Nano composite foaming agent, foaming product, and preparation method and application thereof

A technology of nano-composite and foamed products, applied in the field of composite foaming agent and foaming agent, can solve the problem that the foaming efficiency and quality need to be further improved, the nucleation point of the composite foaming agent needs to be increased, and the size of the cells is difficult to control, etc. problem, to achieve the effect of small particle size, improved agglomeration and good foaming quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

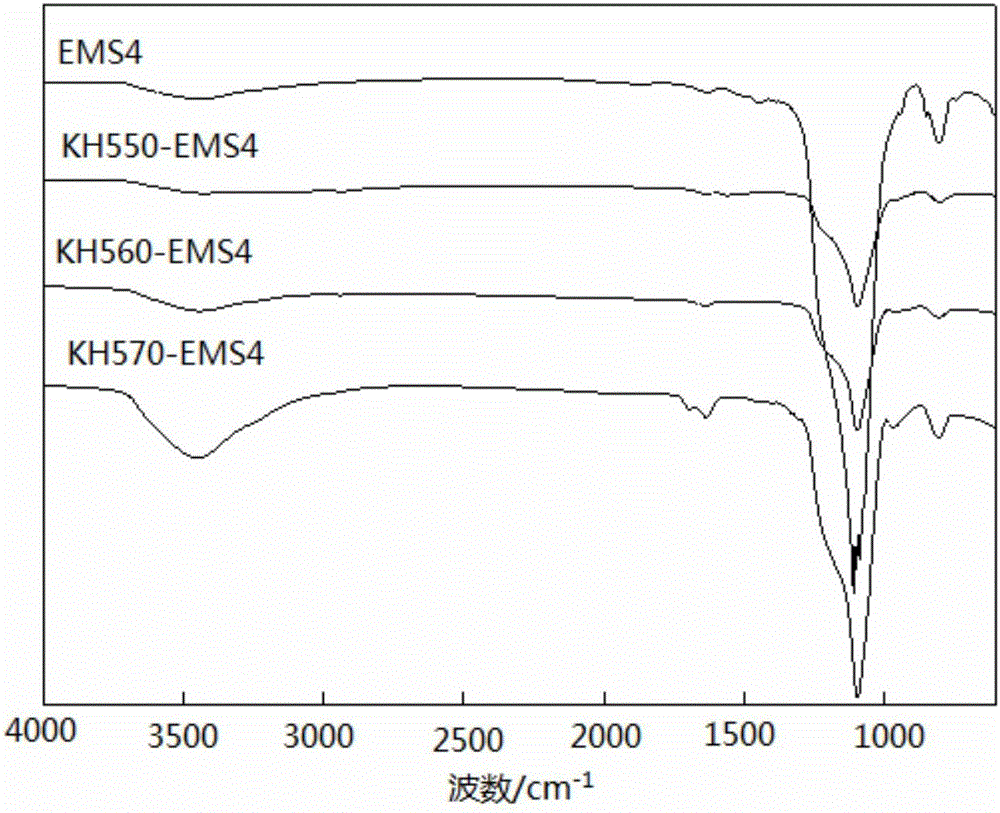

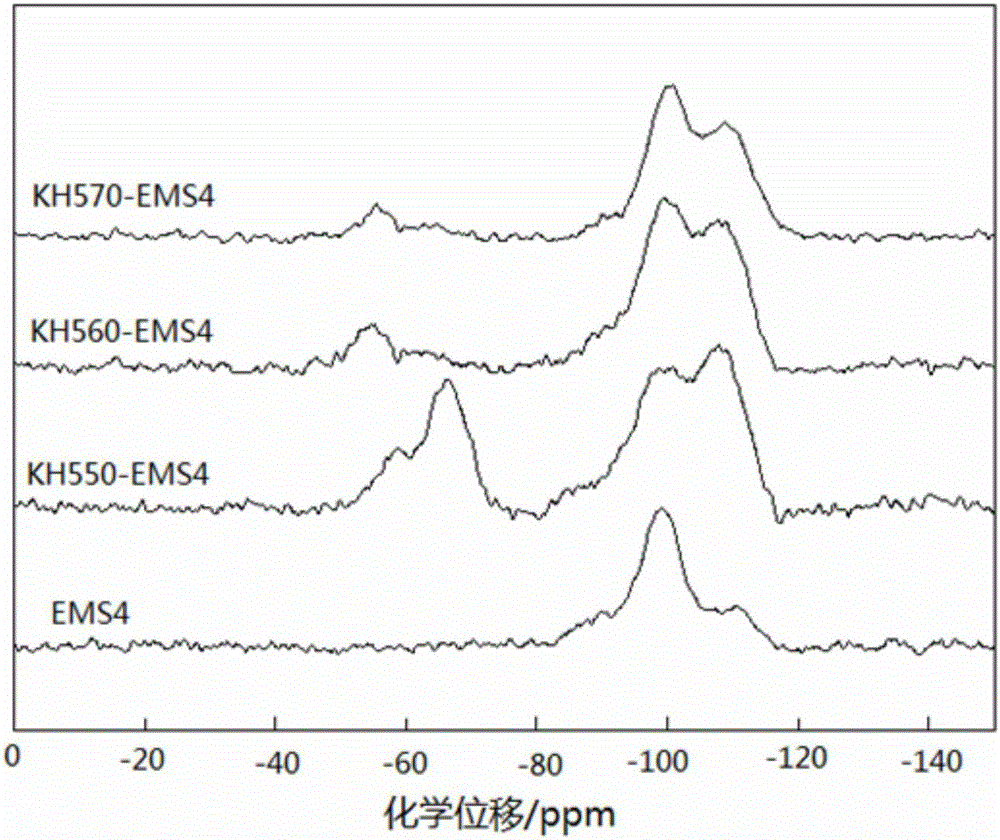

[0089] Preparation of embodiment one nanocomposite blowing agent

Embodiment 11

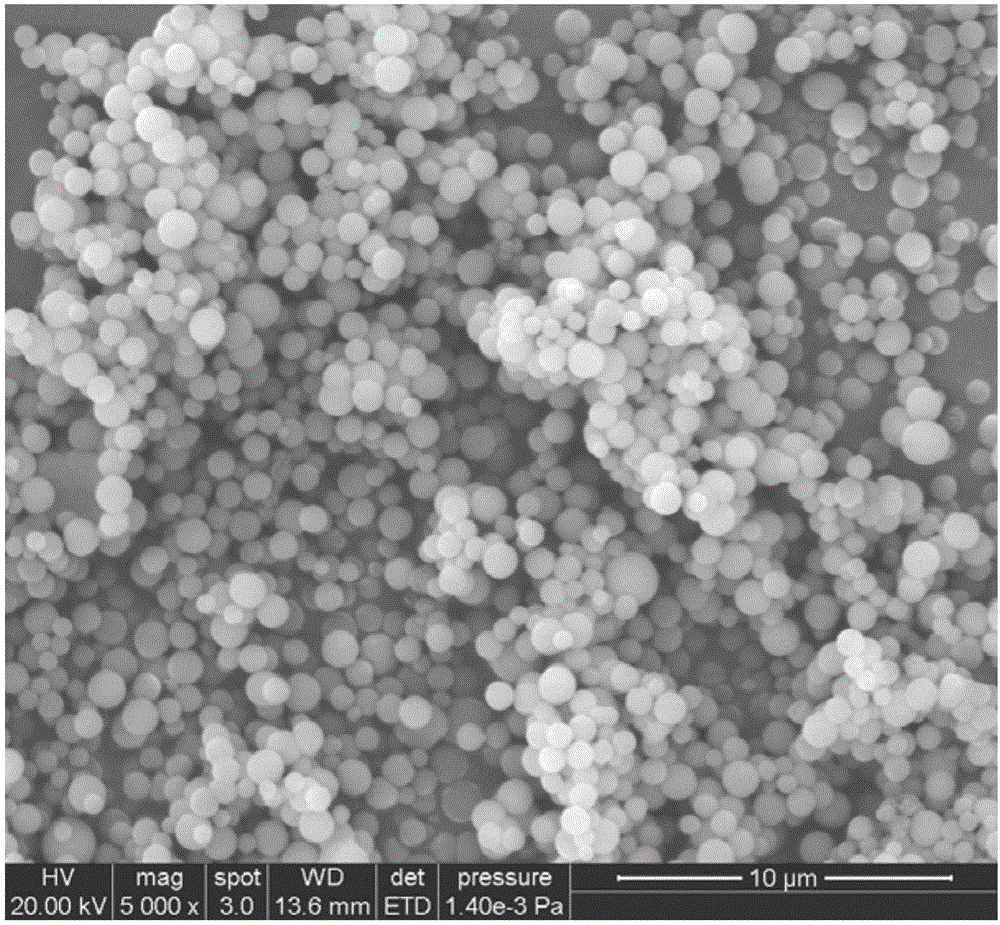

[0090] Example 1.1 Pore expansion process of mesoporous silica

[0091] At 30°C, dissolve 6g of hexadecylamine in 600mL of isopropanol and 540mL of water, add 8.4mL of 28% ammonia solution, adjust the pH to 11.2, add 34.8mL of tetraethyl orthosilicate (TEOS) dropwise, at 30°C Let stand for one day, wash with absolute ethanol, and prepare by calcining with programmed temperature method to obtain mesoporous silica MS; Raise the temperature to 450°C and keep the temperature constant for 50 minutes; (3) raise the temperature to 600°C and keep the temperature constant for 4 hours.

