Preparation method of branched polystyrene-maleic anhydride and application thereof

A technology of maleic anhydride and polystyrene, applied in chemical instruments and methods, chemical/physical processes, transportation and packaging, etc., can solve the problems of poor dispersion stability, large dispersion index, and high reaction temperature of the dispersion, and achieve The effect of controllable polymer structure and properties, good product application performance and mild polymerization conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

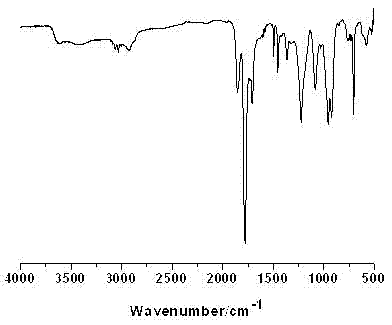

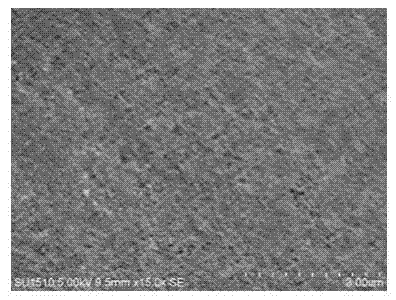

Embodiment 1

[0027] Add 1.04g (10mmol) styrene, 1.176g (12mmol) maleic anhydride, 0.1g (0.67mmol) p-vinylbenzylmercaptan to a 100ml four-neck round bottom flask equipped with a thermometer, reflux condenser and stirrer , 0.232g AIBN, and then add 44g of toluene as a polymerization solvent, place the flask in a constant temperature oil bath, heat and stir to 30°C and pass N 2 After 15 minutes, close the system, raise the temperature to 65°C, and stir for 10 hours at a constant temperature. After the reaction, the product is suction-filtered and rinsed with hot toluene (about 40°C) for several times, then dissolved in acetone, and a small amount of insoluble impurities are filtered off. Dissolving, precipitating, and purifying three times were repeated and dried in a vacuum oven to obtain 2.138 g of branched polystyrene maleic anhydride product with a monomer conversion rate of 92.3%.

Embodiment 2

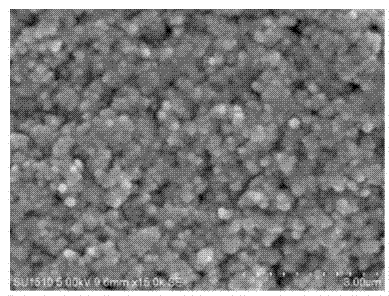

[0029] Add 1.04g (10mmol) styrene, 1.176g (12mmol) maleic anhydride, 0.2g (1.34mmo) p-vinylbenzylmercaptan to a 100ml four-neck round bottom flask equipped with a thermometer, a reflux condenser and a stirrer , 0.29g AIBN, and then add 46g of toluene as the polymerization solvent, place the flask in a constant temperature oil bath, heat and stir to 35°C and pass N 2 After 20 minutes, close the system, raise the temperature to 70°C, and stir at constant temperature for 15 hours. After the reaction, the product is suction filtered and washed with hot toluene (about 40°C) for several times, then dissolved in acetone, and a small amount of insoluble impurities are filtered off. Precipitate and separate with toluene. After repeated dissolution, precipitation, and purification three times, vacuum oven drying obtained 2.160 g of branched polystyrene maleic anhydride product, and the monomer conversion rate was 89.4%.

Embodiment 3

[0031] Add 1.04g (10mmol) styrene, 1.176g (12mmol) maleic anhydride, 0.3g (2mmol) p-vinylbenzylmercaptan, 0.327g AIBN, and then add 35g of toluene as polymerization solvent, place the flask in a constant temperature oil bath, heat and stir to 40°C and turn on N 2 After 25 minutes, close the system, raise the temperature to 75°C, and stir for 20 hours at a constant temperature. After the reaction, the product is suction filtered and washed with hot toluene (about 40°C) for several times, then dissolved in acetone, and a small amount of insoluble impurities are filtered off. Precipitate and separate with toluene. After repeated dissolution, precipitation, and purification three times, vacuum oven drying obtained 2.204 g of branched polystyrene maleic anhydride product, and the monomer conversion rate was 87.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com