Epoxy resin and nano inorganic particle compounded foam material and preparation method thereof

A technology of nano-inorganic particles and epoxy resin, which is applied in the field of nano-inorganic material composite foaming materials and its preparation, and epoxy resin. It can solve the problems of difficult control of microporous structure, generation of toxic gas, and complicated operation. The effect of small average diameter, increased melt viscosity, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

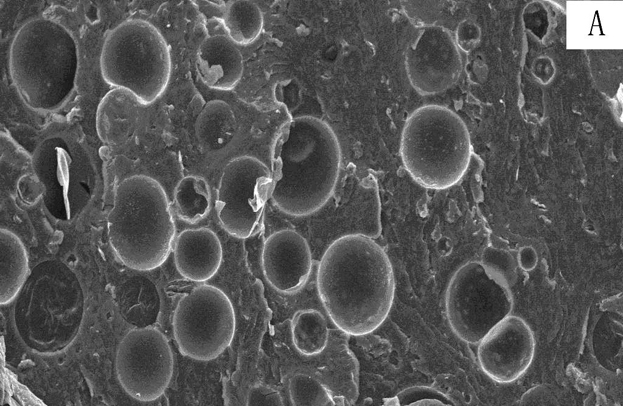

[0026] Embodiment 1. The influence of the content of composite nano-inorganic particles on the foaming quality of the epoxy resin-based foaming material was tested.

[0027] 1. Raw materials

[0028] Epoxy resin, grade E51, Shanghai Resin Factory; curing agent, grade 504, Shanghai Resin Factory; curing aid, grade DMP-30, Guangzhou Zhiyi Chemical Co., Ltd.; expandable expandable microspheres, commercially available; Soil removal, commercially available; nano-silica, commercially available.

[0029] 2. Sample preparation

[0030] Take 100g of epoxy resin, 80g of curing agent, 0.1g of curing aid, 4g of expandable expandable microspheres, composite nano-inorganic particles (a mixture of nano-organic montmorillonite and nano-silica, mass ratio 1:2), press Composite nano-inorganic particles and epoxy resin mass percentage content are 1%, 5%, 10%, 15%, 20% respectively. In the mold cavity, epoxy resin and nano-inorganic particle composite foaming materials are prepared by moldin...

Embodiment 2

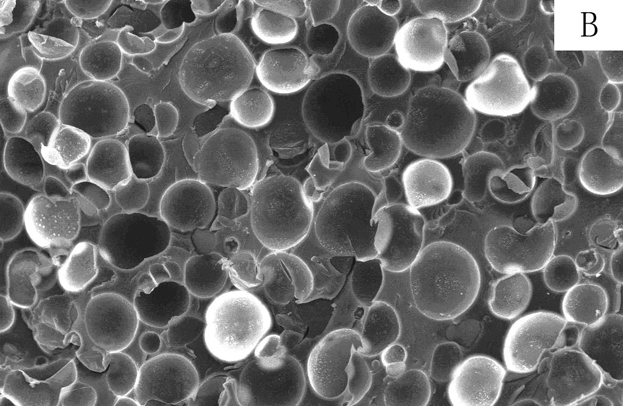

[0035] Embodiment 2. The effect of the proportion of composite nano-inorganic particles on the foaming quality of the epoxy resin-based foaming material was tested.

[0036] 1. Raw materials

[0037] Epoxy resin, grade E51, Shanghai Resin Factory; curing agent, grade 504, Shanghai Resin Factory; curing aid, grade DMP-30, Guangzhou Zhiyi Chemical Co., Ltd.; expandable expandable microspheres, commercially available; Soil removal, commercially available; nano-silica, commercially available.

[0038] 2. Sample preparation

[0039] Get 100g of epoxy resin, 80g of curing agent, 0.1g of curing aid, 4g of expandable expandable microspheres, and mix nano-organic montmorillonite and nano-dioxide After the silicon is stirred evenly according to the mass ratio of 3:1, 2:1, 1:1, 1:2, 1:3, the stirring rate is 200 rpm, and then the evenly mixed melt is poured into the mold cavity and passed through the molding process. The molding method is to prepare epoxy resin / composite nano-inorga...

Embodiment 3

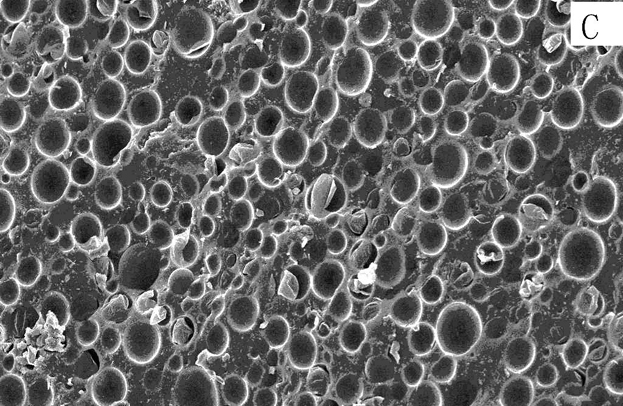

[0044] Embodiment three, test the influence of different foaming agent types on composite nano-inorganic material / epoxy resin material

[0045] 1. Raw materials

[0046]Epoxy resin, grade E51, Shanghai Resin Factory; curing agent, grade 504, Shanghai Resin Factory; curing aid, grade DMP-30, Guangzhou Zhiyi Chemical Co., Ltd.; expandable expandable microspheres, commercially available; modified AC Foaming agent, Guizhou Kaikete Material Co., Ltd.; nano-organic montmorillonite, commercially available; nano-silica, commercially available.

[0047] 2. Sample preparation

[0048] Take 100g of epoxy resin, 80g of curing agent, 0.1g of curing aid, compound nano-inorganic particles (a mixture of nano-organic montmorillonite and nano-silicon dioxide, mass ratio 1:2), press the composite nano-inorganic particles and epoxy resin The mass percentage content is 10%. After mixing and stirring with different expandable expandable microspheres and modified AC foaming agent in a ratio of 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com