Anti-fuzzing and anti-pilling clothing detergent

A laundry detergent and anti-pilling technology, applied in the directions of detergent compounding agent, detergent composition, surface active detergent composition, etc. The effect of improving the finish

Inactive Publication Date: 2020-04-17

南京市检捷生物信息科技有限公司

View PDF5 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, in the actual operation process, due to the need for certain process conditions when the existing finishing agent is applied to the fabric, it is difficult to meet the dyeing requirements in the normal temperature and pressure stirring and washing process

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

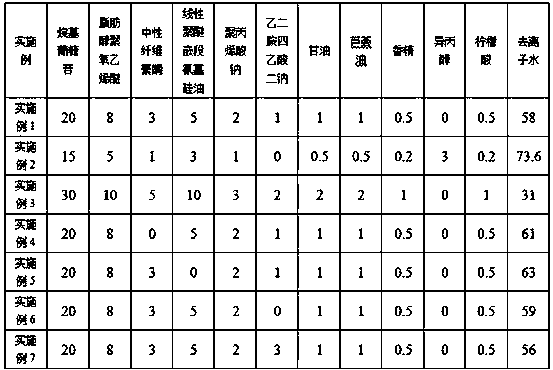

Embodiment 2~7

[0027] The compounding process of Examples 2 to 7 is the same as in Example 1, wherein, what is used in Example 7 is the compounding of anionic surfactant and nonionic surfactant, and the compounding process of alkyl glucoside in Example 7 in the table below The corresponding numerical value is sodium dodecylbenzenesulfonate, and its specific raw material components (unit: mass percent) are as follows:

[0028]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses an anti-fuzzing and anti-pilling clothing detergent, and belongs to the field of multifunctional detergents. The detergent comprises, by weight, 20-40 parts of a nonionic surfactant, 1-5 parts of cellulase, 3-10 parts of high-hydrogen silicone oil, 0-2 parts of ethylenediamine tetraacetic acid disodium salt, 1-3 parts of sodium polyacrylate, 1-3 parts of glycerol, 1-3 partsof aloe oil, 0.2-1 part of essence, 0.2-1 part of citric acid and 34-71 parts of deionized water. A certain amount of cellulase is added into the detergent, and the smoothness of the surface of fabric is improved through bio-enzyme finishing, so that the anti-fuzzing and anti-pilling effects are achieved; and a small amount of high-hydrogen-content silicone oil is used for assistance, and the silicone oil is uniformly cross-linked and gathered on the surface of the fabric, so that the fiber end is adhered to yarns, and the anti-fuzzing and anti-pilling effects are not prone to occuring duringfriction.

Description

technical field [0001] The invention belongs to the field of multifunctional cleaning agents, in particular to a laundry detergent for anti-pilling. Background technique [0002] During the wearing process of the fabric, especially during the washing process, due to the fabric itself and the friction between various external forces and the outside world, before obvious damage occurs, some microfibers will break away from their crystallization area and gather and wind on the surface of the fiber. Pompoms are formed, so there will be varying degrees of pilling. Fabric pilling not only affects the aesthetic feeling of clothing, but also reduces wearing performance and wearing fastness. Although some high-grade fabrics will be finished with anti-pilling after fabric dyeing, silicone oil or resin will penetrate, enter and fix inside the fiber through padding, drying and other processes, and resin, silicone oil and other finishing agents will be used as bonding points, limiting ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C11D1/825C11D1/83C11D3/60C11D3/386C11D3/33C11D3/37C11D3/382C11D3/20C11D3/50

CPCC11D1/22C11D1/662C11D1/721C11D1/825C11D1/83C11D3/2017C11D3/2065C11D3/2086C11D3/33C11D3/3742C11D3/3765C11D3/382C11D3/38645C11D3/50

Inventor 余根芳

Owner 南京市检捷生物信息科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com