High-density plain looped pile all-in-one pants and making method thereof

An integrated, terry technology, applied in trousers, textiles, papermaking, clothing, etc., can solve the problems of rough surface, unsuitable for outer wear, and difficult to wear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to describe the present invention in more detail, reference is made below to the accompanying drawings.

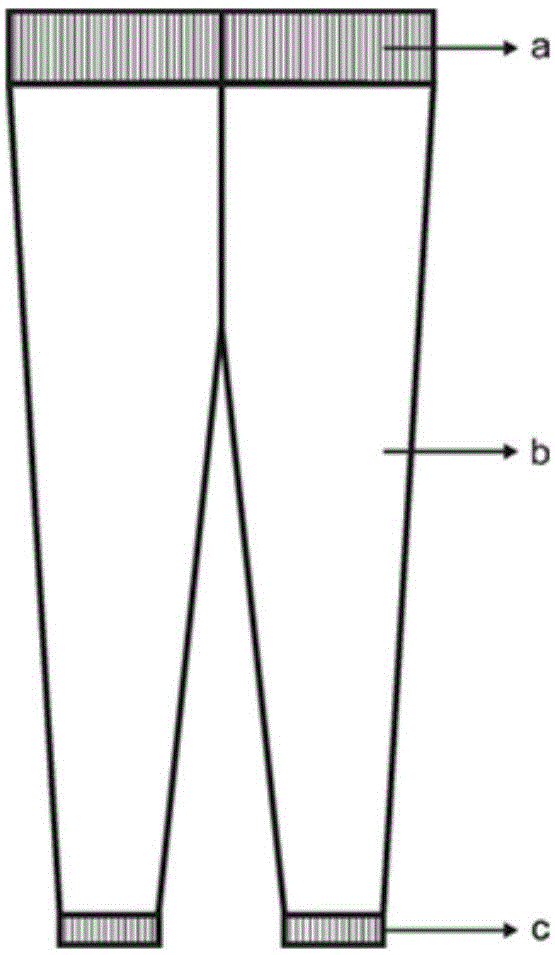

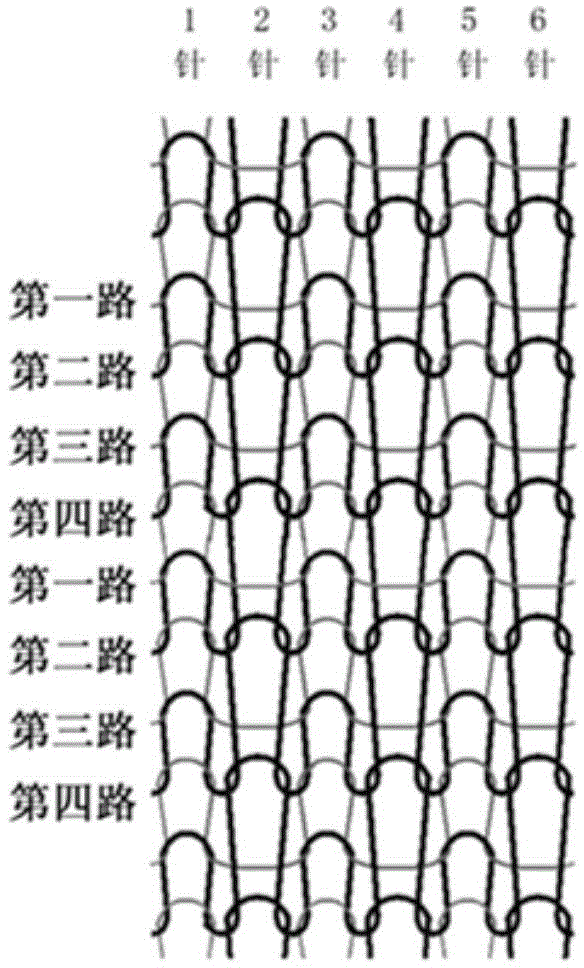

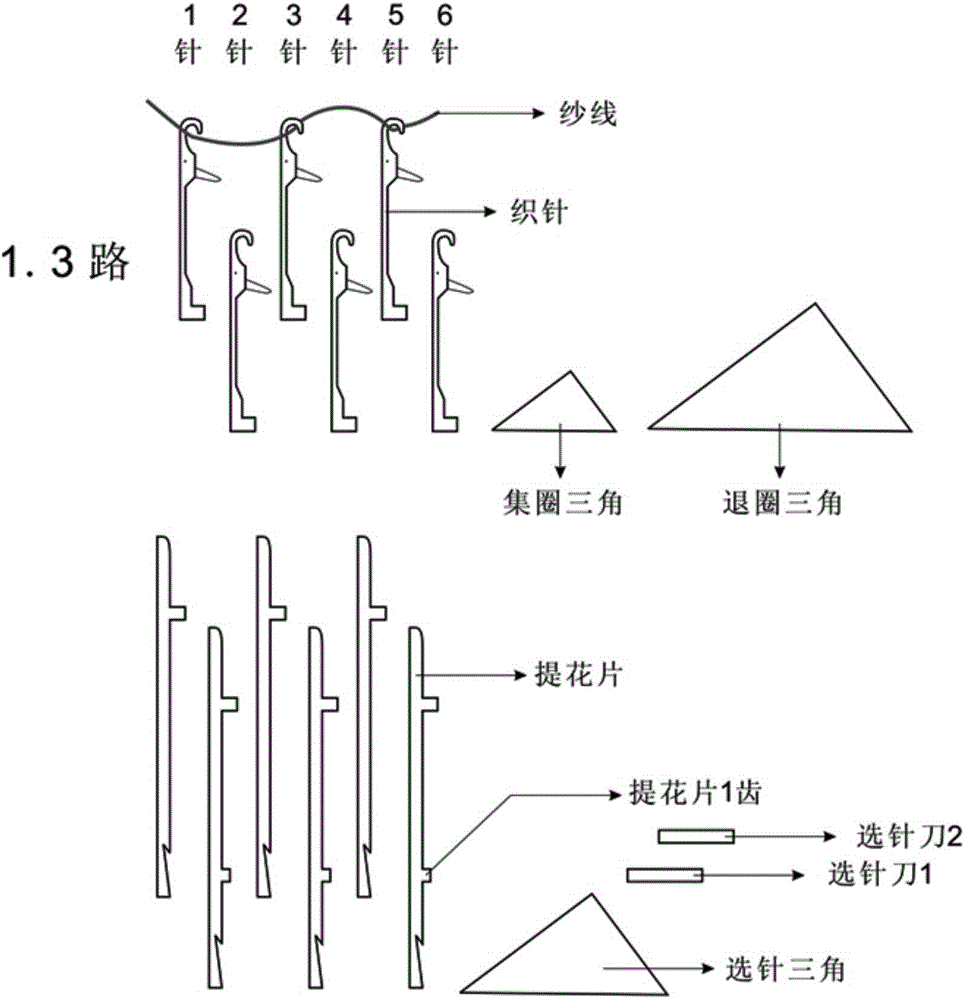

[0035] like figure 1 As shown, the all-in-one trousers of the present invention are composed of a trouser waist a, a trouser body b and a trouser leg c. Among them, trousers waist a and trousers c are woven with a four-way incoming thread stocking machine, and 1*1 fake rib weave is used to weave double-layer tie. like Picture 1-1 As shown in the schematic diagram of 1*1 false rib structure, the 1st, 3rd, 5... odd-numbered stitches form a loop, and the 2, 4, 6... even-numbered stitches do not form a loop to form a floating thread; the second and fourth way Stitch all in a loop; then repeat the knitting. To achieve such an organization, such as Figure 1-2 As shown, remove 1 tooth of 1, 3, 5... odd-numbered jacquard pieces, leave 1 tooth of 2, 4, 6... Needle knife 2 quits working. On the one hand, because 2, 4, 6... even-numbered jacquard pieces have 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com