Chemical fiber material prepared from mixed polyester

A technology for chemical fibers and mixed materials, applied in the field of fabrics and/or other products and yarns, can solve the problems of difficulty in dyeing polytrimethylene terephthalate, and achieve excellent dyeing effect, excellent smoothness, and good processing feasibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] Preparation of chemical fiber materials

[0057] Unless otherwise indicated, the samples and controls in the Examples were prepared as follows.

[0058] The preparation of spinning includes mixing at least one polyester pellet, such as PTT polyester chip, and at least one other polyester particle, such as PBT polyester chip, in different ratios, such as 10 / 90, 20 / 80, 30 / 70, 40 / 60, 50 / 50, 60 / 40, 70 / 40, 80 / 20 and 90 / 10, put into the feed port of the screw extruder after physical mixing. After the material is sheared and melted in the extruder, a mixed polyester melt, such as a PTT / PBT mixed polyester melt, is obtained, and the mixed polyester melt is transported to the spinning assembly by a pump.

[0059] The mixed polyester melt can be passed through the spinning pack alone, bundled into strands to make long fibers, or cut into short fibers.

[0060] Blended polyester melts can also be co-formed with melts of other polyester fiber materials to form composite fibers...

Embodiment 1

[0082] Example 1: Preparation and physical property test of PBT / PTT mixed polyester chemical fiber

[0083] 1.1 Preparation and Characterization of Unicomponent Filaments of Uniform Composition

[0084] Polytrimethylene terephthalate (commercially available trade name Intrinsic viscosity of 1.02) chips and polybutylene terephthalate chips (intrinsic viscosity of 1.10) were physically mixed in different proportions, and the mixed polyester chips were put into the extruder from the feed port. The extruder is a single-screw extruder, which is divided into three temperature zones. The mixed polyester raw materials are heated and sheared in the extruder, melted and then passed through the spinning assembly and extruded from the spinneret. The first drawing roll and the second drawing roll are drawn and finally wound to form a fully drawn yarn (FDY) sample.

[0085] The polytrimethylene terephthalate chips alone were used as the raw material and put into the extruder, as the co...

Embodiment 2

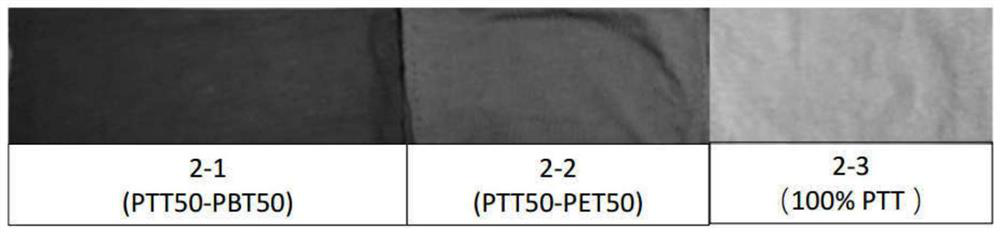

[0121] Example 2: Samples and properties of PTT mixed with different polyesters

[0122] Referring to the method in Example 1, PTT / PBT mixed polyester chemical fibers and PTT / PET mixed polyester chemical fibers were obtained. The chemical fiber using PTT alone was used as a control. The yarns of the above three kinds of chemical fiber materials are prepared by the same processing technology, and are further made into fabrics. Fabric specifications are 40s (40).

[0123] The obtained fabric was dyed, and the dyeing was carried out at a temperature of 90° C., and the procedures of heating, cooling and post-treatment were referred to the steps in Example 1. The dye was 3% Navy Blue. The dyed fabric is obtained by finishing after dyeing. Dyeing effect such as figure 1 shown.

[0124] For the above-mentioned PTT / PBT mixed polyester chemical fiber, PTT / PBT mixed polyester chemical fiber, and the control using PTT alone, the breaking strength, elongation at break, shrinkage of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com