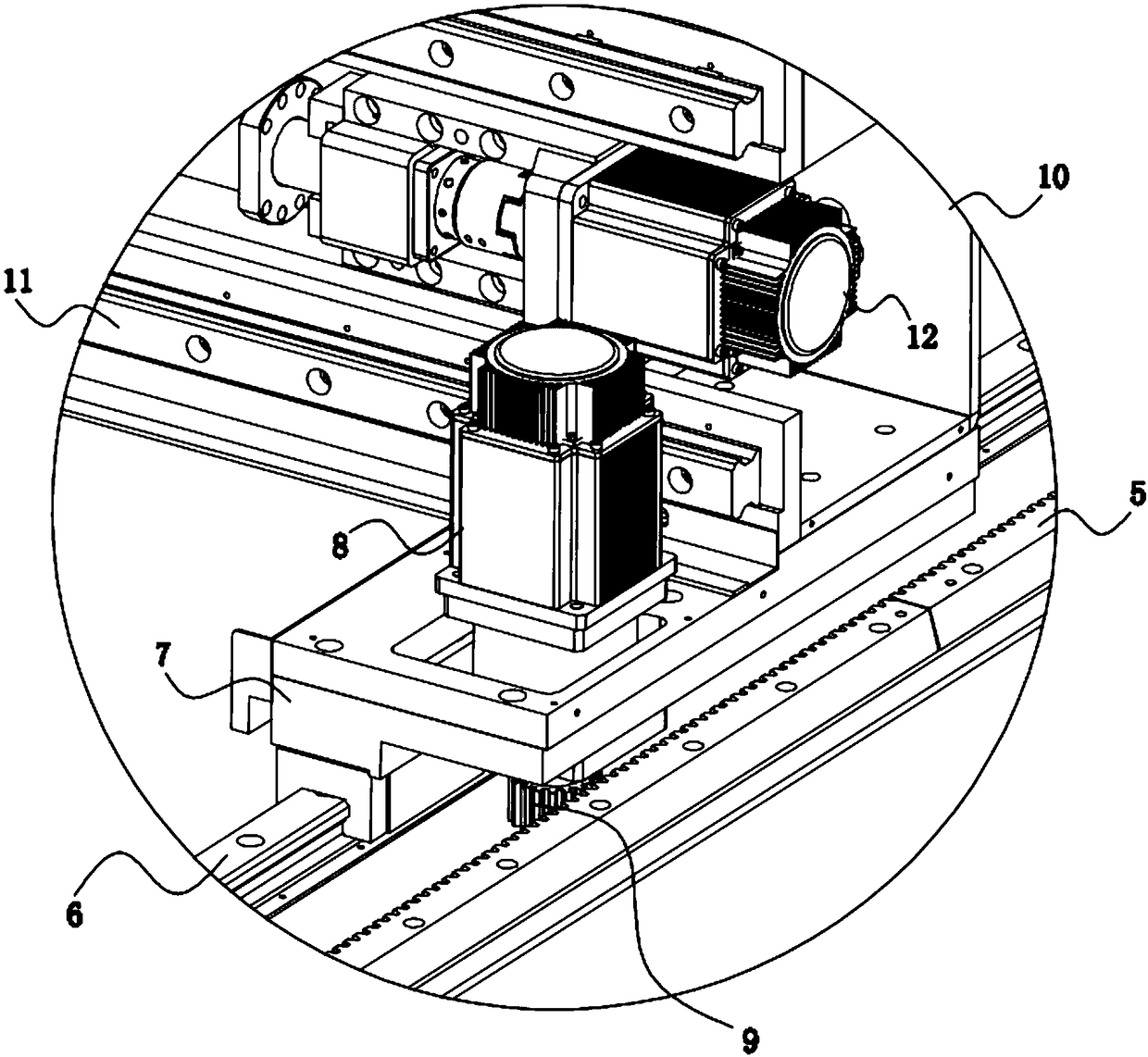

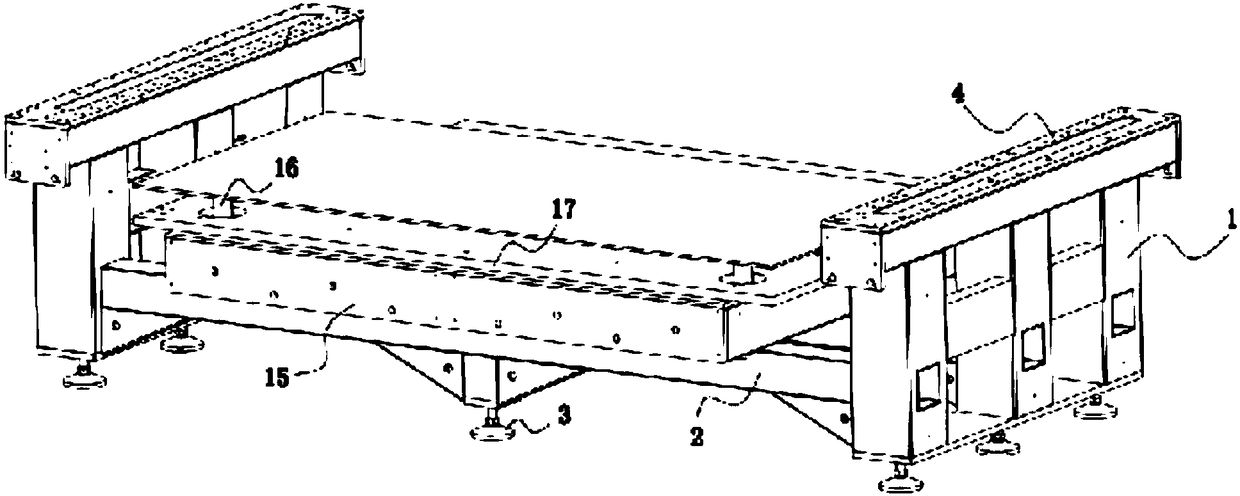

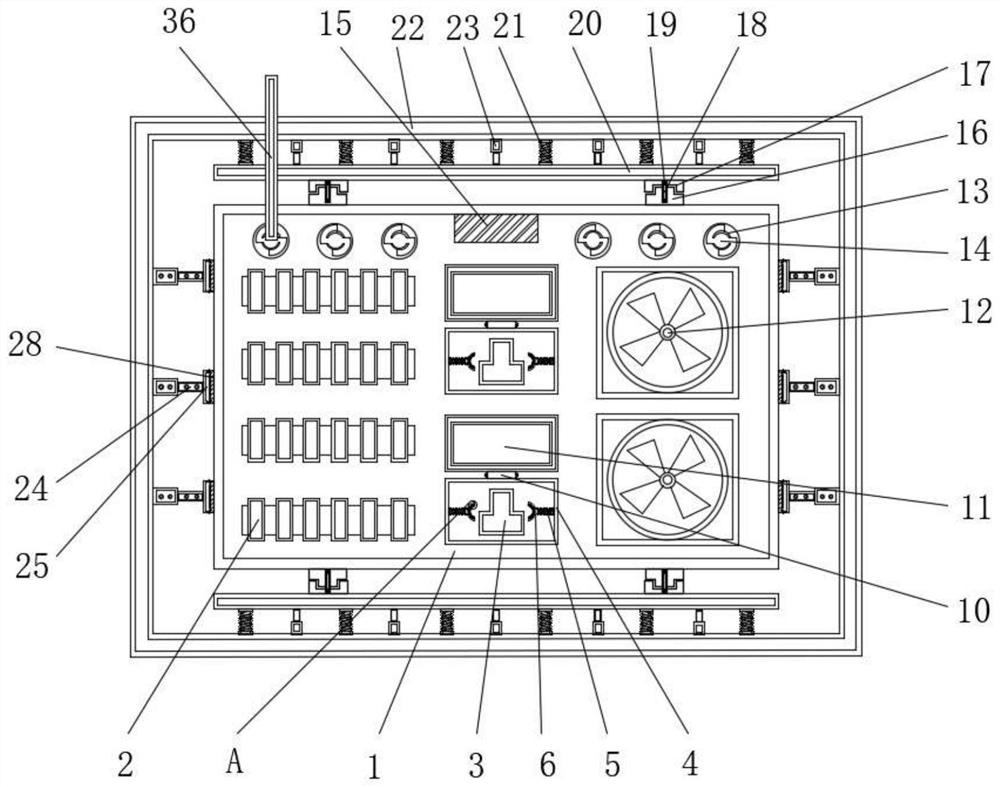

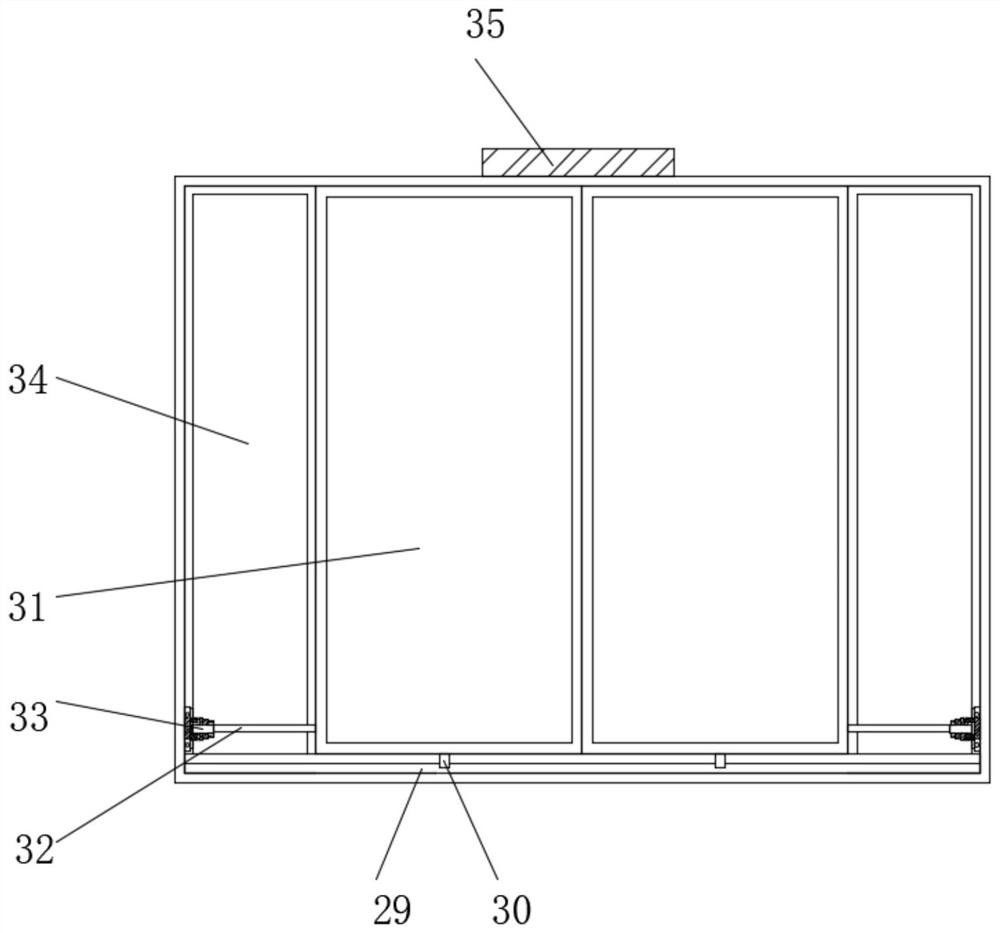

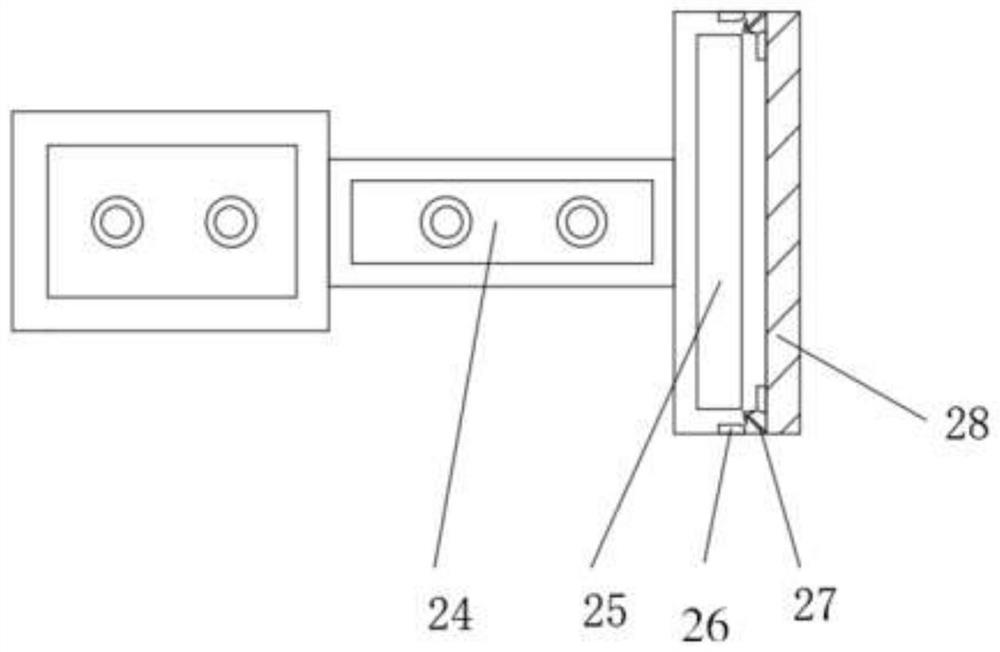

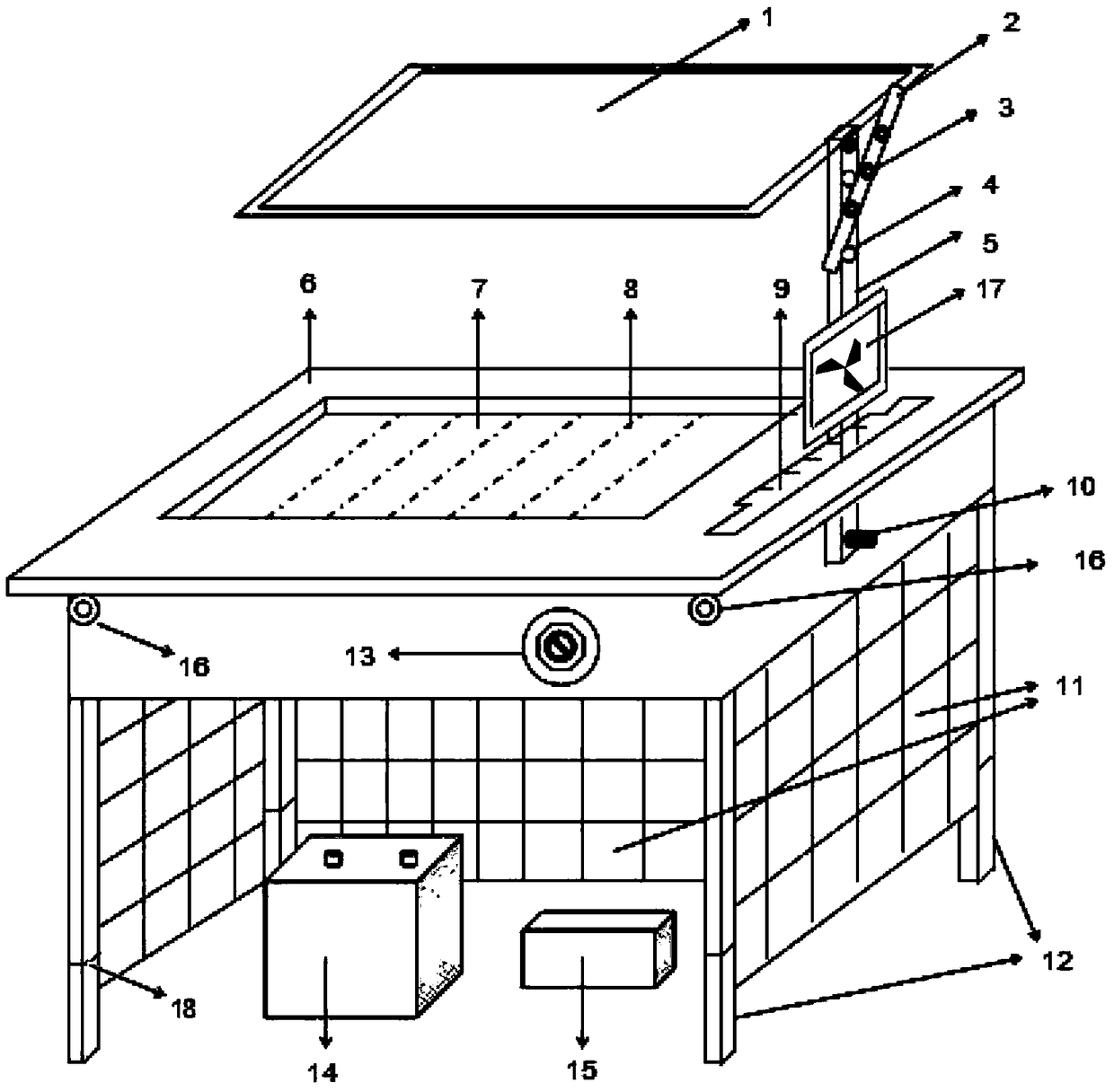

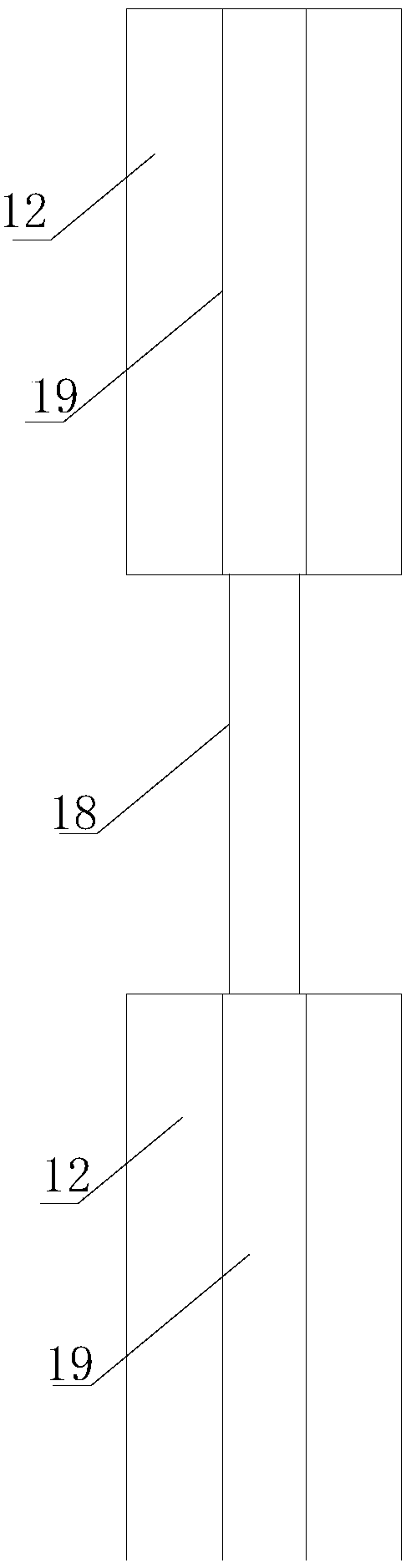

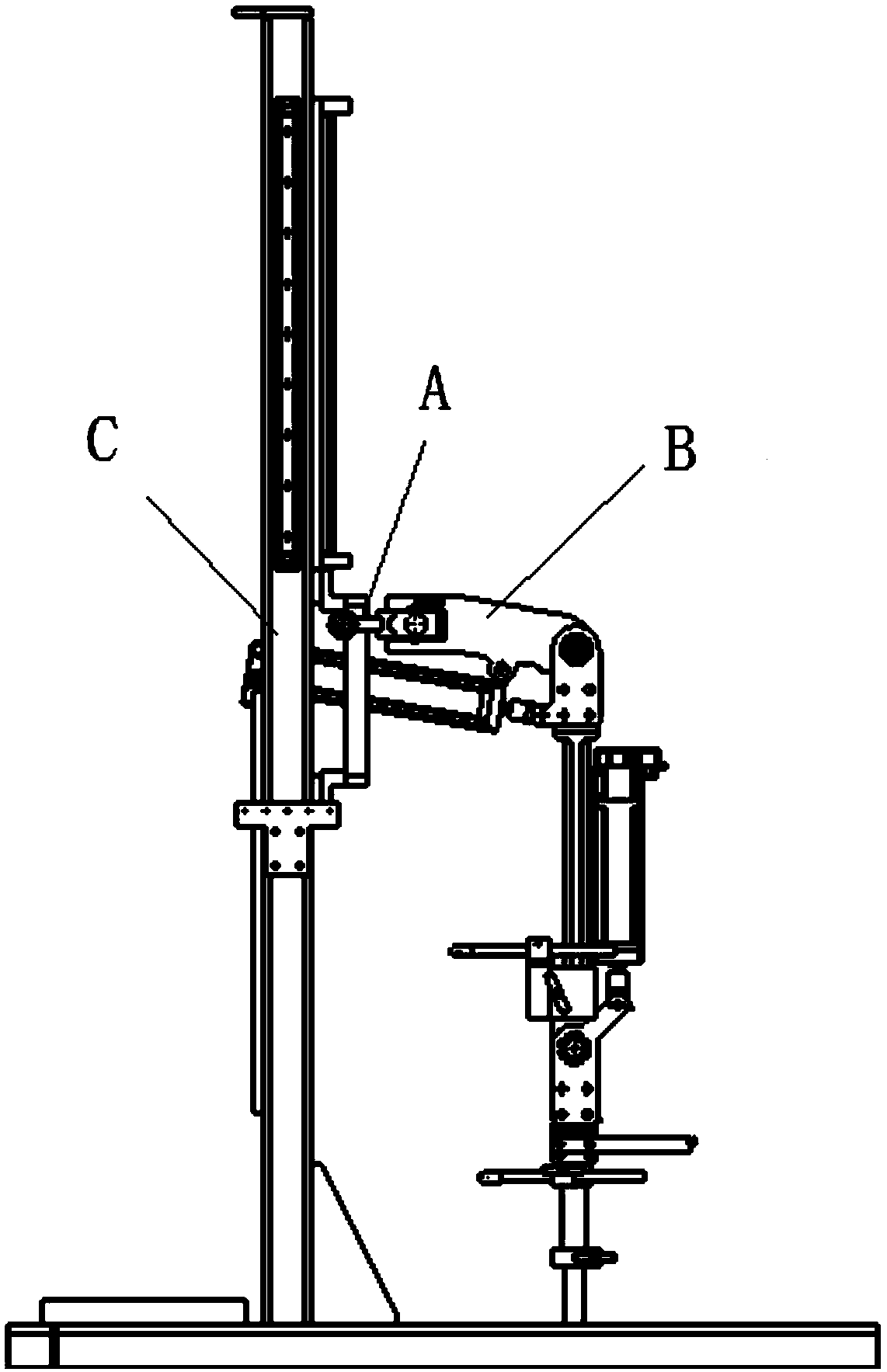

Multifunctional glass machining device

PendingCN109434610AEasy to processImprove work efficiencyEdge grinding machinesGrinding carriagesLinear motionMechanical equipment

The invention relates to a multifunctional glass machining device which comprises a machining base and a machining cross beam. An X-axis guide rail and a machining head are arranged on the cross beam.The machining head conducts linear motion along the X-axis guide rail. A machining table is arranged at the upper portion of the machining base, and the machining platform is arranged at the exact lower portion of the cross beam correspondingly. The multifunctional glass machining device is characterized in that rack guide rail structures are arranged on the two edges of the machining base; the machining cross beam conducts linear motion along the rack guide rail structures at the two ends; splicing structures are arranged on the other two side faces, corresponding to the rack guide rail structure, of the machining base; the width of the machining base is limited within 2 meters, multiple machining bases can be spliced; at least two round holes are formed in the machining platform; and pneumatic lifting sucker structures are arranged in the round holes. One platform can be used for achieving machining work of various kinds of glass, the machining platform can ensure that the width isnot changed, stability of a machining machine head is ensured, and meanwhile it is ensured that mechanical equipment achieves loading and unloading transportation or demounting and mounting of containers and flexible arrangement of working space.

