Flexible plate die-cutting gilding press with high-precision adjusting structure

A die-cutting hot stamping machine, a technology for adjusting structure, applied in the direction of object supply, pile separation, thin material processing, etc., can solve the problem that the die-cutting hot stamping machine does not have flexible adjustment, adjustment of feeding and feeding distance, die-cutting hot stamping Solve problems such as singleness of machine to achieve the effect of improving convenience, ensuring continuity and improving practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

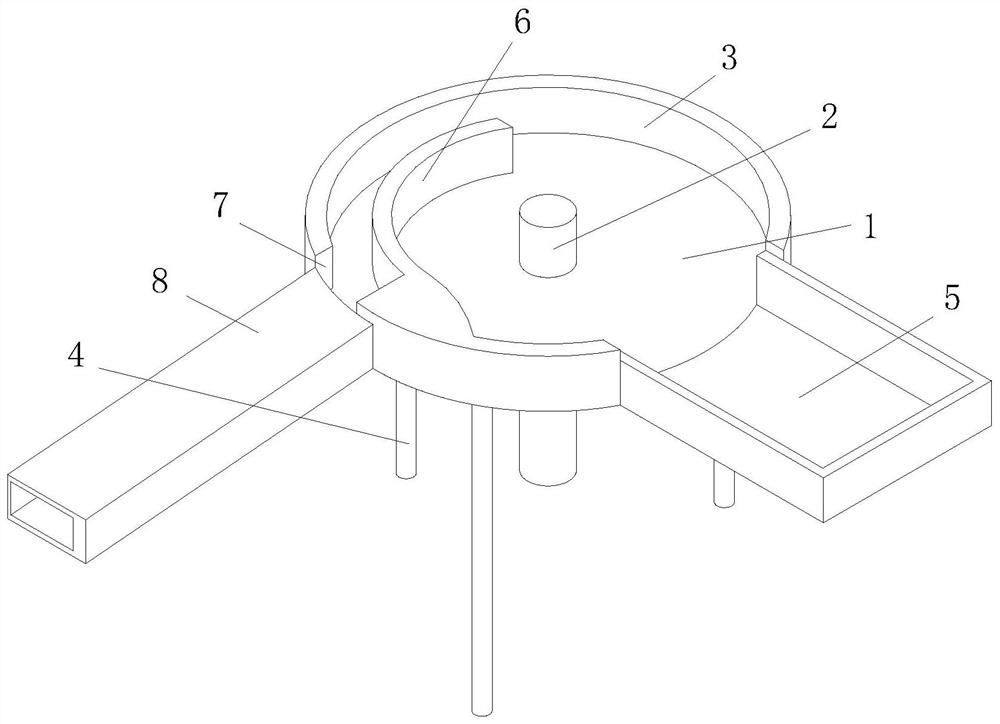

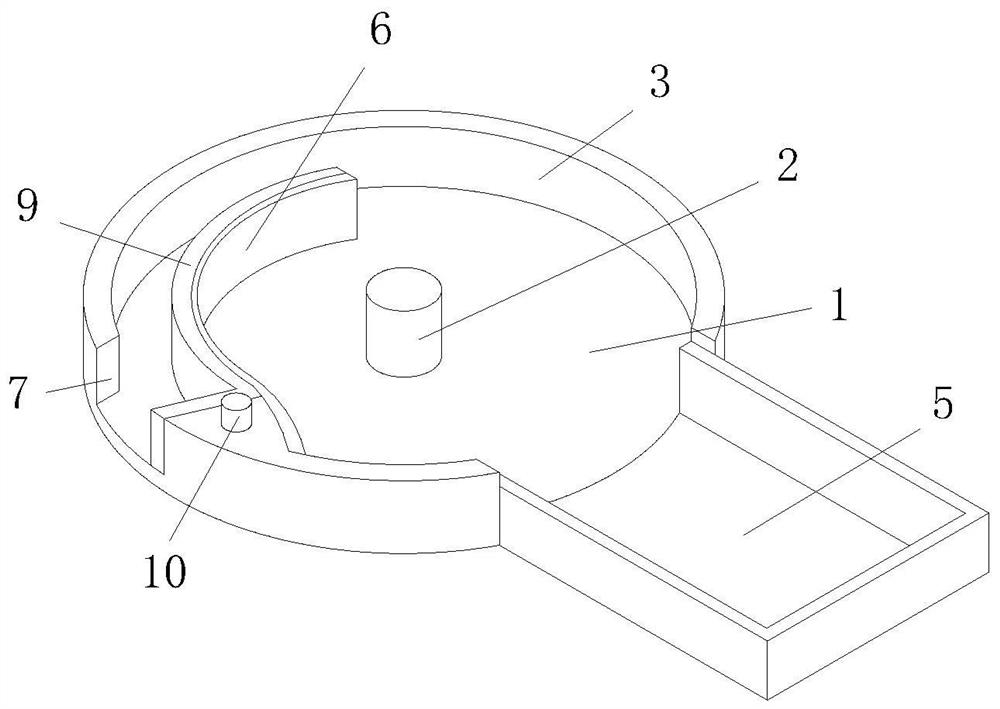

[0034] Example 1: See Figure 1-2, a flexographic die-cutting bronzing machine with a high-precision adjustment structure, including a feeding tray 1, a rotating shaft 2 is fixedly connected to the inside of the feeding tray 1, and a protective shell 3 is connected to the upper side of the feeding tray 1 for rotation, and the protective shell 3 is connected to the upper side of the feeding tray 1. The lower side of the shell 3 is fixedly connected with the support rod 4, the rear side of the protective shell 3 is fixedly connected with the placement plate 5, and the inside of the feeding tray 1 is fixedly connected with the limited-distance outer plate 6, and the lower side of the limited-distance outer plate 6 is connected with the feeding The upper side of the disc 1 is slidingly connected, the left side of the protective shell 3 is provided with a feeding port 7, the left side of the feeding disc 1 is fixedly connected with a feeding plate 8, and the left side of the distanc...

