Patents

Literature

35results about How to "Not easy to pilling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Deoxidizing and polishing one-bath process dyeing of polyester cotton knitted fabric

The invention discloses deoxidizing and polishing one-bath process dyeing of a polyester cotton knitted fabric and belongs to the technical field of dyeing or printing of textiles. The deoxidizing and polishing one-bath process dyeing of the polyester cotton knitted fabric comprises the following steps of: adjusting temperature to 40-60 DEG C; adjusting a PH value to 5-7; adding 1%-2% of polishing enzyme 988, adding dyes and dyeing assistants after 0-15 minutes, adding sodium sulphate after 30 minutes, adding sodium carbonate after 20 minutes; keeping the temperature for 60 minutes, wherein the polishing enzyme 988 is cellulose bio-enzyme and the addition amount is 1%-2%; the dyeing assistants are scouring and dyeing one-bath agents and are added in two steps with the total addition amount of 1%-2%; the dye bath ratio is 1:5-1:20, and assistant scouring and bleaching, dispersing alkali one-bath dyeing of polyesters and reduction clearing need to be sequentially carried out before the deoxidizing and polishing one-bath process dyeing. By adoption of the technical scheme, the polishing effect which is same to or better than that of separated-bath processing can be achieved; processed cotton fabrics have the advantages of less surface fuzz, clear textures and enhanced anti-pilling level; and dyeing coloured light and depth can not be influenced.

Owner:绍兴市华绅纺织品整理有限公司

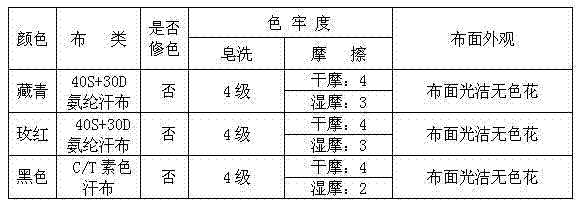

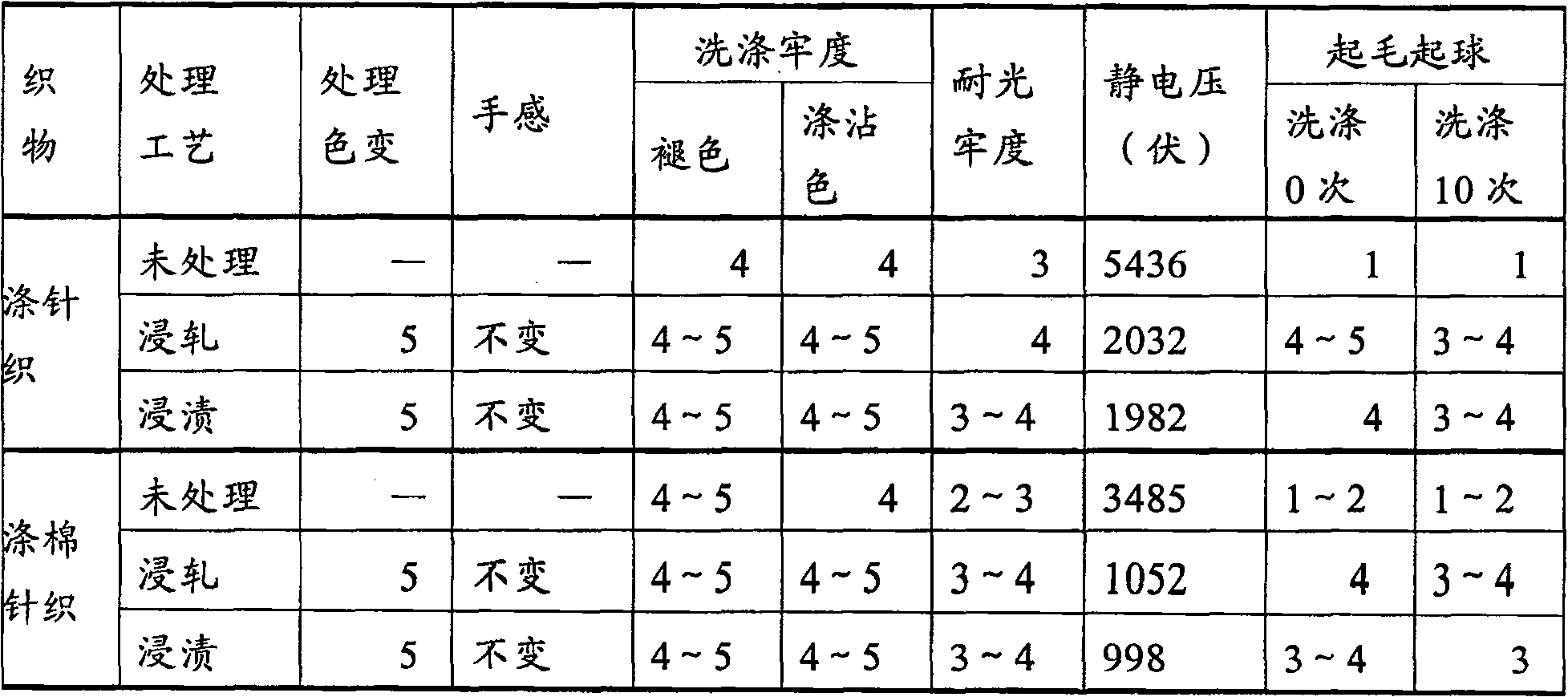

Anti-fuzzing and anti-pilling finishing agent for fabric

The invention relates to an auxiliary agent in the printing and dyeing industry, in particular to a surface finishing auxiliary agent for fabric. An anti-pilling finishing agent for the fabric is nonionic macromolecular polymer, and is characterized in that the anti-pilling finishing agent for the fabric is formed by copolymerizing 10 to 20 portions of high-hydro silicone oil, 30 to 50 portions of polyurethane prepolymer and 30 to 50 portions of polypropylene ester copolymer under the conditions of catalyst and heating; and the portion is weight portion. The fabric anti-pilling finishing agent is suitable for various fibers and fabrics; and in particular, polyester fabric treated by the anti-pilling finishing agent has basically unchanged tone and handfeel, improves the fastness to washing and light fastness, greatly improves the antistatic performance, has certain dust resistance and obviously improves the anti-pilling performance.

Owner:上海德桑精细化工有限公司

Pure cotton knitted fabric deoxidizing polishing one bath process dyeing

ActiveCN102978978ASimple processUniform colorBiochemical fibre treatmentDry-cleaning apparatus for textilesCelluloseHydrogen

The invention discloses pure cotton knitted fabric deoxidizing polishing one bath process dyeing, and belongs to the technical field of dyeing or printing of textile. The pure cotton knitted fabric deoxidizing polishing one bath process dyeing comprises cooking liquid, draining liquid, hot cleaning and final treatment, and deoxidizing polishing one bath process dyeing is further constituted between the hot cleaning and the final treatment. The deoxidizing polishing one bath process dyeing is that temperature of soft water is raised to 40-60 DEG C a potential of hydrogen (PH) value is adjusted to 5-7, polishing enyme 988 is added to run for 15 minutes, and the dye bath rate is kept as 1:5-1:20. Dye is added (30 minutes) to run for 15 minutes, anhydrous sodium sulphate (30 minutes) is added to run for 30 minutes, and soda ash is added (40 minutes) to keep warm for 60 minutes. The polishing enyme 988 is cellulose biology enzyme, and additive amount is 1-2%. An equivalent effect or a good polishing effect with bath treatment can be obtained, surface of baffeta after treatment is little in lousiness and clear in lines, anti-pilling grades are improved, and at the same time, dye colored light and depth are not affected.

