Tray turning and mold stripping machine

A demoulding machine and pan-turning technology, applied in baking, food science, application, etc., can solve the problems of unavoidable contact between human hands and food, reduce food hygiene and safety, and reduce the number of turns at one time, so as to reduce occupation and release. The effect of fast mold speed and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

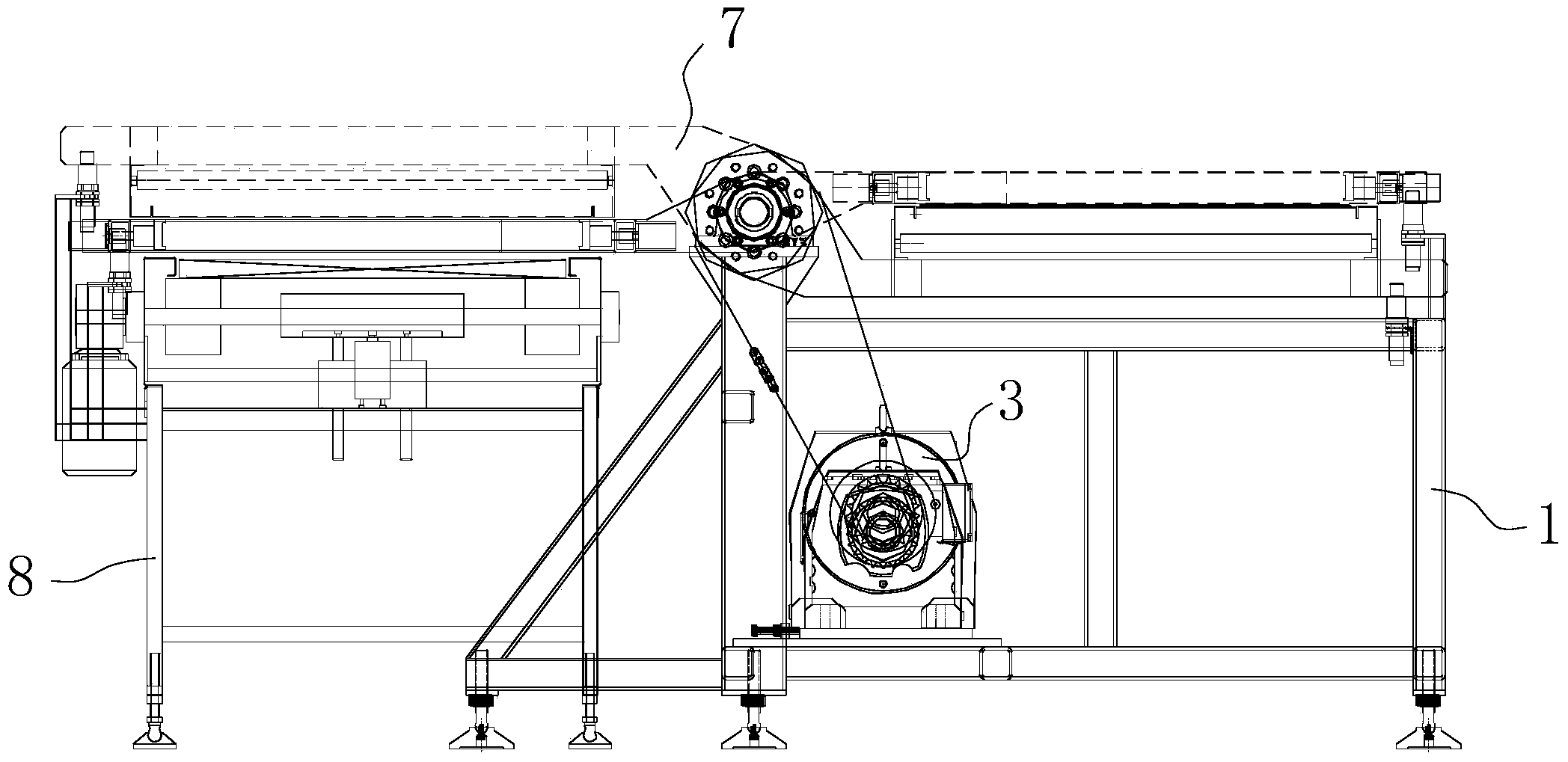

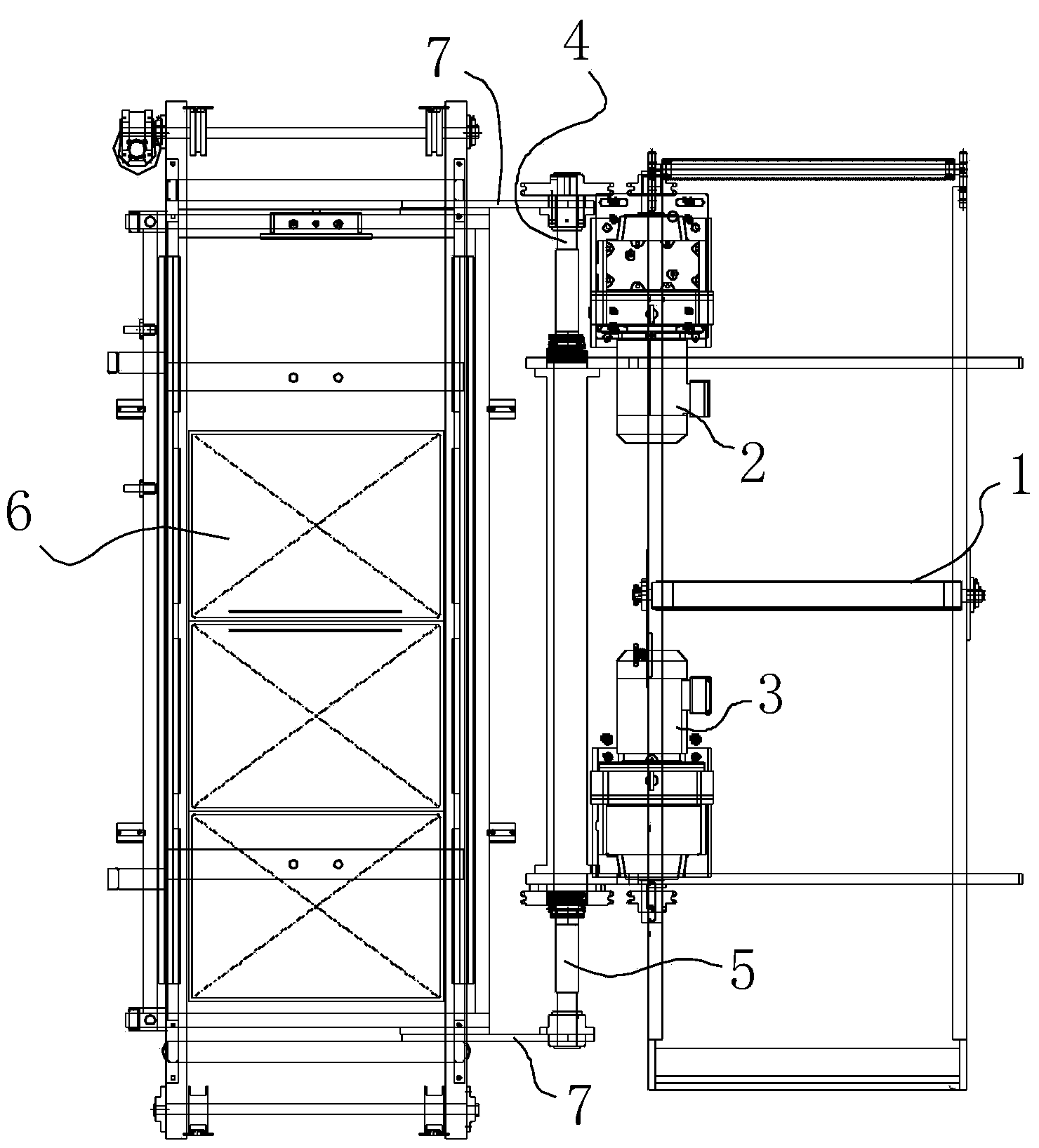

[0020] Such as figure 1 with figure 2 Shown, a kind of turning plate demoulding machine comprises frame 1, and the bottom of described frame 1 is provided with first motor 2 and second motor 3, and the top edge of described frame 1 is provided with first rotating shaft 4 and The second rotating shaft 5, the first rotating shaft 4 is connected to the output shaft of the first motor 2 by chain transmission, the second rotating shaft 5 is connected to the output shaft of the second motor 3 by chain transmission, the The first rotating shaft 4 is connected with a turning mechanism, which includes a clamping cylinder, a chuck plate 6 and two turning arms 7, and the ends of the two turning arms 7 are connected to the first rotating shaft 4 and the second turning arm respectively. The rotating shaft 5 is connected, the chuck plate 6 is arranged on the turning arm 7 , and the clamping cylinder is arranged on the chuck plate 6 .

[0021] In this embodiment, the turning plate strippi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com