Owner:佛山市博斯马克机器人有限公司

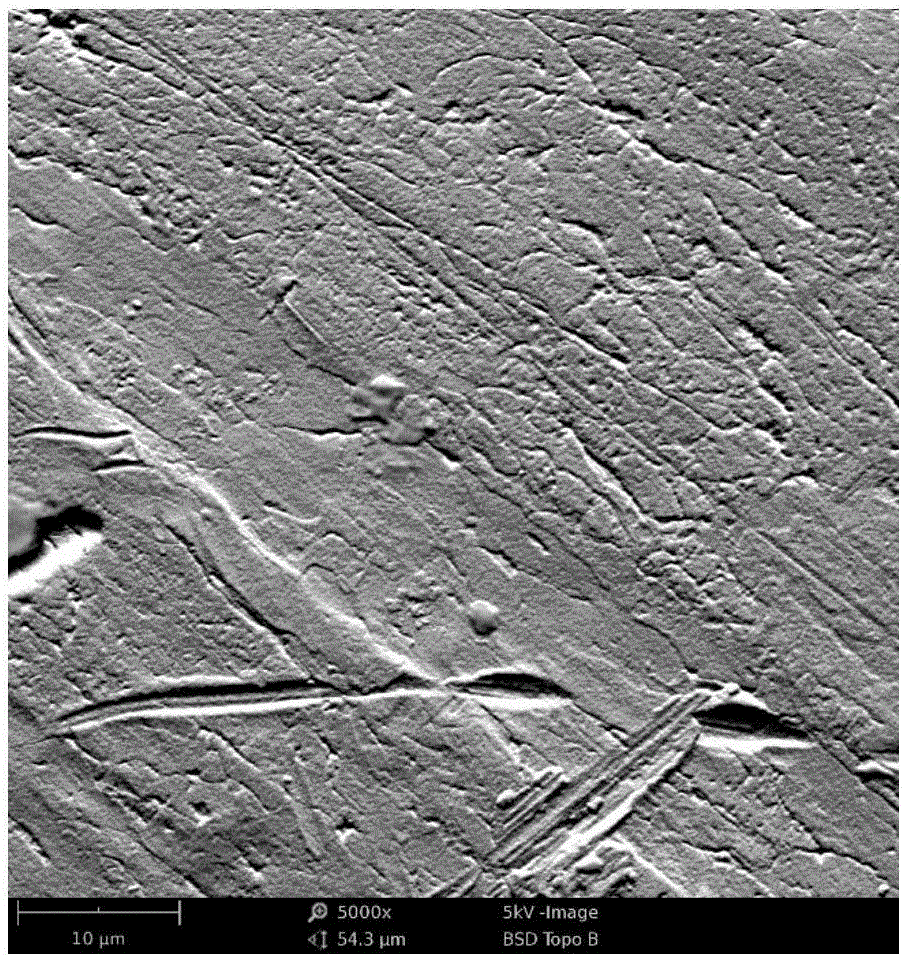

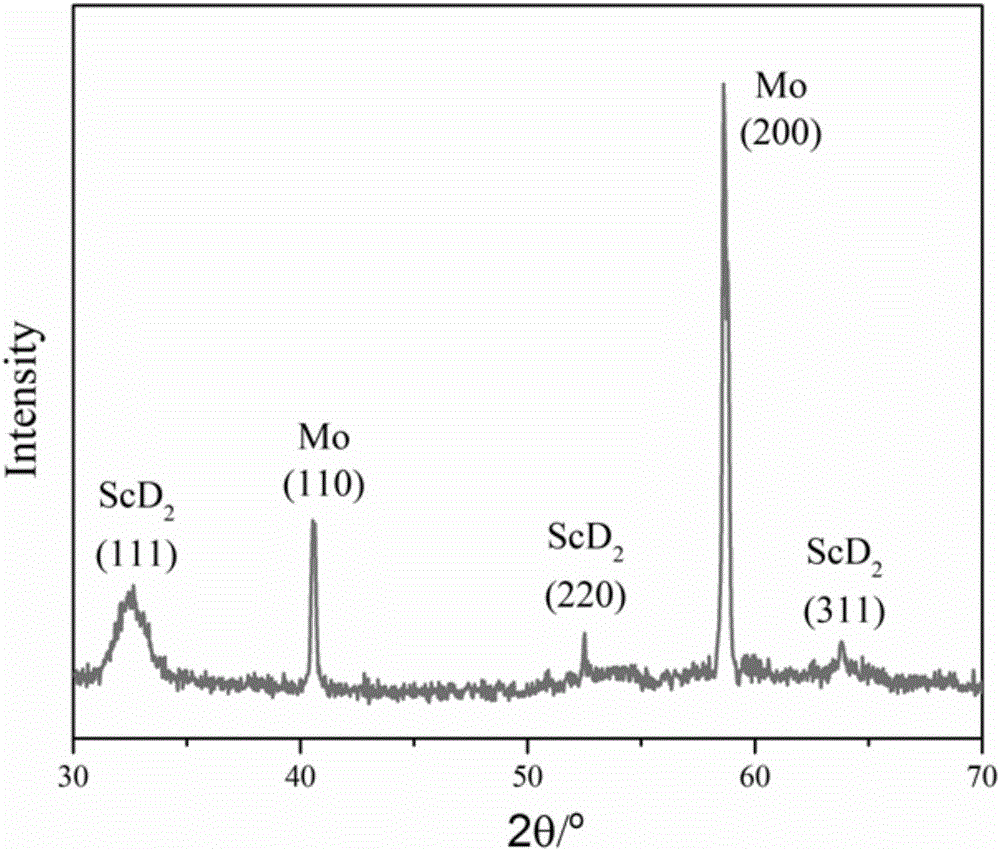

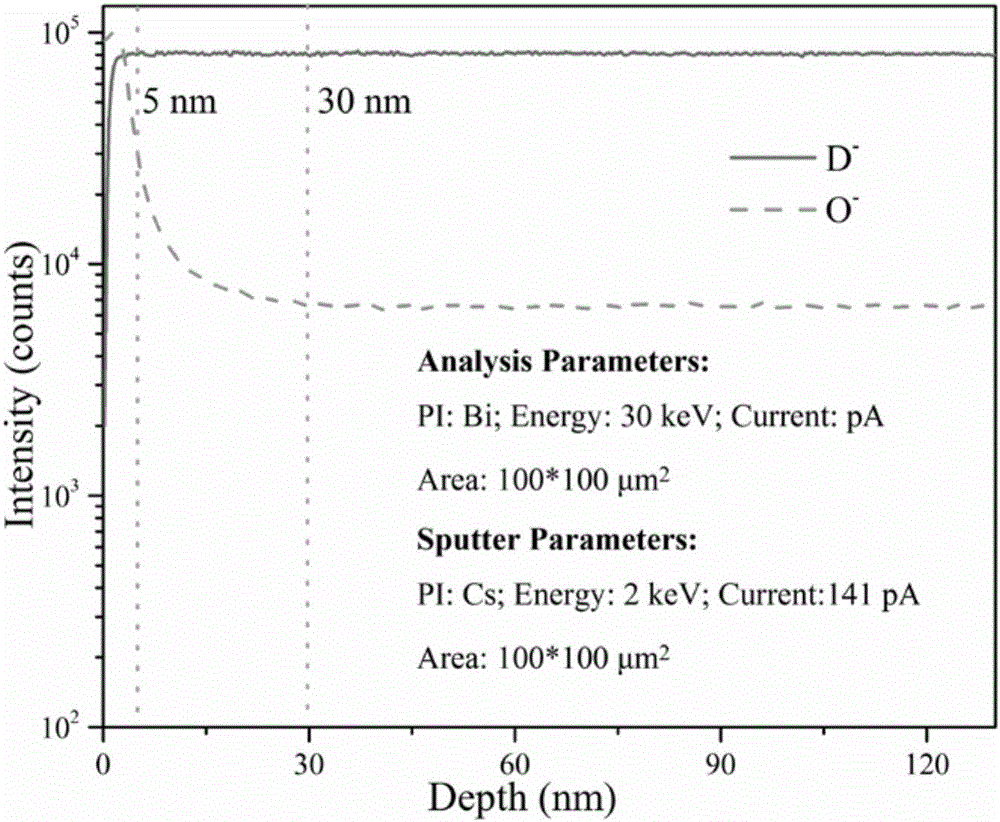

Preparation method for deuterium-containing metal film target

ActiveCN106544628AExtended service lifeHigh purityVacuum evaporation coatingSputtering coatingNeutron yieldMaterials science

The invention discloses a preparation method for a deuterium-containing metal film target. The preparation method comprises the following steps: firstly, using high-purity molybdenum or high-purity copper as a substrate material of the deuterium-containing metal film target, and performing surface pretreatment on the substrate material; secondly, mounting and placing the substrate into a physical vapor deposition (PVD) vacuum coating machine, bombarding the surface of the substrate with argon ions, removing an oxide layer on the surface of the substrate by sputtering; thirdly, setting the coating temperature of the substrate, introducing high-purity deuterium gas in a vacuum cavity, starting the coating machine, and directly preparing the deuterium-containing metal film; fourthly, turning off the coating machine, continually introducing deuterium gas into the vacuum cavity, and turning off a deuterium gas flower meter until an appropriate air pressure is reached in the cavity. By adopting the preparation method, the mechanical performance of the deuterium-containing metal film target is improved, the brittleness and occurrence of cracks are controlled effectively, and adhesive force of the target film is enhanced; meanwhile, the thickness of a dead layer on the surface is decreased, the purity of the target film is increased, the neutron yield of a neutron generator is increased, and the service life of the target is prolonged.

Owner:INST OF FLUID PHYSICS CHINA ACAD OF ENG PHYSICS

Method for enriching and stabilizing mercury in coal-fired flue gas by using blast furnace slag modified desulfurizer

ActiveCN108159870APromote enrichmentLess catchGas treatmentDispersed particle separationAtmospheric airSlag

The invention discloses a method for enriching and stabilizing mercury in coal-fired flue gas by using a blast furnace slag modified desulfurizer. The method comprises the following steps: using an FGD desulfurizer slurry, using blast furnace slag as a modifier, and mixing the blast furnace slag and the desulfurizer slurry according to a mass ratio of the blast furnace slag to a dry desulfurizer of 1 to 2-3 to form iron manganese oxide-desulfurizer mixture system so as to prepare a desulfurizing-mercury capturing composite slurry; then using the desulfurizing-mercury capturing composite slurryfor desulfurizing the coal-fired flue gas and enriching and absorbing the mercury in the coal-fired flue gas. According to the method, the blast furnace slag and the desulfurizer are mixed to preparethe desulfurizer slurry for desulfurizing flue gas in a coal-fired power plant; toxicity leaching and volatilization testing are performed on the mercury in an obtained desulfurization material, themercury in the obtained desulfurization material is more stable than ordinary desulfurization gypsum, the concentration of the leached mercury is lowered, the volatile release rate is greatly reduced,and the inhibitory effect on an environmental mercury pollution source is strong. Therefore, the method is of a great significance in atmospheric environmental protection.

Owner:SHANGHAI UNIV

Wireless communication system device for communication

InactiveCN112039788AAvoid breakingPlay the role of shock absorberCouplings bases/casesData switching networksCommunications systemEngineering

The invention belongs to the related technical field of communication, and particularly relates to a wireless communication system device for communication, which comprises a router, wire passing grooves, fans, limiting blocks, a thermal inductor, a supporting plate, a lifting rod, a sliding groove, an ultraviolet sensor and an antenna. The outer wall of the router is provided with cooling fins, and the wire passing grooves are formed in the outer wall of the router; and a first protective shell is arranged on the outer side of each wire passing groove, telescopic strips are arranged on innerwalls of each first protective shell, a first fixed plate is arranged on one side of each telescopic strip, first movable blocks are arranged in each first fixed plate, first hooks are arranged on theinner sides of the first movable blocks, and meanwhile first rubber cushions are arranged on one sides of the first hooks. According to the wireless communication system device for communication, through the arrangement of the springs, the telescopic rods and the supporting plates, a damping and buffering effect can be achieved on the device, the situation that a router is broken when the devicefalls from a high position is prevented, and therefore the using effect of the device is greatly improved.

Owner:广州融益科技有限公司

Container for hot fill food packaging applications

InactiveUS20050184073A1Not stablePromote crashDomestic stoves or rangesLighting and heating apparatusPlastic materialsFood packaging

A plastic container suitable for hot-fill food packaging applications is disclosed which is characterized by walls of proportionately decreasing thickness from the mouth of the container to a predetermined collapsible point. The wall thickness is designed such that the container walls will collapse, or deform, only at the collapsible point during cooling after hot-filling of food product or during transportation of the container between locations of varying altitudes and pressures. The container preferably collapses in the base area such that the collapse is not visible to the consumer and also the collapse does not affect stability of the container while in use or during loading and storage. The container of the invention is advantageous in that it requires less plastic material to form than other known hot-fill containers, and also can be formed out of any suitable food-grade plastic material or by any process.