Owner:浙江七色彩虹科技有限公司

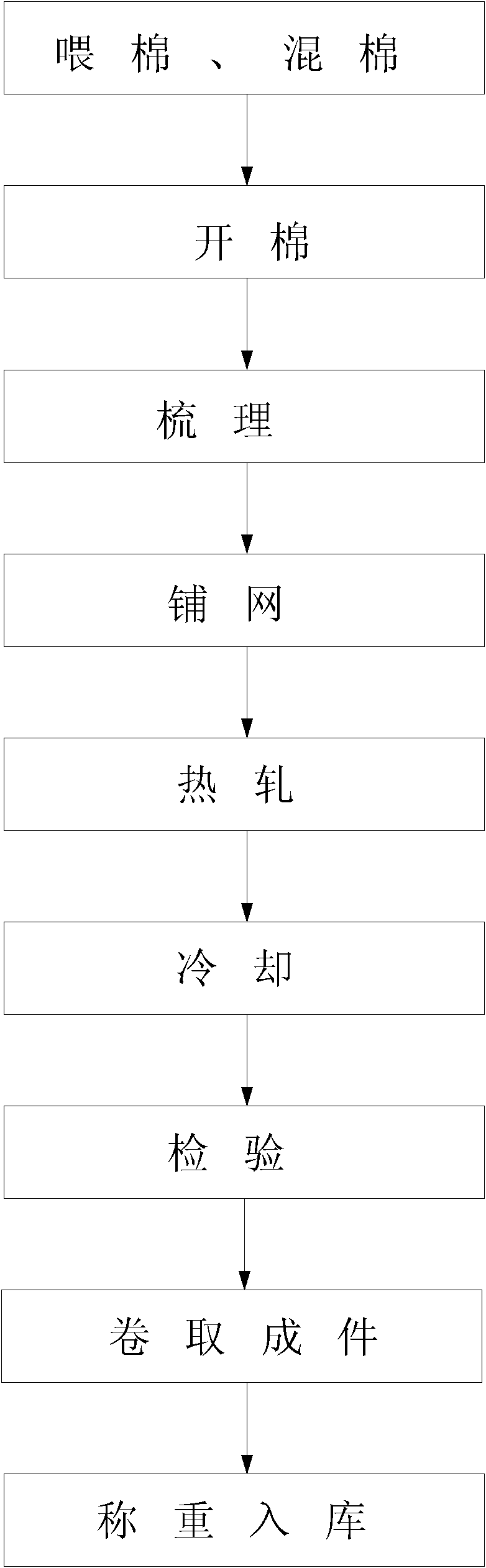

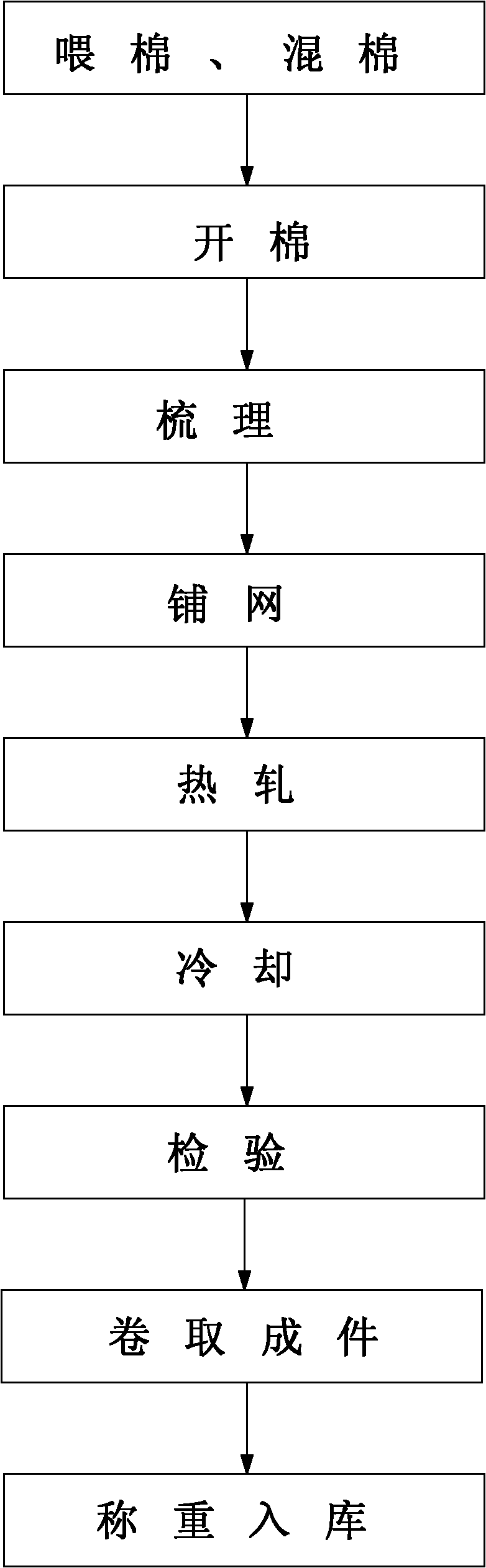

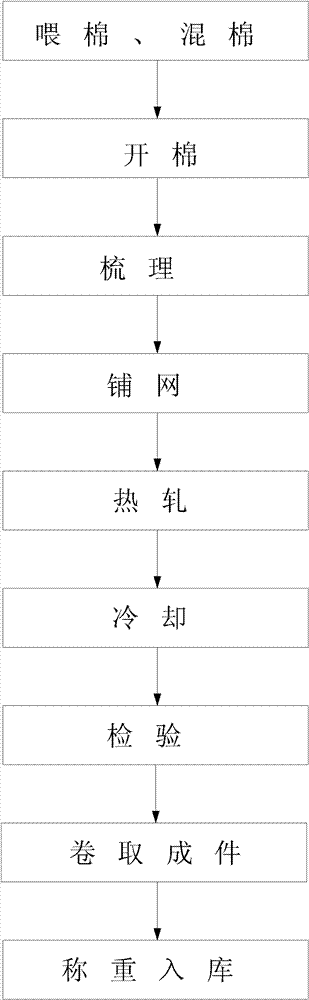

Process for producing hot rolling thin nonwoven fabric

The invention discloses a process for producing hot rolling thin nonwoven fabric, sequentially comprising the following steps of: feeding cotton, mixing cotton, adding ES fiber (ethylene-propylene side by side) in fiber raw material, opening, carding, lapping, hot rolling, cooling, testing, reeling into products, weighing and warehousing. The process disclosed by the invention has the advantages that: ES fibers are added, thus washing fastness of the supported hot rolling thin nonwoven fabric is greatly improved compared with a common nonwoven fabric, and the supported hot rolling thin nonwoven fabric is resistant to pilling; the cloth cover of a base fabric is smoother and the fastness is greatly improved, the washing fastness, washing shrinkage and heating shrinkage are all obviously improved, and the quality is above the national textile industry standard FZ / T6004-93.

Owner:HANGZHOU JINMUZHI GARMENT ACCESSORIES

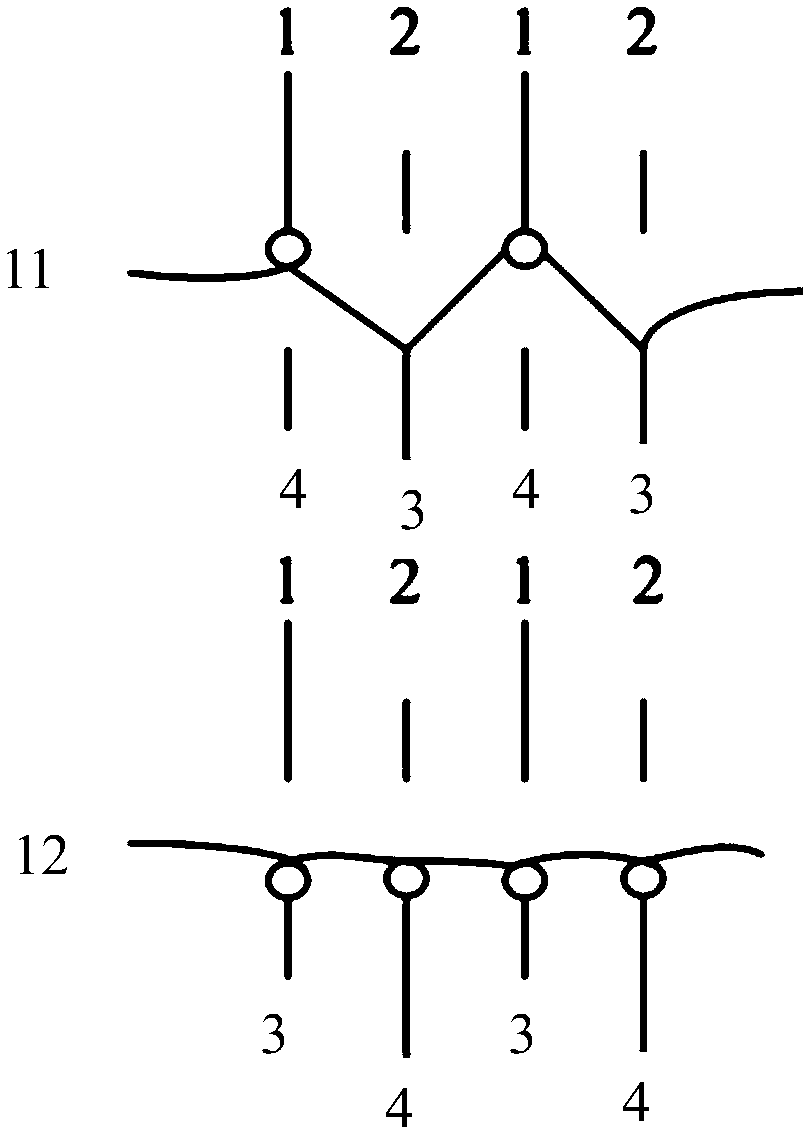

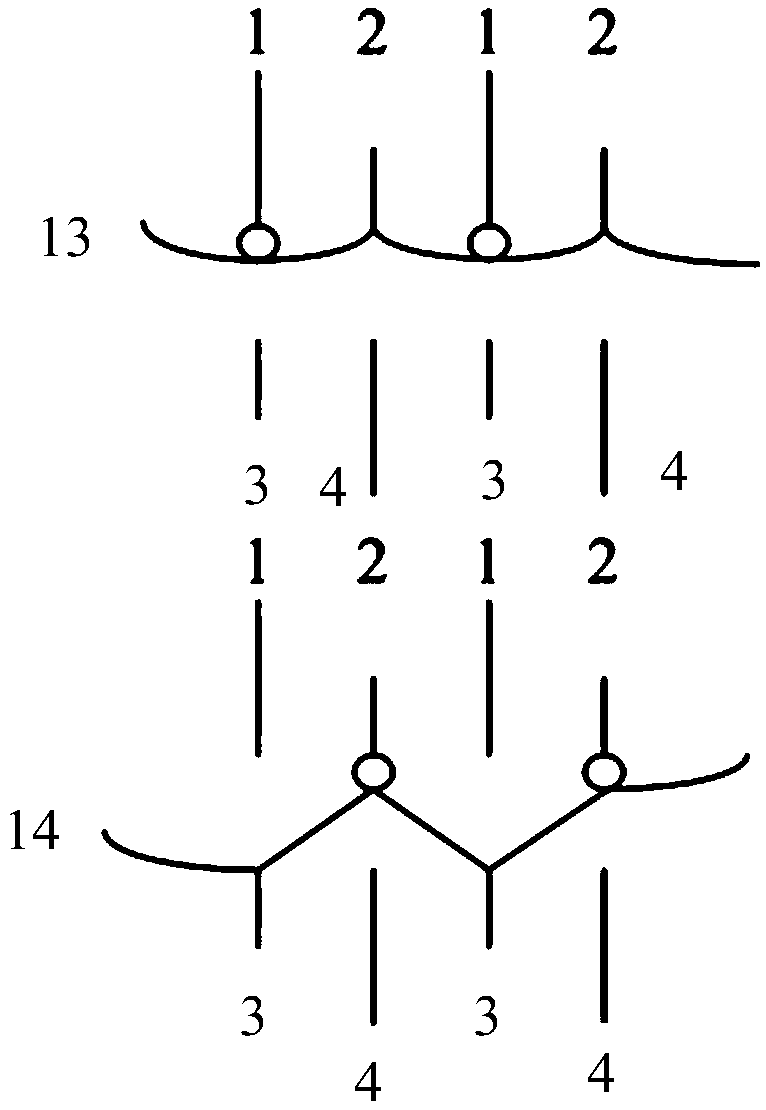

Method for producing and processing wool blended yarn

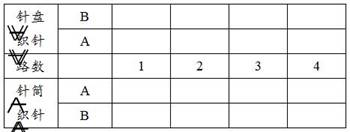

The invention discloses method for producing and processing a wool blended yarn, and the method comprises the steps of 1 selecting raw materials, namely selecting wools as long as possible, using a filament as a chemical fiber, and controlling the denier of the chemical fiber as small as possible to reduce of the proportion of the chemical fiber in the yarn under the prerequisite that spinning can be carried out; 2 blending and combing a top with a first needle, a second need, a third needle and a forth needle; then merging and drawing-off the wool fiber to get a wool top; carding the wool top to make it as straight as possible; and then stretching the wool top gradually until a required gram weight is realized to obtain a rove. According to the method for producing and processing a wool blended yarn, a wrapped yarn that has a smooth and clean yarn surface, little hairiness, good anti-pilling effect can be produced with basic wool characteristics.

