Container for hot fill food packaging applications

a technology for food packaging and containers, applied in the field of plastic containers, can solve the problems of similar expansion and/or contraction of containers, container collapse, and container pressure reduction, and achieve the effect of not affecting the stability of containers when standing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0058] The following example is provided as a further description of one embodiment of the invention, and is not intended to be limiting.

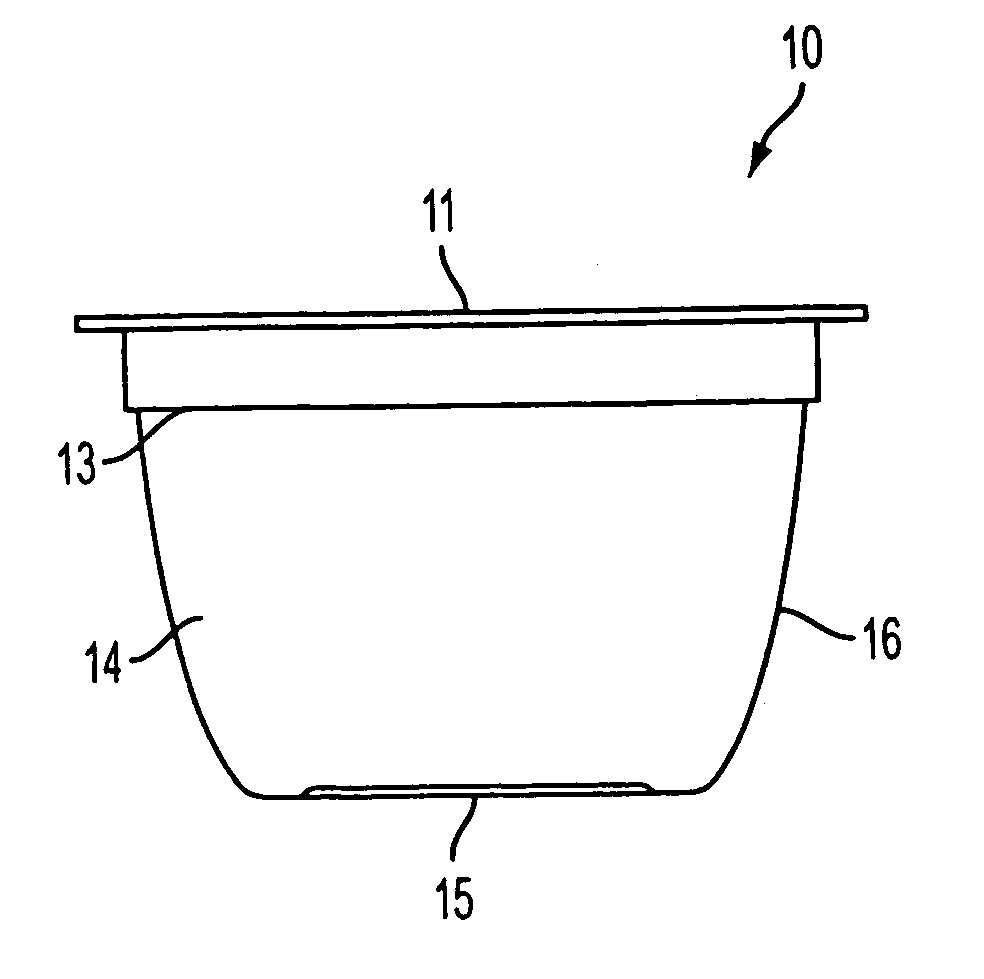

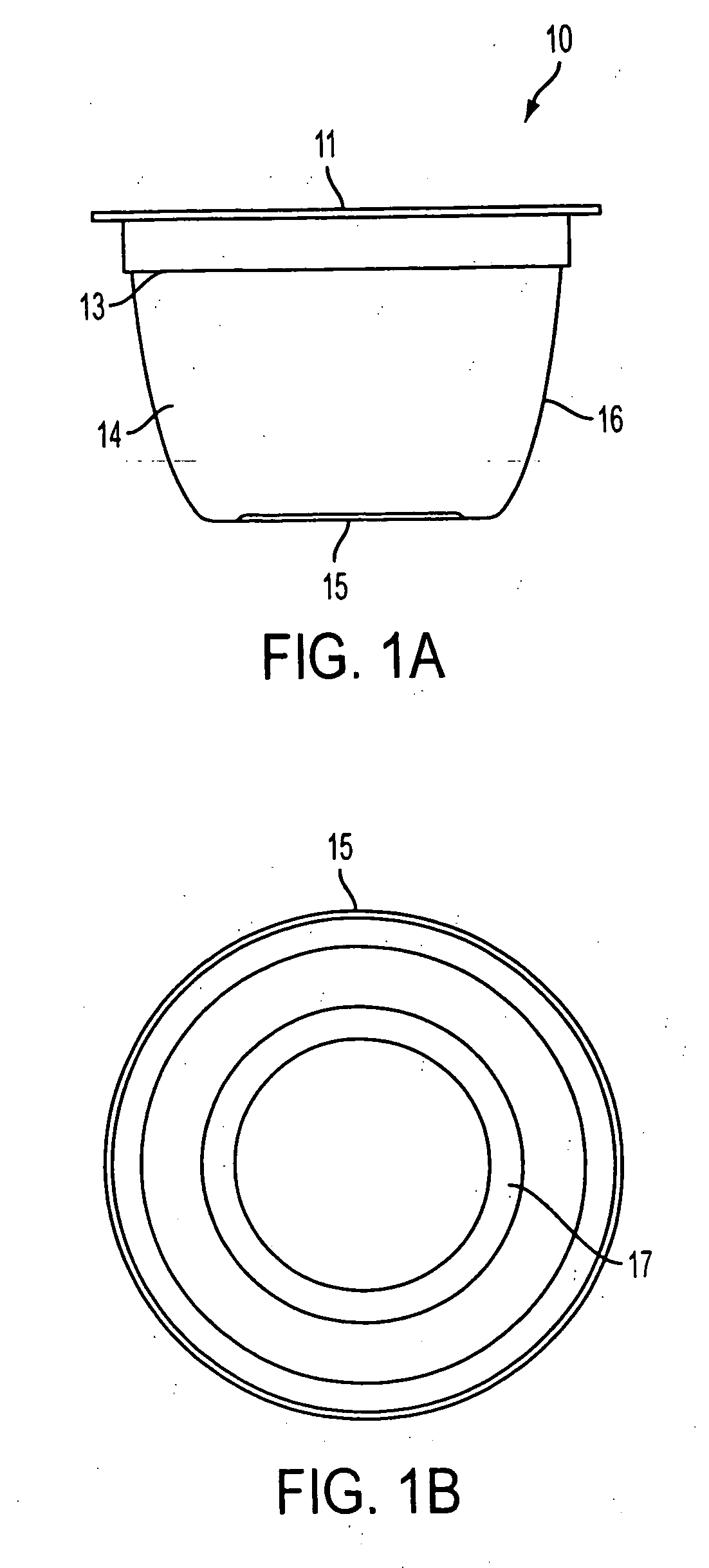

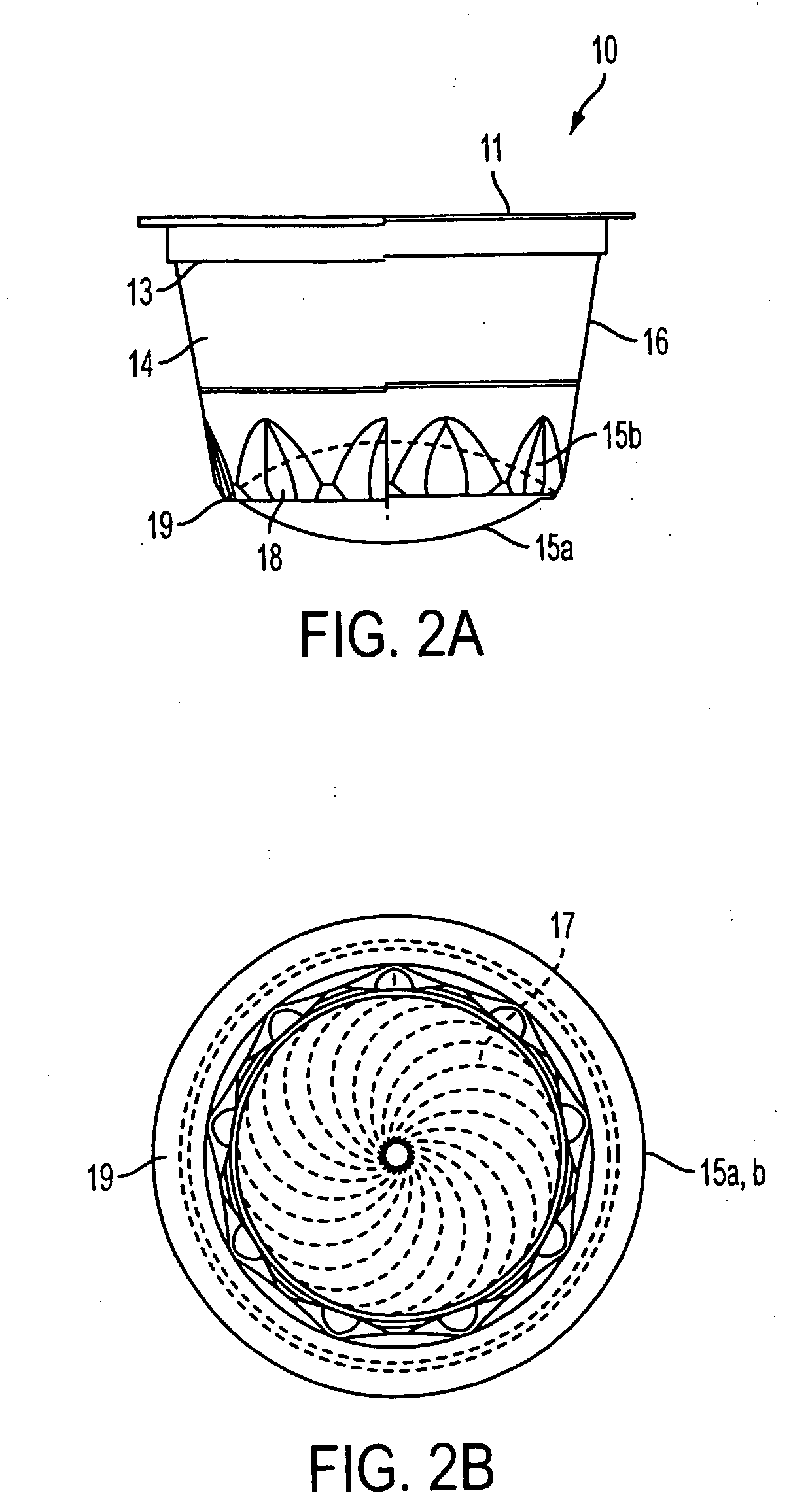

[0059] A four ounce cup was made according to the invention that corresponds to the cup depicted in FIG. 1 by the thermoforming process. The place of manufacture was Medellin, Colombia, having an altitude above sea level of about 6500 feet. Note that the forming conditions should be adjusted according to the ambient conditions of the location of the manufacturing facility.

[0060] A starting plastic multilayer sheet comprising about 70-80 volume % EVAL™ J102B resin, about 2040 volume % PROPILCO™ 03H96 PP and about 15-20 volume % Comai 745-2AS™ adhesive, based on a total thickness of the multilayer sheet of about 1.02 mm, was formed by coextrusion. The approximately 49 mm wide sheet was continuously fed at a rate sufficient to mold four ounce cups, ten cups at a time, 14 cycles per minute. The plastic sheet was fed into an Illig 50K™ thermoforming m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com