Owner:PHOENIX CAPITAL

Dart with dual action arrangement

InactiveUS20070161437A1Improve stabilityEasy to disassembleAmmunition projectilesThrow gamesDual actionHead parts

A dart includes a dart barrel, a shaft having a sliding end portion, and a dual action arrangement. The dart barrel has a head portion and a shaft channel coaxially extending at the head portion, and defining a head opening at the head portion to communicate with the shaft channel. The dual action arrangement includes a tubular shaft housing detachably mounted at the head opening of the dart barrel, wherein the shaft housing has a sliding slot coaxially aligning with the shaft channel for the a sliding end portion of the shaft sliding therealong. The tubular elastic element is coaxially mounted at the sliding end portion of the shaft for applying an urging force against an inner circumferential wall of the sliding slot so as to minimize a clearance between the sliding slot and the sliding end portion of the shaft.

Owner:CHEN TE TSAO

Collar and sleeve singeing mechanism

ActiveCN107475973AClear textureNot easy to pillingSingeingStructural engineeringMechanical engineering

The invention discloses a collar and sleeve singeing mechanism. The collar and sleeve singeing mechanism comprises feed roller, an edge stirring assembly, a humidifying assembly, fire spraying assemblies, a singeing assembly, a fire extinguishing assembly, and a discharge roller; the edge stirring assembly comprises a pair of edge stirring rods matching each other; a edge stirring gap only used for passing of collar and sleeve cut-parts is left between the two edge stirring rods; the feed roller, the humidifying assembly, singeing rollers, fire extinguishing rollers, and the discharge roller are arranged successively; the edge stirring assembly is arranged between the feed roller and the humidifying assembly; the singeing assembly is provided with the first singeing roller and the second singeing roller; the first singeing roller and the second singeing roller are arranged with a gap left between the first singeing roller and the second singeing roller; the fire spraying assemblies are arranged on the outside of the first singeing roller and the outside of the second singeing roller respectively; the fire spraying holes of the corresponding fire spraying assemblies are arranged toward the first singeing roller and the second singeing roller; the fire extinguishing assembly is used for fire extinguishing treatment of collar and sleeve cut-parts. The collar and sleeve singeing mechanism is short in process flow, is capable of reducing cost, and is capable of improving singeing effect effectively.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