Owner:ZHEJIANG XINAO

Core-spun yarn with rabbit hair imitation effect and preparation method thereof

The invention discloses a core-spun yarn with a rabbit hair imitation effect and a preparation method thereof. The core-spun yarn comprises an outer yarn and a core yarn, wherein the outer yarn is prepared from viscose fiber, common nylon staple fiber and special-shaped nylon staple fiber in the ratio of 72 to 14 to 14; the core yarn is 50 DPBT low elastic filament. Compared with the prior art, the core-spun yarn has the advantages that (1) the core-spun yarn has a rabbit hair imitation appearance, the characteristics of high strength, less hairiness and the like of the yarn are realized at the same time, the defects of low strength and poor spinnability of rabbit hair are overcome, fabrics made by the core-spun yarn are insusceptible to hair drop, pilling and deformation and are easy to wash, and the production cost is lowered at the same time; (2) in the method, the arrangement of three kinds of fibers in the outer yarn can be controlled by transferring fibers in the spinning process, and the rabbit hair imitation appearance of the yarn is realized finally.

Owner:江苏品创纺织科技有限公司

Heating red bean velvet fabric

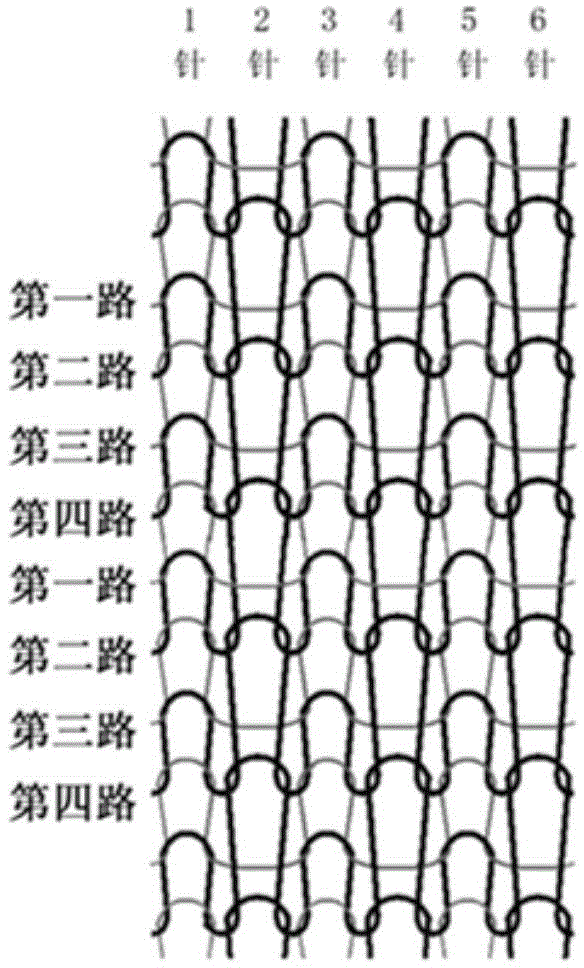

PendingCN108950832AGood heat retention and comfort performanceIncrease the number of still airWeft knittingUndergarmentsFiberYarn

The invention relates to a heating red bean velvet fabric, and belongs to the technical field of knitting fabric preparation. The red bean velvet fabric is woven on a double-face weft knitting machine, an overall design of the fabric is carried out from the aspects of fibers, yarns, structures, post finishing schemes and the like, a product is provided with a heating function while having good softness and a fluffy style, and the softness and comfort of close-fitting wearing are obviously improved. The invention provides the heating red bean velvet fabric, and the fabric has the advantages ofsoftness, warmness and comfort performance, can solve the contradiction between the softness and warmth of traditional winter clothes and massiness and fatness, provides a novel scheme for the designof autumn and winter underwear products, fills the gap in market heating functional fabrics, and meets demands for comfortable winter wearing of customers.

Owner:无锡红豆纺织服装有限公司

Production process of copper ion modified polyester staple fiber socks

The invention discloses a production process of copper ion modified polyester staple fiber socks. The production process of copper ion modified polyester staple fiber socks is finished by raw materialselection, sock knitting, sewing and sizing processes. The production process has the advantages that copper ion modified polyester staple fibers are selected from raw materials, the socks can achieve stronger breathability and are not easy to fuzz and pill, durable, flat and smooth in surface, antibacterial, bacteriostatic and odor-resistant, the production process is simple to operate, and massproduction of enterprises is easily performed.

Owner:IANGSU COLLEGE OF ENG & TECH

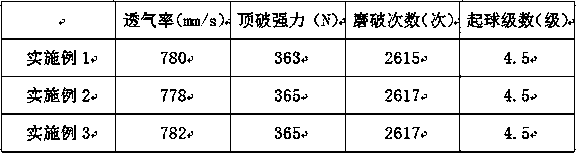

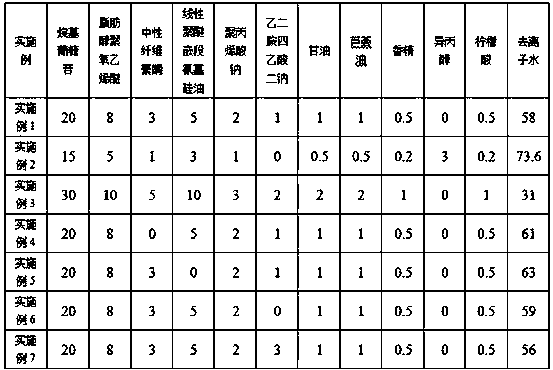

Anti-fuzzing and anti-pilling clothing detergent

InactiveCN111019768AImprove the finishAchieve anti-pilling effectNon-ionic surface-active compoundsOrganic detergent compounding agentsYarnFiber

The invention discloses an anti-fuzzing and anti-pilling clothing detergent, and belongs to the field of multifunctional detergents. The detergent comprises, by weight, 20-40 parts of a nonionic surfactant, 1-5 parts of cellulase, 3-10 parts of high-hydrogen silicone oil, 0-2 parts of ethylenediamine tetraacetic acid disodium salt, 1-3 parts of sodium polyacrylate, 1-3 parts of glycerol, 1-3 partsof aloe oil, 0.2-1 part of essence, 0.2-1 part of citric acid and 34-71 parts of deionized water. A certain amount of cellulase is added into the detergent, and the smoothness of the surface of fabric is improved through bio-enzyme finishing, so that the anti-fuzzing and anti-pilling effects are achieved; and a small amount of high-hydrogen-content silicone oil is used for assistance, and the silicone oil is uniformly cross-linked and gathered on the surface of the fabric, so that the fiber end is adhered to yarns, and the anti-fuzzing and anti-pilling effects are not prone to occuring duringfriction.

