Nano-imprinting template, system thereof and imprinting method

A technology of nanoimprinting and templates, which is applied in the direction of nanotechnology, nanotechnology, and nanotechnology for information processing, etc., and can solve the problem of repeated step-by-step thermoplastic nanoimprinting and roll-to-roll thermoplastic nanoimprinting Difficulty and cost increase in printing and template making, inability to complete the nanoimprinting process, etc., to achieve the effects of reducing graphic replication defects, improving process throughput, and broadening the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

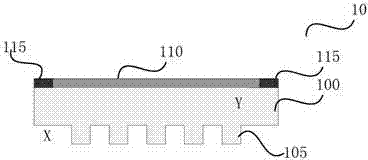

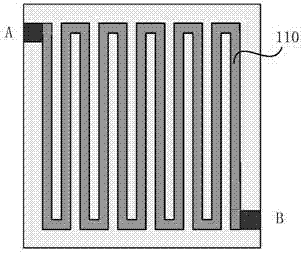

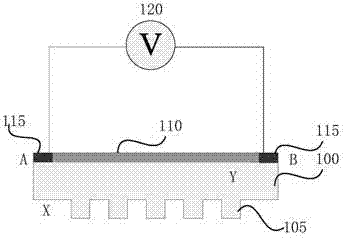

[0077] Figure 1(a)-1(c) It shows a nanoimprint template 10 according to the first embodiment of the present invention, wherein FIG. 1(a) is a front view of the nanoimprint template 10; FIGS. Top view, showing two arrangements of the heating elements.

[0078] As shown in FIG. 1( a ), the nanoimprint template 10 includes: a first substrate 100 transparent to ultraviolet light; an imprint pattern structure 105 formed on the first surface of the first substrate (indicated by X in the figure); The heating part 110 is formed on the second surface (indicated by Y in the figure) opposite to the first surface of the first substrate, wherein the heating part 110 is transparent to ultraviolet light; and the first electrode pair 115 is formed on the second surface , for supplying current applied by an external power source to the heating component 110 so that the heating component 110 generates heat.

[0079] Wherein, the first substrate 100 may be made of a UV-transparent double-side...

no. 2 example

[0082] As a modification of the nanoimprint template 10 in the above embodiment, such as image 3 As shown, the nanoimprint template 10 also includes a second substrate 200 transparent to ultraviolet light, wherein the second substrate 200 has the following two functions: one is to fix the first substrate 100, and apply mechanical pressure around the second substrate support frame , can provide the required working pressure for nanoimprinting. Fixation can be done in two ways, mechanical or electromagnetic. Wherein, for electromagnetic fixation, the nanoimprint template further includes a thin film of magnetic material, which is formed on the surface (indicated by W in the figure) opposite to the second surface of the first substrate of the second substrate 200, and is used to heat the component when the current passes through it. 110 to attract the first substrate 100 and the second substrate 200 by electromagnetic force when forming an electromagnetic field. Another functi...

no. 3 example

[0086]The present invention also provides a nanoimprint system, including the nanoimprint template 10 as described in the first embodiment or the second embodiment and a substrate carrying platform 30 for carrying a substrate 20 to be imprinted, such as Figure 4 shown. Notice, Figure 4 Shown in is the case of including the nanoimprint template 10 in the second embodiment (ie, having the second substrate 200 ).

[0087] Different from traditional nanoimprinting using water cooling or air cooling, the present invention can install a thermoelectric cooler on the substrate carrying platform 20 to rapidly cool the substrate and precisely control the cooling temperature. In addition, the use of thermoelectric coolers can generate temperatures lower than ambient, so they can be used for embossing adhesives whose curing temperature is lower than room temperature. Specifically, the thermoelectric cooler includes a thermoelectric cooling control circuit (not shown in the figure) and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com