Nanometer inorganic material/polyolefine foaming material and preparation method thereof

A technology of polyolefin foaming and nano-inorganic particles, which is applied in the field of polyolefin foam materials, and can solve problems such as complex process, limitation of application and popularization of process, and decline in mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

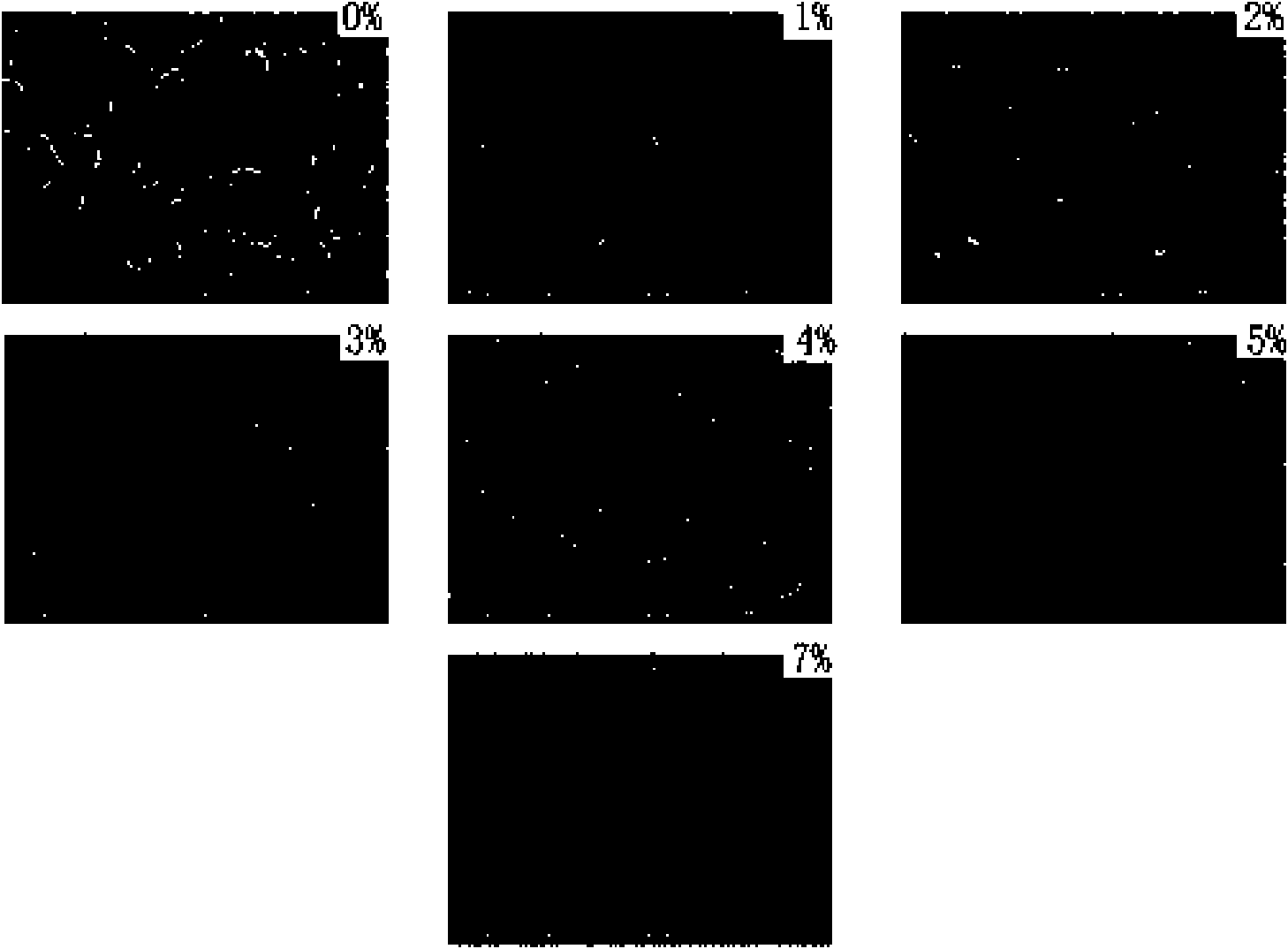

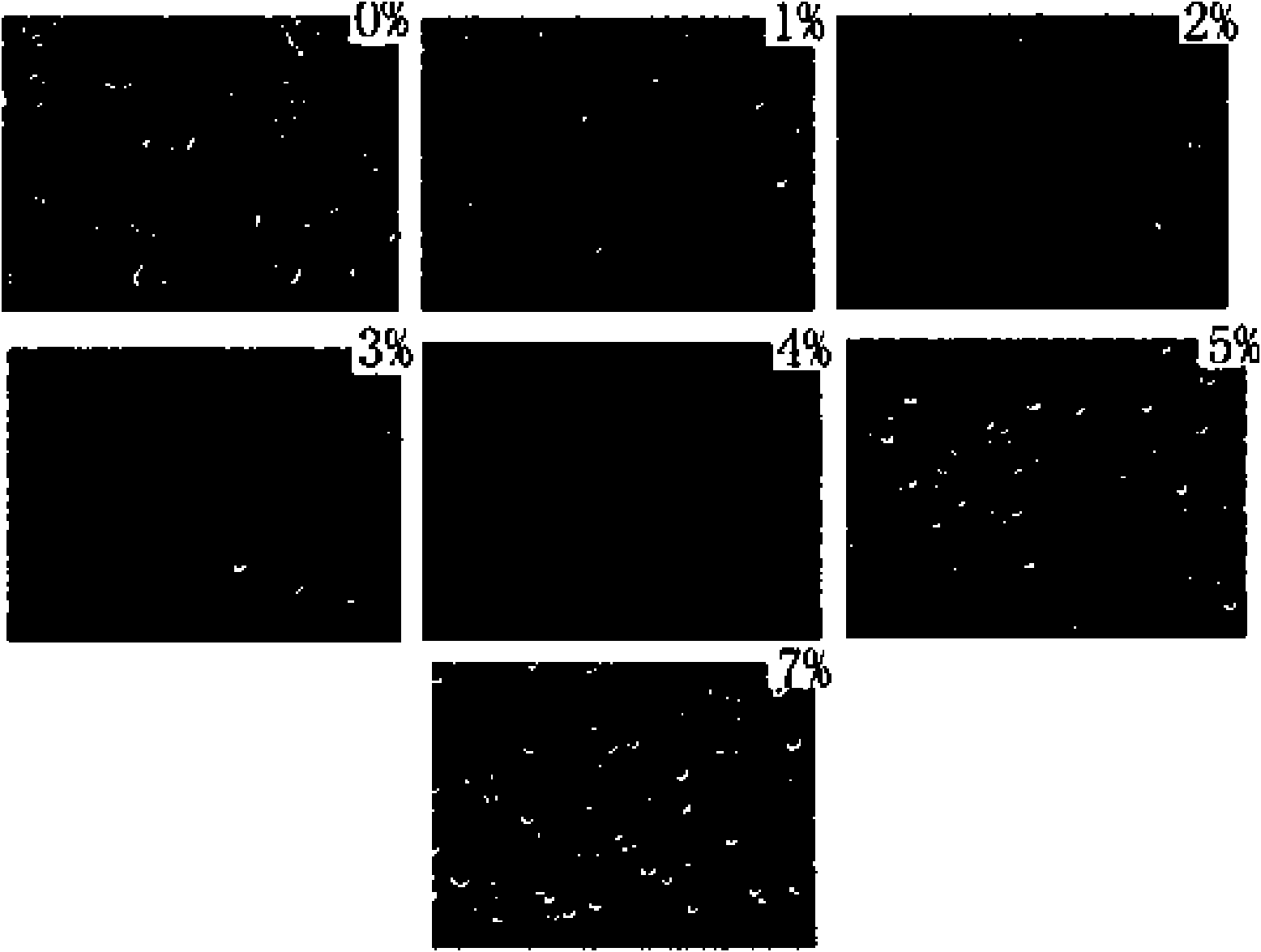

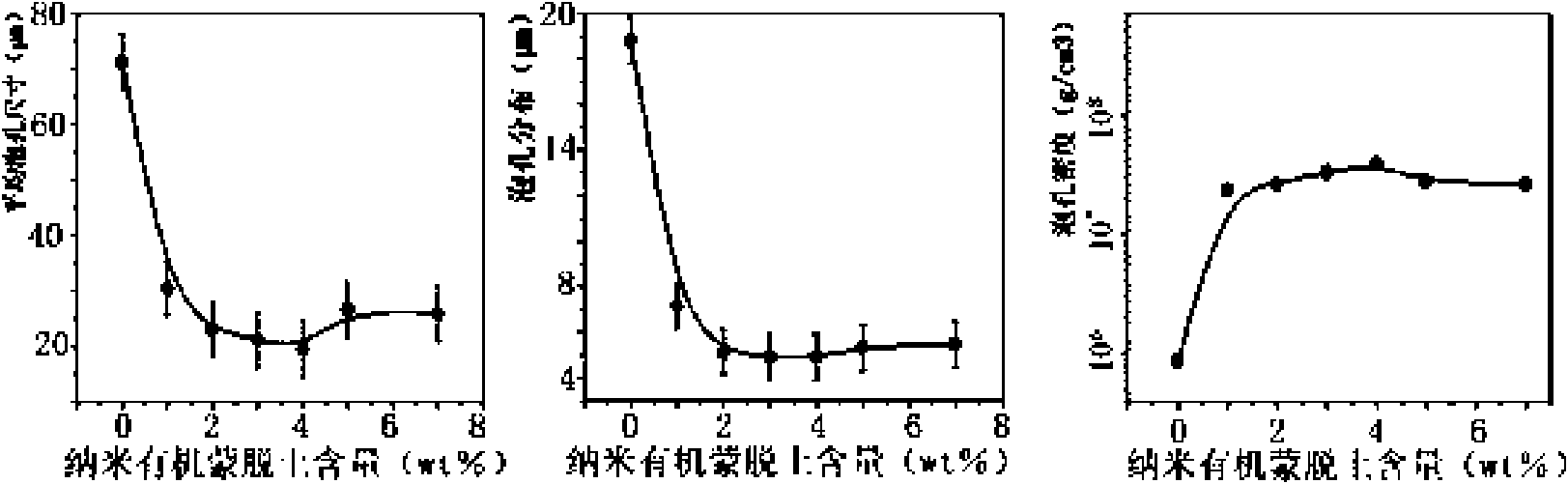

Image

Examples

Embodiment 1

[0065] Embodiment 1: (1) preparation of composite material: get nano-organic montmorillonite 4kg and polypropylene 12kg, mix homogeneously, extrude and make masterbatch on extruder, the masterbatch of extruding mixes with 54kg polypropylene again, The composite material is obtained by secondary extrusion on the extruder. The extrusion temperature of the two extrusions is 180°C, 185°C, 190°C, 195°C, 200°C, and 205°C from the blanking to the die opening temperature of the extruder. , 210°C, the speed is 200 rpm;