Owner:南京市检捷生物信息科技有限公司

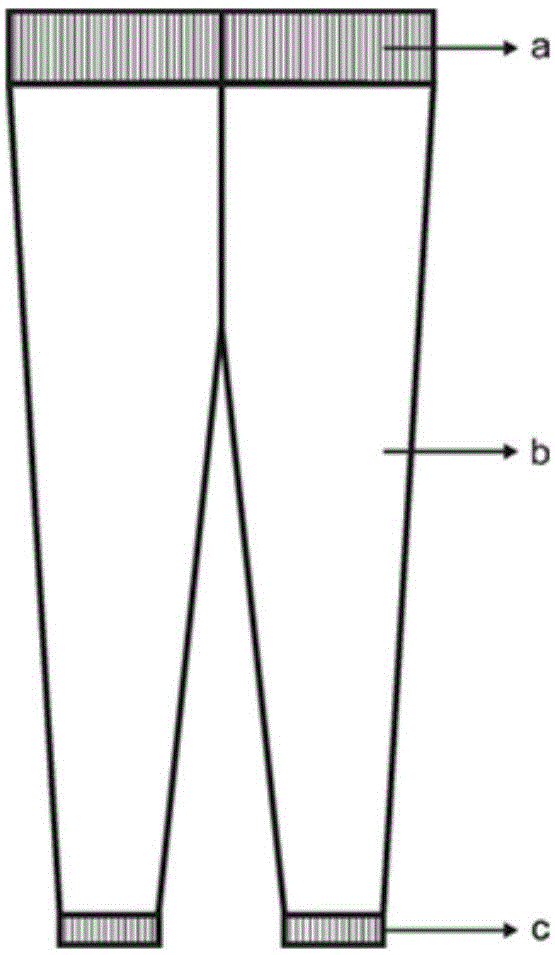

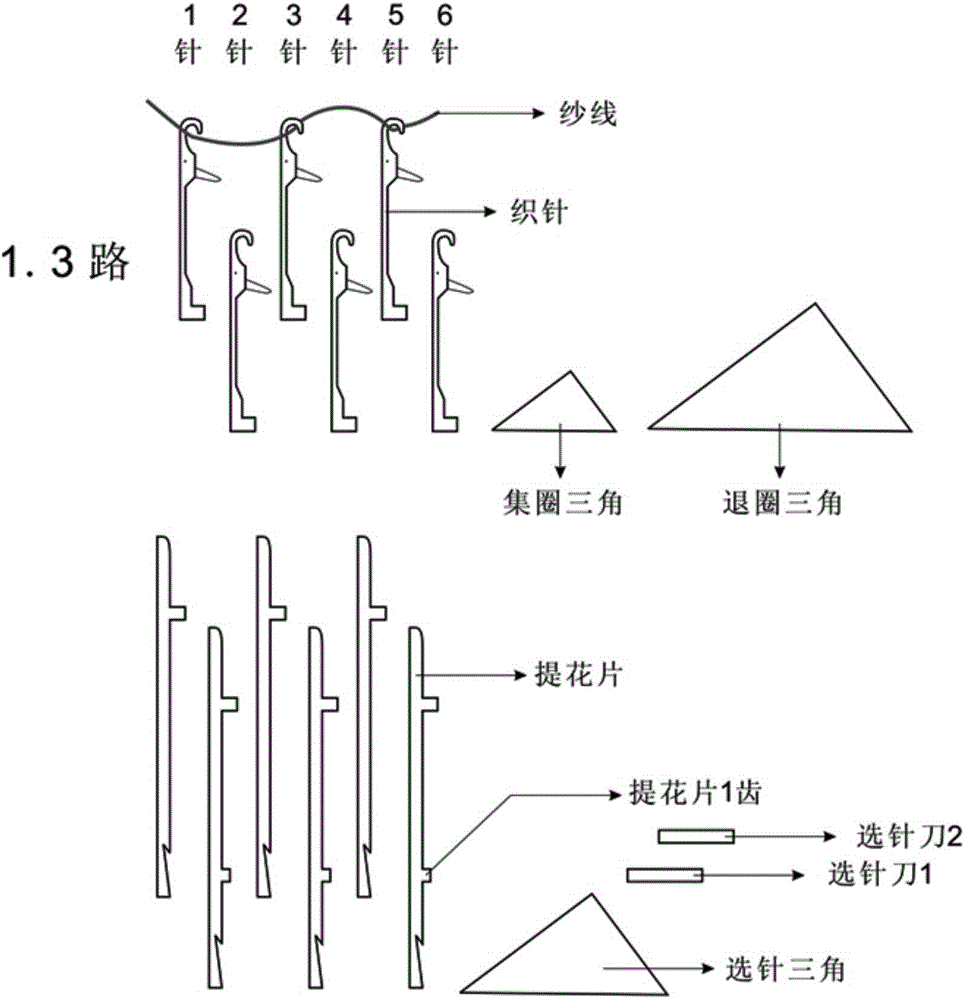

High-density plain looped pile all-in-one pants and making method thereof

The invention relates to high-density plain looped pile all-in-one pants. The high-density plain looped pile all-in-one pants comprise a pant waist, a pant body and pant legs; and the pant body is made of single-layer double-face small tubular fabric with high-density plain weaves on the front face and looped pile stitches on the back face. The invention further provides a method for weaving the high-density plain looped pile single-layer double-face small tubular fabric and a double-face type plain looped pile small-diameter circular knitting machine. The all-in-one pants are smooth and bright in front face and warm and soft in back face, has the dual effects of being attractive in appearance and warm in interior, and is suitable for wearing outside.

Owner:肇庆红雨伞服饰有限公司

Method for preparing oil absorption cotton

InactiveCN105483935AEasy to control changes in flow rateGood fastness and toughnessNon-woven fabricsArtifical filament manufactureEngineeringHigh pressure

The invention discloses a method for preparing oil absorption cotton. The oil absorption cotton is made of fibers made of polypropylene through melt-blowing and non-woven fabrics through special treatment. The method comprises the steps of conducting stretching action on sprayed cellosilk with air flow sprayed at the high pressure, so that compact micrometer cellosilk is formed; arranging an ultrasonic generator on a spray nozzle of a pressure squeezing device so that liquid raw materials can be pushed to be sprayed out of spray orifices in the spray nozzle. The oil absorption cotton prepared through the method is integrally formed, better fastness and toughness are achieved, no delamination is generated in the using process, and the oil absorption cotton is not prone to hair slip or pilling, easy to use and environmentally friendly.

Owner:SUZHOU BD ENVIRONMENTAL PROTECTION

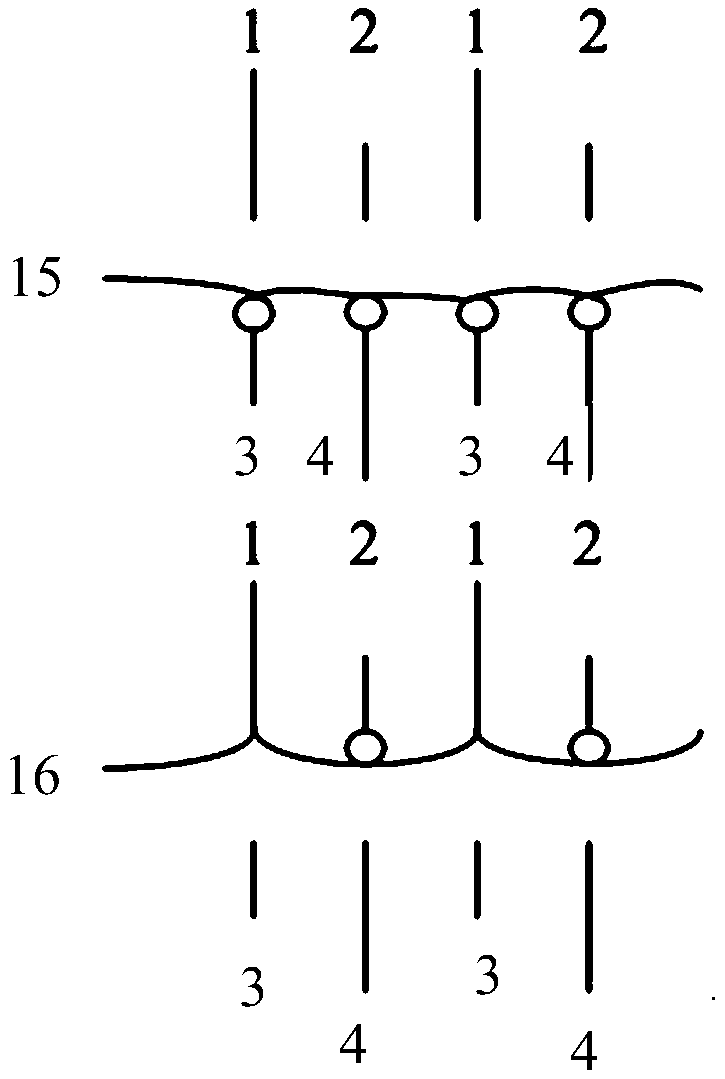

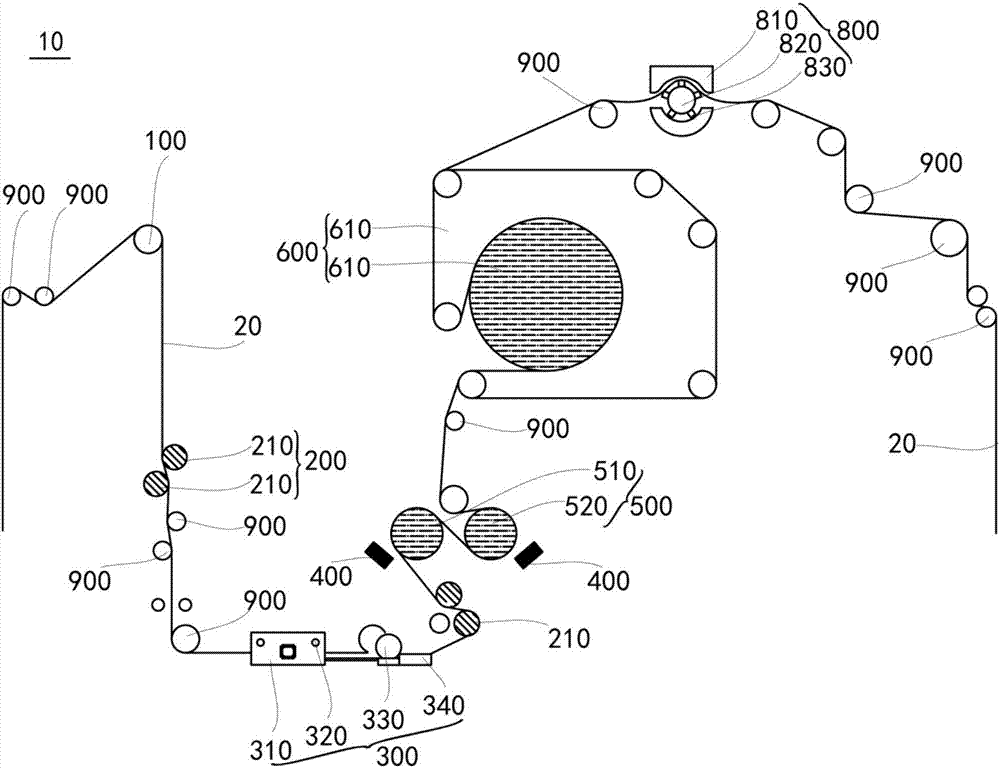

Collar and sleeve singeing mechanism

ActiveCN107475973AClear textureNot easy to pillingSingeingStructural engineeringMechanical engineering

The invention discloses a collar and sleeve singeing mechanism. The collar and sleeve singeing mechanism comprises feed roller, an edge stirring assembly, a humidifying assembly, fire spraying assemblies, a singeing assembly, a fire extinguishing assembly, and a discharge roller; the edge stirring assembly comprises a pair of edge stirring rods matching each other; a edge stirring gap only used for passing of collar and sleeve cut-parts is left between the two edge stirring rods; the feed roller, the humidifying assembly, singeing rollers, fire extinguishing rollers, and the discharge roller are arranged successively; the edge stirring assembly is arranged between the feed roller and the humidifying assembly; the singeing assembly is provided with the first singeing roller and the second singeing roller; the first singeing roller and the second singeing roller are arranged with a gap left between the first singeing roller and the second singeing roller; the fire spraying assemblies are arranged on the outside of the first singeing roller and the outside of the second singeing roller respectively; the fire spraying holes of the corresponding fire spraying assemblies are arranged toward the first singeing roller and the second singeing roller; the fire extinguishing assembly is used for fire extinguishing treatment of collar and sleeve cut-parts. The collar and sleeve singeing mechanism is short in process flow, is capable of reducing cost, and is capable of improving singeing effect effectively.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

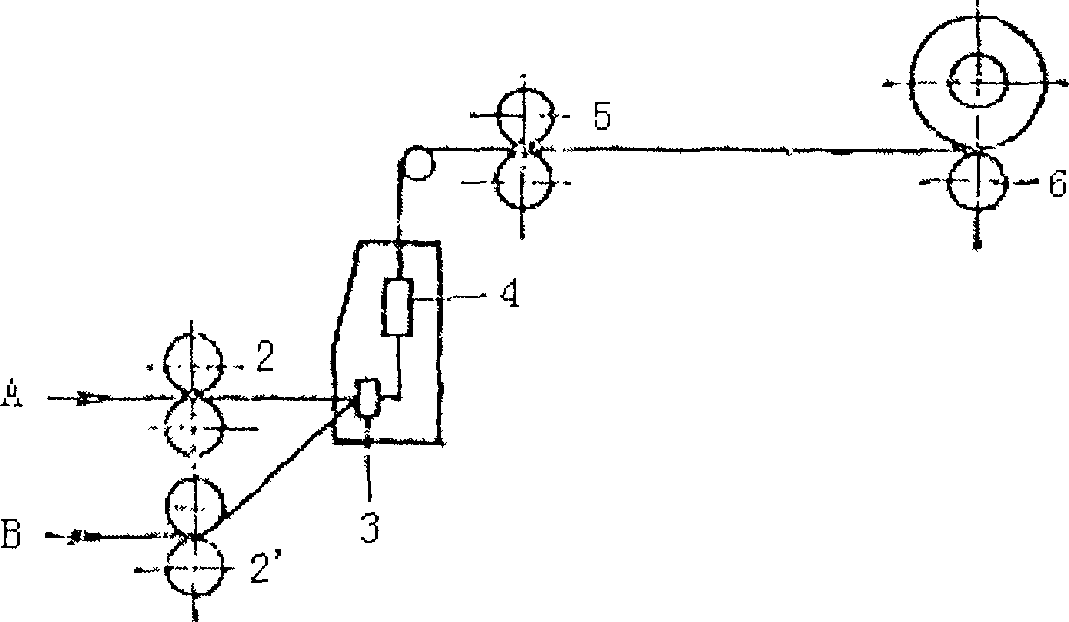

Manufacturing method of diacetate and terylene/cotton filament composite blank variable yarn having short fibrous effect

InactiveCN1718884AGive full play to the short fiber effectSoft lusterTextiles and paperEngineeringFilament yarn

The present invention utilizes the combination of characteristics of diacetate filament and air-texturing technique, and fully utilizes the short fibrillation effect of diacetate filament in air-texturing production process, and has no need of adding loop-abrading device, and can produce the air-textured yarn with more rich natural spun yarn style.