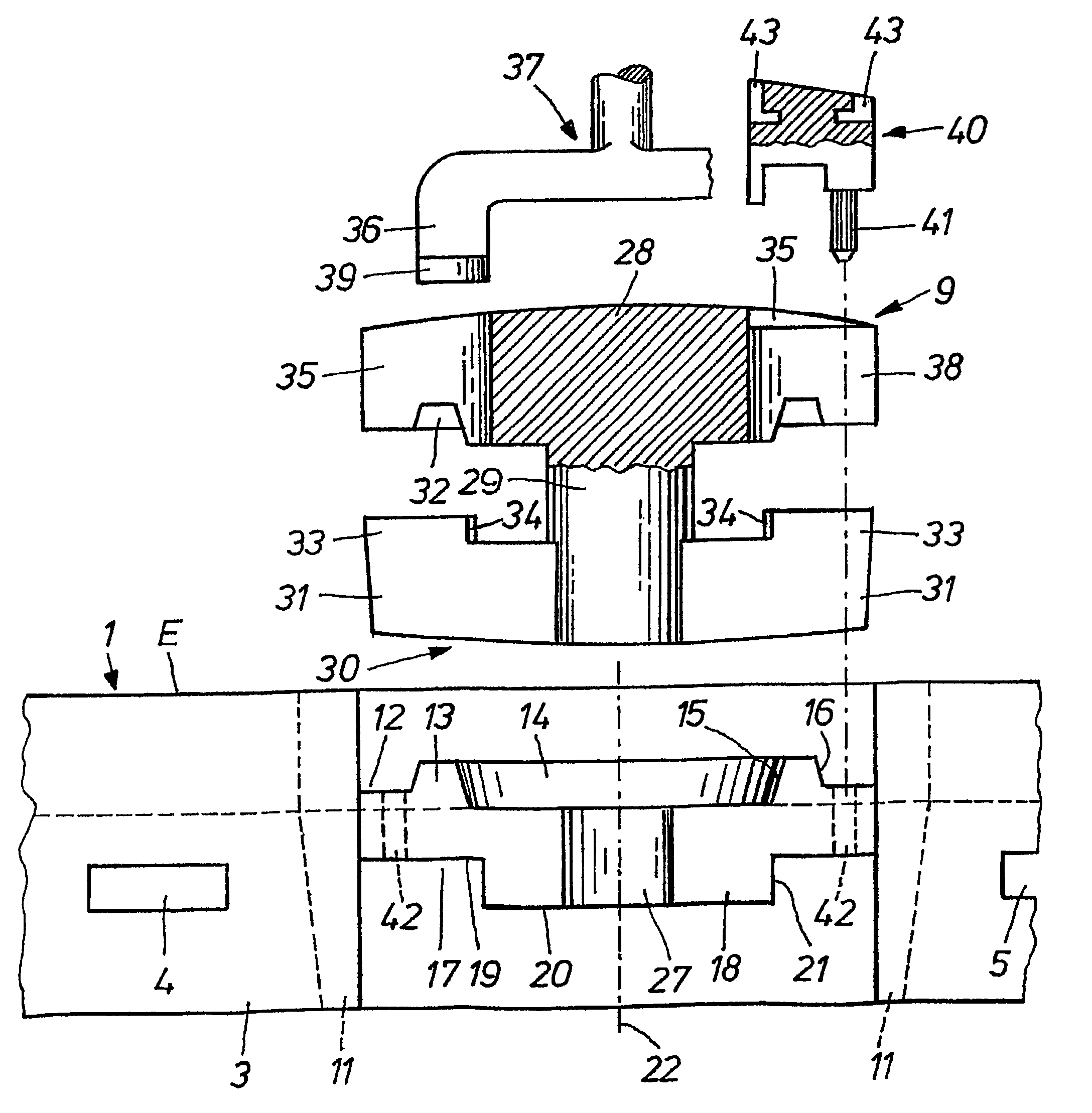

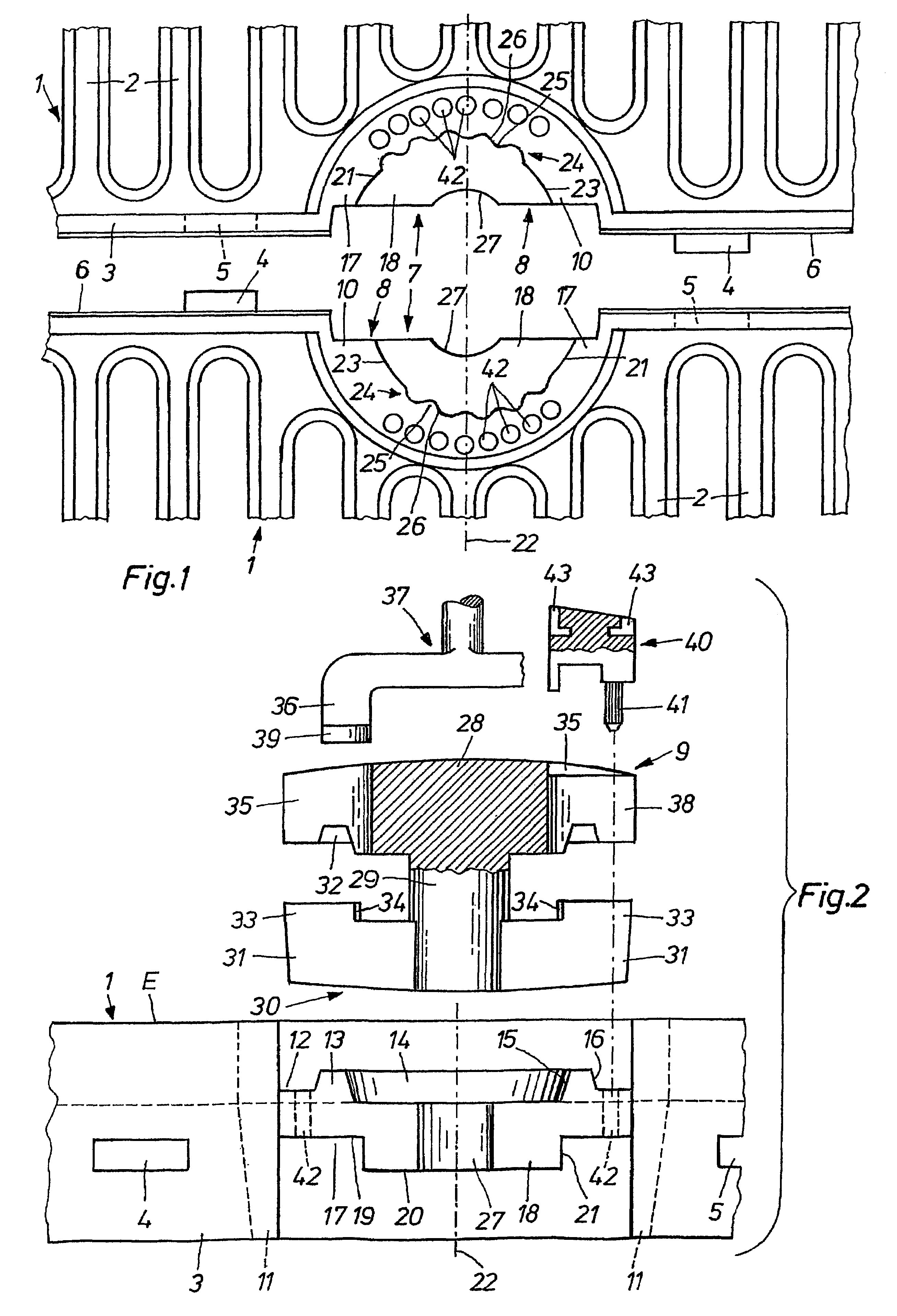

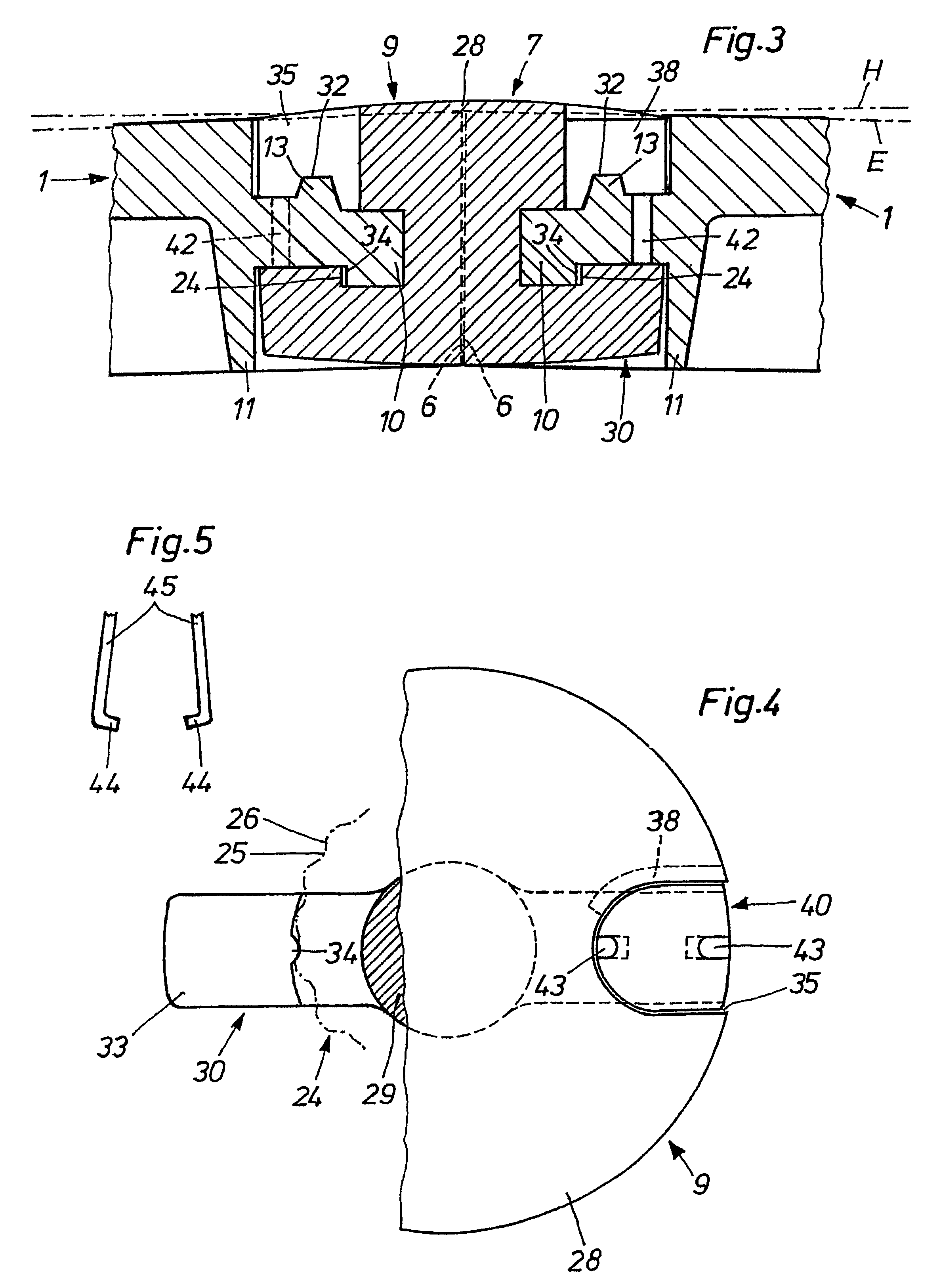

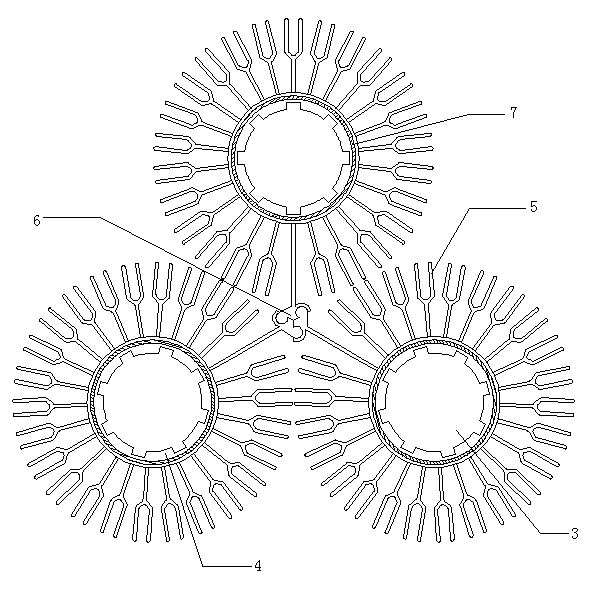

Tree grille system

InactiveUS7637687B2Reworking of the fluting is clearly simplifiedEasy accessGround-workPaving gutters/kerbsCouplingClassical mechanics

The invention relates to a tree grille system for covering tree grates. Said system consists of grille sections (1), which are interconnected by couplings (7) to form a self-supporting tree grille. The couplings (7) consist of two fixed coupling parts (8) configured on the grille sections (1) and a coupling part (9) that can be inserted between the other parts and then rotated into a locking position. An arc-shaped rib (18) is configured on the underside of the fixed coupling parts (8), the outer peripheral face (21) of said rib being configured as a ramp-type clamping surface (23). One section of said surface (23) is provided with undulating fluting (24). When the displaceable coupling part (9) is rotated into the locking position, teeth (34) that are formed on said part slide over the fluting (24), causing the displaceable coupling part (9) to be locked by a friction and positive fit in the locking position. Inserts (40), which can be introduced into two receiving holes (35) of the displaceable coupling part (9), comprise a pin (41) that projects outwards and engages in one of several arched bores (42) of the fixed coupling parts (8). This permits a more secure, positive-fit locking position to be achieved for the displaceable coupling part (9).

Owner:F VON LANGSDORFF LICENSING

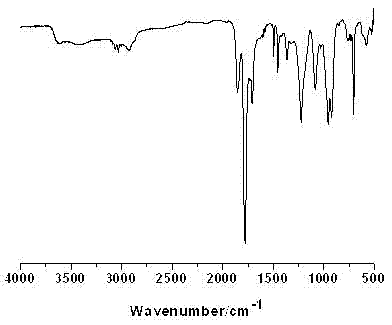

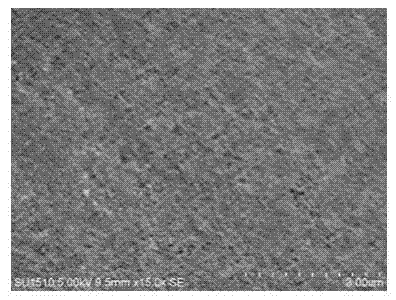

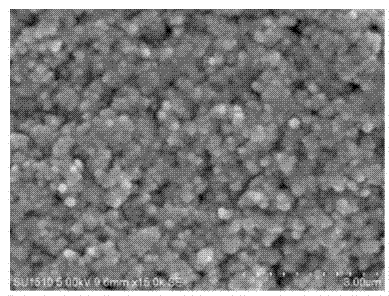

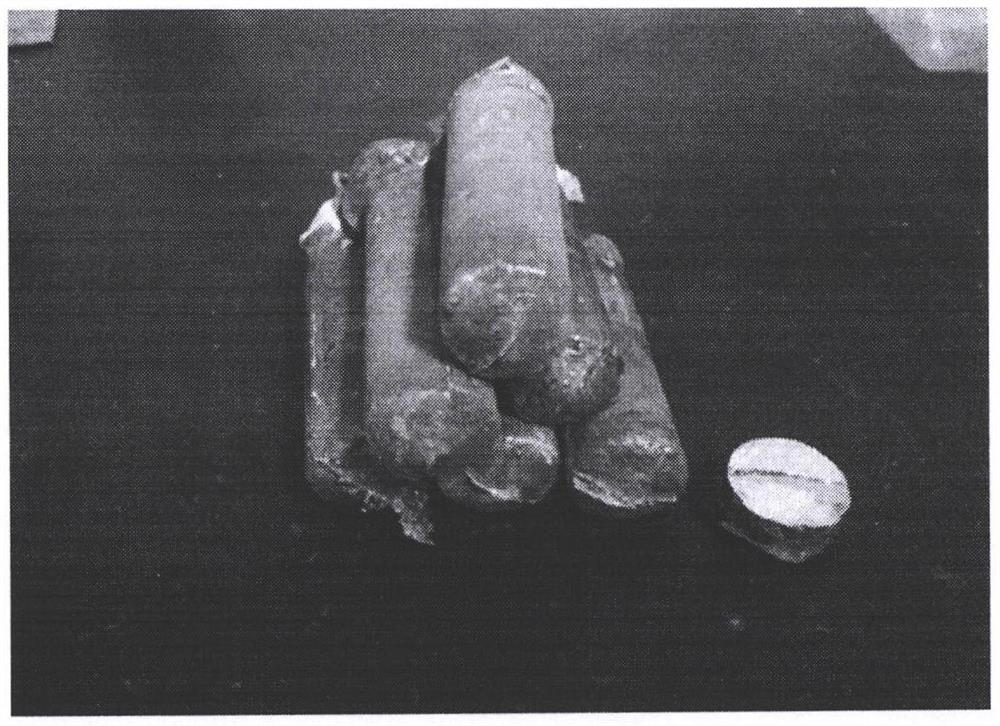

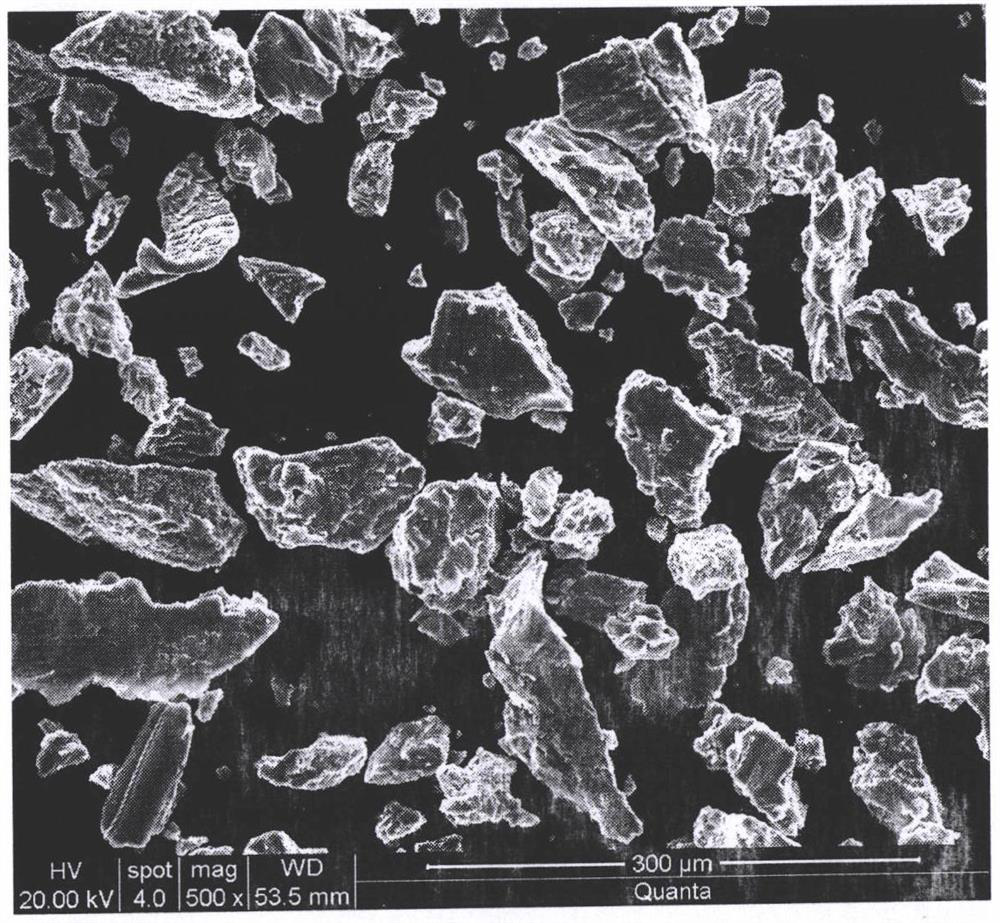

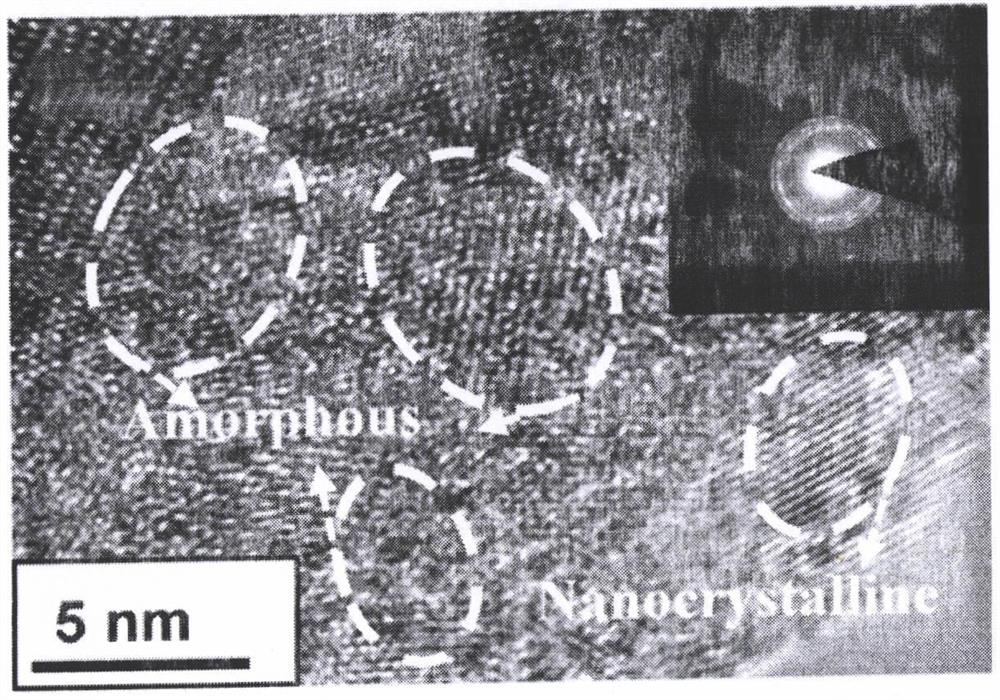

Fluoride-doped high-capacity Gd-Mg-Ni-based composite hydrogen storage material and preparation method thereof

