Foaming production line for water tank heat-insulation layers

An insulation layer and production line technology, applied in the field of insulation layer foam production line, can solve the problems of poor production continuity, hidden dangers of hygiene and safety, and difficulty in guaranteeing the quality of the foam layer, and achieve the effect of avoiding waste and improving foam quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

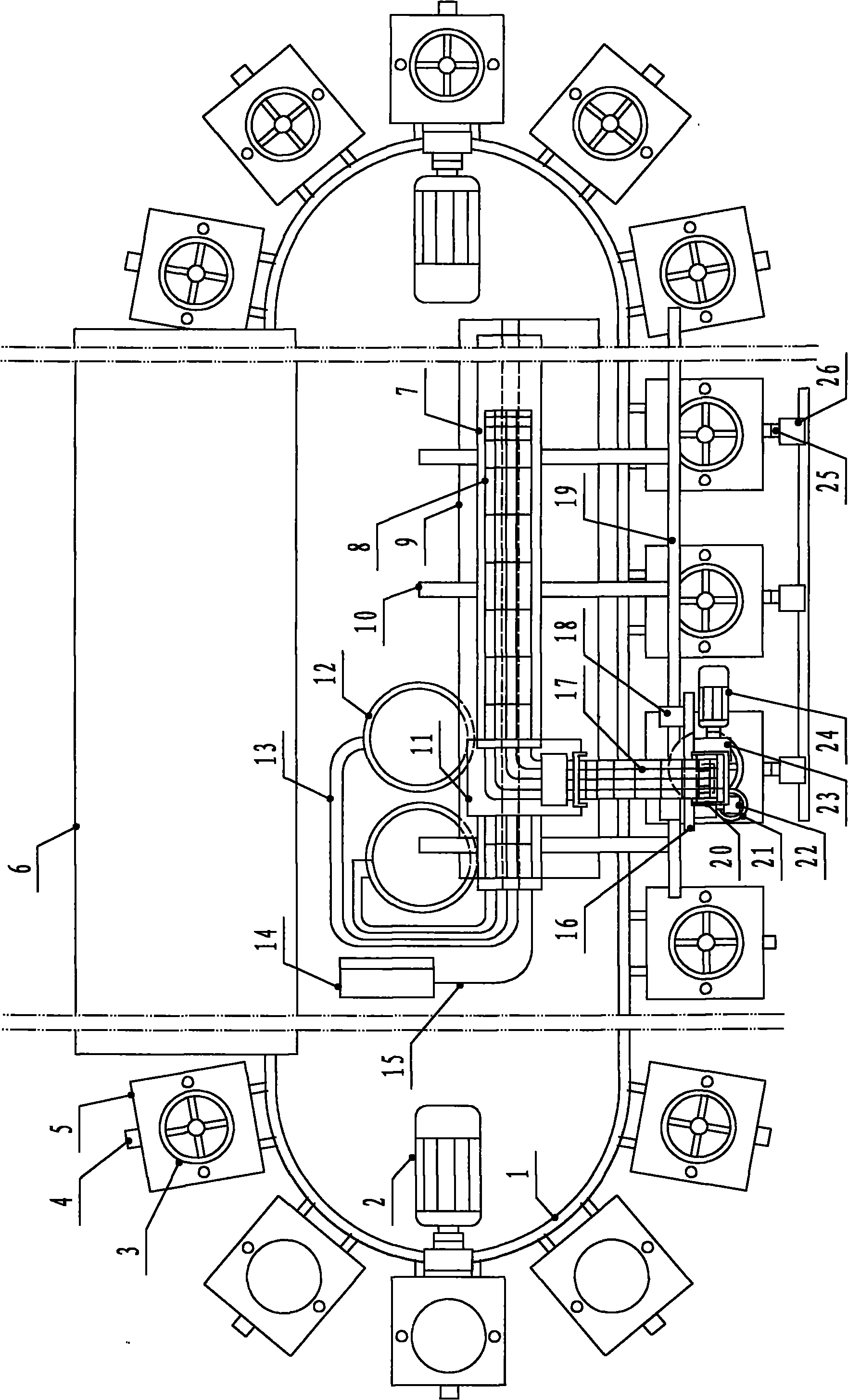

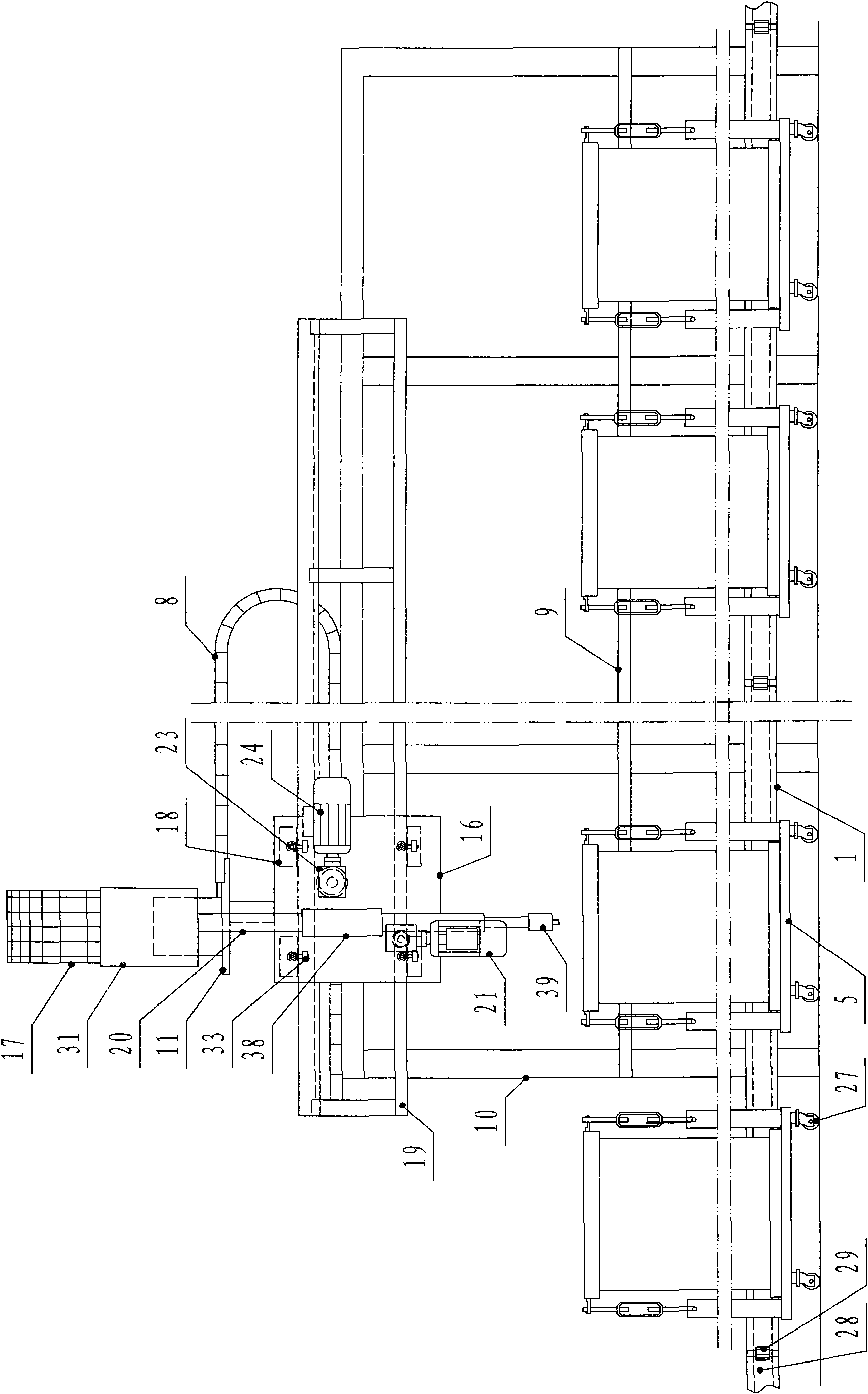