Owner:DONGHUA UNIV

Anti-fuzzing and anti-pilling finishing agent for fabric

The invention relates to an auxiliary agent in the printing and dyeing industry, in particular to a surface finishing auxiliary agent for fabric. An anti-pilling finishing agent for the fabric is nonionic macromolecular polymer, and is characterized in that the anti-pilling finishing agent for the fabric is formed by copolymerizing 10 to 20 portions of high-hydro silicone oil, 30 to 50 portions of polyurethane prepolymer and 30 to 50 portions of polypropylene ester copolymer under the conditions of catalyst and heating; and the portion is weight portion. The fabric anti-pilling finishing agent is suitable for various fibers and fabrics; and in particular, polyester fabric treated by the anti-pilling finishing agent has basically unchanged tone and handfeel, improves the fastness to washing and light fastness, greatly improves the antistatic performance, has certain dust resistance and obviously improves the anti-pilling performance.

Owner:上海德桑精细化工有限公司

Preparation method for bio-polishing enzyme, and method for applying bio-polishing enzyme to fabric printing and dyeing

InactiveCN108823989ANot easy to polluteNot easy to bring pollutionBiochemical treatment with enzymes/microorganismsGrip property fibresCellulasePigment

The invention relates to a preparation method for a bio-polishing enzyme, and a method for applying the bio-polishing enzyme to fabric printing and dyeing. The preparation method comprises the following steps: (1) weighing, by weight, 20% of neutral cellulase, 5% of an auxiliary agent, 10% of dye-resistant powder, 46.95% of starch, 10% of microcrystalline cellulose, 8% of dextrin and 0.05% of caramel pigment; and (2) uniformly mixing the above components in the step (1) to prepare the finished bio-polishing enzyme. The bio-polishing enzyme of the invention is convenient to use, good in usage effect, friendly to environment and wide in an application scope, and can be widely applied to polishing, softening, faded-effect finishing and the like of fabrics.

Owner:湖南隆森生物科技股份有限公司

Chitosan anti-bacterial anti-mite functional fabric used for starred hotel and production method thereof

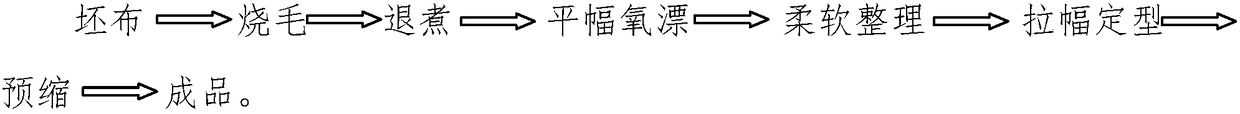

InactiveCN108286106AFull styleSmooth to the touchSucessive textile treatmentsWoven fabricsYarnCotton fibre

The invention discloses chitosan anti-bacterial anti-mite functional fabric used for a starred hotel and a production method thereof. Warp yarn of the fabric is pure-cotton yarn of J12.5tex, weft yarnis blended yarn in which the content of J12.5tex cotton is 90%, and the content of chitosan is 10%, warp-wise density is 787.5 pieces / 10 cm, and weft-wise density is 433 pieces / 10 cm. Biological element chitosan fibers and cotton fibers are subjected to mixed knitting to prepare the fabric, and the fabric is full in style, smooth in touch, soft, comfortable and quite suitable for close fitting; the natural fibers are adopted as product raw materials and completely meet the demand for environmental protection of people, no harmful substance is included, and with the fibers containing the chitosan, the fabric has the beneficial functions of natural mite resistance and dispelling, peculiar smell elimination, formaldehyde and metal ions adsorption, and others.

Owner:JIANGSU YUEDA HOME TEXTILE

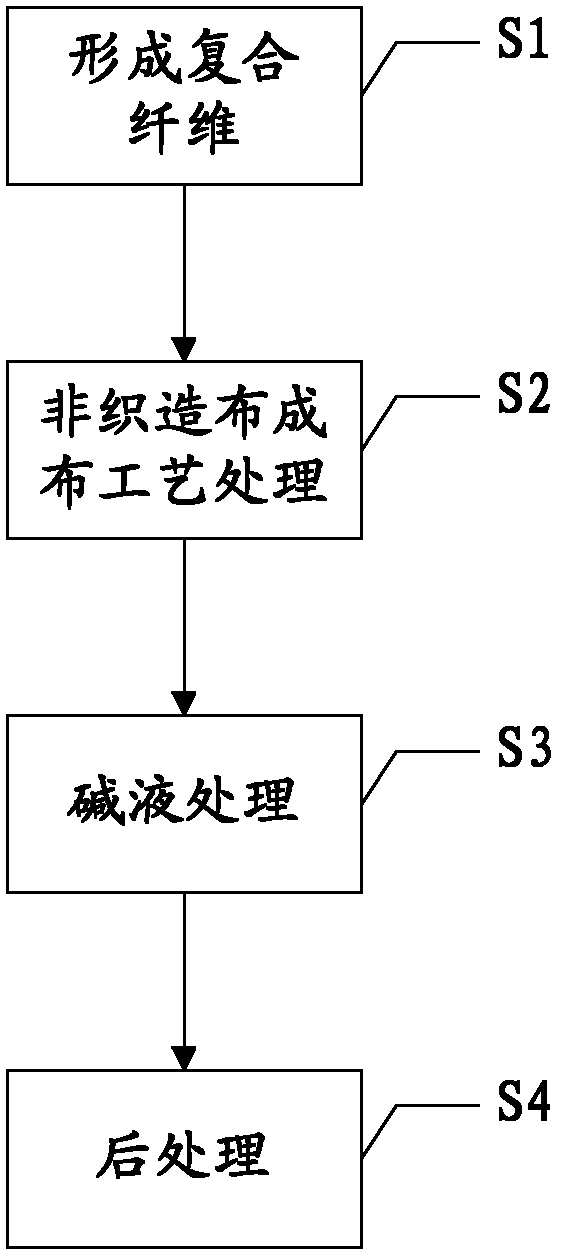

Elastic non-woven fabric, production method thereof and elastic product

ActiveCN102230256BImprove breathabilityNot easy to pillingNon-woven fabricsVegetal fibresPolymer scienceCellulose fiber

