Buffer stamping and shaping die convenient for rapid demolding

A technology for shaping molds and demoulding, which is applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of affecting the quality of formed products and slow demoulding speed, and achieve high usable value, fast demoulding speed, structural novel effect

Inactive Publication Date: 2018-02-02

TIANJIN XINYUAN HONGDA TECH CO LTD

View PDF7 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The forming mold is a mold that directly copies the rough or semi-finished workpiece according to the shape of the convex and concave molds in the figure, and the material itself only produces local plastic deformation. The mold structure in the prior art is relatively simple, and the product is easy to adhere to the concave mold after forming. On the inner surface, the demoulding speed is slow, which affects the quality of the formed product. In addition, it is very important to ensure that the mold has a buffer function during the stamping process, which can reduce stamping vibration, so it is necessary to install this device

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

[0017] Embodiment 2: The rubber buffer pad can be replaced by a compression spring, and other structures are the same as in Embodiment 1, and the effect of buffering force can also be achieved.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

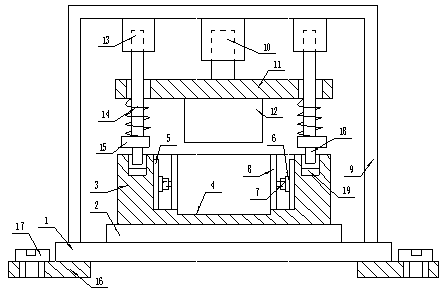

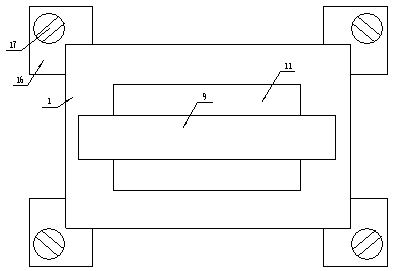

The invention discloses a buffer stamping and shaping die convenient for fast demoulding. The buffer stamping and shaping die comprises a rectangular fixing base, and the upper surface of the rectangular fixing base is fixedly connected with a lower mold base; a lower die body is fixedly connected to the center position of the upper surface of the lower die base, and a concave model cavity is machined in the center position of the upper surface of the lower die body; a pair of strip-shaped sliding grooves are machined on the surface of the two sides in the concave model cavity, a vertical sliding rail is fixedly connected to the inner side surface of each strip-shaped sliding groove, each vertical sliding rail is provided with an electric control trolley, an electric control telescopic cross rod with a telescopic end in a horizontal direction is fixedly connected to the side surface of each electric control trolley, and the telescopic end of each electric control telescopic cross rod is fixedly connected with a strip-shaped extrusion plate matched with each of the strip-shaped sliding grooves; and the upper surface of the rectangular fixing base is fixedly connected with a door type fixing frame. The buffer stamping and shaping die has the beneficial effects of being simple in structure, and high in practicability.

Description

technical field [0001] The invention relates to the field of sizing dies, in particular to a buffer stamping sizing die which is convenient for rapid demoulding. Background technique [0002] With the continuous advancement of science and technology, the products processed by machinery are becoming more and more advanced. Stamping equipment is an advanced machinery for manufacturing various parts. [0003] The forming mold is a mold that directly copies the rough or semi-finished workpiece according to the shape of the convex and concave molds in the figure, and the material itself only produces local plastic deformation. The mold structure in the prior art is relatively simple, and the product is easy to adhere to the concave mold after forming. On the inner surface, the demoulding speed is slow, which affects the quality of the formed product. In addition, it is very important to ensure that the mold has a buffer function during the stamping process, which can reduce stamp...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B21D37/10B21D37/04

CPCB21D37/04B21D37/10

Inventor 马兰

Owner TIANJIN XINYUAN HONGDA TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com