Production process of copper ion modified polyester staple fiber socks

A polyester staple fiber and production process technology, which is applied in the production process field of copper ion modified polyester staple fiber socks, can solve the problems of single material of socks, unreasonable processing technology, reduction of new materials, etc., and achieve simple operation of the production process and easy Mass production, not easy to fluff and pilling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

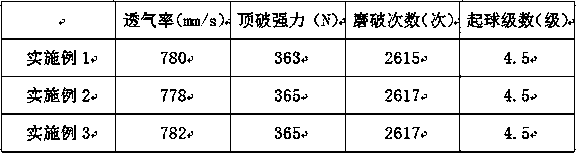

Examples

Embodiment 1

[0017] A production process of copper ion modified polyester staple fiber socks, through the selection of raw materials, hosiery knitting, seaming and shaping processes, the production process of copper ion modified polyester staple fiber socks is completed; the specific steps are as follows:

[0018] (1) Selection of raw materials: Copper ion modified polyester staple fiber yarn and spandex filament are selected as raw materials, and the mass ratio of copper ion modified polyester staple fiber yarn to spandex filament is 97%: 3%; The linear density of copper ion modified polyester staple fiber yarn is 18.5tex, and the linear density of spandex filament is 90dtex; the raw material of socks body is copper ion modified polyester staple fiber yarn, and the raw material of socks opening is copper ion modified polyester staple fiber yarn The arrangement ratio with spandex filament is 1:1;

[0019] (2) Socks weaving: Soosan SS-604 hosiery machine is used to weave the sock body and s...

Embodiment 2

[0023] A production process of copper ion modified polyester staple fiber socks, through raw material selection, spinning, hosiery knitting, seaming and shaping processes, the production process of copper ion modified polyester staple fiber socks is completed; the specific steps are as follows:

[0024] (1) Selection of raw materials: Copper ion modified polyester staple fiber yarn and spandex filament are selected as raw materials, and the mass ratio of copper ion modified polyester staple fiber yarn to spandex filament is 97%: 3%; The linear density of copper ion modified polyester staple fiber yarn is 18.5tex, and the linear density of spandex filament is 90dtex; the raw material of socks body is copper ion modified polyester staple fiber yarn, and the raw material of socks mouth is copper ion modified polyester staple fiber yarn The arrangement ratio with spandex filament is 1:1;

[0025] (2) Socks weaving: Soosan SS-604 hosiery machine is used to weave the sock body and s...

Embodiment 3

[0029] A production process of copper ion modified polyester staple fiber socks, through raw material selection, spinning, hosiery knitting, seaming and shaping processes, the production process of copper ion modified polyester staple fiber socks is completed; the specific steps are as follows:

[0030] (1) Selection of raw materials: Copper ion modified polyester staple fiber yarn and spandex filament are selected as raw materials, and the mass ratio of copper ion modified polyester staple fiber yarn to spandex filament is 97%: 3%; The linear density of copper ion modified polyester staple fiber yarn is 18.5tex, and the linear density of spandex filament is 90dtex; the raw material of socks body is copper ion modified polyester staple fiber yarn, and the raw material of socks mouth is copper ion modified polyester staple fiber yarn The arrangement ratio with spandex filament is 1:1;

[0031] (2) Socks weaving: Soosan SS-604 hosiery machine is used to weave the sock body and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com