The invention relates to a fluoride-doped high-capacity Gd-Mg-Ni-based composite hydrogen storage material and a preparation method thereof. The fluoride-doped high-capacity Gd-Mg-Ni-based composite hydrogen storage material comprises the following components: GdxMg100-x-yNiy + m wt.% (TiF3, NbF5), x and y are atomic ratios, x is more than or equal to 1 and less than or equal to 9, y is more than or equal to 5 and less than or equal to 20, m is the weight percentage of the TiF3 or the NbF5 in an alloy, and m is more than or equal to 2 and less than or equal to 8. Preferably, x is equal to 5, y is equal to 10, and m is equal to 5, namely Gd5Mg85Ni10 + 5wt.% (TiF3, NbF5). According to the preparation method, the preparation method comprises the following steps that medium-frequency induction heating smelting is adopted under the protection of high-purity helium, liquid alloy is injected into a casting mold, and a cylindrical matrix alloy cast ingot is obtained; and an as-cast alloy is crushed mechanically and sieved with a 200-mesh sieve, sieved alloy powder and a certain amount of catalysts (TiF3 and NbF5) are filled into a stainless steel ball milling tank, vacuumizing is achieved, high-purity argon is filled, and ball milling in a planetary high-energy ball mill is carried out for a certain time to obtain the alloy powder with ultrafine grains (nanoscale). According to the fluoride-doped high-capacity Gd-Mg-Ni-based composite hydrogen storage material and the preparation method thereof, through component design, microstructure regulation and control and addition of a multi-element catalyst, the thermal stability of alloy hydride is reduced, and the hydrogen absorption and desorption thermodynamic and dynamic performance of the alloy is improved.

Owner:卜文刚

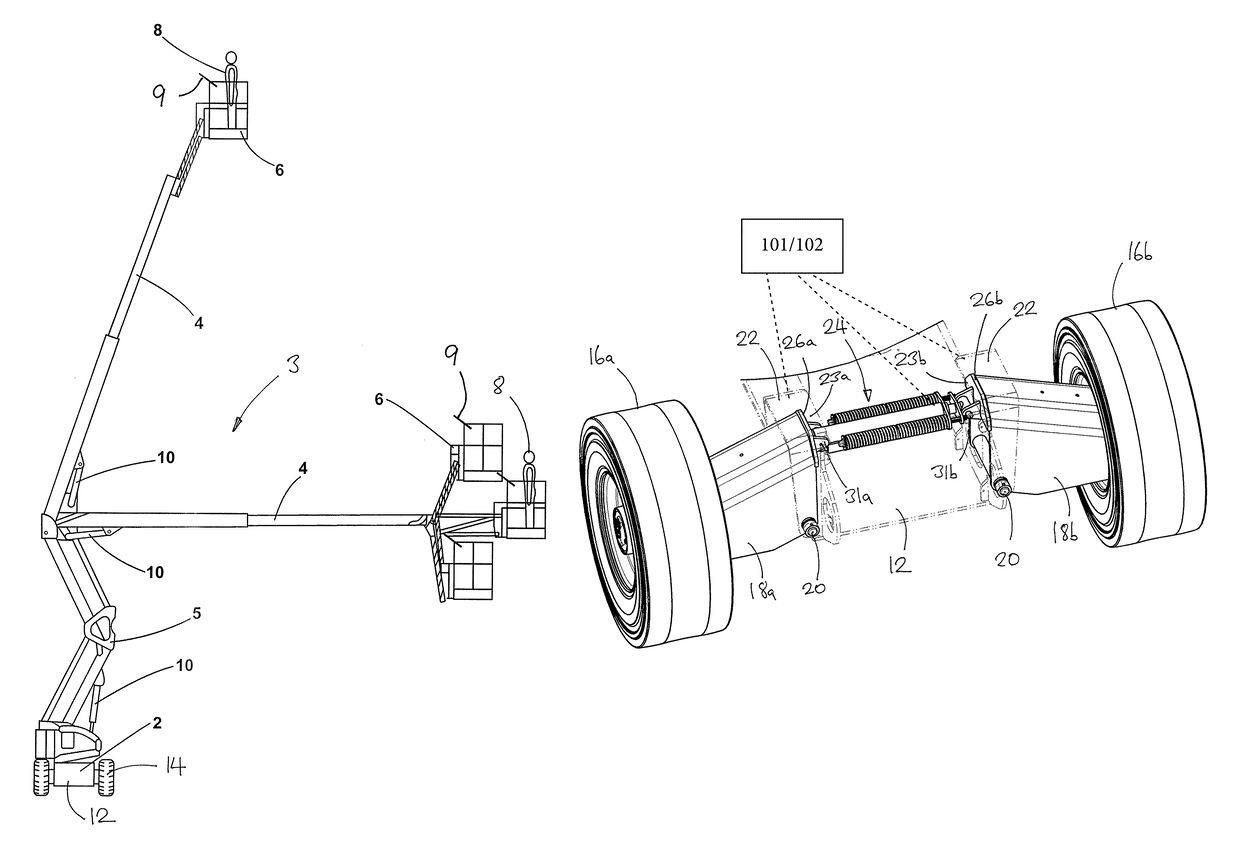

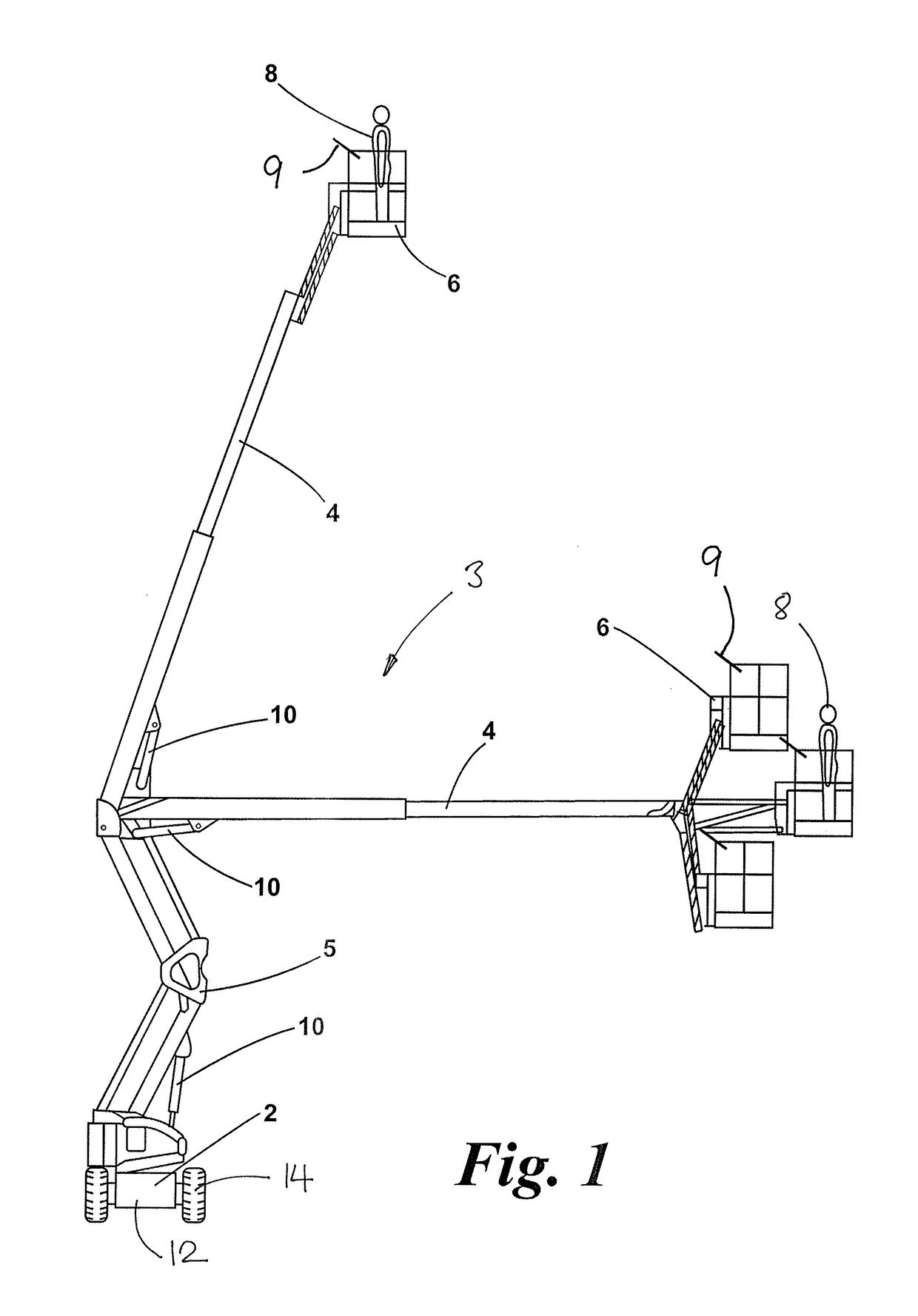

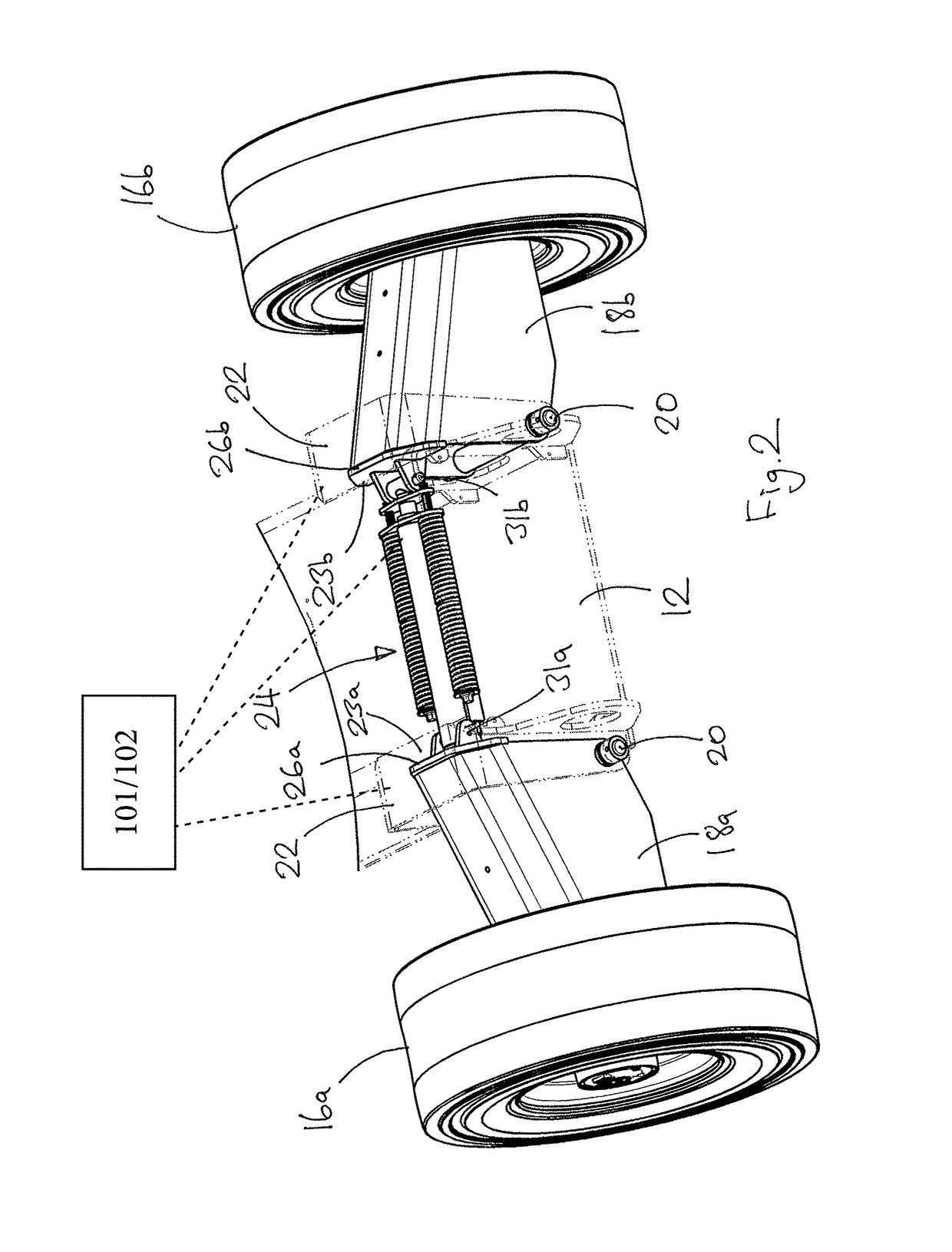

Base unit for a vehicle

A base unit for a vehicle such as a mobile work platform includes a chassis and multiple wheels, at least one of the wheels being mounted on the chassis by a suspension mechanism including a suspension element. The suspension element pivots relative to the chassis about a substantially horizontal pivot axis between an upper position and a lower position, and a stop member engages the suspension element in the upper position to limit its upwards movement. A biasing mechanism exerts a biasing force on the suspension element to urge the suspension element upwards towards the upper position. The biasing mechanism includes an actuator which adjusts the biasing force so that, in a first operating condition, the biasing force is greater than the force needed to maintain the suspension element in engagement with the stop member when the wheel is suspended, and in a second operating condition the biasing force is less than the force needed to maintain the suspension element in engagement with the stop member when the wheel is suspended.

