Combined box girder hydraulic internal mould

A combined box and inner mold technology, applied in ceramic molding machines, manufacturing tools, etc., can solve the problems of difficult box girder prefabrication efficiency and quality, large changes in beam cross-section, and small working space for workers, etc., and achieves high production efficiency. The effect of good molding quality and fast demoulding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

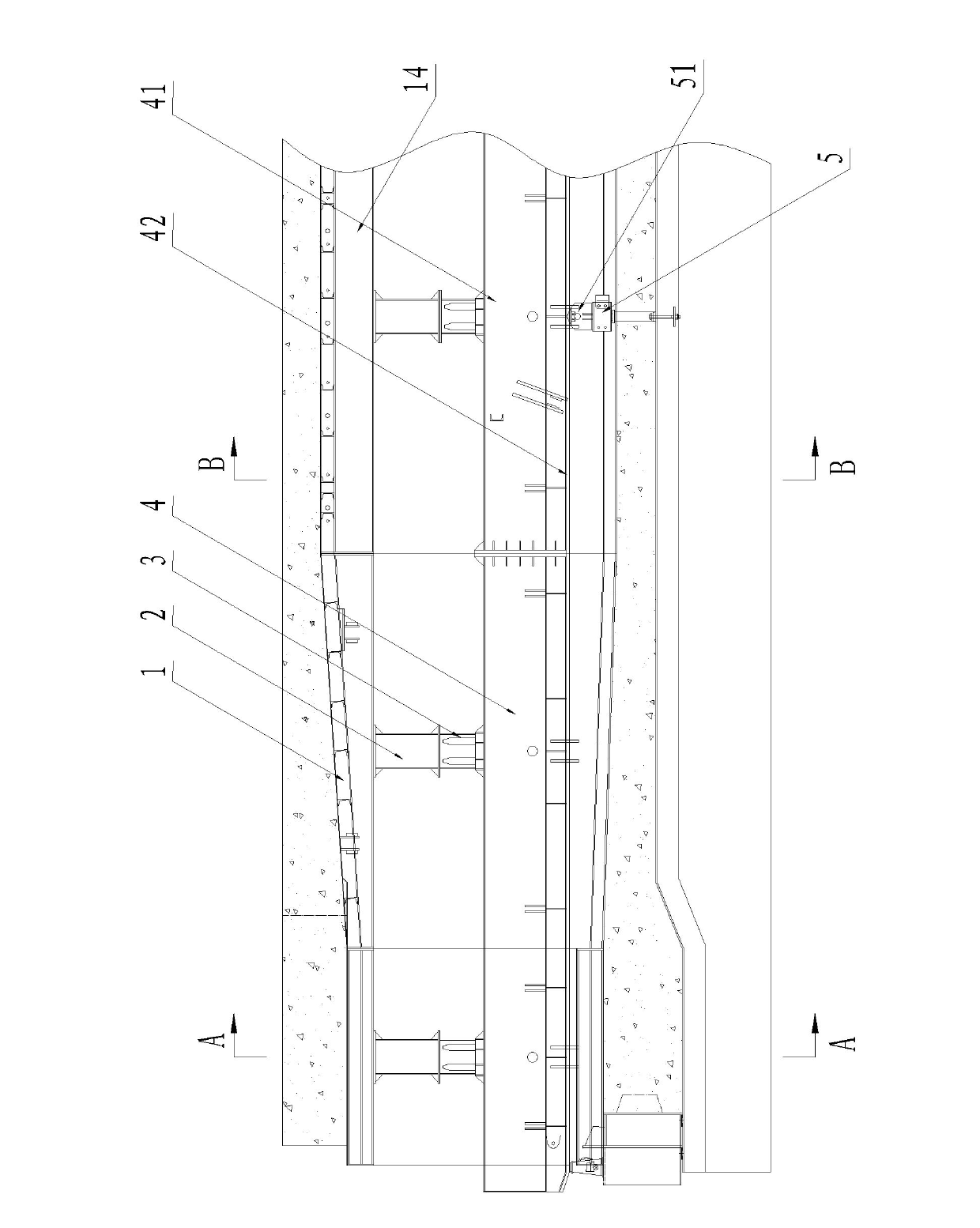

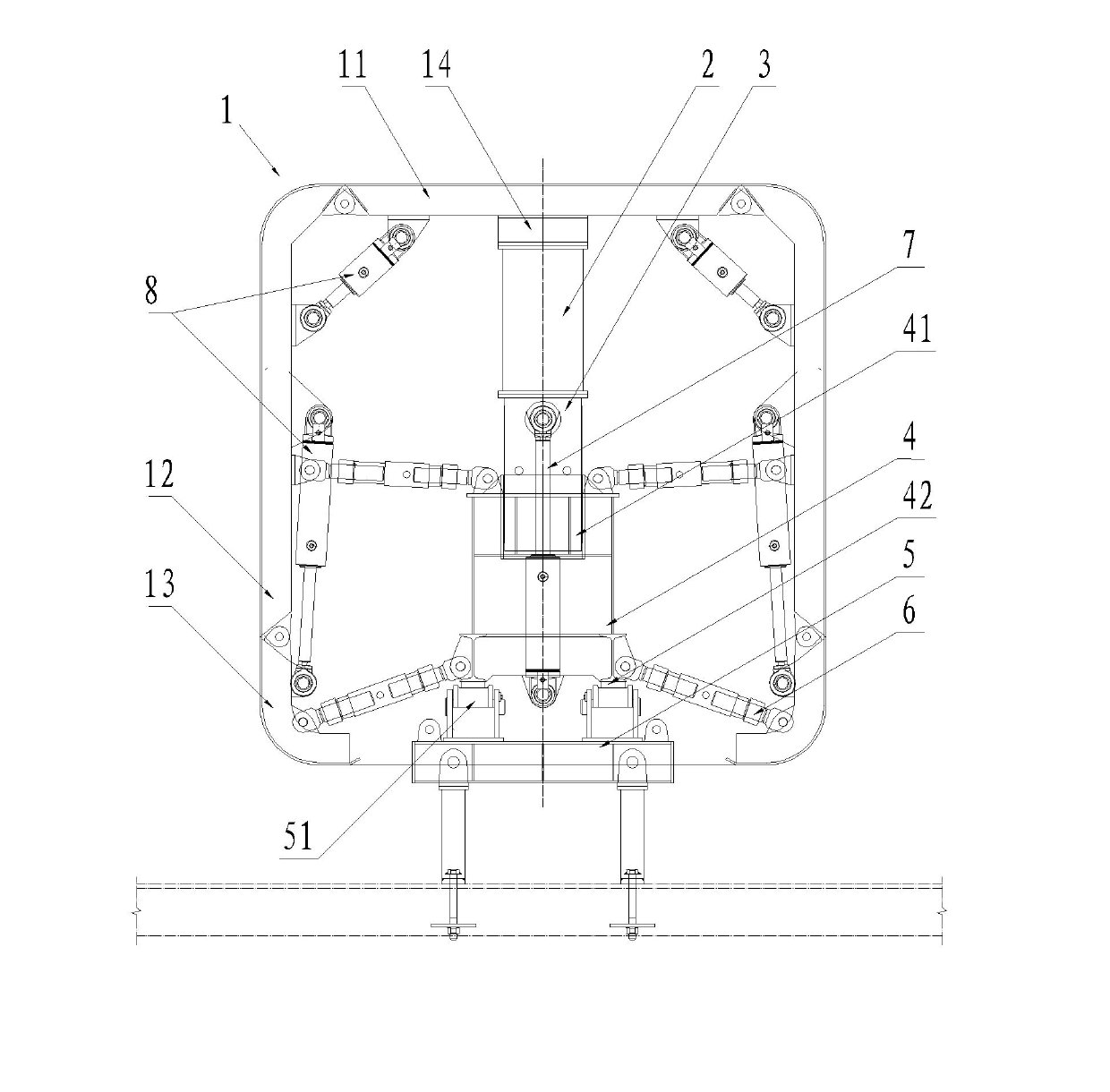