Owner:WINNER MEDICAL CO LTD +2

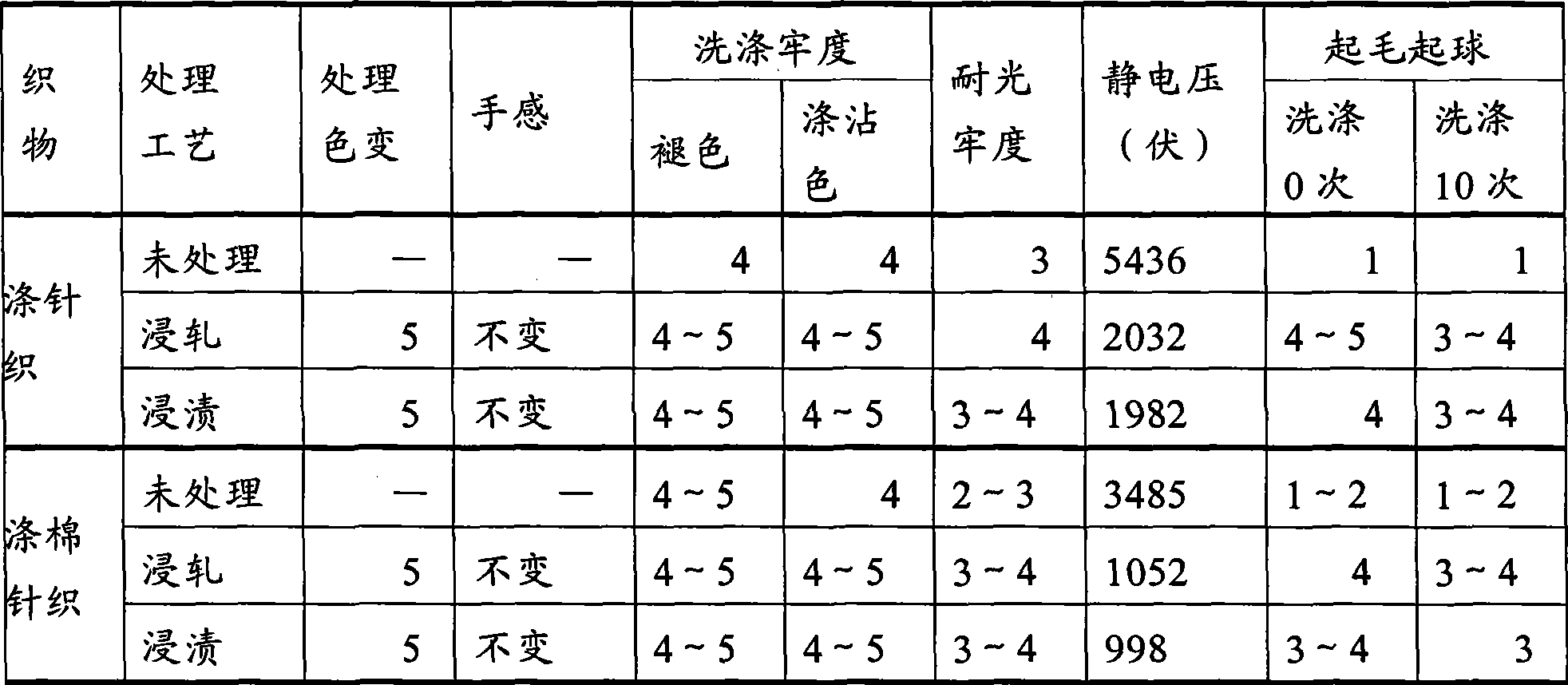

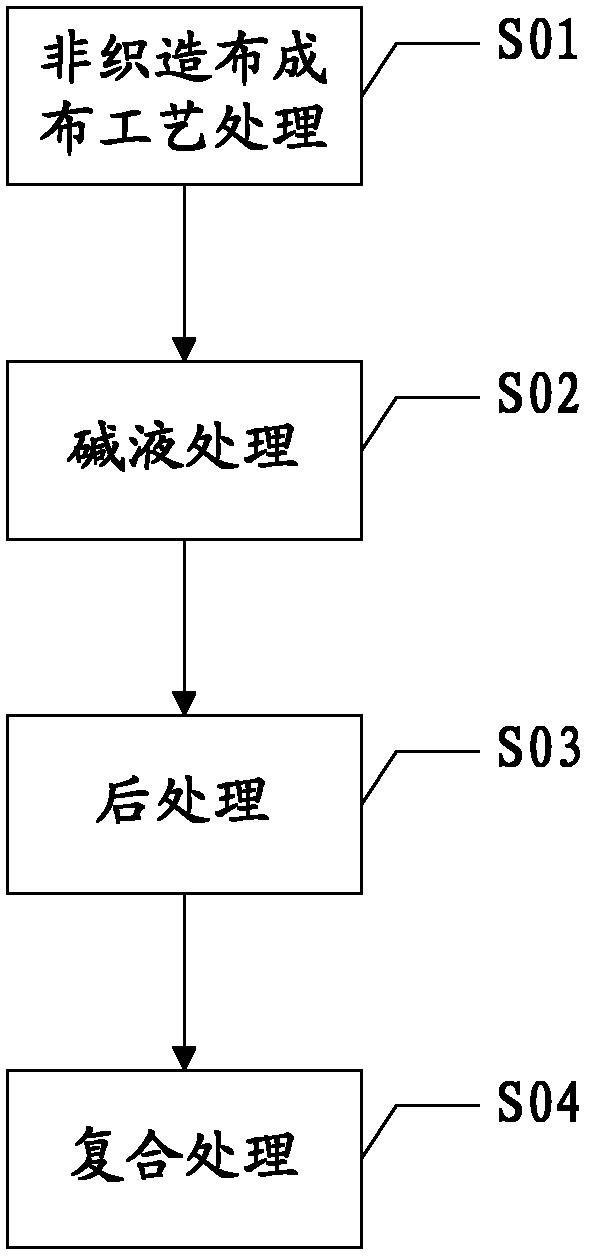

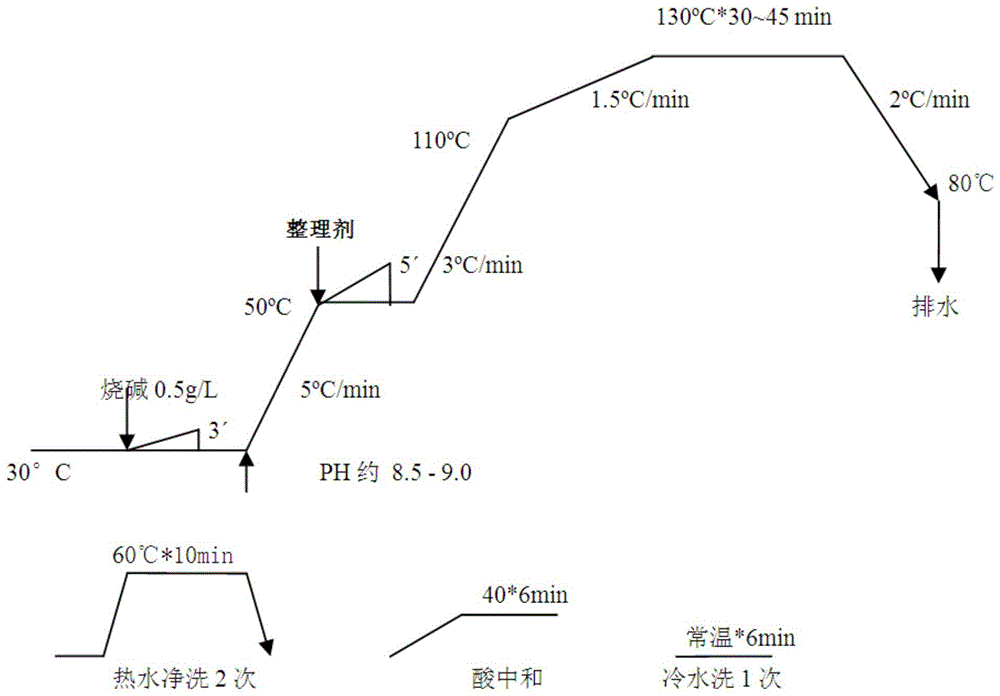

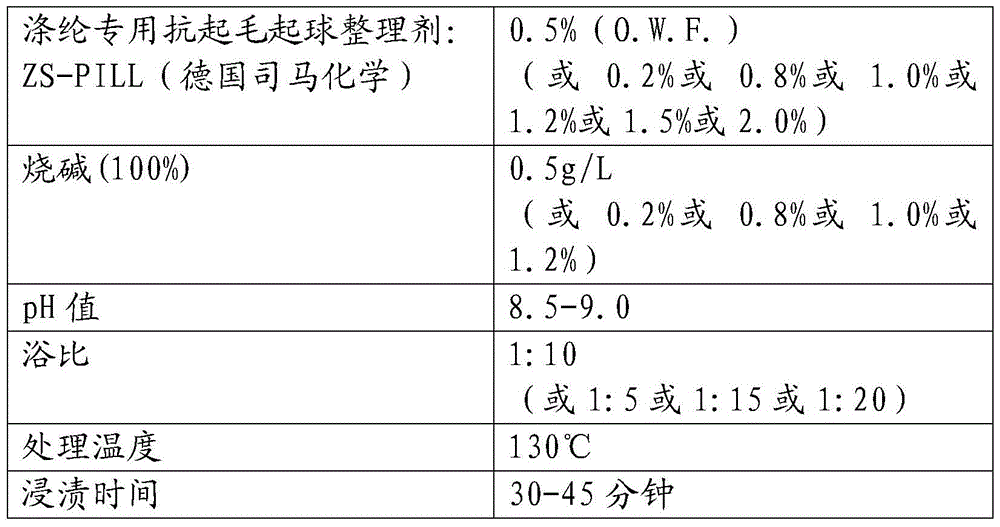

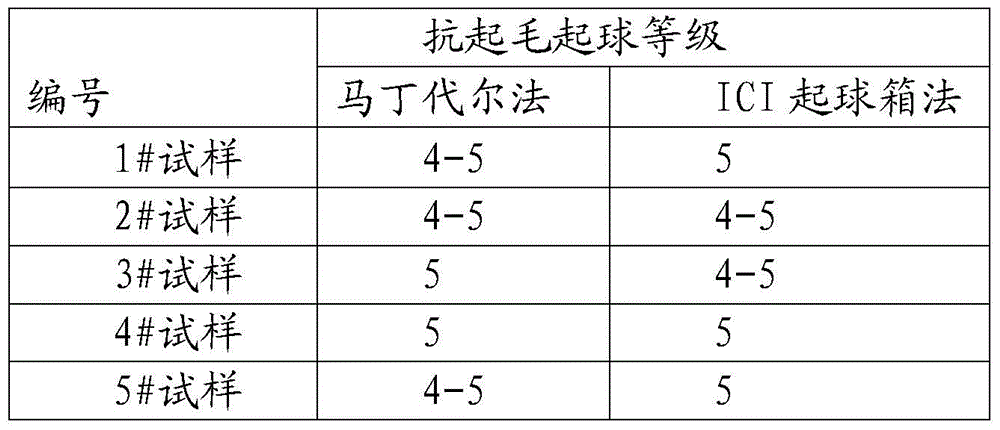

A processing technology of super high anti-pilling polyester fabric

ActiveCN104674556BImprove anti-pilling performanceImprove performanceSucessive textile treatmentsFibre typesHigh resistancePolyester

The invention relates to a processing technology of an ultrahigh anti-pilling polyester fabric. The processing technology is characterized by comprising a multi-section pretreatment enzymolysis process, wherein the multi-section pre-treatment enzymolysis process comprises a step for treating the fabric by adopting a special anti-pilling arrangement agent for polyester. The special anti-pilling arrangement agent for the polyester is adopted in the processing technology disclosed by the invention, so that the produced polyester fabric is ultrahigh in anti-pilling performance, the comfort and the appearance hand feeling of the produced polyester fabric are further improved, and due to the unique style and good application performance, the ultrahigh anti-pilling polyester fabric is popular in the market.

Owner:SHANGHAI JIALE

One-bath dyeing of pure cotton knitted fabrics by deoxidizing and polishing

ActiveCN102978978BSimple processUniform colorBiochemical fibre treatmentDry-cleaning apparatus for textilesCelluloseAfter treatment

The invention discloses pure cotton knitted fabric deoxidizing polishing one bath process dyeing, and belongs to the technical field of dyeing or printing of textile. The pure cotton knitted fabric deoxidizing polishing one bath process dyeing comprises cooking liquid, draining liquid, hot cleaning and final treatment, and deoxidizing polishing one bath process dyeing is further constituted between the hot cleaning and the final treatment. The deoxidizing polishing one bath process dyeing is that temperature of soft water is raised to 40-60 DEG C a potential of hydrogen (PH) value is adjusted to 5-7, polishing enyme 988 is added to run for 15 minutes, and the dye bath rate is kept as 1:5-1:20. Dye is added (30 minutes) to run for 15 minutes, anhydrous sodium sulphate (30 minutes) is added to run for 30 minutes, and soda ash is added (40 minutes) to keep warm for 60 minutes. The polishing enyme 988 is cellulose biology enzyme, and additive amount is 1-2%. An equivalent effect or a good polishing effect with bath treatment can be obtained, surface of baffeta after treatment is little in lousiness and clear in lines, anti-pilling grades are improved, and at the same time, dye colored light and depth are not affected.