Owner:NIFTYELEVATOR

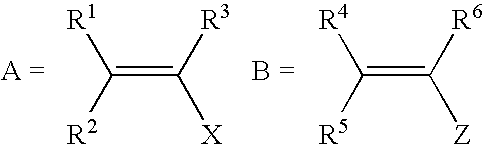

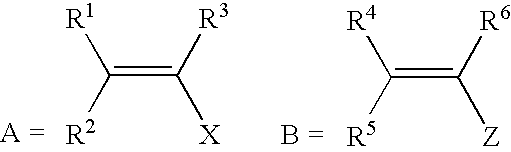

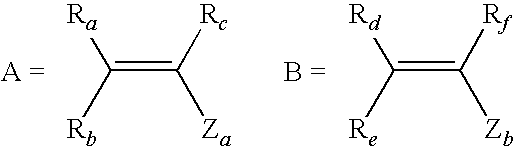

Aqueous inkjet inks with ionically stabilized dispersions and polyurethane ink additives

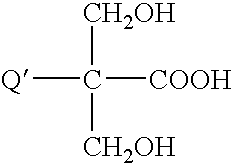

InactiveUS20130022746A9Modest water solubilityLittle miscibilityInksCoatingsPolymer sciencePolymer chemistry

Inks that contain ionically stabilized dispersions and selected polyurethane ink additives are described. These ionically stabilized dispersions are obtained from polymeric dispersants where the hydrophilic components are minimized. These stabilized dispersions can be utilized to prepare ink jet inks which when printed result in improved optical density, chroma, gloss and especially distinctness of image. The stability of the ionically stabilized dispersions are sufficient for ink jet inks. The polyurethane ink additives are chosen from polyurethanes which are urea terminated or crosslinked.

Owner:EI DU PONT DE NEMOURS & CO

A dual heating solar grill

InactiveCN105902188BImprove grilling efficiencyBest heating angleClimate change adaptationEngineeringSolar cell

The invention discloses a dual-heating solar barbequing grill. The dual-heating solar barbequing grill comprises a barbequing grill frame, a Fresnel large lens, a solar cell panel, a controller, a storage battery and a supporting part, the parts can be assembled and disassembled, and the solar cell panel is arranged on the lateral side of the barbequing grill frame or is close to the barbequing grill frame to achieve photovoltaic conversion. The upper plane of the barbequing grill frame is a barbequing face, the barbequing face comprises a barbequing plate, an electric heating wire is arranged below the barbequing plate, the controller is respectively connected with the storage battery and the electric heating wire, and a switch is arranged between the controller and the electric heating wire to control heating. A clamping groove is formed in the edge of the barbequing face, the lower end of the supporting part penetrates through the clamping groove and is connected with the barbequing grill frame, the Fresnel large lens is erected right above the barbequing plate through the supporting part, and the angle can be adjusted according to the direction of sunlight to gather heat. In this way, dual-face heating can be achieved, and barbequing efficiency is greatly improved.

Owner:ANQING NORMAL UNIV

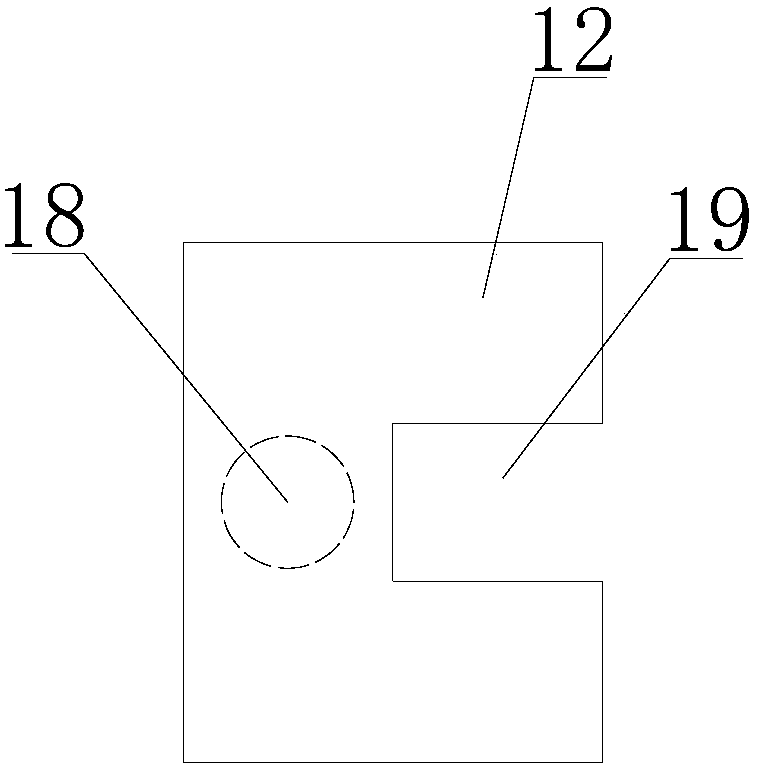

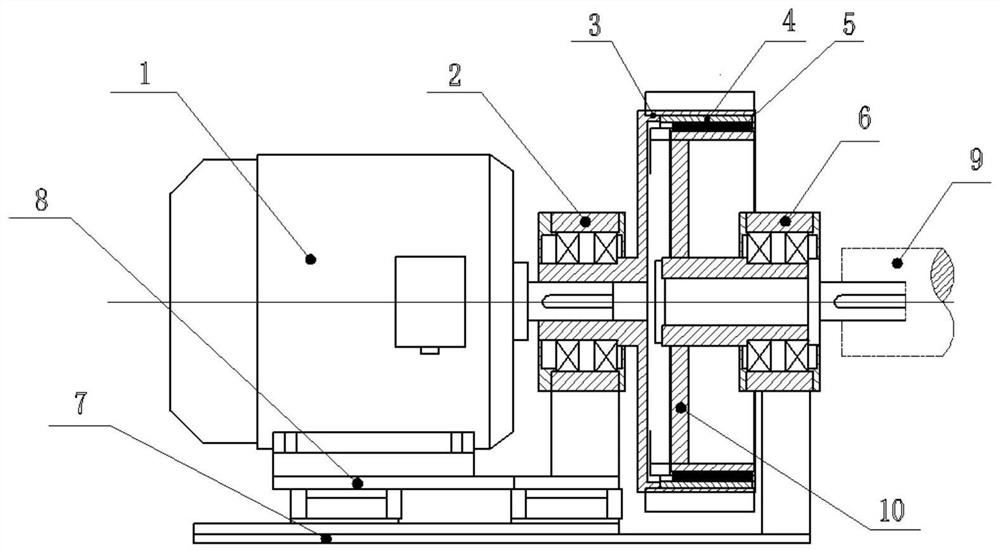

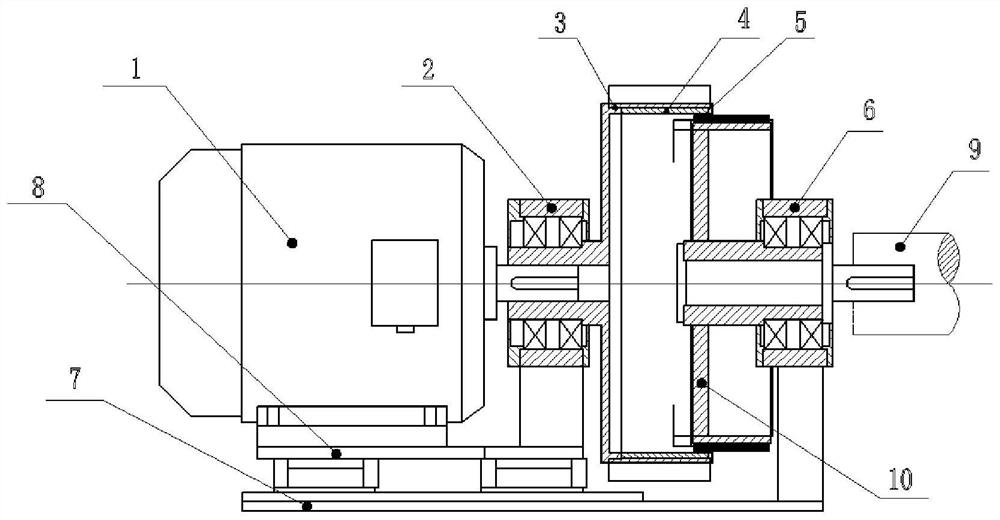

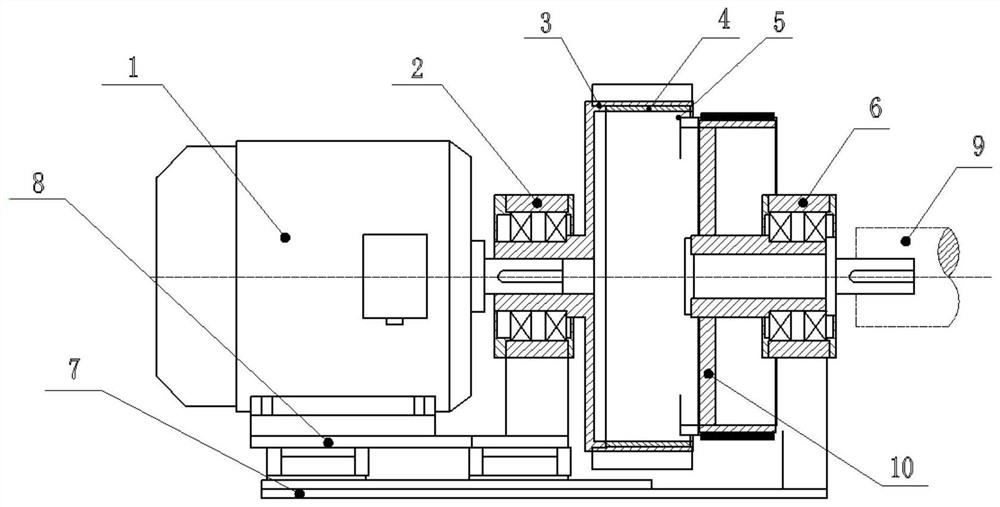

Speed regulation type magnetic coupler with completely separated power source and load and small axial space

PendingCN112532018ASimple structureThe speed regulation process is stablePermanent-magnet clutches/brakesMechanical energy handlingMagnetElectrical conductor

The invention provides a speed regulation type magnetic coupler with a completely separated power source and load and a small axial space, and the magnetic coupler comprises a first transmission ringand a second transmission ring; good conductors are uniformly distributed on the first transmission ring, good conductor end rings for completely short-circuiting the good conductors are arranged at two ends of the good conductors, and the first transmission ring uniformly distributed with the good conductors is a conductor ring; permanent magnets are uniformly distributed on the second transmission ring, and the second transmission ring on which the permanent magnets are uniformly distributed is a permanent magnet ring; the conductor ring and the permanent magnet ring are not in mechanical contact in the axial direction and the radial direction and are air gaps; the first transmission ring is in rigid connection with the power source through a first bearing seat, the power source and thebearing seat are installed on the linear moving platform, and the linear moving platform is installed on the bottom plate. The second transmission ring is in rigid connection with a load through a second bearing seat, and the second bearing seat is installed on the bottom plate and keeps coaxial and concentric with the first bearing seat. The speed regulation type magnetic coupler has the advantages of being short in axial speed regulation length, high in speed regulation reliability, good in vibration isolation effect and the like.

