Preparation method of foam glass

A foam glass and glass powder technology, which is applied in the preparation of foam glass and the field of glass preparation, can solve the problems of affecting the quality of foam glass products, uneven distribution of bubbles, uneven surface, and achieve uniform foaming, obvious volume expansion, The effect of uniform pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The technical scheme adopted in the present invention is: a preparation method of foam glass, wherein graphite powder is used as foaming agent, mixed with pretreated raw glass powder and fired to obtain foam glass products; the specific steps are as follows:

[0025] (1) Raw material: Waste glass in daily life is used as raw material, such as waste flat glass or bottle glass, etc.;

[0026] (2) Pretreatment of raw materials: clean and dry the raw materials, pulverize and spheroidize the glass powder with a particle size of less than 300 microns;

[0027] (3) Preparation of mixture: after mixing glass powder and an appropriate amount of graphite powder, ball mill in a ball mill and pass through a 50-mesh sieve;

[0028] (4) Firing of foam glass: take an appropriate amount of mixture and mold it under a certain pressure, put it into a stainless steel mold coated with a release agent and fire it to obtain a foam glass product.

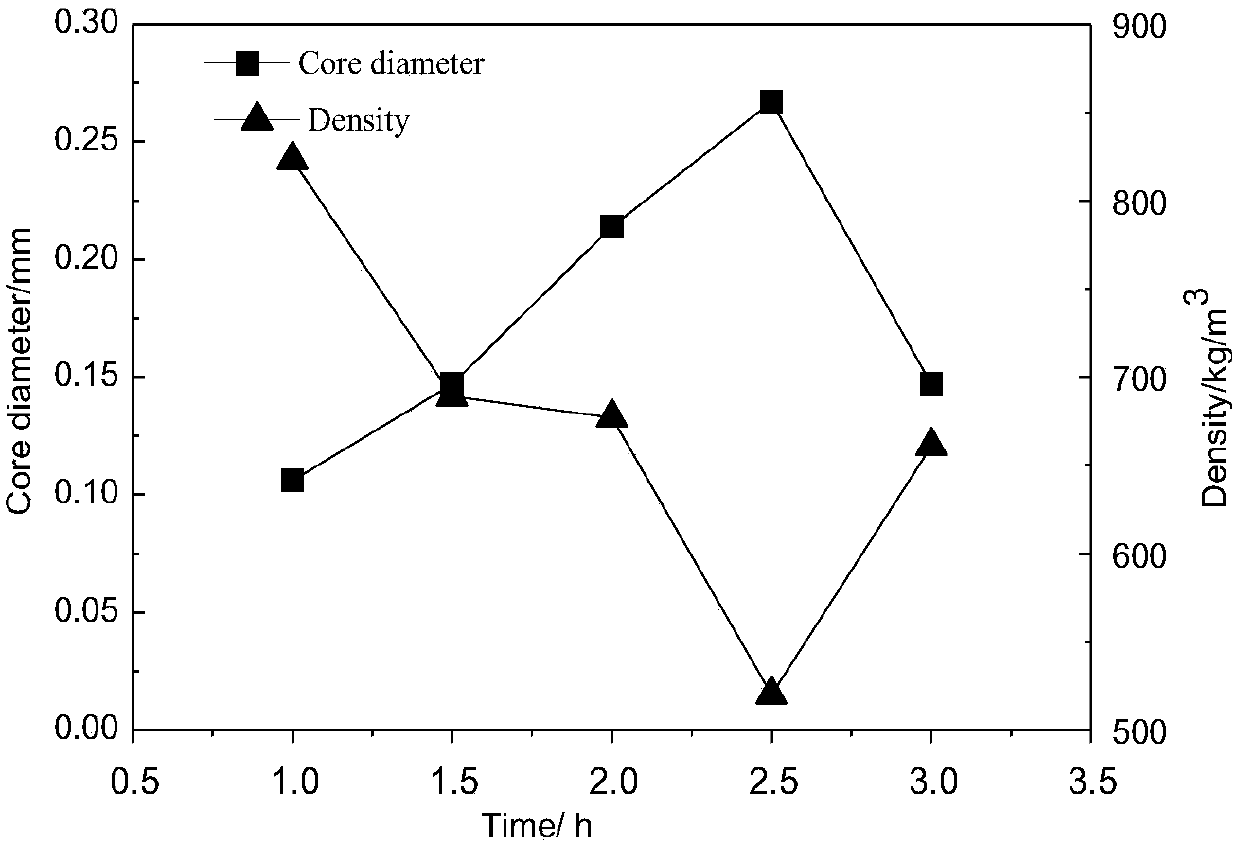

[0029] Take the above-mentioned glass powde...

Embodiment 1

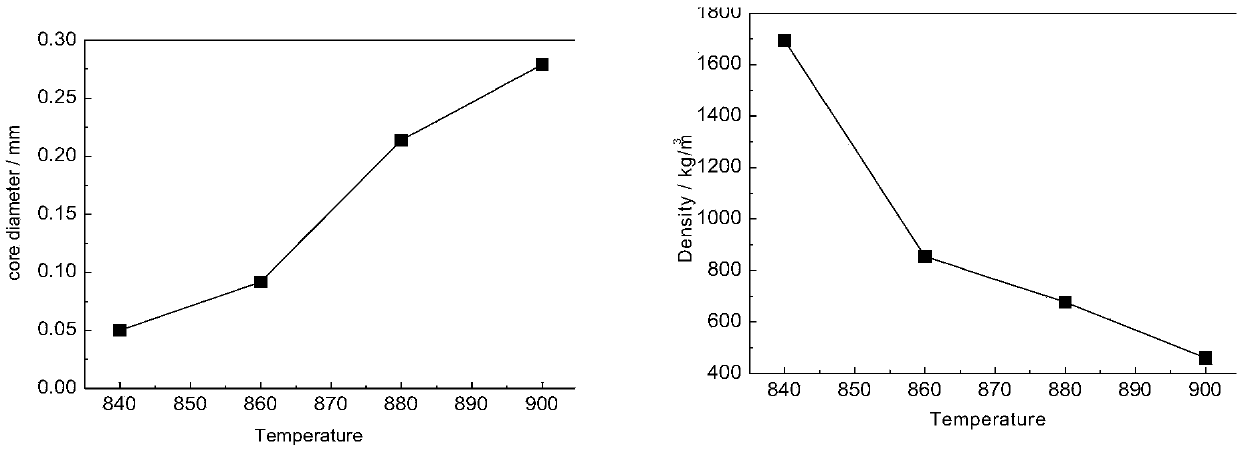

[0038] A method for preparing cellular glass, the preparation process conditions are:

[0039]The foaming agent graphite content is 1%, the grinding time is 1 hour, the firing temperature is 820°C, and the holding time is 5 minutes;

Embodiment 2

[0041] A method for preparing cellular glass, the preparation process conditions are:

[0042] The foaming agent graphite content is 2%, the grinding time is 2 hours, the firing temperature is 880°C, and the holding time is 10 minutes;

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com