Foaming and expanding-shrinking mold for box body

A box and mold technology, which is applied in the field of refrigerator liner molding, can solve the problems of poor mold stability, easy interference, and influence on foaming quality, and achieves the effects of compact transmission structure, improved foaming quality, and less interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following examples are a further description of the content of the present invention as an explanation of the technical content of the present invention, but the essential content of the present invention is not limited to the following examples, those of ordinary skill in the art can and should know any Simple changes or replacements of the essential spirit of the invention shall fall within the scope of protection required by the present invention.

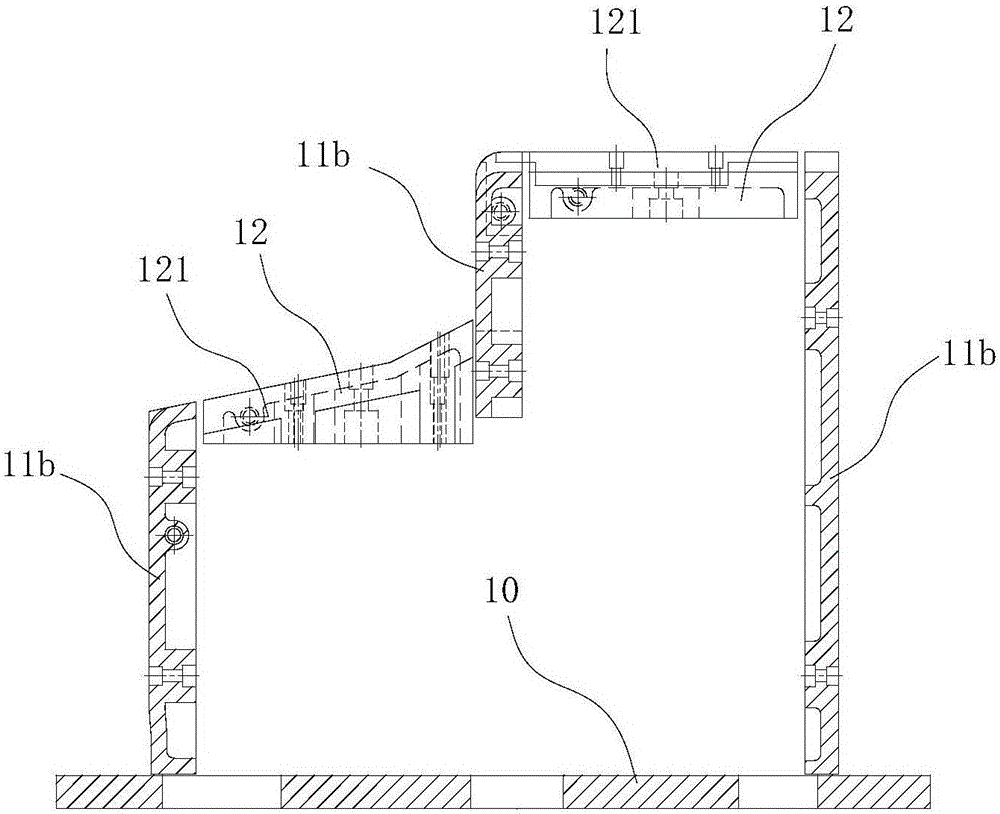

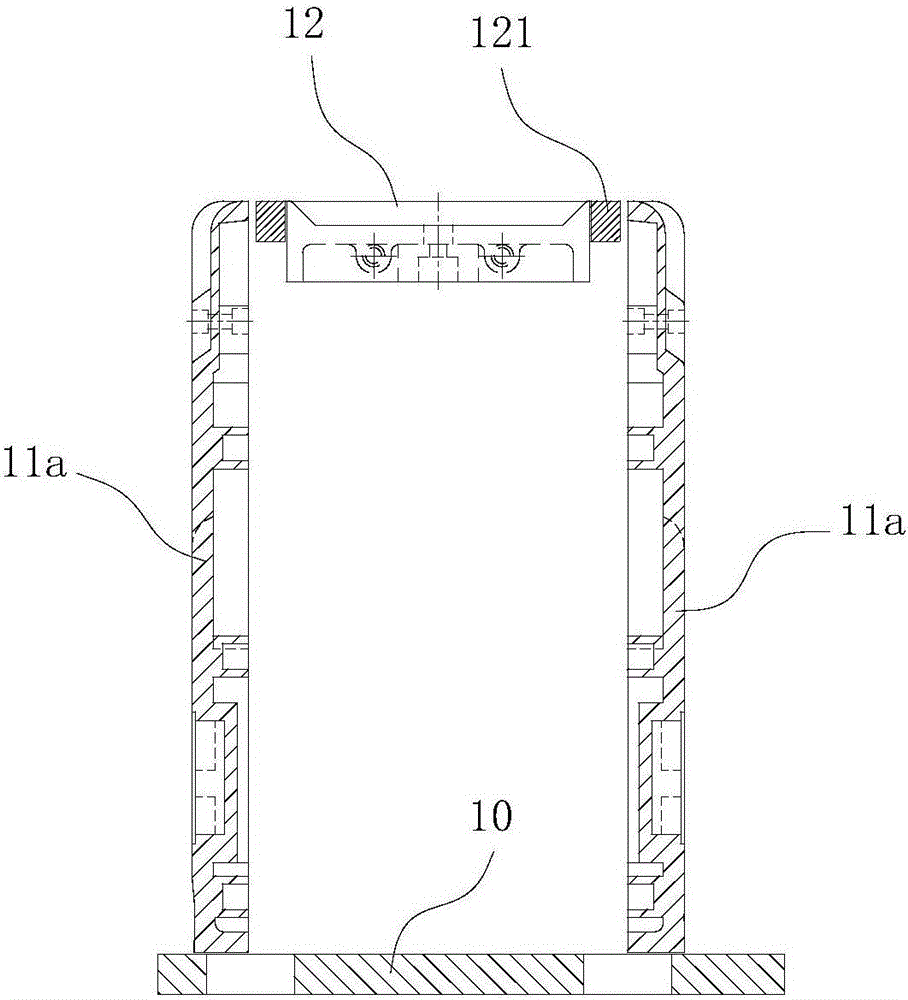

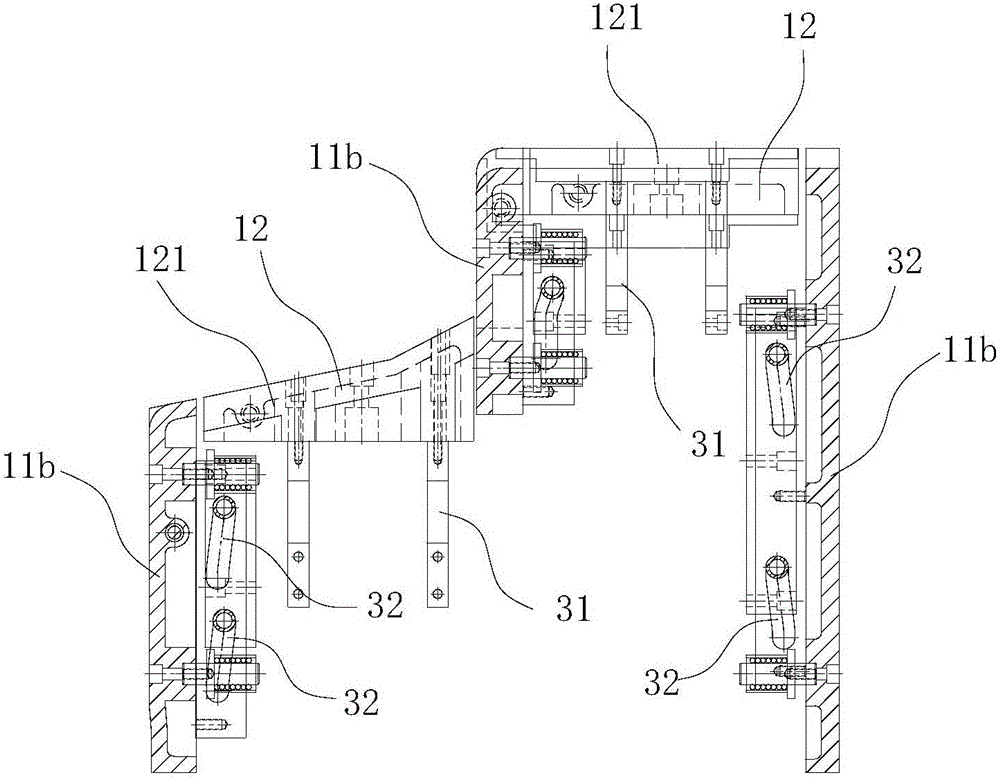

[0023] like Figures 1 to 9 As shown, a box foam expansion and contraction mold, such as figure 1 , 2 As shown, the mold includes a base plate 10 and a punch body, and the punch body is composed of a top plate 12, a side plate 11a and an end plate 11b, and each top plate 12, side plates 11a and end plates 11b are split structures , and each side plate 11a and end plate 11b are arranged to reciprocate along their respective normal directions, so that the volume of the punch body can expand or shrink laterally, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com