Owner:浙江七色彩虹科技有限公司

Core-spun yarn with imitation rabbit fur effect and preparation method thereof

The invention discloses a core-spun yarn with a rabbit hair imitation effect and a preparation method thereof. The core-spun yarn comprises an outer yarn and a core yarn, wherein the outer yarn is prepared from viscose fiber, common nylon staple fiber and special-shaped nylon staple fiber in the ratio of 72 to 14 to 14; the core yarn is 50 DPBT low elastic filament. Compared with the prior art, the core-spun yarn has the advantages that (1) the core-spun yarn has a rabbit hair imitation appearance, the characteristics of high strength, less hairiness and the like of the yarn are realized at the same time, the defects of low strength and poor spinnability of rabbit hair are overcome, fabrics made by the core-spun yarn are insusceptible to hair drop, pilling and deformation and are easy to wash, and the production cost is lowered at the same time; (2) in the method, the arrangement of three kinds of fibers in the outer yarn can be controlled by transferring fibers in the spinning process, and the rabbit hair imitation appearance of the yarn is realized finally.

Owner:江苏品创纺织科技有限公司

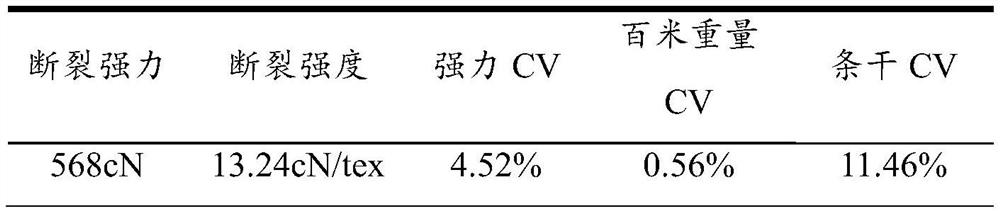

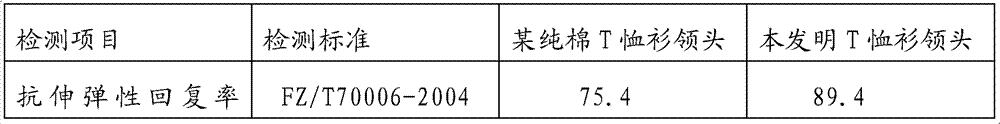

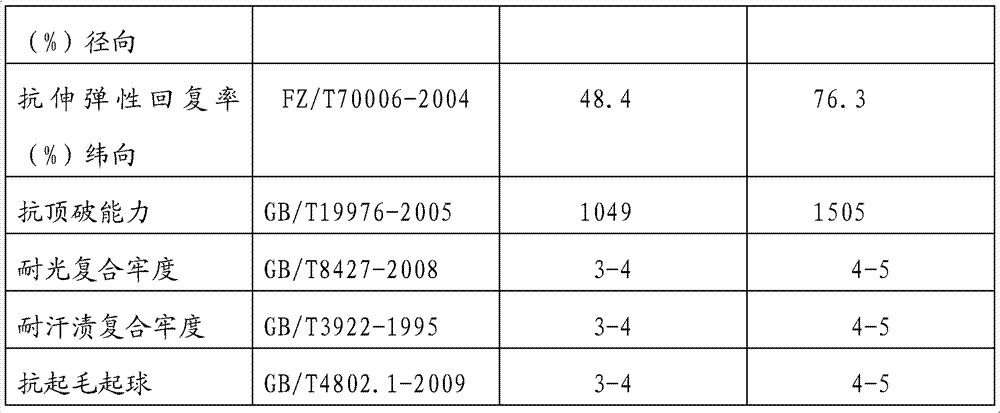

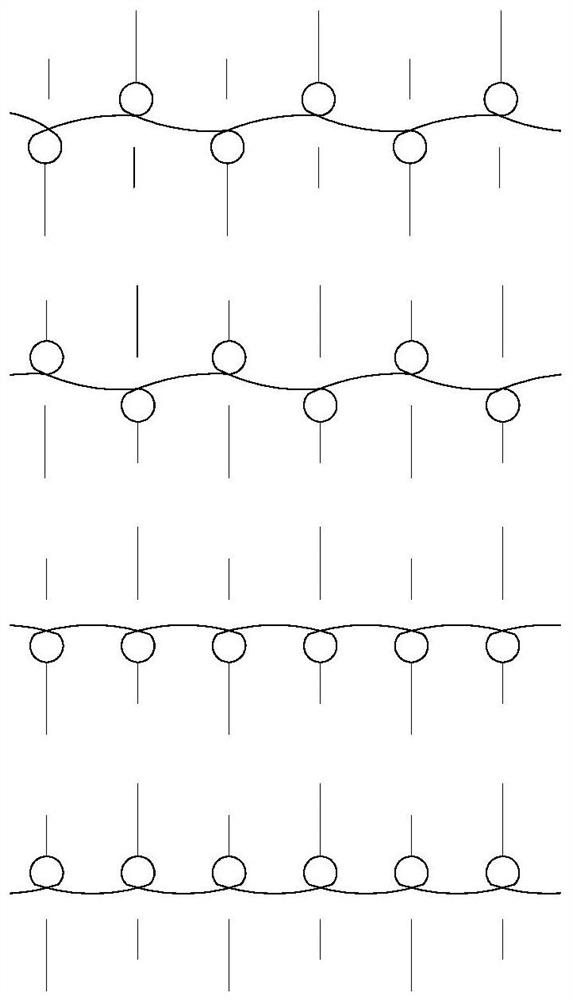

Cotton coated yarn collar and production method thereof

The invention relates to a collar, in particular to a cotton coated yarn collar and a production method thereof. The collar is woven by adopting the following components in percentage by weight: 52 to 56 percent of cotton yarns, 27 to 31 percent of polyester yarns and 15 to 19 percent of polyurethane coated yarns. Compared with the prior art, the invention has the advantages that: the polyester yarns and the polyurethane coated yarns with low cost are adopted for greatly substituting cotton yarns to weave the collar, and the performance of the produced cotton coated yarn collar is even superior to that of a pure cotton collar, so that the production cost of the collar is greatly reduced, the collar is hardwearing and durable, and the market competitiveness of the collar is improved; and proved by detection, the produced collar keeps the original appearance of the pure cotton collar, is close to the skin and comfortable, has thermal insulation property and air permeability, is light, elastic, stiff and smooth, and is not easily deformed or pilled.

Owner:泉州市劲超针织实业有限公司

Method for producing balling resistant cashmere sweater

InactiveCN100404741CIncrease binding forceNot easy to pillingWeft knittingFibre treatmentYarnEngineering

The production process of no-pilling cashmere sweater includes the following steps: 1. selecting cashmere fiber material of fineness 14-16 micron and length 28-34 mm; 2. spinning, which has twisting step to form single yarn with twist of 450-500 / m and for common cashmere yarn of 35.7x2-41.7x2 tex fineness, doubling with twist of 248-340 / m and twist direction of s direction, and doubling / single yarn twist ratio of 0.55-0.68; 3. knitting cashmere sweater pieces in one flat knitting machine; 4. sewing the pieces in sewing machine into cashmere sweater in the required style; and 5. finishing. The present invention is superior to background technology, which has the technological problems of fuzzing and pilling.

Owner:XI'AN POLYTECHNIC UNIVERSITY

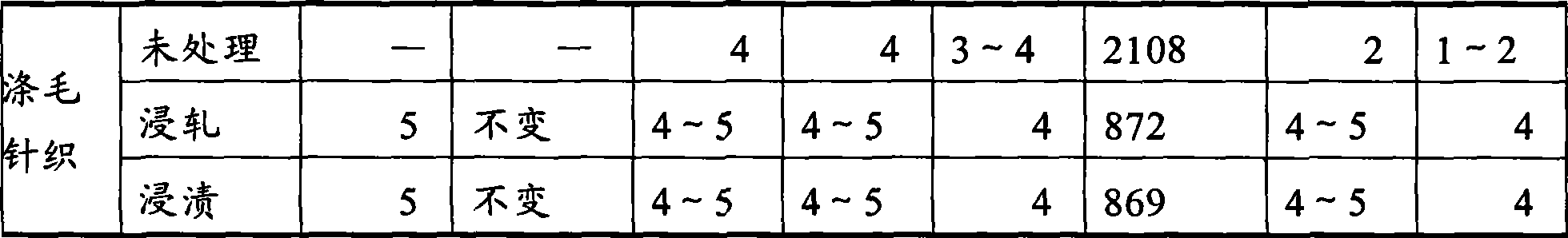

Finishing agent endowing modal knitted fabrics with antibacterial property and pilling resistance and finishing method of finishing agent

ActiveCN103243565BImprove antistatic performancePrevent slippingBiochemical fibre treatmentVegetal fibresCelluloseEngineering

The invention discloses a finishing agent endowing modal knitted fabrics with antibacterial property and pilling resistance and a finishing method of the finishing agent. The finishing agent is prepared from cellulose, chitosan and a softening agent respectively occupying 1-3%, 0.5-1% and 2-3% of the fabrics in percentage by weight. According to the finishing agent, the modal knitted fabrics have antibacterial property, and at the same time, the pilling resistance grade is up to 3-4.

Owner:南通金滢纺织产品检测中心有限公司

An antibacterial knitted fabric

ActiveCN112458605BHigh antibacterial rateNot easy to pillingWeft knittingBiochemical fibre treatmentPolymer scienceAnti bacterial

The invention discloses an antibacterial knitted fabric and a preparation process thereof. The knitted fabric is composed of 75D / 48F Solona high-elastic monofilament, 50D / 48F Solona high-elastic monofilament and 20D spandex bare silk weft It is braided to form a fiber longitudinal network with fine network points, and the antibacterial auxiliary agent is distributed in the fiber longitudinal network. The knitted fabric woven by the present invention has a high antibacterial rate, can maintain good warmth retention and elasticity while maintaining lightness, is not easy to fluff and pilling, and can give consumers a great comfortable experience; at the same time, through the weft knitting machine The knitted fabric produced has a good cotton touch, high elasticity and recovery, is not easy to pilling, and has a good wearing experience.

Owner:厦门欣思源新材料科技股份有限公司

Process for producing hot rolling thin nonwoven fabric

The invention discloses a process for producing hot rolling thin nonwoven fabric, sequentially comprising the following steps of: feeding cotton, mixing cotton, adding ES fiber (ethylene-propylene side by side) in fiber raw material, opening, carding, lapping, hot rolling, cooling, testing, reeling into products, weighing and warehousing. The process disclosed by the invention has the advantages that: ES fibers are added, thus washing fastness of the supported hot rolling thin nonwoven fabric is greatly improved compared with a common nonwoven fabric, and the supported hot rolling thin nonwoven fabric is resistant to pilling; the cloth cover of a base fabric is smoother and the fastness is greatly improved, the washing fastness, washing shrinkage and heating shrinkage are all obviously improved, and the quality is above the national textile industry standard FZ / T6004-93.