[0066] (2) Preparation of foam masterbatch and auxiliary agent masterbatch: with 1kg chemical blowing agent AC, take the same polypropylene as the carrier to make foam masterbatch containing AC10wt%; 2kg zinc oxide and 0.4kg zinc stearate Use the same brand of PP as the carrier to make a masterbatch of additives containing 10wt% of additives.

[0067] (3) Preparation of foaming material: Mix the composite material, 10kg of AC masterbatch and 20kg of foaming aid master...

Embodiment 2

[0068] Embodiment 2: (1) preparation of composite material: get nano-organic montmorillonite 5kg and high-density polyethylene 15kg, mix uniformly, extrude masterbatch on extruder, the masterbatch of extruding is mixed with 45kg high-density polyethylene again The ethylene is mixed evenly, and the composite material is obtained by secondary extrusion on the extruder. The extrusion temperature of the two extrusions is 180°C, 185°C, 190°C, 195°C, 200 ℃, 205℃, 210℃, the speed is 200 rpm;

[0069] (2) Preparation of foaming masterbatch and auxiliary agent masterbatch: with 1kg chemical blowing agent AC, take the same high-density polyethylene as the carrier to make foaming masterbatch containing AC10% (weight); 2kg zinc oxide and 0.4 kg zinc stearate and the same brand of high-density polyethylene as the carrier made of additives containing the total amount (zinc oxide+zinc stearate) / (zinc oxide+zinc stearate+PP) is 10 (weight)% same.

[0070] (3) Preparation of foaming material...

Embodiment 3

[0071] Embodiment 3: (1) preparation of composite material: get nano silicon dioxide 10kg and polypropylene 35kg, mix homogeneously, extrude and make masterbatch on extruder, the masterbatch of extruding mixes with 20kg polypropylene again, in The composite material is obtained by secondary extrusion on the extruder. The extrusion temperature of the two extrusions is 180°C, 185°C, 190°C, 195°C, 200°C, 205°C, 210°C, the speed is 220 rpm;

[0072] (2) masterbatch preparation: the preparation of foaming masterbatch and auxiliary agent masterbatch: with 5kg chemical blowing agent AC, make the foaming masterbatch that contains AC10% (weight) with same polypropylene as carrier; 10kg zinc oxide And 2kg zinc stearate and PP of the same grade are made as carrier and contain additive total consumption (zinc oxide+zinc stearate) / (zinc oxide+zinc stearate+PP) be 10 (weight)%.

[0073] (3) Preparation of foaming material: Mix the composite material, 10kg AC masterbatch and 20kg foaming ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com