Novel injection mold for inverse buckle demolding

An injection mold and upside-down technology, applied in the field of new-type upside-down injection molds, can solve the problems of tearing of the nozzle, low yield rate, and inability to demold, and achieve fast demolding speed, high yield rate, and simple structure. reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

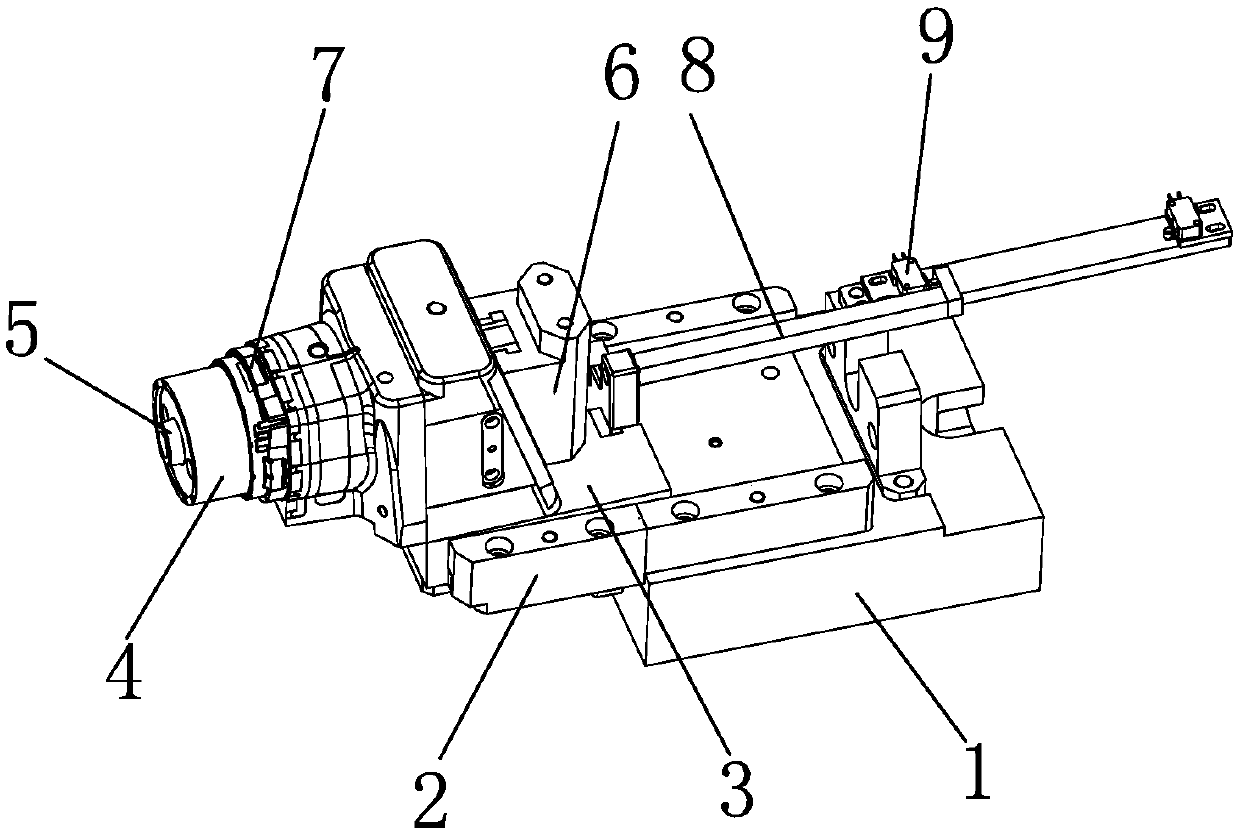

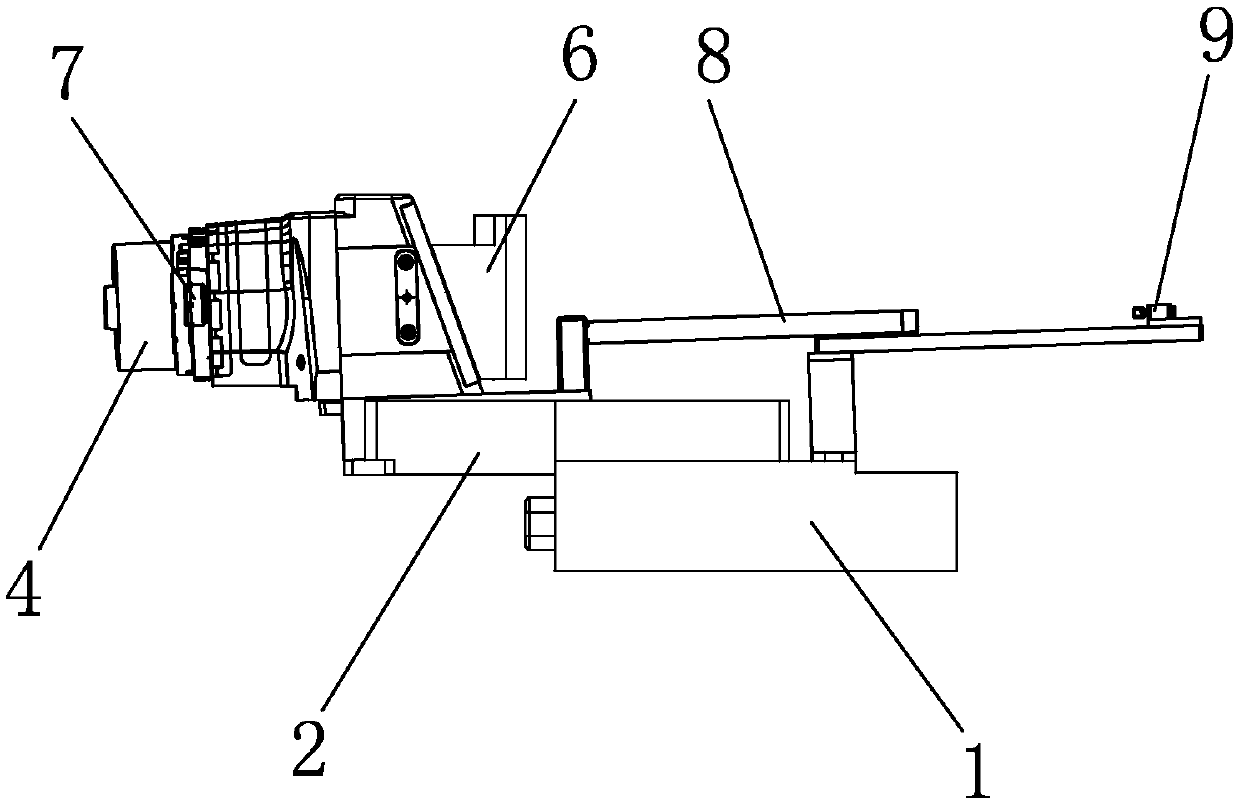

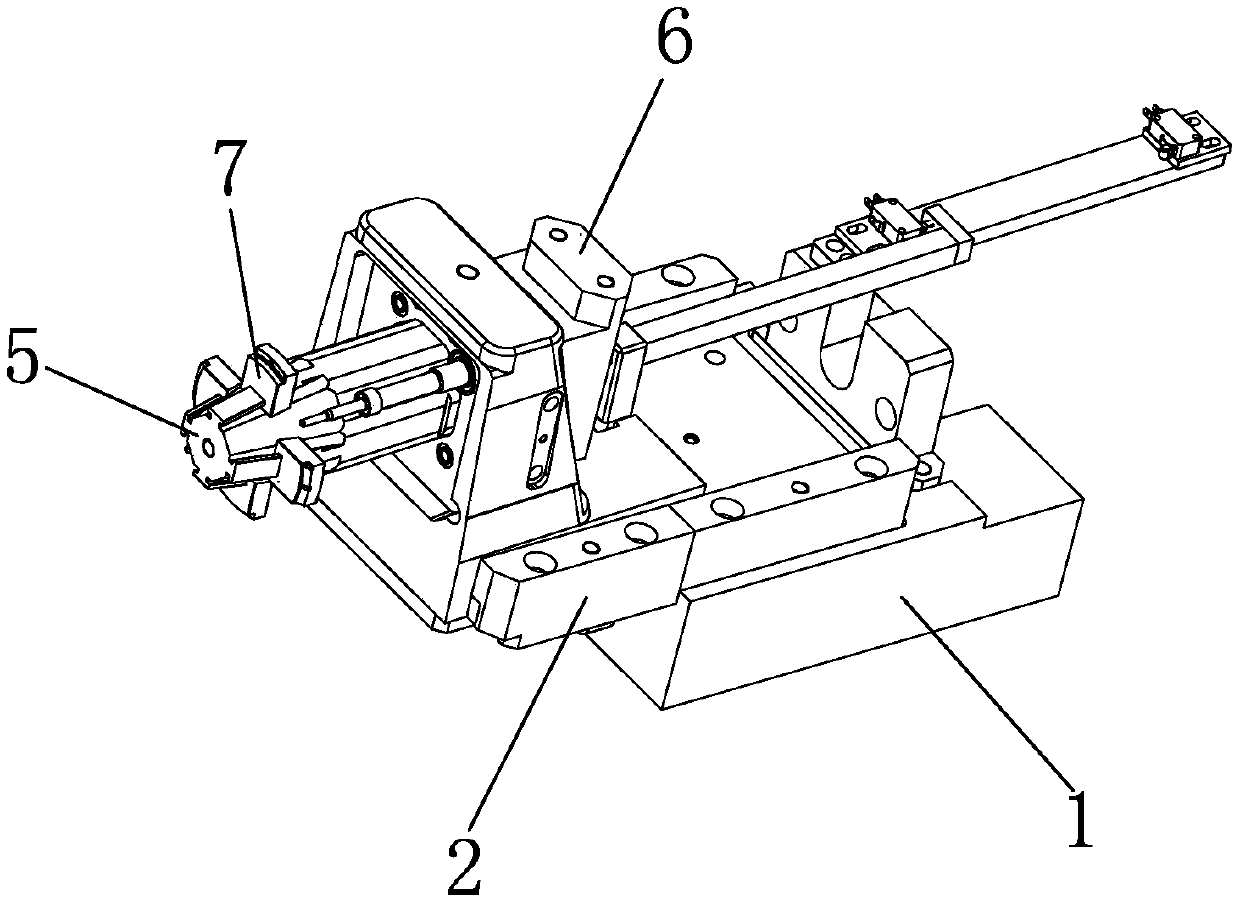

[0018] combine Figure 1 to Figure 3 , the invention discloses a new type of injection mold for breaking off and upside down, which includes a movable mold and a fixed mold, and is used for injection molding of an air filter housing. In order to be able to successfully demould the undercut at the mouth of the injection molding product, the present invention adds an inclined guide block 6 connected to the movable mold and a mounting seat 1 and a slide table installed on the fixed mold on the basis of the conventional mold structure. 2. Skateboard 3. Drive cylinder and mold core 4. The mold core 4 of the present invention adopts an embedded composite structure, and the movable insert 7 is withdrawn and demoulded through the movable insert 7 movably installed on the mold core 4 .

[0019] Specifically, the sliding table 2 and the driving cylinder are fixedly installed on the mounting base 1 . A linear chute is provided on the slide table 2 . The sliding plate 3 is movably clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com