[0092] Prepare NaCl solution with molar concentration of 5mol / L, LiCl solution with 5mol / L and KNO with 5mol / L respectively 3 solution, and NaCl, LiCl, KNO with a mass ratio of 4:1:1 3 The double salt solution, and the mass fraction of the double salt solution is 23%. Add 2g of the above-mentioned mesoporous silica to 100ml of the above-mentioned four kinds of salt solutions respectively, stir evenly...

Embodiment 13

[0096] Preparation of embodiment 1.3 nanocomposite blowing agent

[0097] Weigh 2.69g of chemical foaming agent 4,4'-oxobisbenzenesulfonamide (OBSH), dissolve it in 15Ml N,N'-dimethylformamide (DMF), and magnetically stir until uniform. Weigh 0.5 g of KH550-EMS4 prepared in Example 1.2 and add it to the above solution, stir evenly, ultrasonicate for 10 min, soak at room temperature for 24 h, and filter with a microporous filter. Wash with 10mL mixed washing solution (2g 4,4'-oxobisbenzenesulfonyl hydrazide, 10mL N,N'dimethylformamide and 10mL methanol), then wash with 10mL methanol, and dry in an oven at 60°C for 24h to obtain Nanocomposite blowing agent OBSH-KH550-EMS4, denoted as F1. In this example, F1 and OBSH-KH550-EMS4 refer to the same nanocomposite foaming agent.

[0098] Similarly, change the washing method in the above method to no washing or 10mL methanol washing instead of 10mL mixed washing solution (2g 4,4'-oxobisbenzenesulfonyl hydrazide, 10mL N,N'dimethylform...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com