A special skeleton composite new material yarn and its preparation method

A new material and skeleton technology, applied in the direction of yarn, plant fiber, fiber treatment, etc., can solve problems such as poor coating of skeleton composite materials, achieve good appearance, good moisture absorption, and improve cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

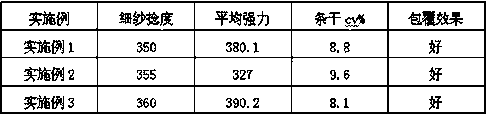

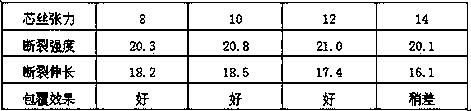

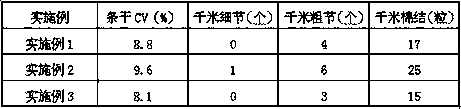

Examples

Embodiment 1

[0042] Example 1 A special skeleton composite new material yarn and its preparation method

[0043] Include the following steps:

[0044] Step 1 raw material selection

[0045] (1) Yarn outsourcing fiber raw materials

[0046] The outsourcing fiber raw material is cotton fiber;

[0047] The cotton fiber: high-quality Xinjiang long-staple cotton, grade 1, length 37.00mm, micronaire value 4.15, single fiber breaking strength 48.52cN / tex, uniformity 87.81%, short fiber 10.3%, moisture regain 6.93%, containing impurities 3.7%;

[0048] (2) Yarn core fiber raw material

[0049] The core fiber is a polyester filament fiber;

[0050] The polyester filament fiber: linear density 100dtex, root number 48F, dry breaking strength 3.88cN / tex, dry elongation at break 29.3%;

[0051] Among the outsourcing fiber raw materials and the core fiber raw materials, the quality of the outsourcing fibers accounts for 45% of the total raw material mass, and the core fiber accounts for 55% of the...

Embodiment 2

[0078] Example 2 A special skeleton composite new material yarn and its preparation method

[0079] Include the following steps:

[0080] Step 1 raw material selection

[0081] (1) yarn outsourcing fiber

[0082] The outsourcing fiber raw material includes cotton fiber and modal fiber;

[0083] The cotton fiber: high-quality Xinjiang long-staple cotton, grade 1, length 37.00mm, micronaire value 4.15, single fiber breaking strength 48.52cN / tex, uniformity 87.81%, short fiber 10.3%, moisture regain 6.93%, containing impurities 3.7%;

[0084] The modal fiber: the modal specification is 1.3dtex*39mm, the dry breaking strength is 3.5cN / dtex, and the moisture regain is 9.98%.

[0085] (2) Yarn core fiber

[0086] The core fiber raw material adopts nylon filament fiber;

[0087] The nylon filament fiber has a linear density of 100dtex, a root number of 48F, a dry breaking strength of 5.18cN / tex, and a dry breaking elongation of 20.5%.

[0088] Among the outsourcing fiber and c...

Embodiment 3

[0114] Example 3 A special skeleton composite new material yarn and its preparation method

[0115] Include the following steps:

[0116] Step 1 raw material selection

[0117] (1) yarn outsourcing fiber

[0118] The outsourcing fiber raw material comprises bamboo cellulose fiber and fine denier polyester fiber;

[0119] The bamboo cellulose fiber: the specification is 1.33dtex*38mm, the dry breaking strength is 2.52cN / dtex, and the moisture regain is 11.2%.

[0120] The fine-denier polyester fiber: the specification of the fine-denier polyester is 0.89dtex*38mm, the dry breaking strength is 6.22cN / dtex, and the moisture regain is 0.36%.

[0121] (2) Yarn core fiber

[0122] The yarn core fiber raw material is polyester filament fiber;

[0123] The polyester filament fiber: linear density 100dtex, root number 48F, dry breaking strength 3.88cN / tex, dry elongation at break 29.3%.

[0124] Among the outsourcing fiber and core fiber raw materials, bamboo cellulose fiber acco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| twist factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com