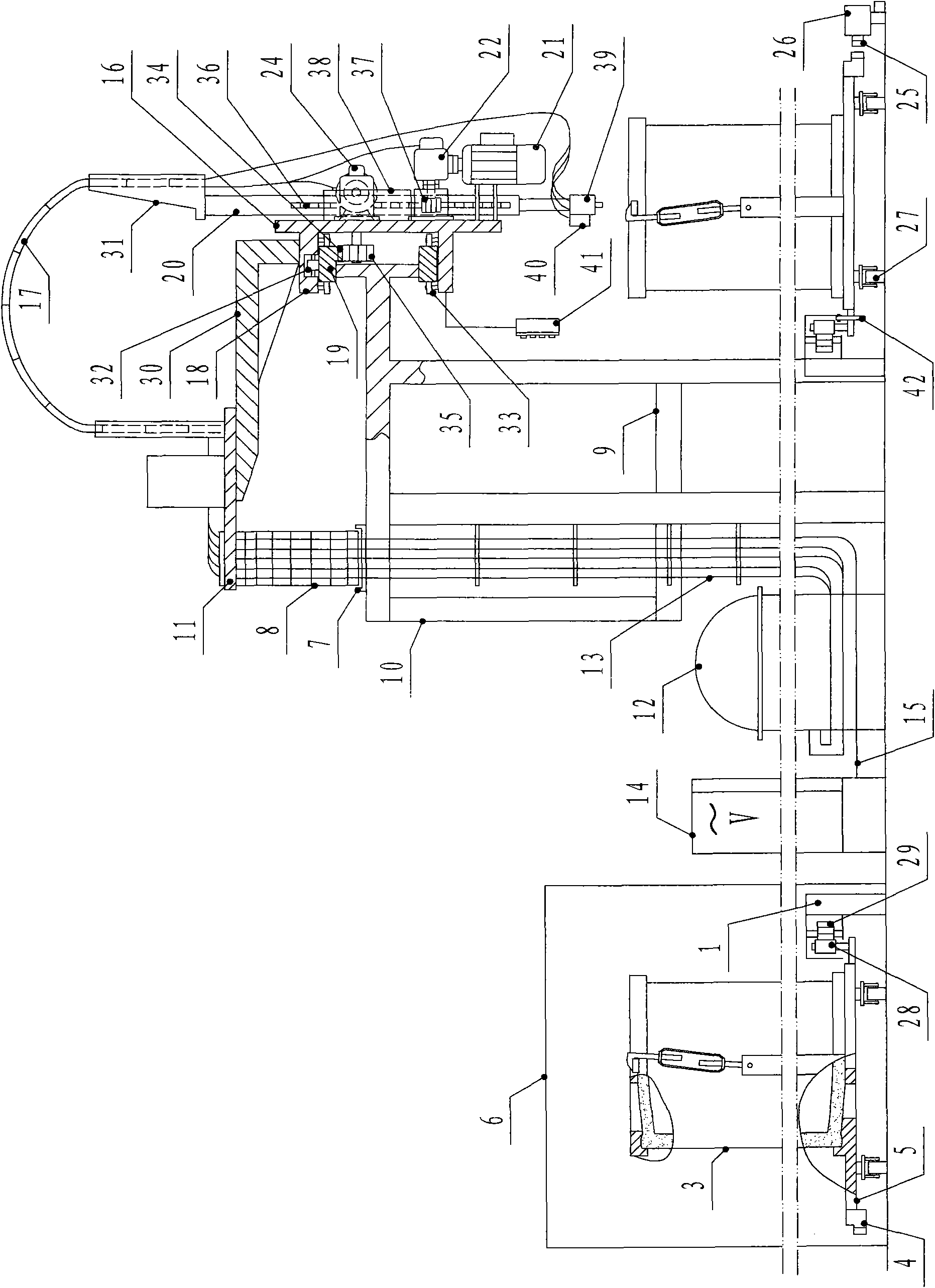

[0015] Example: such as figure 1 , figure 2 and image 3 As shown, a foaming production line for water tank insulation layer is designed and installed on a circular track, and is divided into water tank assembly area, foaming work area, foam layer aging area and finished product unloading area, forming an automated production line.

[0016] The production line is equipped with an electric control mechanism and a blowing agent injection mechanism for the water tank insulation layer. The electric control mechanism is mainly composed of an electric control box 14, a connecting wire 15 and a control switch 41. The tank 12, the delivery pipe 13 and the injection head 39 are composed of: an annular track 1 is also installed on the production line, and the water tank delivery mechanism and the positioning and locking mechanism of the water tank delivery mechanism are installed on the annular track 1, and a water tank delivery mechanism is installed on one side. The water tank deli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com