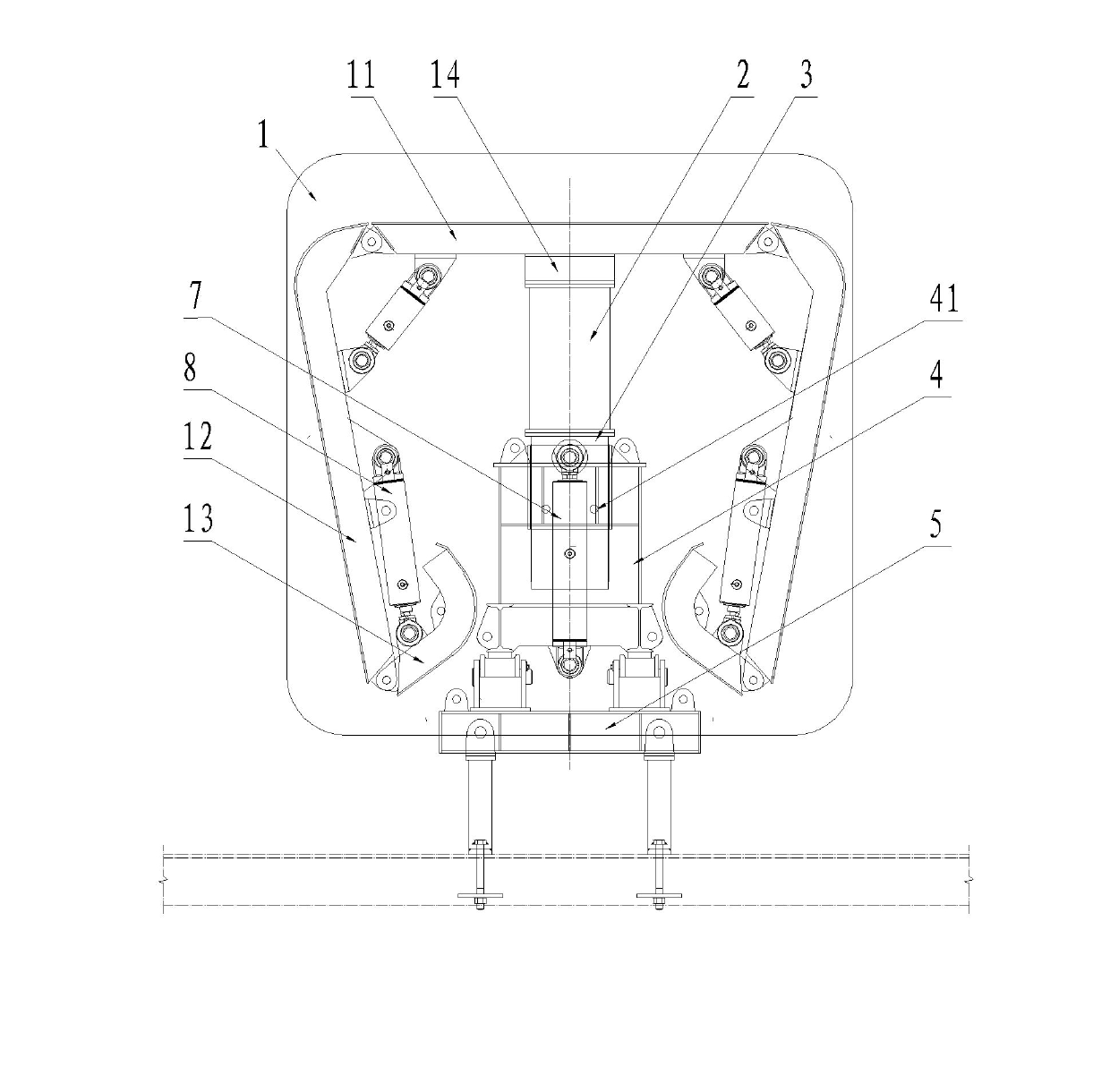

[0015] From figure 1 It can be seen that the combined box girder hydraulic internal mold of the present invention includes a template 1, an adjustment column 2, a guide column 3, a main beam 4, a support base 5, a telescopic strut 6, a jacking cylinder 7 and a lateral cylinder 8, Wherein main girder 4 is equipped with guide sleeve 41, and its bottom is equipped with guide rail 42, and anti-roller 51 is installed on support base 5. The template 1 is connected with the guide column 3 through the adjustment column 2. The guide column 3 is installed in the guide sleeve 41 in the main beam 4 and can slide in it. The main beam 4 is placed on the anti-roller of the support base 5 through the guide rail 42 at the bottom. 51 and can slide on it to drag the internal mold out of the beam body, and the jacking cylinder 7 is connected between the guide column 3 and the main beam 4, and is used to drive the template 1 to rise or fall.

[0016] From Figure 2 to Figure 5 It can be seen tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com