Owner:DALIAN JIAOTONG UNIVERSITY

Preparation method of branched polystyrene-maleic anhydride and application thereof

InactiveCN102344526BStructural and controllableImprove performanceTransportation and packagingMixingPolystyreneOrganosolv

Owner:JIANGNAN UNIV

Flexible plate die-cutting gilding press with high-precision adjusting structure

InactiveCN114084706AGuaranteed synchronicityImprove practicalityArticle feedersRight triangleForward sliding

The invention relates to the technical field of die-cutting gilding machines, in particular to a flexible die-cutting gilding machine with a high-precision adjusting structure, which comprises a feeding disc, a rotating shaft is fixedly connected in the feeding disc, a protective shell is rotatably connected to the upper side of the feeding disc, and a supporting rod is fixedly connected to the lower side of the protective shell. A containing plate is fixedly connected to the rear side of the protective shell, a distance limiting outer plate is fixedly connected into the feeding disc, and the lower side of the distance limiting outer plate is slidably connected with the upper side of the feeding disc. By means of the right triangle shape of a distance adjusting block, it is guaranteed that the distance adjusting block can be attached to the inner side of a feeding plate to slide leftwards, by means of the inclined shape of the distance adjusting block, a distance adjusting plate can be extruded to slide forwards in the feeding plate, and the attaching conveying stability of materials with different diameters is improved; and it is guaranteed that the distance between the protective shell and a distance limiting inner plate and the distance between the feeding plate and the distance adjusting plate can be synchronously adjusted, and the practicability that the feeding disc can convey materials with different radiuses is improved.

Owner:南通普林派克机电科技有限公司

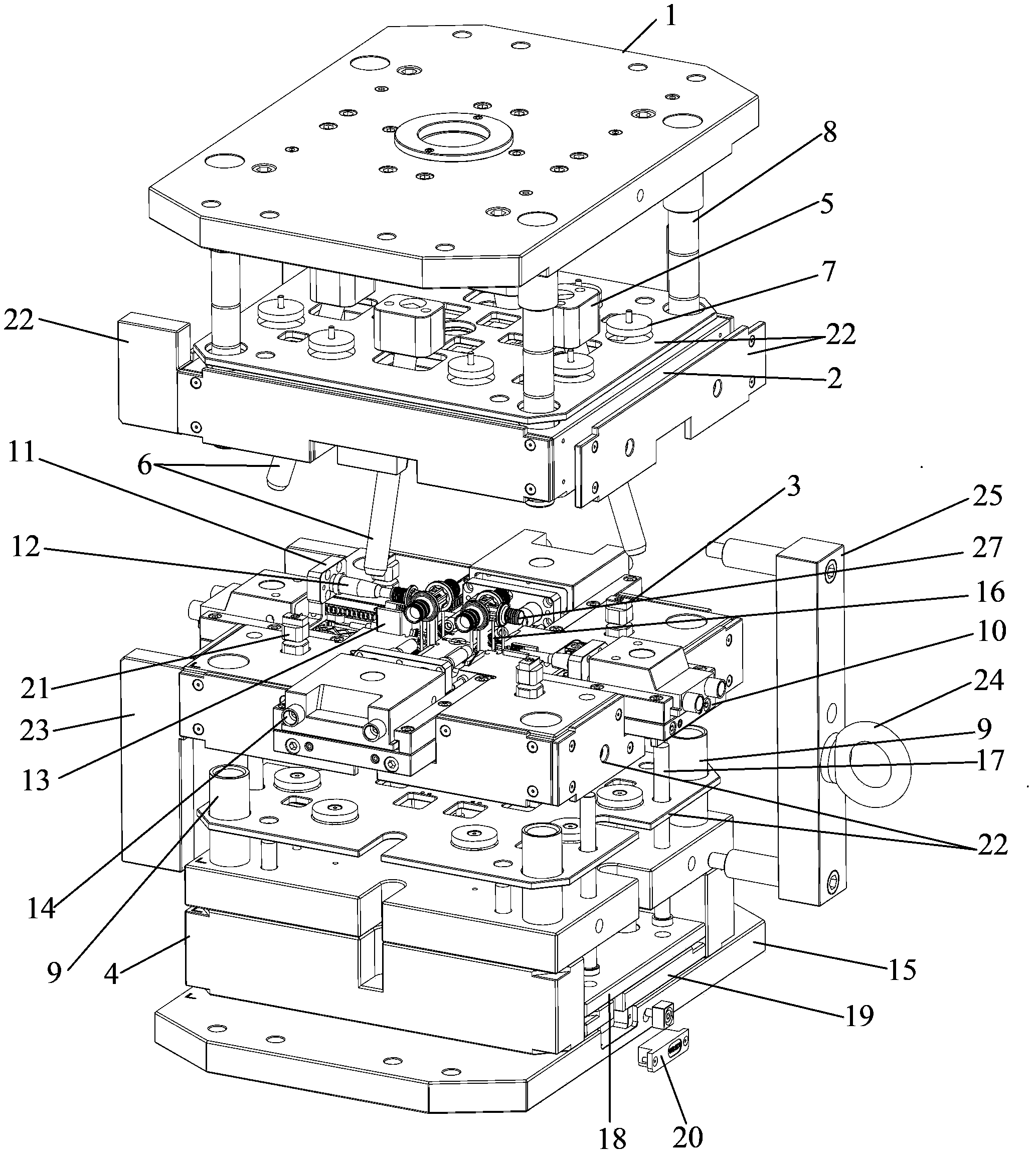

Thermosetting mould

The invention discloses a thermosetting mould. The thermosetting mould comprises a front mould panel, a front mould plate A arranged below the front mould panel, a rear mould plate B and a rear mould supporting plate used for supporting the rear mould plate B, wherein the rear mould plate B is arranged below the front mould plate A and matched with the front mould plate A. The thermosetting mould also comprises an inclined guide pillar mechanical parallel block and a slide inclined guide pillar connected with the inclined guide pillar mechanical parallel block, wherein the inclined guide pillar mechanical parallel block is arranged on the front mould plate A, and the slide inclined guide pillar passes through the front mould plate A to be connected with the rear mould plate B. The thermosetting mould adopts the structure, so that the situation that a conventional mould is easy to fracture when the stroke of a sliding block exceeds a conventional stroke, and the inclined guide pillar of the sliding block is in an ultra-long working state can be avoided.

Owner:易模塑科技(深圳)有限公司

Combined heat radiation oil pipe

InactiveCN104454802AImprove cooling effectIncrease the heat exchange areaPipe heating/coolingFluid-pressure actuator componentsEngineeringRadiation

The invention provides a combined heat radiation oil pipe composed of connected heat radiating oil pipe units. Two ends of a pipe body are provided with an oil inlet and an oil outlet respectively; the pipe units are in hollow cylindrical structures and comprise pipe layers and heat radiating layers from interior to exterior; cylindrical heat radiation projections are distributed on the outer surfaces of the pipe layers evenly; the inner sides of the heat radiating layers are provided with cylindrical heat radiating grooves, the outer sides are provided with Y-shaped radiating sheets evenly, and the outer side of each oil pipe unit comprises an inserting connection sheet; the heat radiating grooves match with the heat radiation projections; the tail ends of the inserting connection sheets are provided with inserting ends and connecting ends, and the inserting ends match with the connecting ends. The combined heat radiation oil pipe is simple in structure, convenient to install, large in heat radiating area and high in heat radiating efficiency and stability.

Owner:JIANGSU JINPAI AUTOMOTIVE PARTS CO LTD

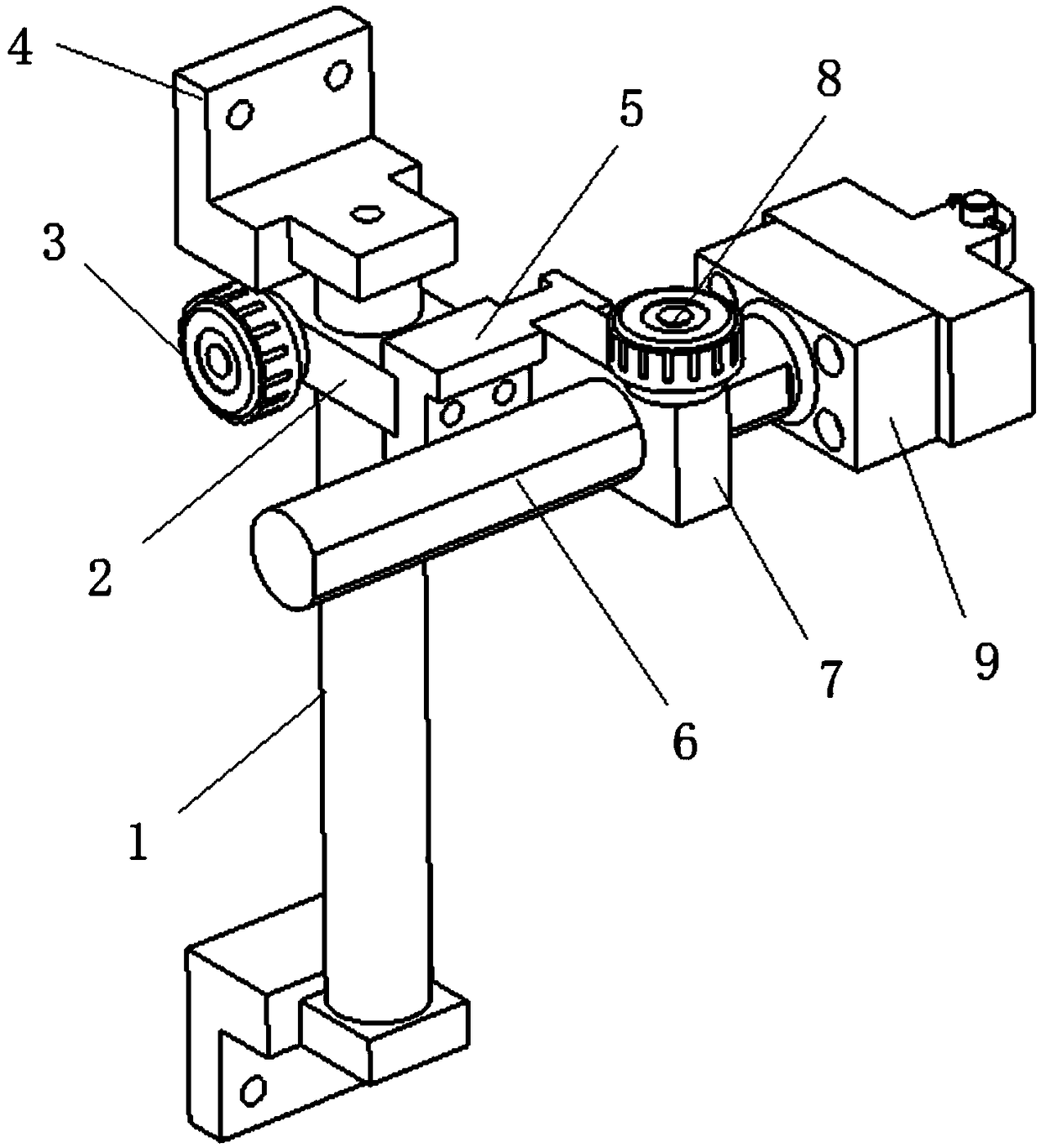

Exoskeleton adjustment mechanism

The invention discloses an exoskeleton adjustment mechanism. The mechanism is composed of a sliding rod a, a sliding block a, a fastening bolt a, a frame connecting member, a connecting member, a sliding rod b, a sliding block b, a fastening bolt b and an exoskeleton connecting member, the sliding rod a is fixed to the frame by a frame connecting member, and the sliding block a sleeves the slidingbar a and is positioned and fixed by the fastening bolt a; the sliding rod b is connected with an exoskeleton through the exoskeleton connecting member, and the sliding block b sleeves the sliding rod b and is positioned and fixed by the fastening bolt b; the sliding block a and the sliding block b are connected together by the connecting member. The mechanism can reduce the incompatibility of apatient wearing the exoskeleton during rehabilitation, improve the rehabilitation effect, and make the exoskeleton and the shape of the patient match better. Modular design can be used for adding or subtracting or replacing each module. When parts are damaged, a corresponding modules can be replaced to reduce maintenance time.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com