Anti-haze window gauze and preparation method thereof

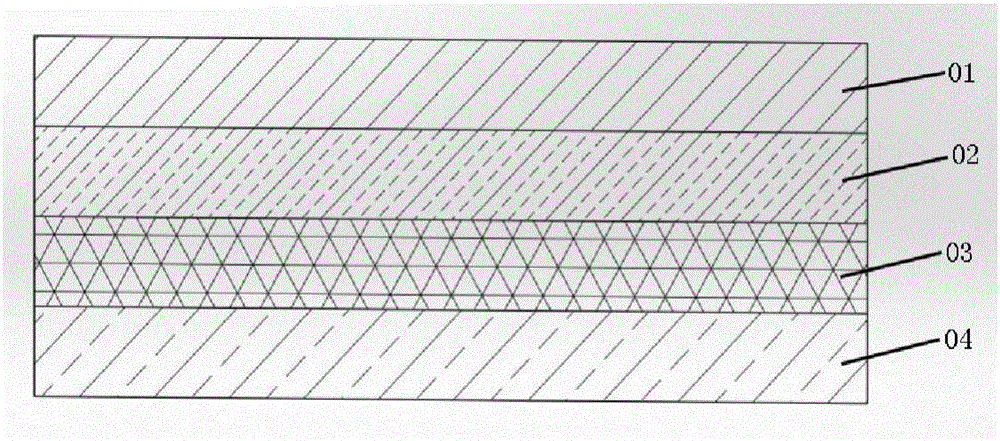

A manufacturing method and technology for window screens, which are applied in separation methods, chemical instruments and methods, and insect control, can solve problems such as hindering air exchange, failing to prevent haze, and detrimental to physical and mental health. The effect of enhancing mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The receiving layer is made of non-woven fabric, using 15g PET warp-knitted organza. The receiving surface on the warp-knitted organza is pre-treated with glue spraying. The glue used is water-based neoprene spray glue, and the weight of the glue layer is 0.1g.

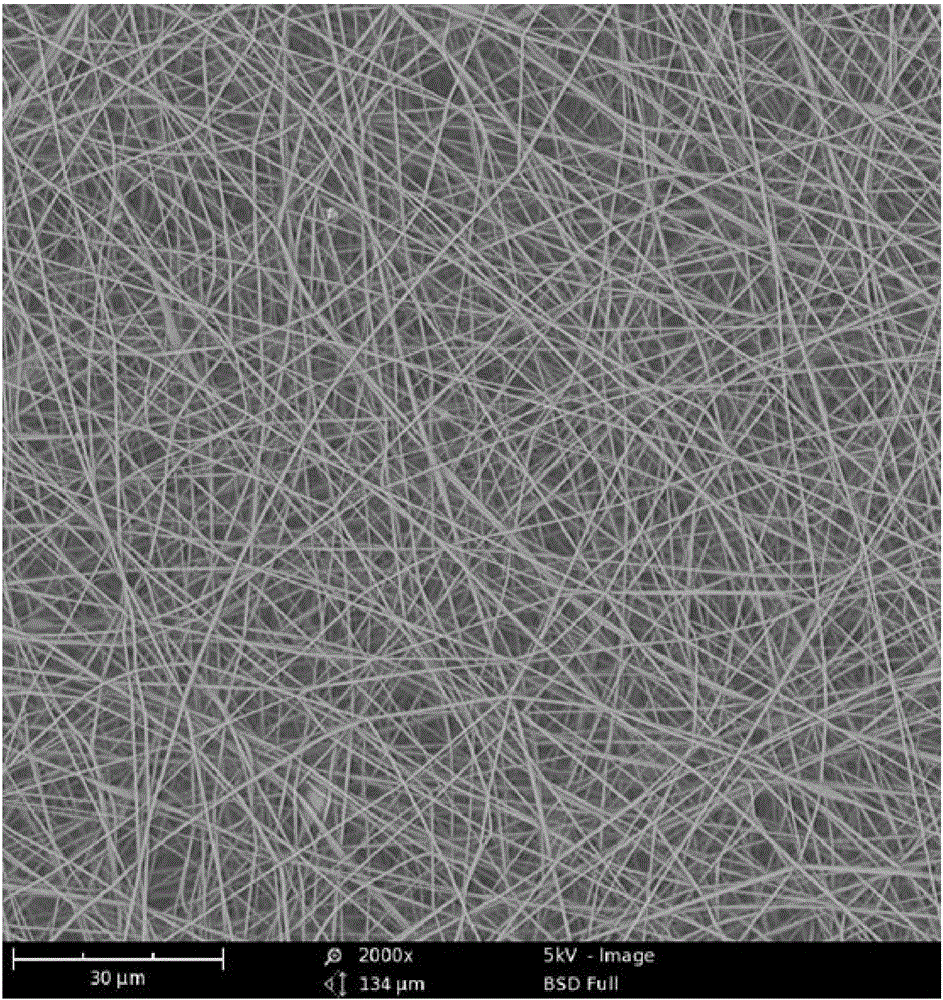

[0047] Dissolve 150g of polyamide 6 (PA6) in 850g of 98% formic acid solution to make a 15% PA6 solution and spin the solution into a filter membrane by electrospinning. The temperature of the spinning solution is 30°C and the ambient temperature is 30°C , the relative humidity is 30wt%, the spinning voltage is 50000V, the distance from the spinneret to the receiving layer is 20cm, and the weight of the polymer nanofiber is 0.1g / m 2 . The ejected polymer nanofibers are attached to the adhesive layer of the receiving layer, so that the polymer nanofibers are not easy to fall off, tightly combined with the substrate, and have high mechanical properties. The morphology of the finished polymer nanofiber layer is a...

Embodiment 2

[0050] The receiving layer is a stainless steel wire mesh with a mesh spacing of 0.1 mm. A layer of ethylene-vinyl acetate (EVA) hot melt adhesive is sprinkled on the receiving surface of the stainless steel wire mesh in advance, and the weight of the adhesive layer is 0.5 g.

[0051] Dissolve 100g of thermoplastic polyurethane (TPU) and 900g of N,N-dimethylformamide to make a 10% PVDF solution and spin the solution into a filter membrane by electrospinning. The temperature of the spinning solution is 40°C and the ambient temperature The temperature is 40°C, the relative humidity is 30wt%, the spinning voltage is 50000V, the distance from the spinneret to the receiving layer is 30cm, and the nanofiber weight is 0.05g / m 2 . The polymer nanofibers are attached to the EVA hot melt adhesive of the receiving layer, and then processed at a high temperature of 100°C, so that the polymer nanofibers will not fall off, and are tightly combined with the substrate, with high mechanical pr...

Embodiment 3

[0054] Mix cellulose acetate butyrate (CAB) and low-density polyethylene (PE) at a mass ratio of 1:9, put them in a vacuum drying oven at 100°C for 24 hours, and then melt-extrude them with a twin-screw blending system . The extruded samples were soaked in acetone solvent at room temperature for 24 h, and ultrasonically treated for 1 h to remove CAB to obtain PE nanofibers.

[0055] The substrate non-woven fabric is 10g of PP melt-blown non-woven fabric, and the receiving surface on the non-woven fabric is pre-treated with water-based polyurethane spray glue, and the weight of the glue layer is 0.3g.

[0056] The PE nanofibers are evenly covered on the adhesive layer of the non-woven substrate, so that the polymer nanofibers will not fall off, and are tightly combined with the substrate, with high mechanical properties.

[0057] The protective layer is made of 15g PET warp-knitted organza, and the polymer nanofiber protective layer is composited on the nanofiber layer, and sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com