Porous material for tissue engineering stent

A tissue engineering scaffold and porous technology, applied in the field of biomedical materials, can solve problems such as unfavorable cell migration and growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

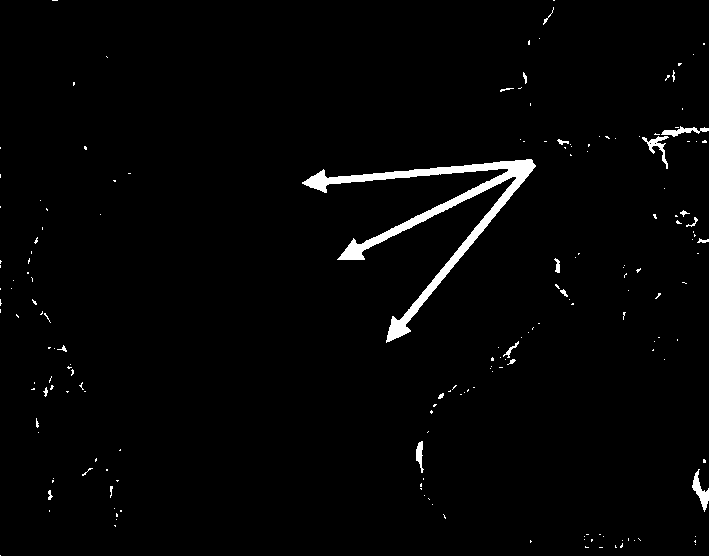

[0020] Polycaprolactone (granule), polyethylene oxide (powder), and sodium bicarbonate (powder) were prepared at a volume ratio of 1:1:1, and blended on a twin-screw extruder (BMP, US) and For granulation, the blending temperature was set at 100°C to prevent the premature decomposition of sodium bicarbonate. Then, injection foam molding was performed on a micro-foaming injection molding machine (Arburg Allrounder 320S equipped with Drexel Mucell gas supply system), and the molding temperature was set at 155°C (at this temperature, the thermal decomposition rate of sodium bicarbonate reached the maximum), and micropores were obtained. Foam injection molding products. Then put the injection molded product in a circulating water bath and leach for 72 hours to leach out sodium carbonate, the decomposition product of polyethylene oxide and sodium bicarbonate, and finally dry it in a vacuum oven for 48 hours to obtain an interconnected porous material . The porosity of the resulti...

Embodiment 2

[0022] Polycaprolactone (granular), polyethylene oxide (powder), and sodium bicarbonate (powder) were prepared according to the volume ratio of 3:2:3. Under the same steps and conditions as in Example 1, the internal The interconnected porous material has a porosity of 73.8%, a cell size of 20 microns to 250 microns, and an internal interconnected channel size of 20 microns to 200 microns.

Embodiment 3

[0024] Polycaprolactone (granular), polyethylene oxide (powder), and sodium bicarbonate (powder) were prepared according to a volume ratio of 2:3:2, and under the same steps and conditions as in Example 1, prepared The internal interconnected porous material has a porosity of 70.9%, a cell size of 20 microns to 250 microns, and an internal interconnected channel size of 20 microns to 200 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com