Heating red bean velvet fabric

A technology of red bean velvet and fabric, which is applied in the direction of trimming, application, and roughening of the fabric surface, which can solve the problems of thickness, poor air permeability, and bloat, and achieve the effect of improving thermal performance, soft touch, and enhancing thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

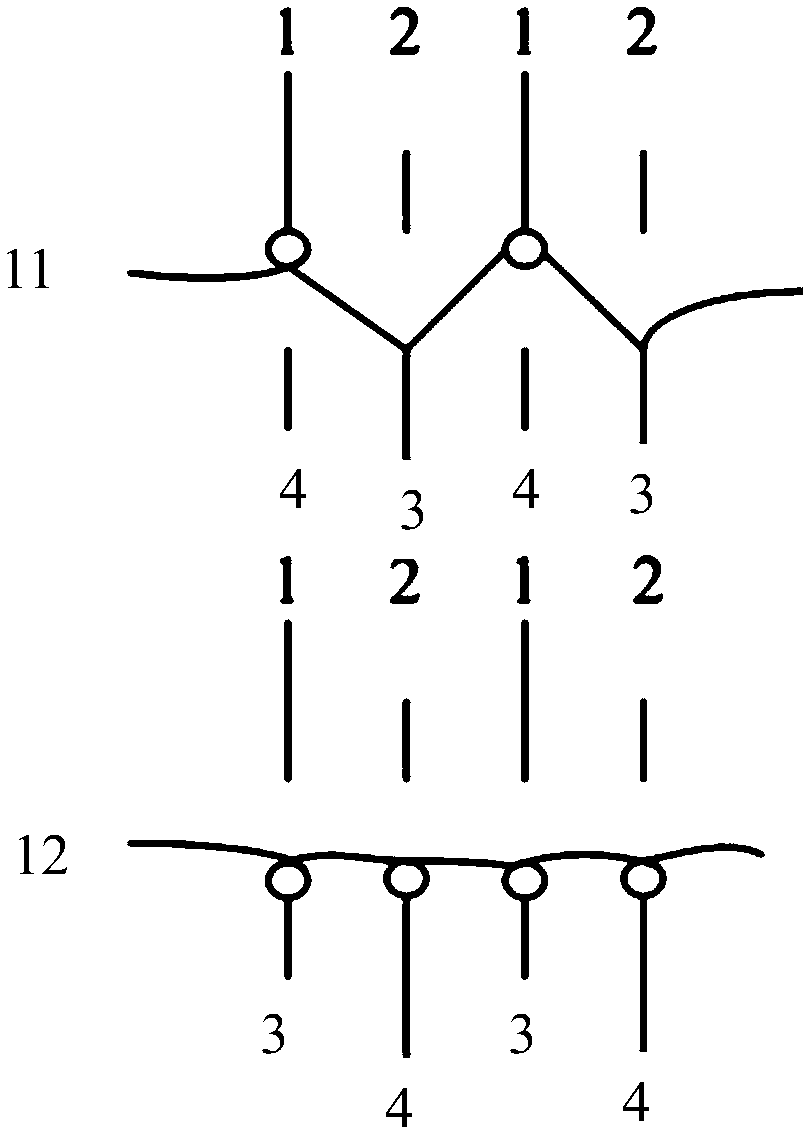

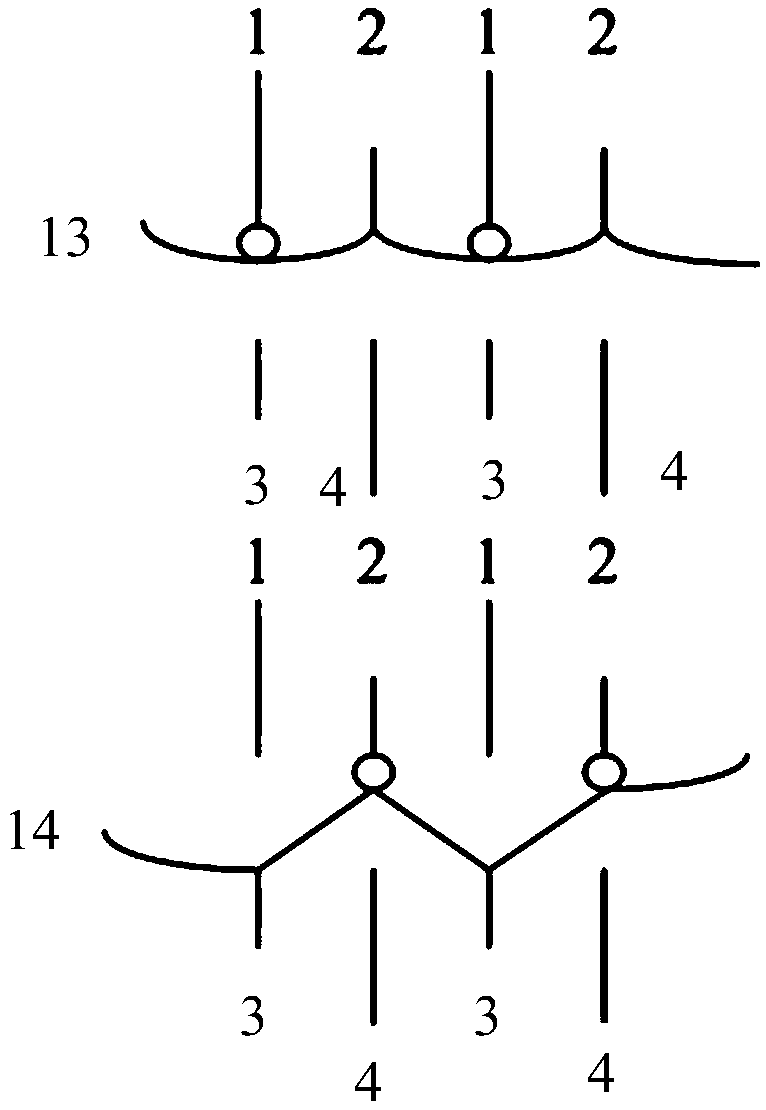

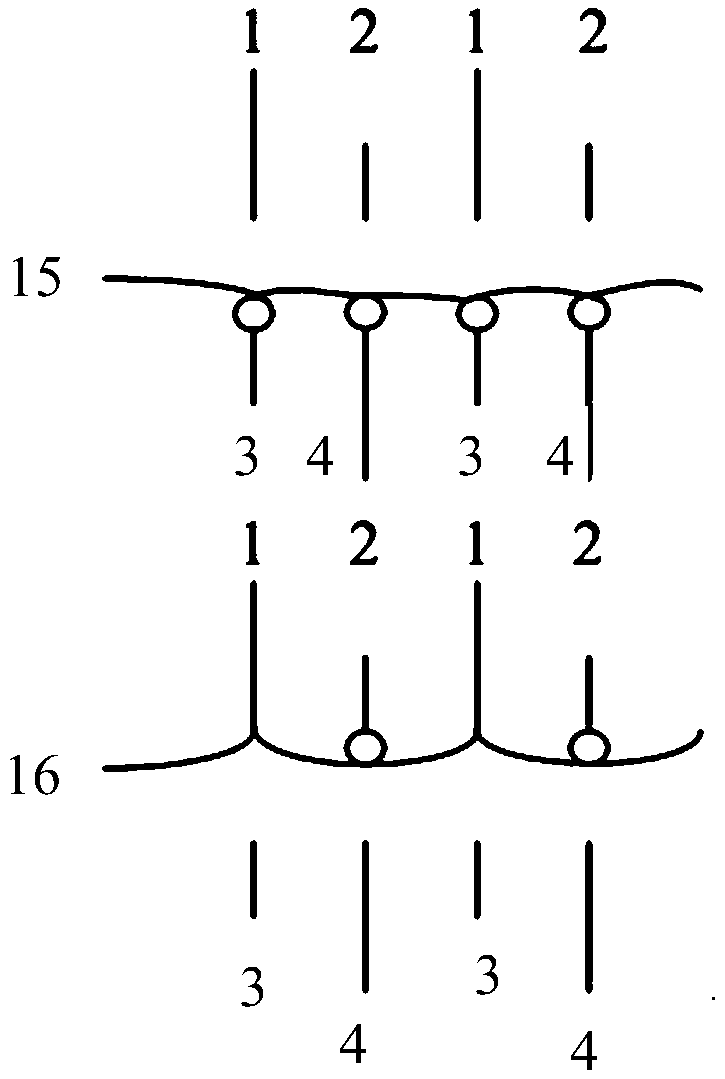

[0031] A heating red bean velvet fabric is woven on a double-sided weft knitting machine with a gauge of 24 needles per inch. The weaving structure is shown in the attached drawing.

[0032] The first yarn 11 adopts heat-generating functional yarn, which is 50S 70 / 30 viscose / acrylic blended yarn. The high needle 2 of the upper dial is knitted into a circle, and the low needle 2 of the upper dial is not involved in knitting to form a floating thread. Needle 4 does not participate in knitting to form a floating thread, and needle 3 in the lower needle cylinder participates in knitting but does not form a loop and becomes a tuck;

[0033] The second yarn 12 adopts 40S combed cotton yarn, 40D spandex and cotton yarn are fed into the weaving fabric together to form loops on the surface layer of the fabric, and the high needle 1 of the upper dial and the low needle 2 of the upper dial do not participate in weaving to become floating threads. The low needle 3 of the needle cylinder a...

Embodiment 2

[0044] A heating red bean velvet fabric is woven on a double-sided weft knitting machine with a gauge of 28 needles per inch. The weaving structure is shown in the attached drawing.

[0045] The first yarn 11 adopts heat-generating functional yarn, which is 50S 70 / 30 viscose / acrylic blended yarn. The high needle 2 of the upper dial is knitted into a circle, and the low needle 2 of the upper dial is not involved in knitting to form a floating thread. Needle 4 does not participate in knitting to form a floating thread, and needle 3 in the lower needle cylinder participates in knitting but does not form a loop and becomes a tuck;

[0046]The second yarn 12 adopts 40S combed cotton yarn, 40D spandex and cotton yarn are fed into the weaving fabric together to form loops on the surface layer of the fabric, and the high needle 1 of the upper dial and the low needle 2 of the upper dial do not participate in weaving to become floating threads. The low needle 3 of the needle cylinder an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com