Automatic turnover demolding system in automatic production line for heat-insulating and decoration integrated boards

An automatic production line and automatic turning technology, which is applied in the direction of unloading device, covering/lining, manufacturing tools, etc., can solve the problems of time-consuming and labor-intensive, and achieve the effect of increasing demoulding speed, increasing production speed and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

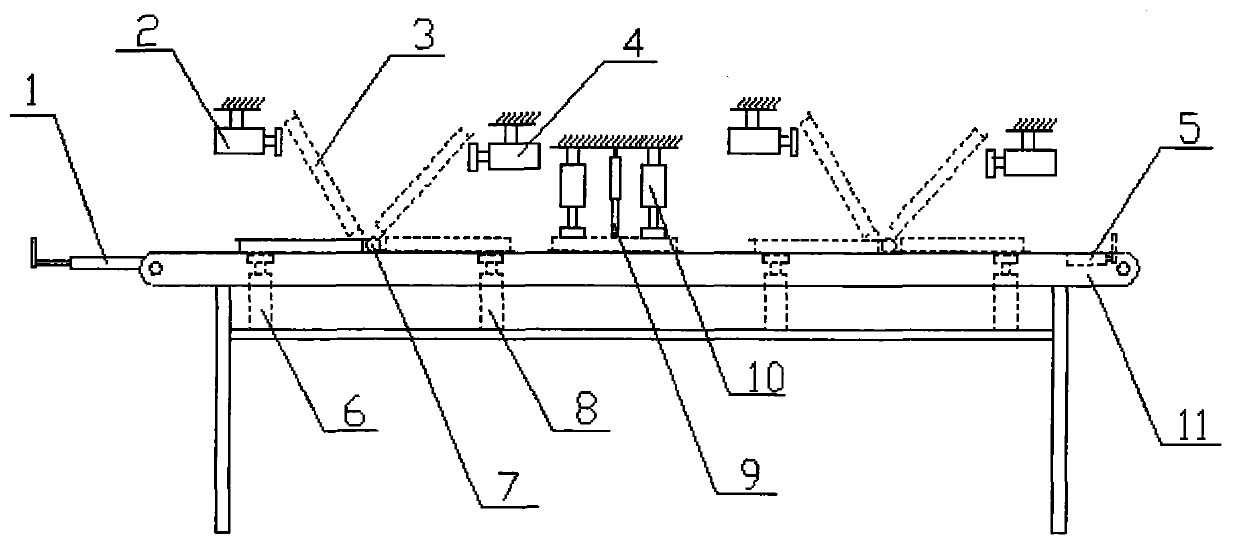

[0011] The automatic flip demoulding system in the automatic production line of thermal insulation and decoration integrated board. The automatic flip demoulding system includes two sets of 180° flipping devices arranged on the conveyor belt, and a stripping device. The stripping devices are set on two sets of 180° flipping devices. In the middle of the device; the 180° turning device includes an input device 1, a first cylinder 6, a second cylinder 2, a blocking device 7, a third cylinder 4, and a fourth cylinder 8 in sequence according to the running order of the production line; the demoulding device Including blowing pipe 9, vibration and percussion device 10, output device 5; the above devices are all equipped with in-position detection devices;

[0012] Wherein, the input device 1, the first cylinder 6, the blocking device 7, the fourth cylinder 8, the output device 5 are arranged on the frame 11 with the transmission mechanism, the second cylinder 2, the third cylinder 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com