Owner:HANGZHOU JINMUZHI GARMENT ACCESSORIES

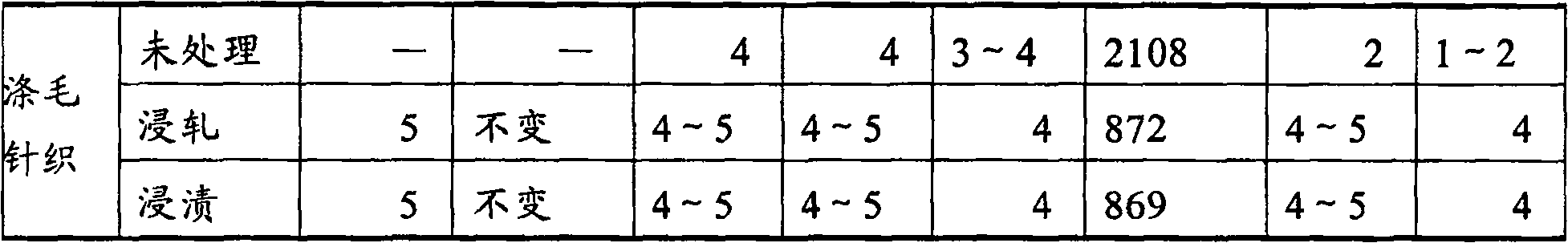

A high-count and high-density feather-proof fabric and its processing method

ActiveCN104894724BEasy to organizeSoft touchBiochemical fibre treatmentWoven fabricsTextile technologyPolymer science

The invention relates to a high-count, high-density feather-proof fabric and a processing method thereof, belonging to the technical field of textiles. The fabric is woven from warp yarns and weft yarns, and the warp and weft yarns are all selected from cotton yarns. The cotton yarns have a yarn count of 80S-100S and are woven according to plain weave. The processing method includes the following steps carried out in sequence: warping → sizing → threading → reeding → weaving → singeing → desizing → scouring → bleaching → sanding → windproof finishing → shaping → preshrinking. The fabric has the characteristics of lightness, softness, low noise, delicate hand feeling, and good windproof and featherproof performance.

Owner:JIANGSU GOLDSUN TEXTILE SCI & TECH

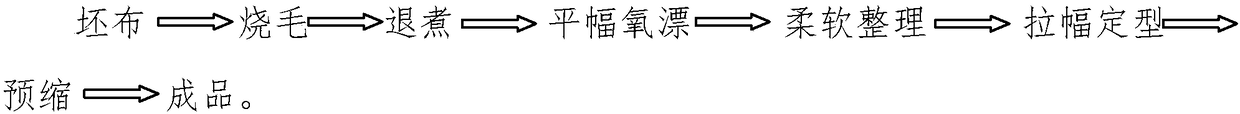

Green and environment-friendly fabric interwoven by Lyocell filament and staple fiber yarn and preparing method of green and environment-friendly fabric

The invention relates to green and environment-friendly fabric interwoven by Lyocell filament and staple fiber yarn and a preparing method of the green and environment-friendly fabric. Regarding the green and environment-friendly fabric interwoven by the Lyocell filament and the staple fiber yarn, the Lyocell filament serves as warp, cellulose fiber stable fiber yarn serves weft, and the green andenvironment-friendly fabric is processed through weaving. The preparing method of the green and environment-friendly fabric comprises the steps of 1, selecting Lyocell FDY (fully-drawn-yarn) and cellulose fiber stable fiber yarn as raw materials; 2, beaming the Lyocell filament; 3, sizing the Lyocell filament; 4, re-beaming the Lyocell filament; 5, leasing the Lyocell filament; 6, drafting and reeding the Lyocell filament; 7, weaving into the fabric. The fabric is high in degradability, and has excellent water absorption performance, draping and abrasive resistance, and is not prone to pilling, high in fastness and little in colored light change; the warp serves as the filament, the spinning process is omitted, the energy and labor are saved, the preparing cost is low, and the method is simple and suitable for industrialized production.

Owner:NINGBO XINDACHANG WEAVING

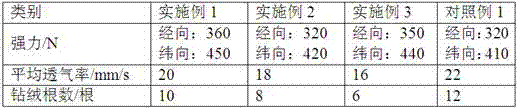

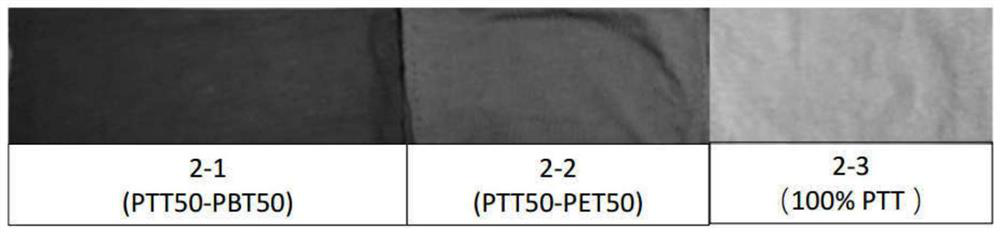

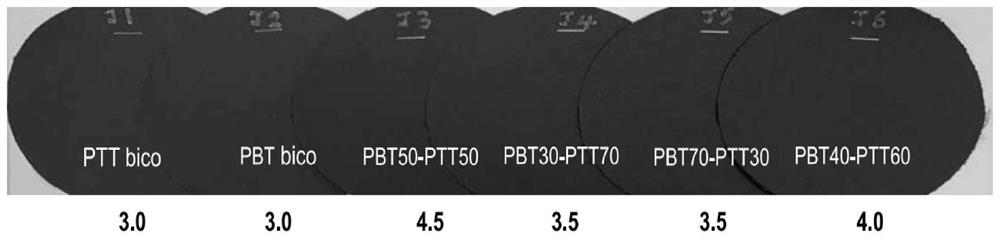

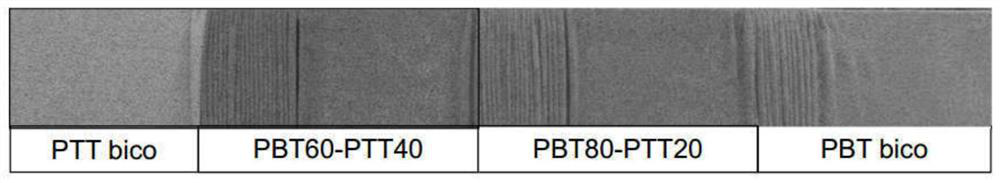

Chemical fiber material prepared from mixed polyester

PendingCN114717684AEasy to processUniform meltingDyeing processConjugated synthetic polymer artificial filamentsPolyesterFiber

The invention relates to a chemical fiber material made of at least one polyester and at least one other polyester, a preparation method and application thereof. The chemical fiber material has acceptable physical characteristics such as good dyeing performance, good hand feeling and the like, has industrial feasibility and is relatively low in cost. The invention also relates to fabrics and / or other products made of the chemical fiber material.

Owner:DU PONT CHINA HLDG CO LTD

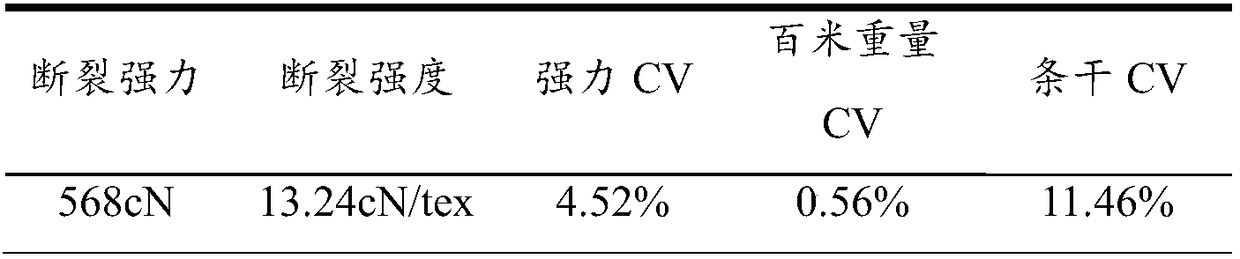

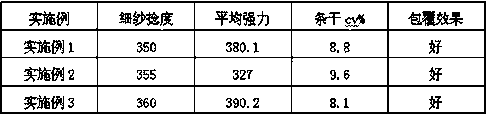

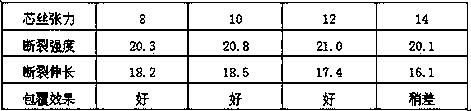

A special skeleton composite new material yarn and its preparation method

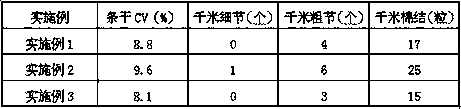

The invention provides a special skeleton composite new material yarn and a preparation method therefor. The yarn comprises outer wrapping fibers and core yarn fibers. The yarn is characterized in that the yarn evenness CV is 8.1-9.6%, the number of thin segments in one thousand meters is 0-1, the number of nubs in one thousand meters is 3-6, and the number of neps in one thousand meters is 16-25. The invention also provides a preparation method for the special skeleton composite new material yarn. The method comprises an outer wrapping fiber raw material pretreatment step of performing spraying pretreatment on outer wrapping fiber raw materials by using a composite oil agent. The composite oil agent comprises, in weight percentage, 4-6% of silica sol, 3-5% of glycerinum, 18-20% of an antistatic agent, 15-17% of peregal, and 51-57% of water, wherein the temperature of water is 45-50 DEG C. The prepared skeleton composite new material yarn is characterized by constant wrapping tension maintenance and favorable wrapping, and is free of such quality problems as naked threads, hollow yarns and thread loop noses.

Owner:潍坊四棉纺织有限公司

Flame-retardant aramid fiber and cotton blended knitted fabric

The invention relates to a flame-retardant aramid fiber and cotton blended knitted fabric. 85% of flame-retardant aramid fibers and 15% of cotton fibers are selected as raw materials and spun by adopting a siro spinning and compact spinning combined spinning method and then the fabric is woven. An antistatic agent is adopted to pretreat flame-retardant aramid fibers before spinning, the flame-retardant aramid fibers are placed for 7-9 hours or longer and the yarns are lubricated and waxed during weaving. According to the flame-retardant aramid fiber and cotton blended knitted fabric, the yarnsare formed by blending the flame-retardant aramid fibers and the cotton fibers so that the fabric has the advantages of softness, smoothness and good hygroscopicity of the cotton fabric and has a certain flame-retardant property.

Owner:JIANGSU YUNFU FASHION CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com