Embodiment 2

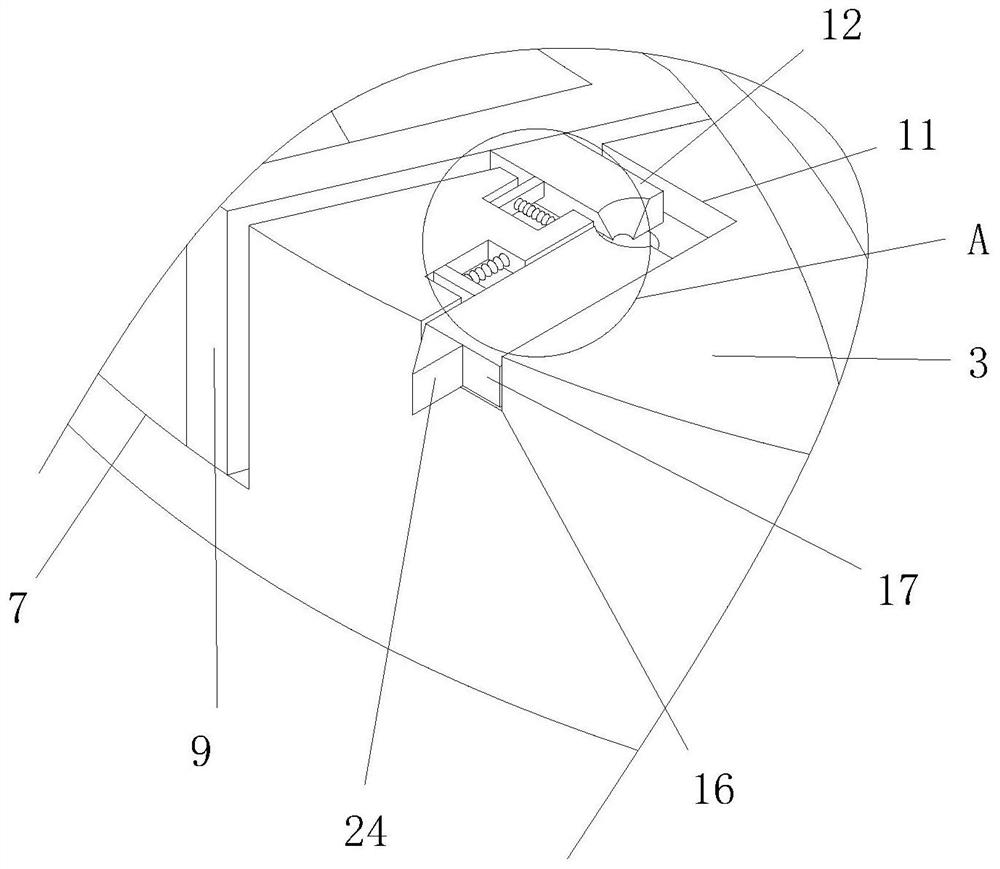

[0036] Example 2: see Figure 3-8 , on the basis of Embodiment 1, the adjustment device includes a moving plate-12, the surface of the moving plate-12 is slidingly connected to the inside of the auxiliary groove-11, and the left side of the moving plate-12 is fixedly connected to the limit plate-13, and the limit The surface of plate one 13 is slidingly connected to the inside of auxiliary groove one 11, the front side of moving plate one 12 is fixedly connected to the rear side of distance limiting inner plate 9, and the rear side of limit plate one 13 is fixedly connected with distance adjustment spring one 14 , the rear end of the distance adjustment spring one 14 is fixedly connected to the inside of the auxiliary groove one 11, the upper side of the moving plate one 12 is provided with a docking groove 15, the shape of the docking groove 15 is a quarter cone shape, and the inside of the protective shell 3 There is an auxiliary groove 16 connected with the auxiliary groove...

Embodiment 3

[0039] Example 3: See Figure 5-7 , the distance adjusting device includes a distance adjusting plate 20, the surface of the distance adjusting plate 20 is slidably connected to the inside of the feeding plate 8, the rear side of the distance adjusting plate 20 is fixedly connected with a slide bar 21, and the rear end of the slide bar 21 is slidably connected to the upper Inside the material plate 8, the surface of the slide bar 21 is slidingly sleeved with a back-moving spring 22, and the front and rear ends of the back-moving spring 22 are respectively fixedly connected to the rear side of the distance-adjusting plate 20 and the inside of the feeding plate 8. The interior is fixedly connected with a semicircular drag-reducing column 23. While the distance-adjusting column 10 is used to drive the moving plate 12 to adjust the distance-limiting inner plate 9, the distance-adjusting column 10 will push the moving plate 2 17 to drive the distance-adjusting block 24 in the auxili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com