Cotton coated yarn collar and production method thereof

A production method and cotton yarn technology, applied in textiles, clothing, applications, etc., can solve the problems of flat knitting manufacturers having no profit margins, rising prices of flat knitting machines, and insufficient supply of raw materials, so as to improve market competitiveness, increase sweat absorption, Strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The cotton-covered silk collar of the present invention, taking the T-shirt collar as an example, adopts 2 strands of 40S cotton yarn + 2 strands of 75D / 72F polyester yarn + 1 strand of 40 / 75 spandex polyester-covered yarn, and the ingredients are 54%, 29%, and 17% respectively , Both cotton yarn and polyester yarn are single yarn.

[0020] The weaving method adopts 2 strands of 40S pure cotton, 2 strands of 75D polyester yarn and 1 strand of spandex polyester yarn, and the fabric weave adopts upper and lower plain weave.

[0021] The leading square gram weight is 630-650 grams per square meter.

[0022] The collar of the cotton-covered T-shirt is washed with water after finishing and extruded by a stenter setting machine to improve the feel of the collar and make it comfortable for the skin.

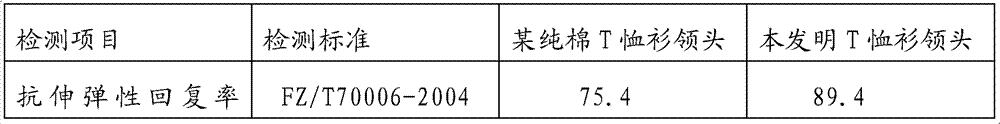

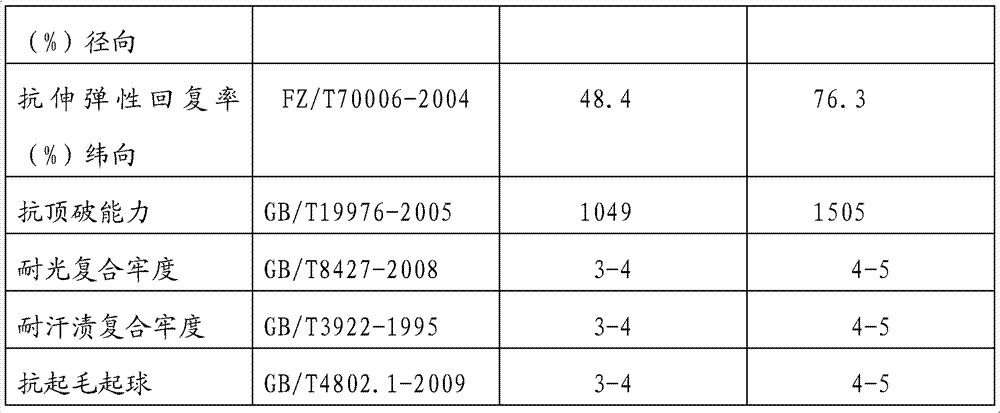

[0023] After washing, the details are as follows:

[0024] The washing aid uses Feida brand fabric bulking agent QP-37P-28 and fabric wool nitrile smoothing agent produced by X...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com